Introduction

In the world of electrical systems, understanding the nuances of various components is crucial for ensuring optimal performance and safety. One such component that often flies under the radar is the bolted type PG connector. This little hero, part of a broader family known as PG connector types, plays an essential role in creating reliable and robust connections in a myriad of applications.

Understanding the Bolted Type PG Connector

The bolted type PG connector stands out due to its design, which allows for a secure and durable connection between conductors. Unlike other connection methods that may rely on soldering or crimping, this type utilizes bolts to fasten conductors together, providing excellent conductivity and mechanical strength. This feature makes it particularly appealing for high-load scenarios where reliability is non-negotiable.

Importance of PG Connector Types in Electrical Systems

PG connector types are pivotal in maintaining the integrity of electrical installations across various industries. Their ability to handle different conductor sizes and configurations ensures flexibility while minimizing downtime during maintenance or upgrades. By choosing the right PG connector, engineers can enhance system efficiency and reduce potential points of failure.

Overview of Parallel Groove Connector PG

Among the various options available within PG connector types, the parallel groove connector PG is particularly noteworthy. It features a unique design that accommodates two conductors running parallel to each other, making it ideal for applications requiring tight space constraints or specific alignment needs. Understanding its functionality can lead to better decision-making when selecting components for your next project.

Anatomy of the Bolted Type PG Connector

Understanding the anatomy of the bolted type Parallel Groove Connector PG is essential for anyone working in electrical systems. These connectors are designed to ensure reliable and efficient connectivity, making them a popular choice among various PG connector types. By breaking down their key components, functionality, and benefits, we can appreciate why they are indispensable in electrical installations.

Key Components of PG Connectors

At first glance, a bolted type PG connector may seem straightforward, but it consists of several vital components that contribute to its effectiveness. The primary elements include the connector body, bolts, and grooves where conductors are inserted. Each component plays a crucial role: the body provides structural integrity, while the bolts create a tight grip on the conductors for optimal conductivity.

Additionally, many PG connectors feature insulators that enhance safety by preventing accidental contact with live wires. The materials used in these connectors often include high-quality aluminum or copper to withstand environmental factors and ensure longevity. Understanding these components helps users select the right PG clamp for their specific application.

How Bolted Connection Works

The magic behind how bolted connections work lies in their design and mechanics. When two conductors are placed within the grooves of a Parallel Groove Connector PG and secured with bolts, they form a strong connection through compression. This compressive force ensures that there is minimal resistance to current flow while also reducing heat generation during operation.

Moreover, this connection method allows for easy disassembly when maintenance or upgrades are needed without damaging the conductors themselves. The simplicity of using tools like wrenches makes installation straightforward yet effective—a significant advantage over other types of connections that may require more complex procedures. In essence, bolted connections provide reliability without unnecessary complications.

Benefits of Choosing Bolted Types

Choosing bolted type PG connectors comes with an array of benefits that make them stand out among other PG connector types in electrical applications. First off, their robust design allows them to handle high current loads effectively while maintaining excellent conductivity—an essential factor for any electrical system's performance.

Additionally, these connectors offer exceptional durability against environmental stressors such as moisture and temperature fluctuations thanks to their solid construction materials and secure fastening methods—making them ideal for outdoor use or harsh conditions. Lastly, ease of installation means reduced labor costs and time spent on projects; once you grasp how these connectors work, you're well on your way to achieving reliable electrical connectivity.

Diverse PG Connector Types Explained

Each type of parallel groove connector PG has its unique features, advantages, and applications that cater to different project requirements. Whether you're working on a large-scale industrial project or a smaller residential setup, knowing your options can make all the difference.

Comparing Different PG Connector Types

Comparing different PG connector types reveals a spectrum of choices tailored for specific needs. From bolted connectors that offer robust mechanical strength to compression types that provide excellent conductivity, each has its place in the world of electrical connectivity. Understanding these distinctions helps you select the right pg connector for your application, ensuring optimal performance and safety.

For instance, while bolted parallel groove connectors are favored for their durability and ease of installation, other designs may excel in particular environments or materials. It's essential to evaluate factors such as current capacity, environmental exposure, and installation conditions when making your choice among various PG connector types. This comparison not only aids in selecting the best fit but also enhances overall system reliability.

Selecting the Right PG Connector for Your Project

Choosing the right pg connector involves more than just picking one off the shelf; it requires careful consideration of your project's specific demands. Start by assessing the electrical load requirements and environmental conditions where the connection will be made—this will guide you toward suitable options among available PG connector types. Additionally, consider factors like ease of installation and maintenance needs when making your selection.

