Introduction

In the world of telecommunications, fiber optic cables have revolutionized data transmission, offering high-speed connectivity that is both reliable and efficient. Understanding the essentials of fiber optic drop cables is crucial for anyone involved in their installation or maintenance. These cables, often made from fiberglass optic material, require specific components to ensure optimal performance—one of which is the cable tension clamp.

Understanding Fiber Optic Drop Cable Essentials

Fiber optic drop cables are designed to connect end-users to a broader network infrastructure, delivering signals with minimal loss and interference. These cables consist of a core surrounded by cladding, which allows light to be transmitted effectively over long distances. Proper handling and installation of fiber optic cable are vital; any stress or strain can lead to performance issues or even damage.

The Role of Tension Clamps in Fiber Setup

Tension clamps play a pivotal role in securing fiber optic cables during installation and throughout their operational life. By providing necessary support and stability, these clamps help maintain the integrity of the connections while minimizing stress on the delicate fibers within the cable. Without adequate tension management through cable tension clamps, installations may face increased risks of failure or degradation over time.

Key Features of Fiber Optic Cable Tension Clamps

When selecting a cable tension clamp for your fiber optic setup, several key features should be considered to ensure optimal performance. High-quality materials that resist environmental factors such as UV exposure and moisture can significantly enhance durability and longevity. Additionally, an effective design should accommodate various sizes and types of fiber optic cable, ensuring compatibility across different installations.

What is a Fiber Optic Drop Cable Tension Clamp?

Fiber optic drop cable tension clamps are essential components designed to secure and support fiber optic cables in various installations. These clamps play a crucial role in maintaining the integrity of the fiber optic cable, ensuring it remains taut and free from stress that could compromise performance. By providing reliable support, a cable tension clamp helps facilitate seamless data transmission over long distances.

Definition and Purpose

A fiber optic drop cable tension clamp is essentially a device used to attach and secure fiber optic cables to poles, buildings, or other structures. Its primary purpose is to maintain proper tension on the fiber optic cable while minimizing movement and vibration that could lead to damage over time. By doing so, these clamps help protect the delicate fibers within the fiberglass optic cable from excessive strain or bending, which can disrupt signal quality.

Importance in Fiber Optic Installations

In any fiber optic installation, the importance of using a quality cable tension clamp cannot be overstated. These clamps not only ensure that the fiber optic cables remain securely fastened but also play a pivotal role in reducing stress at connection points where fibers meet other components of the network. This added layer of protection enhances overall system reliability and longevity, making it an indispensable part of any successful installation involving fiber cables.

Variations in Design and Use

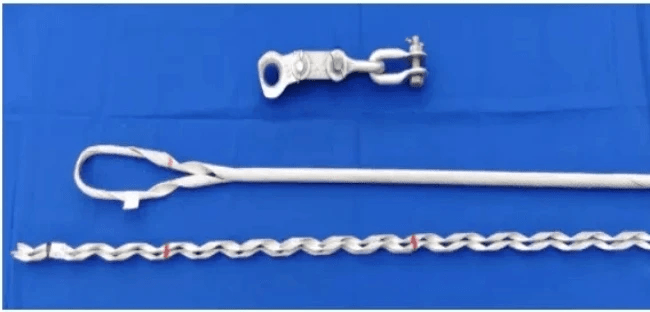

Cable tension clamps come in various designs tailored for specific applications within the realm of fiber optics. Some are made from durable materials like aluminum or stainless steel for enhanced strength and corrosion resistance, while others might incorporate features such as adjustable tension settings or integrated strain relief mechanisms. The choice between different types often depends on factors such as environmental conditions, installation location, and specific requirements related to the type of fiberglass optic cable being used.

Benefits of Using Cable Tension Clamps

When it comes to fiber optic installations, the little things often make a big difference. One such unsung hero is the cable tension clamp, which plays a pivotal role in securing fiber optic cables. By ensuring that these delicate fibers are held firmly in place, we can prevent costly damage and maintain optimal performance for our networks.

Securing Fiber Optic Cables Effectively

The primary function of a cable tension clamp is to secure fiber optic cables effectively, providing stability against environmental factors like wind and temperature fluctuations. This secure hold prevents excessive movement or sagging, which could lead to disruptions in service or even physical damage to the fiber optic cable itself. With proper installation of these clamps, you can trust that your fiberglass optic cable will remain intact and operational for years to come.

Reducing Stress on Fiber Connections

Another significant benefit of using a cable with clamp is its ability to reduce stress on fiber connections. When cables are improperly secured, they can experience strain at connection points, leading to potential failures or degraded signal quality over time. By utilizing a well-designed tension clamp system, you minimize this risk and enhance the overall reliability of your fiber optic setup.

