Introduction

In the realm of power transmission, vibration dampers play a crucial role in maintaining the integrity and efficiency of electrical lines. These unsung heroes work tirelessly behind the scenes, ensuring that high voltage power lines operate smoothly despite the challenges posed by environmental factors. Understanding the function and importance of a vibration damper in transmission line systems is essential for anyone involved in power transmission infrastructure.

Understanding Vibration Dampers in Transmission Lines

Vibration dampers are specialized devices designed to reduce oscillations and vibrations within transmission lines, particularly in overhead power lines. By mitigating these vibrations, they help maintain structural stability and prolong the lifespan of cable lines. The mechanics behind these dampers are fascinating, as they absorb energy from vibrations caused by wind, ice, and other environmental forces affecting high voltage power lines.

Importance of Vibration Dampers in Power Transmission

The significance of vibration dampers cannot be overstated when it comes to optimizing power transmission systems. They not only enhance reliability but also prevent damage that could lead to costly repairs or downtime. In a world where electricity is essential for everyday life, ensuring that electrical lines remain operational without interruptions is paramount—this is where vibration dampers shine.

How Vibration Dampers Enhance Overhead Power Lines

By incorporating vibration dampers into overhead power lines, utility companies can significantly improve overall system performance. These devices help minimize wear and tear on conductors and hardware components, ultimately reducing maintenance costs over time. Additionally, with fewer disruptions caused by excessive vibrations, energy efficiency is enhanced across all cable lines connected to the power grid.

What is a Vibration Damper?

Vibration dampers play a crucial role in maintaining the integrity of transmission lines, especially in high voltage power lines. These devices are designed to mitigate the vibrations that can arise from various sources, including wind and mechanical oscillations. By effectively reducing these vibrations, vibration dampers enhance the performance and longevity of overhead power lines.

Definition and Purpose

A vibration damper in transmission line systems is a device specifically engineered to absorb and dissipate energy from vibrations that occur along electrical lines. Its primary purpose is to minimize the amplitude of oscillations, which can lead to wear and tear on components and ultimately affect power transmission efficiency. In essence, these dampers act as shock absorbers for power lines, ensuring smoother operation under challenging environmental conditions.

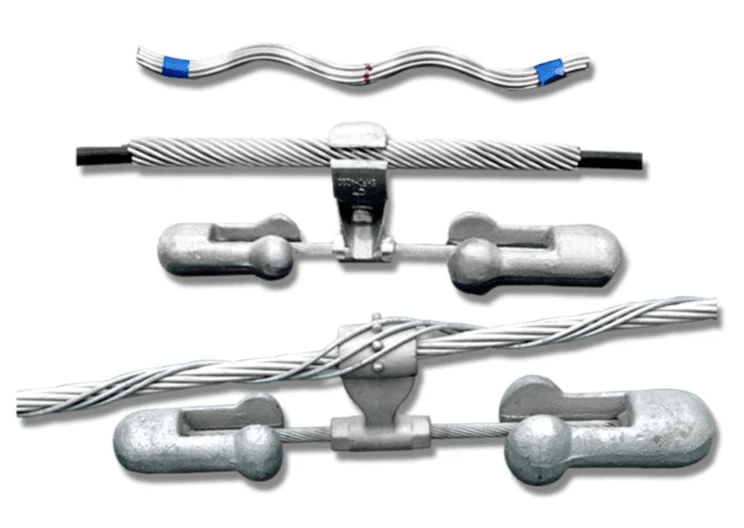

Types of Vibration Dampers

There are several types of vibration dampers used in transmission lines, each tailored for specific applications within high voltage power lines. Common types include stockbridge dampers, which are widely used due to their effectiveness in reducing torsional vibrations; helical dampers that provide excellent damping characteristics; and tuned mass dampers designed for specific frequency ranges. The choice of damper often depends on factors such as the type of cable line being used and the environmental conditions it faces.

Applications in Electrical Lines

Vibration dampers find extensive applications across various electrical lines, particularly in overhead power lines where exposure to wind loads is significant. They help maintain structural integrity by reducing stress on cables and supporting structures caused by vibrations from wind or nearby machinery. Additionally, these devices are employed not only in high voltage power lines but also in other cable lines where minimizing vibration can enhance overall system reliability and efficiency.

