Introduction

In the world of electrical engineering, understanding the role of a PG clamp in transmission lines is crucial for ensuring efficient and safe power distribution. These connectors play a pivotal part in maintaining the integrity of electrical connections, which can significantly impact the overall performance of transmission systems. As we delve into the various applications and variants of PG clamps, it becomes evident that their importance cannot be overstated.

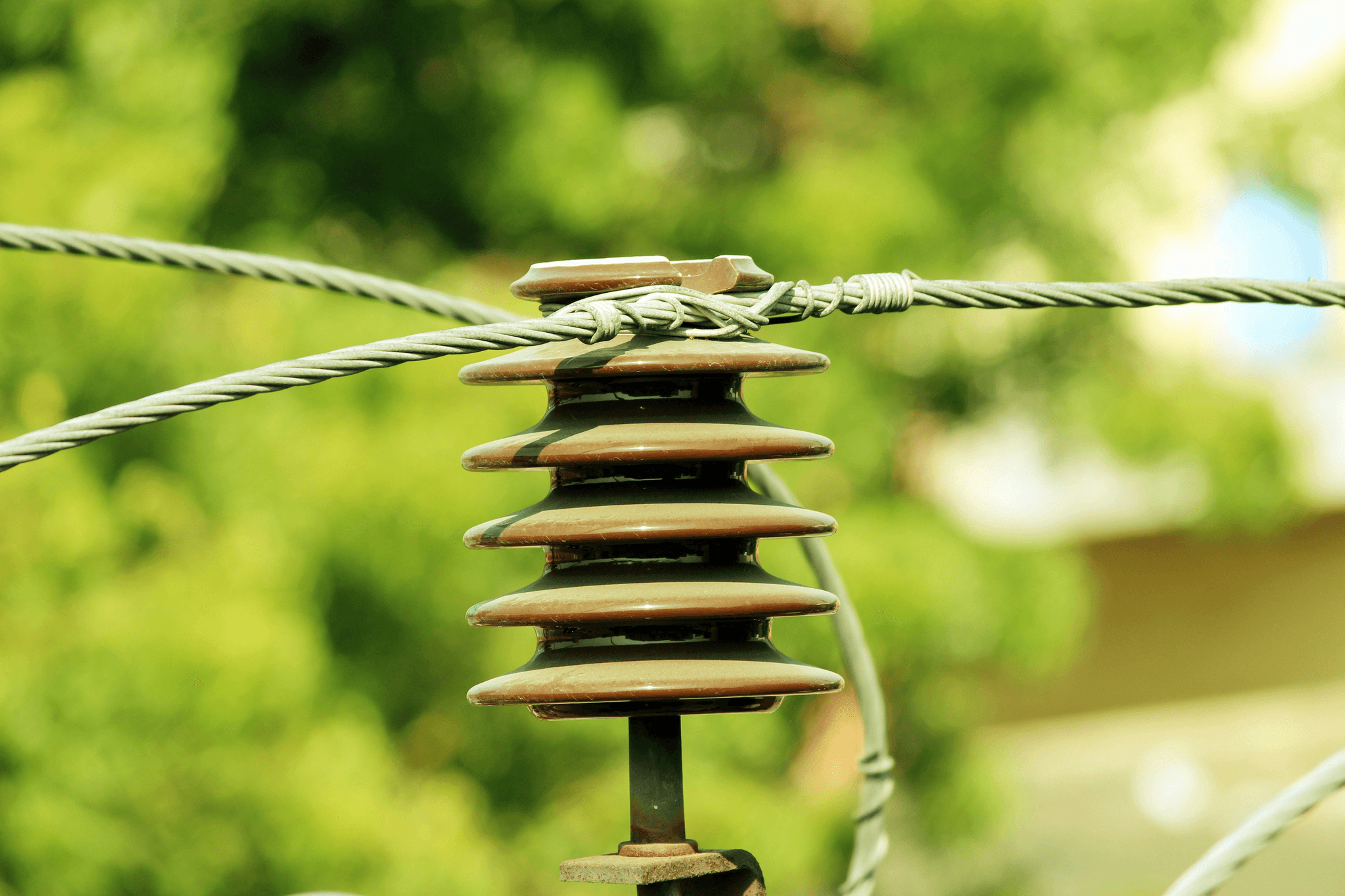

Understanding PG Clamp in Transmission Lines

A PG clamp, often referred to as a plug-in connector, serves as an essential component in transmission lines by providing secure connections between conductors. The full form of PG clamp reveals its purpose: it stands for Panzer-Gewinde, indicating its robust design intended for high-stress environments. When installed correctly, a PG clamp ensures minimal energy loss and enhances system reliability, making it indispensable in modern electrical infrastructure.

