Introduction

In the world of power distribution, overhead line fittings play a crucial role in ensuring that electric wire is securely connected and capable of withstanding various environmental conditions. These fittings are not merely accessories; they are essential components that help maintain the integrity and efficiency of power lines. Understanding their significance can illuminate how they contribute to the overall functionality of our electrical systems.

What are Overhead Line Fittings

Overhead line fittings refer to a range of hardware used in conjunction with electric wires to support, secure, and connect power lines effectively. These fittings include items such as insulators, clamps, and armor rods, which work together to ensure that copper wire and aluminum wire can transmit electricity safely and efficiently over long distances. Without these vital components, the reliability of power distribution would be severely compromised.

Importance of Overhead Line Fittings

The importance of overhead line fittings cannot be overstated; they are fundamental for maintaining safety standards in power distribution networks. Properly designed and installed fittings help reduce wear on electric wires caused by environmental factors like wind, rain, or ice accumulation. Furthermore, these fittings enhance the overall efficiency of electrical systems by minimizing energy loss during transmission through reliable connections between conductors.

Overview of Spark Fittings

Spark Fittings is a name synonymous with quality in the realm of overhead line fittings. They specialize in manufacturing innovative solutions tailored for both copper wire and aluminum wire applications in power distribution systems. By focusing on advancements such as preformed armor rods and customized designs, Spark Fittings ensures that their products meet the evolving needs of modern electrical infrastructure.

Understanding Overhead Line Fittings

When it comes to the intricate world of power distribution, overhead line fittings play a crucial role in ensuring that electric wire is effectively and safely connected. These fittings are essential components that support and maintain the integrity of power lines, allowing for efficient transmission of electricity over long distances. Without these fittings, the entire system could falter, leading to interruptions in service or even dangerous situations.

Definition and Purpose

Overhead line fittings are specialized hardware designed to secure and connect electric wire to various structures such as poles or towers. Their primary purpose is to provide mechanical support, maintain proper tension on the wires, and facilitate safe electrical connections between different segments of the power distribution network. By ensuring that copper wire or aluminum wire is properly secured, these fittings help prevent sagging or breakage under environmental stressors like wind or ice.