Another key aspect is compatibility with existing systems; ensure that your chosen parallel groove connector PG integrates seamlessly with other components in your electrical setup. Collaborating with knowledgeable suppliers can also provide valuable insights into which connectors might best suit your project’s unique challenges. Ultimately, selecting the right pg clamp or connector not only enhances performance but also contributes to long-term reliability.

Versatility in Applications

The versatility of pg connectors makes them indispensable across various industries—from utilities to telecommunications and beyond. Their design allows them to adapt easily to different wire sizes and configurations while maintaining secure connections under varying conditions. This adaptability means that regardless of whether you're connecting overhead power lines or intricate control systems, there's likely a suitable parallel groove connector PG available to meet your needs.

Moreover, as technology evolves and industries grow more complex, so too do the applications for these connectors expand—enabling innovative solutions tailored specifically for modern challenges like renewable energy integration or smart grid technologies. The ability to customize certain features within pg clamps further enhances their applicability across diverse scenarios without compromising safety or performance standards. In summary, understanding this versatility empowers engineers and technicians alike to make informed decisions about their connectivity solutions.

The Role of PG Clamps in Electrical Installations

These essential components secure the connections made by various PG connector types, including the Parallel Groove Connector PG. Without proper clamping, even the best connectors could fail under stress or environmental factors, leading to costly downtime or safety hazards.

Importance of PG Clamps in Connectivity

PG clamps are crucial for maintaining a solid connection between conductors, which is vital for efficient energy transmission. They provide mechanical support and electrical continuity while also protecting against environmental elements that could compromise the integrity of the pg connector. In essence, these clamps help create a robust electrical system that can withstand both operational demands and external conditions.

Moreover, when using different PG connector types, it's important to match them with compatible clamps to achieve optimal performance. A well-chosen clamp not only enhances connectivity but also prolongs the lifespan of your electrical installations. Therefore, understanding the significance of PG clamps can make all the difference in achieving reliable and safe electrical connections.

Installation Tips for Efficient Use

To ensure efficient use of your PG clamps during installation, start with a thorough assessment of your system's requirements. Selecting the right size and type of clamp for your specific pg connector is essential; an ill-fitting clamp can lead to weak connections or even failures down the line. Additionally, always follow manufacturer guidelines regarding torque specifications when tightening bolts—over-tightening can damage both connectors and cables.

While installing Parallel Groove Connector PG systems, make sure to clean surfaces before securing them with clamps; this ensures better contact and reduces resistance at connection points. It's also beneficial to periodically inspect installed clamps as part of routine maintenance; catching issues early can save time and money in repairs later on. Remember that a little extra care during installation goes a long way toward achieving long-lasting reliability.

Common Mistakes to Avoid

One common mistake many make when working with PG connectors is neglecting compatibility between different components—using mismatched pg connector types and clamps can lead to poor performance or failure altogether. Another frequent pitfall is overlooking environmental factors such as moisture or corrosion that may affect clamp effectiveness over time; always opt for corrosion-resistant materials where applicable!

Additionally, some installers forget about proper torque settings during installation; this oversight can result in loose connections that compromise safety and efficiency. Always double-check your work before finalizing installations—it's far better to take an extra moment than face potential issues later on! By avoiding these mistakes, you’ll ensure your electrical installations remain secure and efficient for years to come.

Spark Fittings: Innovators in Armor Rod Solutions

Their offerings are designed to meet the diverse needs of electrical systems while ensuring reliability and efficiency. With a strong focus on quality, Spark Fittings provides various products that integrate seamlessly with PG connectors and other components.

