Introduction

Selecting the right manufacturer for your cable accessories is crucial in ensuring the success of your projects. A reliable cable accessories manufacturer can significantly influence the quality and performance of power systems, from armored cables to overhead power lines. With numerous options available, making an informed choice is essential for achieving optimal results in your power and cables endeavors.

Importance of Selecting the Right Manufacturer

The significance of choosing a reputable cable accessories manufacturer cannot be overstated. Quality manufacturing directly impacts the reliability and safety of cable wire installations, which are fundamental to any power system. A trusted manufacturer not only provides high-quality products but also offers ongoing support and expertise that can prove invaluable throughout your project's lifecycle.

Key Considerations When Choosing a Manufacturer

When evaluating potential manufacturers, several key considerations come into play that can make or break your project. Look for a company with proven experience in producing various types of cable accessories tailored to specific applications within power systems. Additionally, consider factors such as production capacity, engineering expertise, and customization options that align with your unique requirements for armored cables or other fittings.

The Impact on Your Cable Projects

The choice of a cable accessories manufacturer has far-reaching implications on the overall success of your projects. High-quality components ensure seamless integration into existing systems while minimizing downtime due to failures or defects in materials like cable wire or power fittings. Ultimately, investing time in selecting the right partner will pay dividends through enhanced performance and reliability in every aspect of your power systems.

Understanding Cable Accessories

These components might not always be in the limelight, but they play a crucial role in the reliability and efficiency of electrical networks. For anyone involved with power & cables, understanding these accessories is paramount for making informed decisions.

Different Types of Cable Accessories

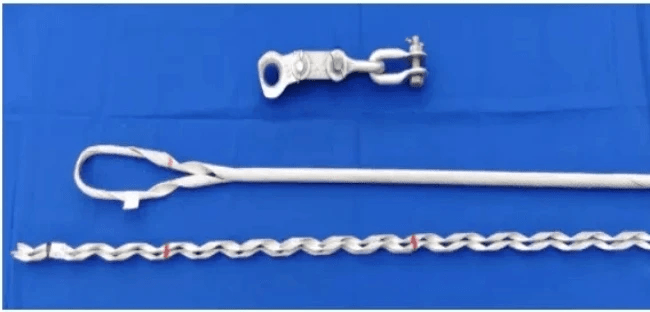

Cable accessories come in various forms, each designed to meet specific needs within power systems. From connectors and terminations to joints and protective coverings, these components are essential for both armored cable installations and overhead power lines. A good cable accessories manufacturer provides a diverse range of products that cater to different applications, ensuring compatibility with various types of cable wire.

The variety doesn't stop there; you also have specialized fittings like heat-shrink sleeves and cold-shrink joints that enhance performance under demanding conditions. Each type serves a unique purpose—some facilitate seamless connections between cables while others protect against environmental factors or mechanical stress. Thus, selecting the right types of cable accessories is critical for maintaining system integrity and longevity.

The Role of Cable Accessories in Power Systems

In any power system, cable accessories serve as the connective tissue that holds everything together. They ensure that electrical energy flows efficiently from one component to another without interruptions or losses—a vital requirement for any successful installation involving armored cables or overhead power lines. Without high-quality cable accessories, even the best-designed systems can suffer from failures or inefficiencies.

Moreover, these accessories help mitigate risks associated with electrical faults by providing necessary insulation and protection against external elements. They also facilitate maintenance activities by allowing easy access points within complex systems—think about how much easier it is to troubleshoot when you have well-placed connectors! Therefore, understanding their role is not just about knowing what they do; it's about appreciating how they contribute to overall system performance.

Importance of Quality in Cable Accessories

Quality should never be an afterthought when it comes to selecting cable accessories; it’s a non-negotiable factor that can make or break your project’s success. A reputable cable accessories manufacturer will adhere to stringent quality standards during production processes—this ensures durability and reliability over time. After all, no one wants to deal with unexpected failures due to subpar components in their power systems!

Investing in high-quality cable wire fittings means fewer maintenance headaches down the line and greater peace of mind for everyone involved—from engineers to end-users. Remember, if you cut corners on quality now, you may end up paying significantly more later when repairs become necessary due to failures caused by inferior products. So always prioritize quality over cost savings when choosing your cable accessories.

Evaluating Manufacturer Capabilities

This evaluation ensures that the manufacturer can meet your specific needs in the realm of power systems and cable wire production. By assessing production capacity, engineering expertise, and customization options, you can make an informed decision that will positively impact your projects involving armored cables and overhead power lines.