Key Components Explained

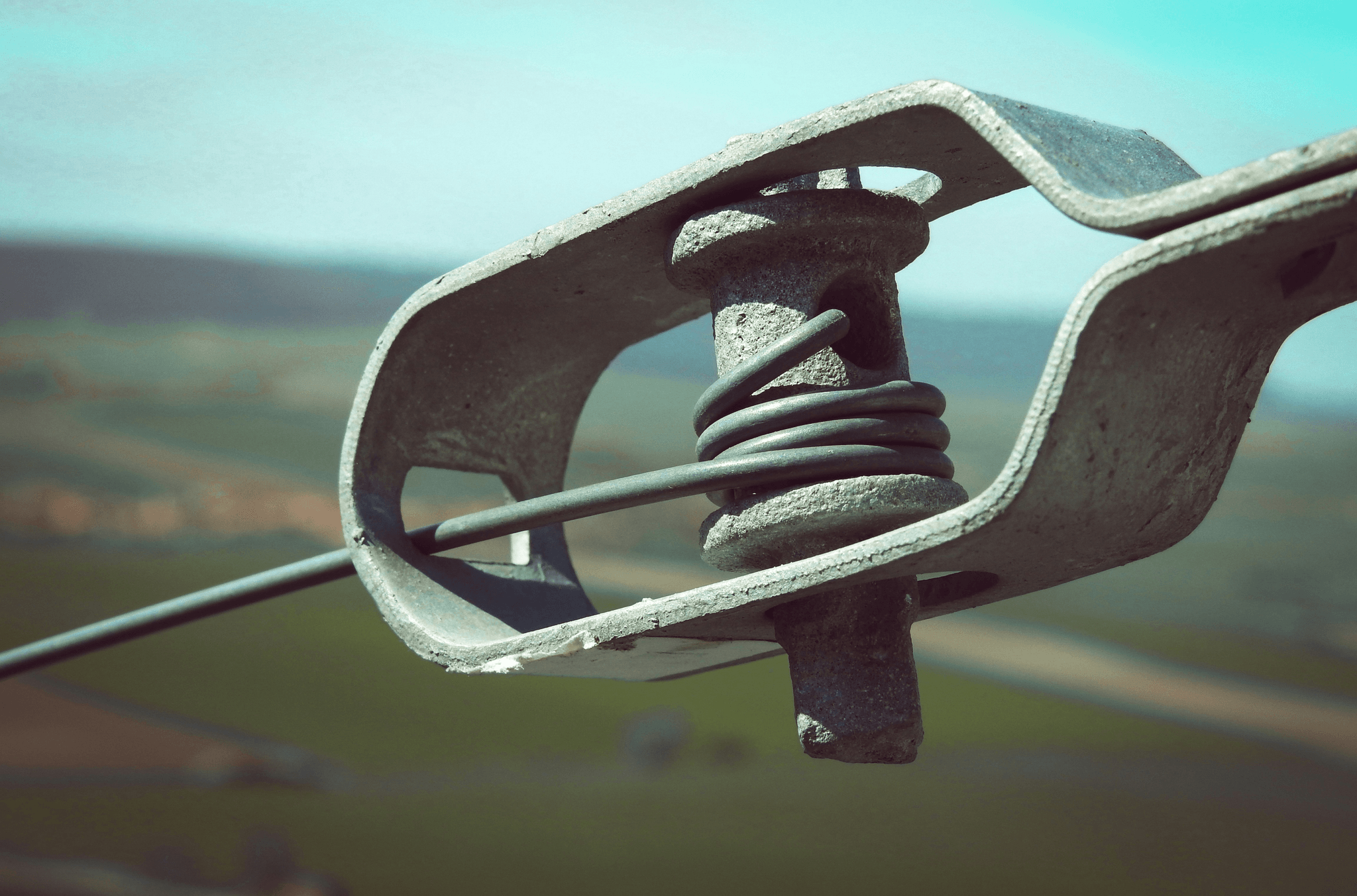

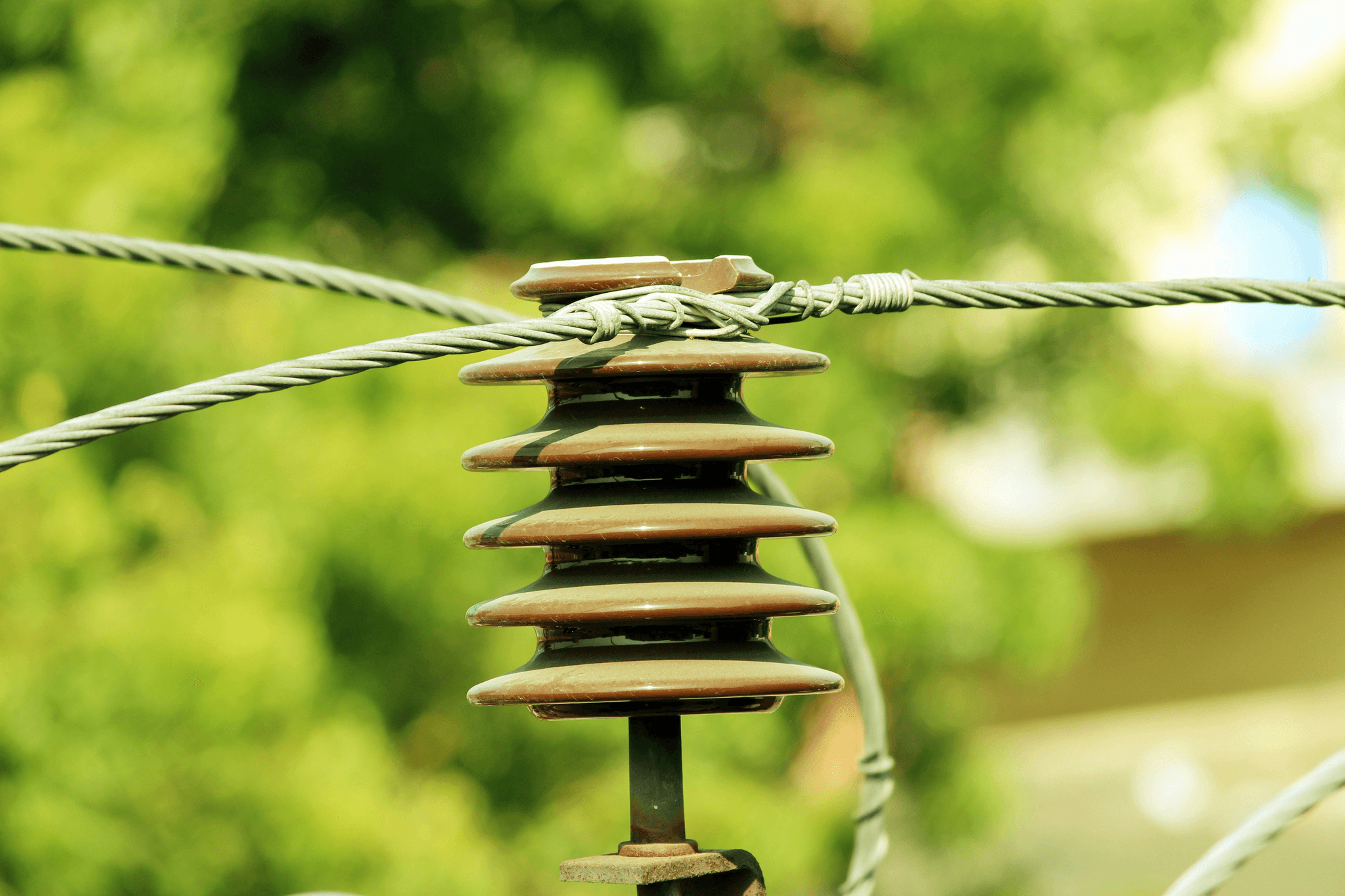

Understanding the key components of overhead line fittings is essential for anyone involved in power distribution. These fittings typically include items such as insulators, clamps, connectors, and armor rods—all vital for maintaining the integrity of electric wire systems. Each component has a specific function; for instance, insulators prevent electrical leakage while clamps secure the wires firmly in place against their supporting structures.

Types of Overhead Line Fittings

There are several types of overhead line fittings available on the market today, each designed for specific applications within power distribution systems. Some common types include suspension clamps used to hold wires at various points along their length and dead-end clamps which anchor wires at their terminations. Additionally, there are specialized armor rods that protect copper wire from abrasion and wear caused by environmental factors—an essential consideration when selecting fittings for your project.

The Role of Armor Rods

Armor rods play a crucial role in the realm of overhead line fittings, acting as protective elements that enhance the durability and longevity of electric wire installations. These specialized fittings are designed to safeguard power lines against various environmental factors and mechanical stresses, ensuring that power distribution remains efficient and reliable. With their strategic placement on conductors, armor rods contribute significantly to the overall performance of the electric wire network.

Material Choices for Armor Rods

When it comes to selecting materials for armor rods, several options are available, each with unique properties suited for specific applications in overhead line fittings. Common materials include fiberglass, aluminum, and composite materials that provide excellent resistance to wear and tear while maintaining lightweight characteristics. Choosing the right material is essential not only for protecting copper wire or aluminum wire but also for enhancing the overall efficiency of power distribution systems.

Benefits of Matching Materials

One significant advantage of matching materials between armor rods and conductors lies in minimizing galvanic corrosion risks when connecting different types of metal wires such as copper wire and aluminum wire. This compatibility helps ensure a longer lifespan for both the armor rods and the electric wire they protect, leading to reduced maintenance costs over time. Additionally, using matched materials can improve electrical conductivity within power lines, promoting optimal performance across the entire power distribution network.

Color Coding System for Identification