The Importance of Quality in Electrical Connections

Quality matters when it comes to electrical connections; subpar materials can lead to failures that could jeopardize entire systems. In this context, investing in high-quality PG clamps is not just wise—it's essential for safety and operational efficiency. Choosing reliable PG Clamp connectors helps prevent issues such as overheating or arcing, which can have dire consequences for both equipment and personnel.

Exploring PG Clamp Applications and Variants

The versatility of PG clamps allows them to be used across various sectors, from electric power distribution to renewable energy projects like wind farms. Each application may require different sizes and specifications; hence understanding available PG clamp sizes is key to successful implementation. Additionally, with an array of variants tailored for specific uses—including those designed specifically for transformers—the right choice can enhance performance while keeping costs manageable amidst fluctuating PG clamp prices on the market.

What is a PG Clamp?

The term PG clamp stands for Polyamide Grommet, which refers to the material and design that allows these clamps to perform their duties effectively. Understanding what a PG clamp is and how it functions can help you appreciate its role in maintaining safety and efficiency in power distribution.

Defining PG Clamp Full Form

The full form of PG clamp is Polyamide Grommet Clamp. This name reflects the material used—polyamide, known for its durability and resistance to various environmental factors. When you hear about PG clamps in transmission lines, think of robust connectors that hold everything together while withstanding the rigors of outdoor conditions.

Key Features of PG Clamp Connectors

PG clamps come with several key features that make them indispensable in electrical applications. For starters, they boast excellent insulation properties, which help prevent electrical leakage—a crucial factor for safety in any project involving high voltage transmission. Additionally, their design allows for easy installation and flexibility across various sizes; whether you're dealing with standard or custom PG clamp sizes, there's likely a solution available.

How PG Clamps Function in Transmission Lines

In transmission lines, the function of a PG clamp is pivotal for maintaining electrical integrity between components like wires and transformers. These clamps securely hold conductors while providing necessary strain relief to prevent damage during fluctuations or environmental stressors such as wind or ice accumulation. When properly installed, a PG clamp ensures that electricity flows smoothly without interruptions or hazards—making them essential not just for efficiency but also for safety across power networks.

PG Clamp Sizes and Specifications

When working with electrical systems, particularly in transmission lines, understanding the various PG clamp sizes and specifications is crucial. The right PG clamp ensures effective connections, which directly impacts the reliability of power distribution systems. This section will delve into common sizes, how to choose the right one for your project, and why proper sizing is essential for electrical safety.

Common PG Clamp Sizes in Use

PG clamps come in a variety of sizes to accommodate different applications within transmission lines and transformers. Commonly used sizes include PG7, PG11, and PG16, each designed to fit specific cable diameters and connection needs. Knowing the different PG clamp sizes helps engineers select the appropriate connector for their projects while ensuring optimal performance.

Choosing the Right Size for Your Project

Selecting the right size of a PG clamp is not just about convenience; it’s about functionality too. When considering a project involving a PG clamp in transmission line applications or even when using a PG clamp for transformer connections, factors such as cable diameter and environmental conditions should guide your choice. A well-chosen size enhances connectivity while minimizing risks associated with loose or overly tight clamps.

Importance of Proper Sizing in Electrical Safety

Proper sizing of PG clamps is paramount in maintaining electrical safety standards across all installations. An incorrectly sized clamp can lead to poor connections that may cause overheating or even electrical failures over time—definitely not something you want on your hands! By ensuring that you use suitable PG clamp sizes tailored to your specific application needs, you are investing in both safety and reliability.

Applications of PG Clamps in Transmission Lines

PG clamps play a pivotal role in the functionality and safety of transmission lines, serving as crucial connectors that ensure reliable electrical connections. Their versatility allows them to be used across various applications, from electric power distribution to renewable energy installations. Understanding these applications can help clarify why selecting the right PG clamp is vital for any project.

Role of PG Clamps in Electric Power Distribution

In electric power distribution, the importance of a robust PG clamp cannot be overstated. These clamps facilitate secure connections between conductors, ensuring minimal resistance and optimal current flow in transmission lines. Properly sized PG clamps not only enhance performance but also contribute significantly to overall system safety by preventing electrical faults.

The PG clamp full form—plug and grip—captures its function perfectly: it plugs into one component while gripping another securely. This design is especially beneficial for high-voltage lines where reliability is paramount. Choosing the right PG clamp sizes for different applications ensures that they can handle specific load requirements without risk of failure.