Assessing Production Capacity

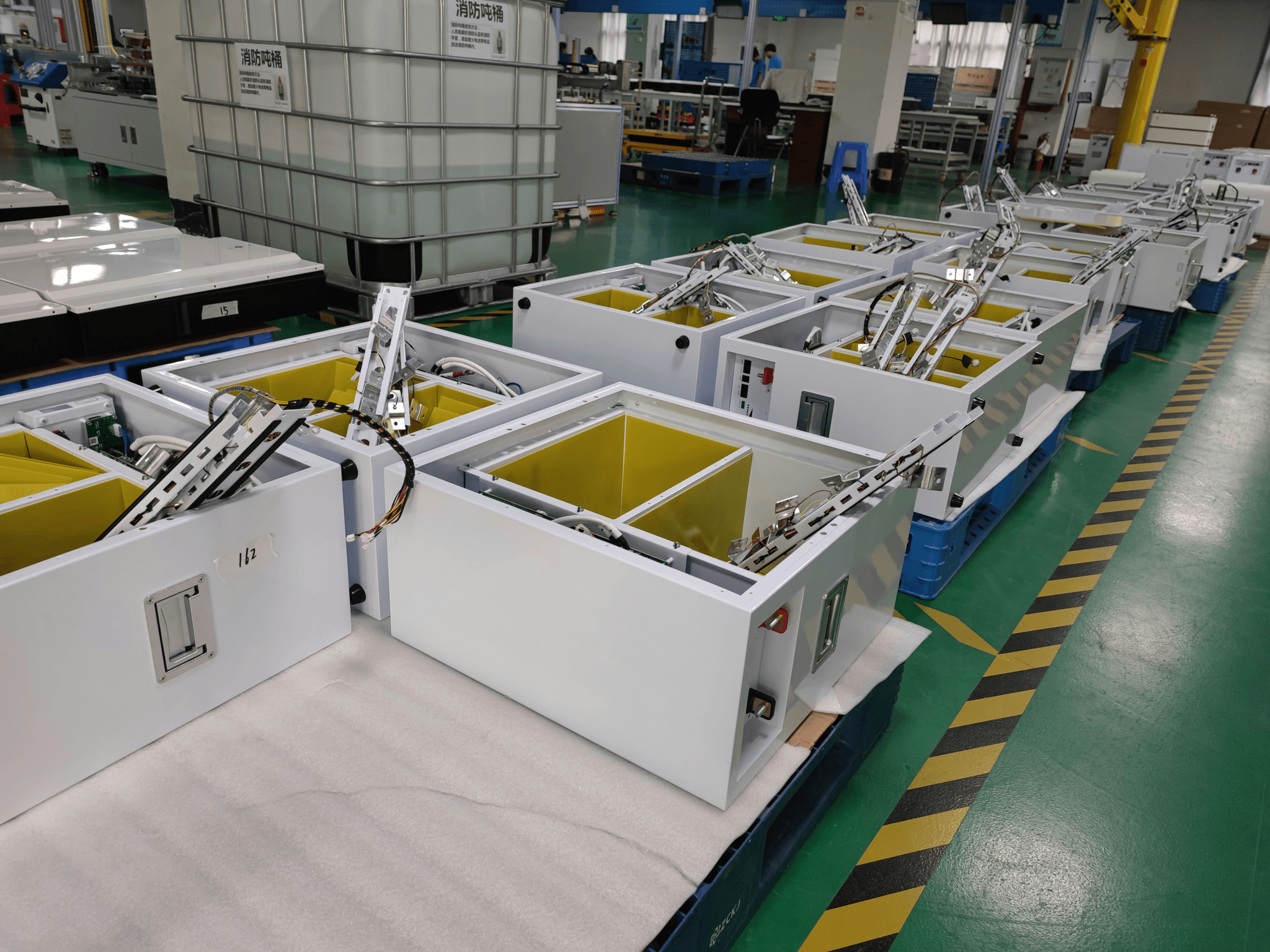

Production capacity is a key factor when evaluating a cable accessories manufacturer. You want to ensure they can handle large orders without compromising quality, especially for essential components like power fittings used in various power systems. A manufacturer with robust production capabilities will not only meet your current demands but also adapt to future needs as your projects grow.

Moreover, consider whether the manufacturer has advanced machinery and technology that streamline their production processes. This efficiency can lead to quicker turnaround times for cable wire and other accessories you may require. Ultimately, a capable manufacturer will help keep your projects on track while maintaining high standards in product delivery.

Review of Engineering Expertise

Engineering expertise plays a pivotal role in the development of reliable cable accessories for power systems. A knowledgeable team can design innovative solutions tailored to specific applications, whether it’s for armored cables or overhead power lines. When evaluating potential manufacturers, inquire about their engineering qualifications and experience within the industry.

Additionally, look for manufacturers who invest in continuous training and education for their engineering staff. This commitment ensures they stay updated on industry trends and technological advancements that can enhance product performance. The right engineering expertise not only leads to superior products but also fosters collaboration on custom solutions that meet unique project requirements.