Mechanics of Vibration in Transmission Lines

Understanding the mechanics of vibration in transmission lines is essential for maintaining the integrity and efficiency of high voltage power lines. Vibrations can originate from various sources, impacting not just the physical structure of overhead power lines but also their operational efficacy. By delving into the causes, environmental influences, and effects of these vibrations, we can better appreciate the role of vibration dampers in transmission lines.

Causes of Vibration in High Voltage Power Lines

Vibrations in high voltage power lines often stem from a variety of factors including wind loads, ice accumulation, and even electromagnetic forces. Wind-induced vibrations are particularly notorious; as gusts sweep across overhead power lines, they create oscillatory movements that can lead to fatigue over time. Additionally, mechanical interactions between cable lines and their fittings can generate vibrations that exacerbate wear and tear on electrical line components.

Impact of Environmental Factors

Environmental factors play a significant role in how vibrations manifest within transmission lines. For instance, temperature fluctuations can cause materials to expand or contract, leading to increased tension and potential vibration issues within the cables. Furthermore, natural events such as storms or earthquakes can introduce sudden shocks that trigger resonant frequencies in high voltage power lines, causing them to sway dramatically.

Effects of Vibration on Transmission Efficiency

The effects of vibration on transmission efficiency cannot be understated; excessive vibrations can lead to energy losses and reduced performance across electrical line systems. Over time, these disturbances may result in increased maintenance costs due to wear on hardware components like insulators and connectors. By utilizing a vibration damper in transmission line setups, operators can mitigate these negative impacts effectively, ensuring smoother operation and enhanced reliability for power transmission networks.

Benefits of Using Vibration Dampers

When it comes to overhead power lines, the inclusion of a vibration damper in transmission line systems can significantly enhance performance. These devices not only protect the structural integrity of electrical lines but also improve overall efficiency in power transmission. By mitigating vibrations caused by environmental factors, vibration dampers play a crucial role in maintaining the longevity and reliability of high voltage power lines.

Reducing Wear and Tear

One of the primary benefits of installing vibration dampers is their ability to reduce wear and tear on cable lines and associated hardware. High voltage power lines are subjected to various stresses, including wind load and ice accumulation, which can lead to fatigue over time. By absorbing these vibrations, vibration dampers in transmission lines help to prolong the life of conductors and fittings, resulting in lower maintenance costs.

Additionally, less wear means fewer replacements are necessary for components within electrical lines, allowing utilities to allocate resources more effectively. This reduction in wear also translates into enhanced safety for both personnel working on or near the power line infrastructure. In essence, using a vibration damper is akin to giving your transmission system a protective shield against relentless environmental forces.

Enhancing System Reliability

Reliability is paramount when it comes to power transmission; any disruption can lead to significant economic losses and inconvenience for consumers. Vibration dampers enhance system reliability by ensuring that high voltage power lines maintain their structural integrity under duress from external forces like wind or seismic activity. The consistent performance offered by these devices minimizes the risk of unexpected failures that could compromise entire electrical grids.

Moreover, reliable operation reduces the likelihood of cascading failures across interconnected transmission lines, safeguarding against widespread outages. With a well-placed vibration damper in transmission line systems, utilities can ensure that their overhead power lines perform optimally even during adverse conditions. This peace of mind allows energy providers to focus on delivering consistent service rather than worrying about potential disruptions.

Minimizing Downtime in Power Transmission

Downtime is an enemy for any utility company; it disrupts service and leads to disgruntled customers while costing money with every minute that passes without electricity flowing through cable lines. Vibration dampers play a pivotal role in minimizing downtime associated with maintenance activities on high voltage power lines by reducing the frequency of repairs needed due to fatigue-related failures. The proactive approach provided by these devices allows utilities to schedule maintenance during planned outages rather than responding reactively after an incident occurs.

Furthermore, when equipment does need servicing or replacement, having effective vibration dampers installed means repairs can often be performed more quickly and efficiently since there’s less damage overall from vibrations over time. This results not only in reduced operational costs but also improves customer satisfaction as services remain uninterrupted longer than they would without such innovations at play within electrical line infrastructure systems.

Selecting the Right Vibration Damper

Choosing the right vibration damper in transmission lines is crucial for ensuring optimal performance and longevity of power transmission systems. With various options available, understanding the specific requirements of your overhead power lines can make all the difference. This section will guide you through important factors to consider, how to match dampers to line specifications, and the role of Spark Fittings in creating customized solutions.