Furthermore, with varying conditions such as temperature and humidity affecting electrical connections, using quality PG Clamp connectors becomes even more critical in power distribution systems. High-quality materials resist corrosion and wear over time, which directly impacts maintenance costs and operational efficiency. Thus, investing in quality clamps pays dividends through increased reliability and reduced downtime.

Use of PG Clamps in Wind Energy Installations

Wind energy installations have seen a surge in popularity as a sustainable power source, making the role of PG clamps increasingly significant. These clamps are essential for connecting wind turbine components to the grid efficiently while maintaining safety standards throughout operation. The robustness required to withstand harsh weather conditions makes choosing appropriate PG clamp sizes crucial for long-term performance.

In wind farms, proper installation practices are vital; hence understanding how a PG clamp functions can lead to better outcomes during setup and maintenance phases. The use of specialized variants like the PG Clamp for Transformer ensures that energy generated from turbines is effectively transmitted without loss or interference due to poor connections.

Moreover, as renewable energy technology advances, so do innovations surrounding connectors like the PG clamp connector; manufacturers continuously improve their designs to optimize performance under varying operational conditions. With increasing demand for wind energy solutions globally, understanding market trends related to factors influencing the overall PG clamp price will be key for stakeholders looking to invest wisely.

PG Clamps in Urban Infrastructure Projects

In densely populated areas where space is limited yet demand on power systems is high, these clamps provide secure connections that support efficient electricity distribution networks without compromising safety standards.

The adaptability of various sizes within the range of available PG clamp sizes allows engineers to select options tailored specifically for urban settings—whether it's overhead lines or underground cabling systems—ensuring compliance with local regulations as well as international standards for electrical safety. Additionally, using well-designed connectors minimizes risks associated with potential failures that could disrupt service or pose hazards.

As cities evolve with smart technologies integrating into their infrastructure frameworks, having dependable components such as those found within the realm of pg clamp in transmission line setups becomes increasingly important. The ongoing development within this sector suggests positive trends ahead regarding both pricing strategies and innovative designs aimed at enhancing efficiency further while keeping costs manageable across different projects.

PG Clamp for Transformers

Transformers are a critical component in electrical systems, and ensuring their safety and reliability is paramount. The use of PG clamps in transmission lines, particularly with transformers, is essential for maintaining secure electrical connections. These connectors not only support the physical infrastructure but also enhance the overall safety and efficiency of power distribution.

Why PG Clamps are Essential for Transformer Safety

PG clamps play a vital role in transformer safety by providing robust support for electrical connections. When it comes to high-voltage applications, the integrity of every connection matters; a failure could lead to catastrophic results. Utilizing quality PG clamps ensures that the connections remain stable under various environmental conditions, thereby minimizing risks associated with electrical faults.

An improper connection can lead to overheating or even arcing, making it crucial to choose the right PG clamp sizes that can handle specific load requirements. The full form of PG clamp—“Pin Grip” clamp—aptly describes its function: securely gripping pins or conductors while allowing for thermal expansion and contraction. This adaptability is especially important in transformer applications where temperature fluctuations are common.

Installation Best Practices for PG Clamps on Transformers

Installing PG clamps correctly on transformers is just as important as selecting the right type and size. First and foremost, ensure that all surfaces are clean and free from corrosion before attaching any PG clamp connector; this promotes better conductivity and reduces resistance at junction points. Additionally, always follow manufacturer guidelines regarding torque specifications when tightening these clamps to avoid damaging components.

It’s also wise to perform regular inspections post-installation to monitor wear over time; even high-quality clamps can experience degradation due to environmental factors or mechanical stress. When selecting your clamps, consider not only the immediate needs but also future demands—this foresight can save time and costs down the road when considering potential upgrades or expansions in your system layout.

Analyzing Performance and Reliability

The performance of PG clamps directly impacts the reliability of transformers within an electrical grid system. By analyzing how well these connectors hold up under varying loads and conditions, engineers can make informed decisions about which products best suit their needs—especially when considering different manufacturers like Spark Fittings that offer competitive pricing options for high-quality products.

Reliability tests often reveal that premium materials used in manufacturing these connectors lead to longer service life compared to cheaper alternatives found on the market today; thus understanding PG clamp price variations becomes essential when balancing budget constraints with quality requirements. Ultimately, investing in reliable components like PG clamps ensures long-term operational efficiency while safeguarding against unexpected failures that could disrupt power distribution networks.