To streamline installation processes and enhance safety protocols within overhead line fittings, a color coding system has been developed for identifying different types of armor rods quickly. Each color corresponds to specific material types or sizes, allowing technicians to make informed decisions during installation or repairs without confusion. This systematic approach not only aids in efficient handling but also ensures that all components work harmoniously together in supporting electric wire networks effectively.

Power Distribution and Fittings

When it comes to efficient power distribution, the connection between overhead line fittings and power lines is crucial. Overhead line fittings serve as the vital link that ensures electric wire functions optimally, allowing for seamless transmission of electricity. These fittings are designed to withstand environmental stresses while maintaining a reliable connection for various types of conductors.

Connection Between Power Lines and Fittings

The connection between power lines and fittings is not just a matter of convenience; it's essential for the safety and reliability of electrical systems. Overhead line fittings must be compatible with both copper wire and aluminum wire, ensuring that they provide a secure grip on the conductors. This compatibility helps prevent issues like arcing or overheating, which can lead to power outages or even hazardous situations.

Impact on Power and Distribution Efficiency

The efficiency of power distribution is heavily influenced by the quality of overhead line fittings used in the system. High-quality fittings minimize resistance at connections, which enhances overall performance in electric wire transmission. When power lines are equipped with suitable overhead line fittings, it results in lower energy losses and improved reliability in delivering electricity to consumers.

Selecting the Right Fittings for Different Conductors

Choosing the right overhead line fittings for different conductors is paramount in optimizing power distribution systems. For instance, copper wire requires specific types of connectors that can handle its unique properties compared to aluminum wire. Understanding these distinctions ensures that each fitting serves its purpose effectively, thereby enhancing both performance and longevity within the electrical infrastructure.

Manufacturing Excellence with Spark Fittings

In the competitive landscape of power distribution, Spark Fittings stands out for its commitment to quality and innovation in overhead line fittings. With years of experience in the industry, they offer a comprehensive suite of services that cater to various needs in electric wire applications. Their expertise ensures that every component is designed to enhance the performance and longevity of power lines.