Customization Options Available

In today's diverse market, having access to customization options from your cable accessories manufacturer is invaluable. Whether you need specific dimensions or unique materials for your cable wire or fittings, the ability to customize ensures that you get exactly what you need for optimal performance in power systems applications. Manufacturers with flexible customization capabilities are more likely to understand the nuances of different projects involving armored cables or overhead power lines.

Additionally, customized products often come with enhanced functionality tailored specifically to your operational needs—think about how certain fittings might be optimized for particular environmental conditions or installation methods! Therefore, engaging with manufacturers who prioritize customization can lead to innovative solutions that stand out from standard offerings in the market.

Quality Assurance Standards

The reliability of power systems hinges on the performance of these components, making it essential to partner with a reputable cable accessories manufacturer that prioritizes stringent quality standards. This section delves into the importance of ISO certifications, factory visits, and testing methods that ensure the highest quality in cable wire and fittings.

Importance of ISO Certifications

ISO certifications serve as a hallmark of excellence for any cable accessories manufacturer. These international standards assure customers that the manufacturer adheres to strict guidelines regarding quality management systems and product consistency. By choosing a manufacturer with robust ISO certifications, you can trust that their armored cable and other products will meet or exceed industry expectations, ensuring safety and reliability in your power & cables infrastructure.

Furthermore, ISO certifications often indicate continuous improvement practices within the manufacturing process. This means that you’re not just getting a one-time guarantee; you’re investing in ongoing quality assurance that evolves with technological advancements in power systems. Ultimately, this commitment to quality helps mitigate risks associated with subpar products failing in critical applications like overhead power lines.

Conducting Factory Visits

Nothing beats firsthand experience when evaluating a potential cable accessories manufacturer’s capabilities—this is where factory visits come into play! Visiting the manufacturing facility allows you to observe their production processes up close and assess whether they align with your standards for quality and efficiency. You can also gauge how well they manage their operations from raw material sourcing for cable wire to final assembly of power fittings.

During your visit, pay attention to cleanliness, organization, and workflow efficiency within the factory setting; these factors are indicative of overall operational excellence. Moreover, interacting directly with staff can provide insights into their expertise and commitment to producing high-quality products like armored cables or specialized connectors for power systems. A well-run facility will reflect positively on the manufacturer's dedication to delivering reliable solutions for your projects.

Testing Methods for Cable Accessories

Testing methods play a crucial role in ensuring that every component meets rigorous safety and performance standards before reaching your hands or being installed in overhead power lines. A reputable cable accessories manufacturer should employ various testing techniques—such as electrical tests, mechanical tests, and environmental simulations—to validate product integrity under real-world conditions. These tests help identify potential weaknesses early on so they can be addressed before installation.

Moreover, standardized testing protocols ensure consistency across all batches produced by manufacturers specializing in cable wire or other essential components used in power & cables infrastructure. By demanding transparency regarding testing methods from prospective manufacturers, you can rest assured knowing you're investing in durable products designed to withstand the demands of modern power systems without compromising safety or performance.

The Reputation of Manufacturers

When it comes to selecting a cable accessories manufacturer, reputation can be your best friend. A manufacturer’s standing in the industry often reflects their commitment to quality and innovation in power systems. In a world where cable wire and armored cable play pivotal roles, understanding a manufacturer's reputation can save you from costly mistakes.

Researching Customer Reviews

Customer reviews are like gold nuggets buried in the vast landscape of information about cable accessories manufacturers. They provide firsthand insights into the quality of products, such as power fittings and overhead power lines, as experienced by others in the field. By diving deep into these reviews, you can gauge not only product reliability but also customer service responsiveness—two crucial factors for any successful partnership.

Additionally, pay attention to recurring themes in reviews; if multiple customers mention issues with specific cable accessories or praise certain aspects of a manufacturer’s offerings, this is invaluable information. A pattern of positive feedback typically indicates that the manufacturer maintains high standards for their products and services. Conversely, consistent complaints might raise red flags about their commitment to quality and customer satisfaction.

Recognizing Industry Leaders

In every sector, some manufacturers stand out as industry leaders due to their innovative approaches and exceptional product lines. When looking for a reputable cable accessories manufacturer, it’s essential to identify these leaders who specialize in power systems and have established themselves through years of experience and success stories. Companies that consistently deliver high-quality armored cables or reliable overhead power lines often set benchmarks that others strive to meet.

Industry awards, certifications, and participation in major trade shows are also indicators of a manufacturer's credibility within the market. These accolades not only highlight their achievements but also reflect their commitment to pushing technological boundaries in manufacturing processes for cable wire solutions. Recognizing these leaders will help you make informed decisions when selecting a partner for your next project.