Enhancing Longevity of Fiber Installations

Investing in high-quality cable tension clamps not only secures your fiber optics but also enhances the longevity of your installations. These clamps are designed to withstand various environmental conditions while protecting the sensitive components within the fiber optic system from wear and tear. Ultimately, using a robust cable tension clamp means fewer maintenance issues down the line and a longer lifespan for your entire network infrastructure.

Spark Fittings: A Leader in Tension Clamps

When it comes to fiber optic installations, Spark Fittings stands out as a premier provider of cable tension clamps. Their extensive range of products is designed to meet the diverse needs of the fiber optic industry, ensuring that every fiber optic cable is secured and protected effectively. With a commitment to quality and innovation, Spark Fittings has earned a reputation for excellence among professionals in the field.

Overview of Spark Fittings’ Offerings

Spark Fittings offers an impressive selection of cable tension clamps tailored for various applications in fiber optic setups. From standard models to specialized designs, their catalog includes everything needed to secure fiber optic cables securely in place. Each product is engineered with precision, ensuring optimal performance and durability for all types of installations involving fiberglass optic cable.

In addition to traditional clamps, Spark Fittings also provides accessories that enhance the functionality and effectiveness of their cable with clamp systems. This comprehensive approach means that customers can find all they need under one roof, simplifying the procurement process and ensuring compatibility across components. Whether you’re working on a small project or a large-scale installation, Spark Fittings has solutions that cater to your specific requirements.

Importance of Material Selection in Clamps

The material used in manufacturing cable tension clamps plays a crucial role in their overall performance and longevity. High-quality materials ensure that these clamps can withstand environmental stresses while maintaining their grip on fiber optic cables over time. Spark Fittings prioritizes material selection by utilizing robust compounds that resist corrosion, UV degradation, and extreme temperatures.

This attention to detail means that when you choose a cable tension clamp from Spark Fittings, you're investing in reliability and peace of mind for your fiber installations. The right materials not only enhance the durability but also reduce maintenance needs over time—an essential factor for any professional dealing with fiber optic systems. By focusing on superior material choices, Spark Fittings ensures their products are built to last.

Custom Armor Rod Solutions from Spark Fittings

One standout feature of Spark Fittings' offerings is their ability to provide custom armor rod solutions specifically designed for unique installation challenges involving fiber cables optic systems. These custom solutions allow installers to address specific site conditions or requirements effectively while ensuring optimal protection for sensitive fibers within the drop cables.

With these tailored offerings, professionals can enhance both security and performance when deploying fiberglass optic cables across various environments—be it urban settings or rugged terrains requiring extra support against tension forces or environmental factors like wind or ice load stressors. This level of customization sets Spark Fittings apart from competitors who may only provide off-the-shelf options without considering unique project specifications.

By leveraging innovative designs alongside high-quality materials, Spark Fittings continues leading the way in providing effective solutions for securing fiber optics through reliable cable tension clamps.

Installing Fiber Optic Cable Tension Clamps

Installing fiber optic cable tension clamps is a crucial step in ensuring the integrity and performance of your fiber optic installations. Proper installation helps secure the fiber optic cables, preventing unnecessary stress and potential damage. With the right tools and techniques, you can effectively set up your cable with clamp for optimal performance.

Tools Required for Installation

Before diving into the installation process, gather all necessary tools to ensure a smooth operation. Essential tools include a torque wrench, pliers, and a suitable screwdriver to tighten screws on the cable tension clamp securely. Additionally, having safety goggles and gloves on hand is wise to protect yourself while handling fiberglass optic cable.

It's also helpful to have a measuring tape handy for precise placement of your fiber optic cables during installation. A level can help ensure that everything is aligned correctly, reducing future maintenance issues. Lastly, consider having a utility knife nearby for trimming any excess cable as needed.

Step-by-Step Installation Guide

1. **Preparation**: Start by identifying the location where you will install the fiber optic cable tension clamp. Ensure that the area is clean and free from debris that might interfere with your setup.

2. **Positioning**: Place the fiber optic cable in its designated pathway and use your measuring tape to determine where to attach the tension clamp securely along its route.

3. **Attaching the Clamp**: Use pliers or a torque wrench to fasten the clamp around the fiber optic cable snugly but not overly tight—remember that excessive force can damage both your cables and connections.

4. **Final Checks**: Once installed, double-check that everything is aligned correctly and there’s no undue stress on any part of your setup—this will enhance longevity in your fiber installations.

5. **Documentation**: Record each installation step taken for future reference or maintenance checks; it’s always useful when troubleshooting later on!

Common Mistakes to Avoid

One common mistake during installation is over-tightening the cable tension clamp, which can lead to damage of both the clamp itself and possibly even breakage of delicate fibers within your fiberglass optic cable system. Always follow manufacturer guidelines regarding torque specifications when securing clamps around cables.

Another frequent oversight involves neglecting proper alignment; misalignment can cause stress points along your fiber optic connections over time, leading to potential failures down the line. Make sure everything sits straight before finalizing each connection with clamps.