Overview of Spark Fittings Services

Spark Fittings provides a wide array of services focused on manufacturing high-quality overhead line fittings tailored for both copper wire and aluminum wire applications. Their offerings include design consultation, production, and installation support, ensuring clients receive comprehensive assistance throughout their projects. By emphasizing customer satisfaction and reliability, Spark Fittings has built a reputation as a go-to provider for efficient power distribution solutions.

Innovations in Preformed Armor Rods

One area where Spark Fittings excels is in the development of preformed armor rods, which play a crucial role in protecting electric wire from wear and tear. These innovative products are designed using advanced materials that not only enhance durability but also reduce installation time significantly. By integrating cutting-edge technology into their manufacturing processes, Spark Fittings ensures that their armor rods meet the highest standards for safety and efficiency in power distribution.

Customized Solutions in Power Distribution

Recognizing that each project has unique challenges, Spark Fittings offers customized solutions tailored specifically to client needs within the realm of overhead line fittings. Whether it’s optimizing designs for specific types of copper wire or addressing particular environmental concerns related to corrosion, their team collaborates closely with customers to deliver effective results. This dedication to personalized service enables clients to achieve greater efficiency and reliability in their power distribution systems.

Effects of Material Selection

The choice of materials in overhead line fittings can significantly impact the efficiency and reliability of power distribution systems. Two primary contenders in this arena are copper wire and aluminum wire, each with its own set of advantages and disadvantages. Understanding these differences is crucial for ensuring optimal performance in electric wire applications.

Copper Wire vs. Aluminum Wire

This means that when power lines utilize copper, they can achieve better efficiency in power and distribution, minimizing energy loss during transmission. However, the added cost of copper can be a deterrent; thus, many opt for aluminum wire due to its lighter weight and lower price point, making it a popular choice in various installations.

Despite the cost benefits associated with aluminum wire, it's important to consider its conductivity drawbacks when selecting electric wire for specific applications. While aluminum may be easier on the budget, it requires larger diameters to match the conductivity levels of its copper counterpart—potentially complicating overhead line fittings design and installation. Ultimately, the decision between copper and aluminum should factor in not only upfront costs but also long-term performance and maintenance needs.

Corrosion Considerations in Fittings

Corrosion is an ever-present concern when discussing overhead line fittings because it can significantly compromise their integrity over time. Both copper and aluminum exhibit different corrosion behaviors; while copper tends to form a protective patina that slows down corrosion, aluminum can suffer from galvanic corrosion when paired improperly with other metals in electric wire configurations. This makes material selection critical—not just for performance but also for ensuring the longevity of power lines.

To mitigate corrosion risks effectively, it's essential to choose compatible materials for all components involved in power distribution systems. For instance, using similar metals or applying protective coatings can help prevent electrochemical reactions that lead to premature degradation of fittings. Understanding these nuances will aid engineers and technicians alike as they select appropriate materials that enhance both durability and safety across various installations.

Longevity and Performance in Installation

The longevity of overhead line fittings directly correlates with material selection; components made from high-quality materials tend to withstand environmental challenges more effectively than inferior options. Copper wires generally offer better resistance against wear-and-tear due to their robust nature compared to aluminum wires which may require more frequent inspections or replacements over time—especially if exposed to harsh conditions or corrosive elements during installation or operation.

Moreover, proper installation techniques play a vital role alongside material selection; even the best electric wires will underperform if not installed correctly within the context of overhead line fittings design principles. Ensuring tight connections without undue stress on cables will extend service life while maximizing performance across all aspects of power distribution systems involved—so never underestimate the importance of skilled workmanship!

Conclusion

In wrapping up our exploration of overhead line fittings, it’s clear that these components play a critical role in the functionality and efficiency of power distribution systems. Understanding the various types of fittings, their materials, and their applications is essential for anyone involved in the installation or maintenance of power lines. The right overhead line fittings not only enhance performance but also ensure safety and longevity for both copper wire and aluminum wire installations.

Key Takeaways on Overhead Line Fittings

Overhead line fittings are indispensable in maintaining the integrity and reliability of electric wire systems. They connect different components seamlessly, ensuring optimal power distribution while minimizing losses. Whether you're dealing with copper wire or aluminum wire, selecting the appropriate fittings can significantly impact overall system performance.

The Future of Power Distribution

The future of power distribution looks promising, with innovations continually enhancing how we manage electric wire infrastructure. As renewable energy sources gain traction, overhead line fittings will evolve to accommodate new technologies and materials. This evolution will not only improve efficiency but also pave the way for smarter power lines that integrate seamlessly into modern grids.

Importance of Choosing Quality Suppliers

Choosing quality suppliers for overhead line fittings is crucial to ensure reliability in your power distribution projects. Quality suppliers understand the nuances between different types of wires—whether it’s copper wire or aluminum wire—and provide products that meet industry standards. By prioritizing quality in your supply chain, you can enhance both safety and efficiency in your installations.