Analyzing Case Studies and Success Stories

Case studies offer concrete examples of how various manufacturers have successfully tackled challenges within the realm of power & cables. By analyzing these success stories related to cable accessories manufacturing, you gain insights into real-world applications that demonstrate product effectiveness under various conditions—be it harsh environments or demanding projects involving complex power systems.

Look for case studies that specifically detail how manufacturers addressed unique challenges with innovative solutions involving power fittings or specialized armored cables tailored for specific applications like overhead power lines installations. This analysis not only showcases the manufacturer's expertise but also provides reassurance regarding their problem-solving capabilities should similar situations arise during your projects.

In summary, examining customer reviews, recognizing industry leaders, and analyzing case studies will provide you with valuable insights into choosing a reputable cable accessories manufacturer capable of meeting your needs while ensuring high standards across all aspects of production.

Innovating with Technology

In today’s fast-paced world, staying ahead in the cable accessories market requires a commitment to innovation and technology. A forward-thinking cable accessories manufacturer embraces cutting-edge equipment that enhances production efficiency and product quality. This investment not only streamlines operations but also ensures that their offerings meet the rigorous demands of modern power systems, including armored cable and overhead power lines.

Emphasis on Cutting-Edge Equipment

The backbone of any successful cable accessories manufacturer lies in its equipment. High-tech machinery enables precise manufacturing of essential components like power fittings and cable wire, which are crucial for reliable power transmission. By utilizing advanced tools, manufacturers can produce innovative designs that improve performance while minimizing the risk of failure in critical applications.

Moreover, employing state-of-the-art technology allows manufacturers to adapt quickly to changing market needs. Whether it’s developing new types of cable accessories or enhancing existing ones, having the latest equipment is vital for maintaining a competitive edge. This adaptability is particularly important in sectors such as renewable energy and smart grids, where demand for high-quality components continues to rise.

Automation in Manufacturing Processes

Automation has revolutionized manufacturing across various industries, and the cable accessories sector is no exception. By integrating automated processes, manufacturers can significantly increase output while reducing labor costs associated with traditional methods. This shift not only boosts productivity but also enhances consistency in product quality—critical for components used in power systems.

Automated systems allow for real-time monitoring and adjustments during production, ensuring that every piece meets stringent safety standards required for applications involving armored cables or overhead power lines. Additionally, automation minimizes human error, which can be detrimental when dealing with complex electrical components like power fittings or specialized cable wire configurations.

As a result of these advancements, a well-automated facility can respond more effectively to customer demands without compromising on quality or lead times—an essential factor when securing contracts in today's competitive environment.

Staying Competitive in the Cable Market

To thrive as a leading player among cable accessories manufacturers, staying competitive involves more than just keeping up with trends; it requires anticipating future needs within the industry. Continuous investment in research and development (R&D) allows companies to innovate their products and services effectively—whether it's enhancing existing solutions or creating entirely new offerings tailored for emerging markets.

Furthermore, understanding customer preferences plays an integral role in shaping product development strategies within this sector. By actively engaging with clients who rely on reliable power systems—including those using armored cables—the manufacturer can refine its offerings based on real-world feedback and evolving technological trends.

Ultimately, success hinges on being proactive rather than reactive; embracing technological advancements ensures that a manufacturer remains relevant amidst an ever-changing landscape filled with opportunities driven by innovation within the realm of cables and their accessories.

Conclusion

In the world of power systems, selecting the right cable accessories manufacturer can make all the difference between a successful project and one fraught with issues. The nuances of quality, reliability, and innovation in cable accessories directly influence both performance and safety in applications ranging from armored cables to overhead power lines. As you navigate this decision-making process, keep in mind that your choice will resonate throughout your projects, impacting everything from installation efficiency to long-term durability.

Key Takeaways for Selecting a Manufacturer

When choosing a cable accessories manufacturer, prioritize their experience and reputation within the industry. Look for manufacturers who not only meet but exceed quality assurance standards; ISO certifications are a good indicator of reliability. Additionally, consider customization options that align with your specific requirements in power & cables; having tailored solutions can enhance performance significantly.

The Role of Spark Fittings in the Industry

Spark fittings play an essential role in ensuring safe and efficient connections within power systems. These components are critical for maintaining integrity across various applications involving cable wire and armored cable setups. A reputable cable accessories manufacturer will offer high-quality spark fittings designed to withstand environmental challenges while ensuring optimal electrical performance.

Final Thoughts on Cable Accessories Selection

Selecting the right cable accessories is not just about functionality; it’s about establishing a partnership with a manufacturer who understands your unique needs in power systems. With advancements in technology reshaping production methods, it’s crucial to choose a forward-thinking partner who embraces innovation while maintaining quality standards across their product range. Ultimately, investing time into this selection process pays off by enhancing the overall success of your projects involving power fittings and beyond.