PG Clamp Prices and Market Trends

The cost of these essential components can vary widely based on a multitude of factors, including material quality, manufacturing processes, and market demand. As technology evolves and new applications emerge, keeping an eye on market trends will help stakeholders make informed purchasing decisions.

Factors Influencing PG Clamp Price

Several elements contribute to the price of a PG clamp in transmission line applications. First off, the materials used play a significant role; high-quality metals or specialized polymers can drive costs up but offer enhanced durability. Additionally, manufacturing techniques—such as whether the clamps are made through standard production or custom fabrication—also affect pricing; custom solutions often come with a premium tag.

Moreover, regional economic conditions can influence PG clamp prices as well. For instance, fluctuations in raw material costs due to supply chain disruptions or tariffs can lead to sudden price hikes. Lastly, demand spikes caused by infrastructure projects or renewable energy initiatives can create scarcity in the market, further pushing up prices.

Comparing Costs Across Manufacturers like Spark Fittings

When comparing costs across various manufacturers such as Spark Fittings, it's essential to consider not just the initial price but also long-term value. While one brand may offer lower upfront costs for their PG clamp connector products, another might provide superior quality that results in fewer failures over time—saving you money on replacements and maintenance down the line.

Another factor to keep in mind is customer service and support offered by manufacturers like Spark Fittings. A company that stands behind its products with warranties or guarantees could justify a higher price point when you factor in peace of mind and reliability. Therefore, it’s wise to evaluate not just the sticker price but also what you're getting for your investment.

Future Trends in PG Clamp Pricing

Looking ahead at future trends in PG clamp pricing reveals some intriguing possibilities for both buyers and sellers alike. With ongoing advancements in materials science and manufacturing techniques, we may see more affordable options emerging without sacrificing quality—think lighter yet stronger clamps designed specifically for demanding environments like those found near transformers.

Moreover, as renewable energy projects continue gaining momentum globally—particularly wind energy installations—the demand for reliable electrical connections will likely increase significantly. This surge could lead to competitive pricing strategies among manufacturers aiming to capture this growing market segment while ensuring that their products meet stringent safety standards associated with applications like PG clamp for transformers.

In summary, keeping abreast of these trends will empower you to make savvy purchasing decisions regarding your next project involving PG clamp sizes or connectors—all while staying within budget!

Conclusion

In wrapping up our exploration of PG clamps, it's clear that these devices play a crucial role in ensuring the safety and efficiency of electrical systems. The benefits of using quality PG clamps in transmission lines cannot be overstated; they contribute to enhanced reliability and longevity of connections. Whether you're dealing with power distribution or transformers, investing in high-quality PG clamp connectors is a smart choice that pays off in the long run.

Benefits of Using Quality PG Clamps

For starters, a well-made PG clamp reduces the risk of electrical faults and enhances overall system stability. Additionally, using premium materials can lead to improved resistance against environmental factors, ultimately extending the lifespan of your electrical installations.

When it comes to specific applications like the PG clamp for transformers, quality becomes even more critical. Transformers operate under high voltage and require secure connections to function safely; thus, investing in reliable clamps is non-negotiable. In essence, choosing high-quality PG clamps ensures that your electrical systems are not just functional but also safe and efficient.

Key Considerations for Selecting PG Clamps

Selecting the right PG clamp involves several key considerations that can greatly affect your project's success. First and foremost is understanding the full form of a PG clamp—it's essential to know what specifications you need based on your application requirements. Additionally, pay close attention to various available sizes; selecting an appropriate size ensures optimal performance and safety.

Another critical factor is pricing; while you may find cheaper options on the market, remember that low-cost clamps often compromise on quality. It's advisable to compare prices across different manufacturers like Spark Fittings while also weighing their reputation for reliability and performance consistency. Ultimately, making informed decisions about size and price will lead you toward selecting the best possible PG clamp connector for your needs.

The Future of PG Clamps in Electrical Engineering

Looking ahead, the future of PG clamps appears promising as technology continues to evolve within electrical engineering fields. Innovations may lead to even better materials and designs that enhance both functionality and safety standards across various applications—including those involving wind energy installations or urban infrastructure projects utilizing these indispensable connectors.

Moreover, as demand increases for renewable energy solutions such as wind power or solar energy setups, so too will opportunities for specialized variants like the PG Clamp for Transformer become more prevalent. This trend suggests an exciting period ahead where advancements could significantly improve both efficiency levels and cost-effectiveness—making it easier than ever before to implement robust electrical systems with confidence.

In summary, whether considering common sizes or delving into specifics regarding pricing trends within this sector—the importance placed upon quality cannot be overstated when selecting any type of pg clamp in transmission line applications.