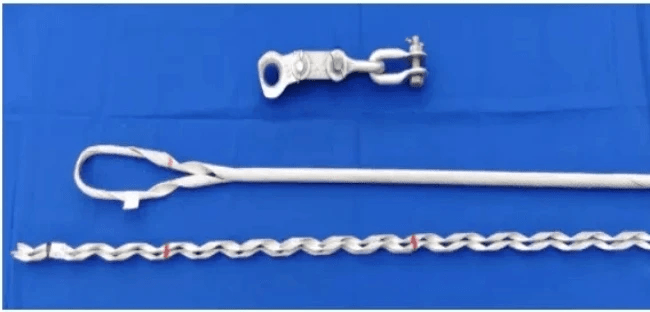

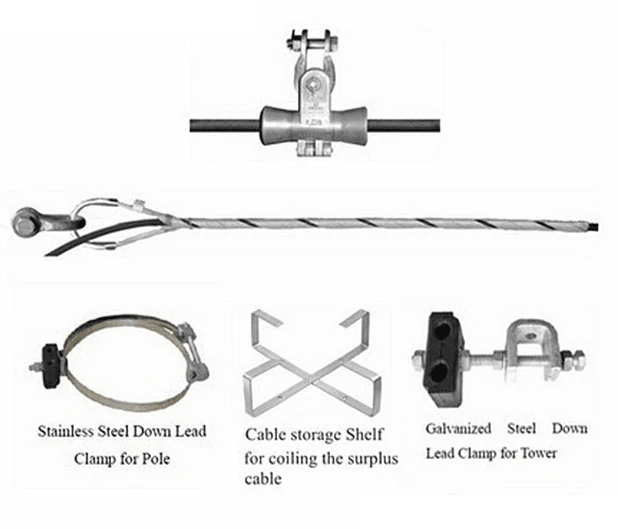

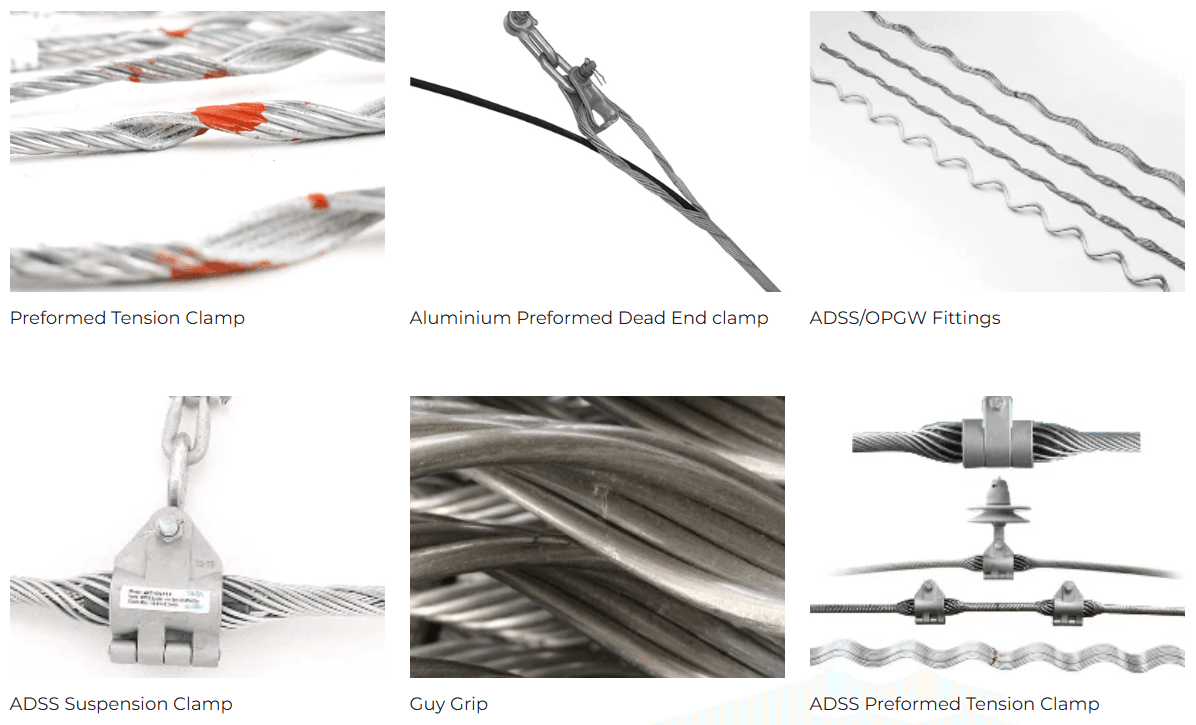

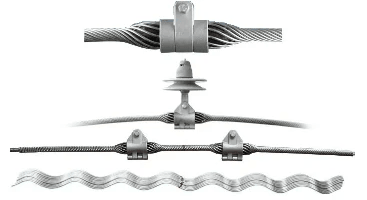

Overview of Spark Fittings and Their Offerings

Spark Fittings has carved a niche for itself by specializing in high-quality armor rods that complement various PG connector types. They offer an extensive range of products designed for different applications, ensuring that every project can find the right solution. From standard options to specialized designs, their catalog reflects a commitment to innovation and performance in electrical installations.

Customization Options for Armor Rods

One of the standout features of Spark Fittings is their dedication to customization when it comes to armor rods. Customers can choose from various sizes, materials, and configurations tailored specifically to their project requirements. This flexibility ensures compatibility with different PG clamps and parallel groove connector PG systems, allowing for optimized performance in any installation.