Lastly, failing to conduct regular inspections post-installation can lead you into trouble later on—make it a habit! Regular checks will help identify wear and tear early before they escalate into bigger issues with your fiber optics setup.

Maintenance and Troubleshooting

Maintaining your cable tension clamp is crucial for the longevity and reliability of your fiber optic installations. Regular checks can help you identify potential issues before they escalate, ensuring that your fiber optic cable remains secure and functional. By following a structured maintenance routine, you can keep your fiber optic systems operating smoothly.

Regular Checks to Ensure Clamps Function Properly

To ensure that your cable tension clamp is functioning as intended, schedule regular inspections of all installed clamps. Look for any signs of looseness or misalignment, as these can compromise the integrity of the entire system. Additionally, checking the condition of the fiber optic cable itself will help prevent any unforeseen issues related to wear and tear.

It's essential to assess not only the physical condition but also how well each clamp secures its respective fiber optic cable. Ensure that there are no visible signs of stress on both the clamps and cables; this includes checking for fraying or excessive bending in the fiber optic fiber itself. By routinely monitoring these components, you'll significantly reduce downtime and maintain optimal performance.

Identifying Wear and Tear

Identifying wear and tear on a cable with clamp is vital for maintaining an effective installation. Common indicators include frayed cables, cracks in the clamp material, or corrosion due to environmental exposure. If you notice any unusual changes in appearance or functionality, it's time to take action before things worsen.

Pay special attention to areas where stress may accumulate—such as bends or joints—since these are often the first places wear becomes evident. A thorough inspection should encompass not just visual assessments but also tactile ones; feel for any irregularities that may indicate underlying issues with either the fiberglass optic cable or its associated clamps. Catching these problems early means you can replace components before they lead to costly repairs.

Addressing Common Issues with Clamps

When it comes to addressing common issues with tension clamps, understanding their typical failures can save you time and effort in troubleshooting. One frequent problem is loosening over time due to vibrations or environmental factors; tightening them back into place often resolves this issue quickly without needing replacements.

Another common concern involves misalignment caused by external forces such as wind or weight from hanging cables; realigning your cable tension clamp can restore stability effectively while reducing stress on both the clamp and fiber optic connections themselves. If persistent problems arise despite regular maintenance efforts, consider consulting a professional who specializes in fiber optics for further assistance.

In conclusion, keeping an eye on your cable tension clamps ensures that your fiber optic installations remain robust over time while minimizing downtime caused by unexpected failures.

Conclusion

In the world of fiber optic installations, selecting the right cable tension clamp can significantly impact the durability and performance of your setup. With various options available, it’s essential to consider factors such as material, design, and compatibility with your specific fiber optic cable. A well-chosen cable with clamp not only secures your fibers but also contributes to a more efficient installation process.

Choosing the Right Cable Tension Clamp

When choosing a cable tension clamp for your fiber optic installation, assess the specific needs of your project first. Different types of clamps are designed for varying environments and applications; some may be better suited for outdoor use while others excel indoors. Additionally, ensure that the selected clamp is compatible with both fiberglass optic cables and standard fiber optic cables to guarantee optimal performance.

Consideration should also be given to the materials used in manufacturing cable tension clamps. High-quality materials can withstand environmental stressors such as temperature fluctuations and moisture exposure, which are crucial for maintaining the integrity of fiber connections over time. By investing in a reliable cable tension clamp that meets these criteria, you can enhance not only the longevity but also the overall efficiency of your fiber installations.

Key Takeaways on Fiber Optic Installations

Fiber optic installations require careful planning and execution to ensure long-lasting performance; this includes understanding how a quality cable tension clamp plays into that equation. Securing fiber optic cables effectively reduces stress on connections, which is key to avoiding future issues like signal loss or physical damage. Remember that regular maintenance checks are vital in identifying wear and tear before they escalate into significant problems.

Moreover, utilizing top-notch components—like those offered by leading manufacturers—can make all the difference in achieving optimal results with your installations. By prioritizing quality over cost-cutting measures when selecting materials or tools, you set yourself up for success in any project involving fiber optics. The right choices today will save time and resources tomorrow.

Final Thoughts on Spark Fittings Solutions

Spark Fittings stands out as a leader in providing high-quality solutions tailored specifically for fiber optic applications including their innovative cable tension clamps. Their commitment to using durable materials ensures that every product contributes positively to enhancing system longevity while reducing risks associated with installation failures or maintenance issues down the line. If you're serious about optimizing your fiber optics setup, exploring Spark Fittings’ range could prove invaluable.

Ultimately, whether you’re working with traditional fiber cables or specialized fiberglass optic cables, having dependable tools—like a robust cable tension clamp—will empower you to achieve superior results consistently across projects. So go ahead: embrace quality solutions from trusted providers like Spark Fittings and watch your installations thrive!