Understanding Armor Rod Materials and Their Importance

The choice of materials used in armor rods is crucial for ensuring durability and effectiveness in electrical applications. Spark Fittings utilizes high-grade materials that enhance conductivity while providing resistance against environmental factors such as moisture and corrosion. This attention to material selection not only prolongs the life of the PG connector but also enhances overall system reliability.

Installation Guides for Parallel Groove Connectors

Installing a Parallel Groove Connector PG can seem daunting at first, but with the right guidance, it becomes a straightforward task. This section will walk you through the installation process step by step, ensuring that you have a secure connection that meets your project requirements. Whether you're dealing with different PG connector types or looking to enhance your electrical systems with PG clamps, we've got you covered.

Step-by-Step Installation Process

To kick off the installation of your PG connector, start by gathering all necessary tools and materials. You'll need the appropriate size of the parallel groove connector PG, a torque wrench, and any additional hardware specified by the manufacturer. Begin by preparing the conductor ends; they should be clean and free of oxidation to ensure optimal conductivity.

Next, position the conductors within the grooves of the connector and align them properly. It’s crucial to ensure that each conductor is seated correctly in its respective groove before proceeding. Once aligned, tighten each bolt gradually using a torque wrench according to manufacturer specifications; this ensures an even distribution of pressure across all connections.

Finally, double-check your work for any loose connections or misalignments. After securing everything tightly, inspect for proper alignment and make sure no wires are exposed outside of their designated areas. Following these steps will help guarantee that your parallel groove connector PG is installed securely and ready for use.

Tips for Ensuring a Secure Connection

When working with any PG connector types, ensuring a secure connection is paramount to avoid future issues like electrical failures or safety hazards. First off, always use high-quality connectors designed specifically for your application; this minimizes risks associated with inferior products failing under load or environmental stressors.

Another key tip is to apply anti-oxidation grease on conductor surfaces before tightening them into place within the PG clamp. This not only enhances conductivity but also reduces corrosion over time—an essential aspect when dealing with outdoor installations or harsh environments where moisture might be present.

Lastly, consider conducting periodic inspections after installation; checking tightness can save you from future headaches caused by loosening connections due to vibration or thermal expansion over time. By adhering to these tips while installing your parallel groove connectors and clamps, you'll set yourself up for long-term success in maintaining reliable electrical connectivity.

Troubleshooting Common Installation Issues

Even seasoned professionals can run into hiccups during installation involving various PG connector types—so don’t fret if things don’t go as planned! One common issue arises from improper torque application; if bolts are either too loose or overtightened, it could lead to connection failure down the line. Always refer back to those manufacturer specifications!

Another frequent problem involves misalignment of conductors within their grooves during installation; this can result in poor contact points and increased resistance over time—a recipe for disaster! If you notice any irregularities post-installation (like heating), it’s wise to revisit those connections promptly before they cause extensive damage.

Lastly, keep an eye out for signs of corrosion around connectors after some time has passed since installation—this could indicate moisture ingress due either directly through poor sealing techniques used during setup or environmental factors at play outside! Regular maintenance checks will help nip potential issues in bud so you can enjoy uninterrupted service from your trusty pg connectors!

Conclusion

In the world of electrical systems, understanding the various PG connector types is crucial for ensuring reliable and efficient connectivity. The parallel groove connector PG stands out for its unique design and functionality, making it a favorite among professionals. Whether you're selecting a bolted type or exploring other options, knowing the key features will help you make informed decisions.

Key Takeaways on PG Connector Types

PG connector types offer a range of solutions tailored to different electrical needs, from simple connections to more complex applications. The versatility of these connectors allows them to be utilized in various environments, enhancing their appeal in both residential and industrial settings. Ultimately, choosing the right PG connector can significantly impact system performance and longevity.

Spark Fittings as a Reliable Partner

When it comes to sourcing quality connectors and clamps, Spark Fittings emerges as a reliable partner in the industry. Their commitment to innovation ensures that each product meets high standards of safety and efficiency, especially with their impressive range of parallel groove connectors PG. By considering Spark Fittings for your next project, you’re not just purchasing components; you’re investing in reliability.

Final Thoughts on Choosing the Right PG Clamp

Selecting the right PG clamp is pivotal for achieving optimal connectivity in any electrical installation. Factors such as material compatibility, load requirements, and environmental conditions should guide your decision-making process when choosing your clamp. With careful consideration and expert guidance from brands like Spark Fittings, you can ensure that your electrical systems remain robust and efficient.