Factors to Consider

When selecting a vibration damper for high voltage power lines, several factors come into play. First, consider the environmental conditions that your electrical line operates in; factors like wind speed, temperature fluctuations, and humidity can significantly influence vibration behavior. Additionally, it's essential to assess the mechanical properties of your cable lines and how they interact with potential dampers—after all, not every damper works well with every type of power line.

Another critical factor is the frequency of vibrations that need damping. Different types of vibration dampers are designed for specific frequency ranges; therefore, understanding these characteristics will help you make an informed choice. Lastly, budget constraints should also be considered; while quality matters greatly in power transmission systems, finding a cost-effective solution without compromising reliability is key.

Matching Dampers to Transmission Line Specifications

Matching vibration dampers to transmission line specifications involves understanding both technical details and operational needs. Each overhead power line has unique attributes such as tension levels, span lengths, and conductor types that must be taken into account when selecting a damper. This ensures that not only does it fit physically but also functions effectively within its intended environment.

Furthermore, evaluating load characteristics is essential for achieving optimal performance from your chosen vibration damper in transmission lines. The load on cable lines can vary based on usage patterns and external conditions; hence dampers should be selected based on their ability to handle these variations without failure or excessive wear over time. In this regard, consulting manufacturer specifications can provide valuable insights into which dampers are best suited for particular high voltage power lines.

Role of Spark Fittings in Customized Solutions

Spark Fittings plays a pivotal role when it comes to customized solutions for vibration dampers used in electrical lines. Their expertise allows them to design tailored damping solutions that cater specifically to unique project requirements or environmental challenges faced by overhead power lines. By offering bespoke options rather than one-size-fits-all products, Spark Fittings ensures enhanced compatibility and effectiveness across various applications.

Moreover, their innovative approach helps address complex issues related to installation and maintenance by providing solutions that integrate seamlessly with existing infrastructure while minimizing disruption during setup or upgrades. This level of customization not only enhances system reliability but also contributes significantly to reducing downtime during maintenance activities—an absolute win-win scenario for any power transmission operation! Ultimately, investing in quality products like those offered by Spark Fittings can lead you toward more resilient high voltage power lines equipped with effective vibration control measures.

Installation and Maintenance of Vibration Dampers

Installing a vibration damper in transmission lines is crucial for optimizing the performance and longevity of overhead power lines. Proper installation ensures that these devices function effectively, reducing the wear and tear on electrical lines caused by vibrations. Additionally, regular maintenance helps to identify potential issues before they escalate, ensuring a reliable power transmission system.

Best Practices for Installation

When installing a vibration damper in transmission lines, it’s essential to follow best practices to achieve optimal results. First, ensure that the dampers are correctly matched to the specific type of high voltage power lines being used; this can significantly influence their effectiveness. Secondly, consider the environmental conditions—such as wind speed and temperature fluctuations—that may affect installation; securing dampers adequately can help mitigate these external factors.

Another important aspect is selecting the appropriate location for installation along the cable lines; placing dampers at strategic points can maximize their impact on reducing vibrations. It’s also advisable to work with qualified personnel who understand both electrical line specifications and installation techniques to avoid common pitfalls during setup. Finally, always adhere to safety protocols when handling equipment near high voltage power lines.

Common Maintenance Issues

Maintaining vibration dampers in transmission lines is vital for ensuring their continued effectiveness and preventing unexpected failures in power transmission systems. One common issue arises from wear and tear due to environmental factors like UV exposure or extreme weather conditions; regular inspections can help identify signs of degradation early on. Additionally, loose fittings or connections can lead to reduced performance; tightening these components should be part of routine maintenance checks.

Another concern is corrosion, especially in coastal areas where saltwater exposure is prevalent; using protective coatings can prolong the life of dampers installed on overhead power lines exposed to harsh environments. Moreover, accumulation of debris around dampers may hinder their functionality—keeping installations clean will support optimal operation over time. Regular maintenance schedules should include thorough inspections at least once a year or more frequently depending on local conditions.

Tips for Longevity and Performance

To ensure that vibration dampers in transmission lines provide long-lasting performance, there are several tips worth considering. First off, invest in quality products like those offered by reputable manufacturers—this choice often pays dividends over time with fewer replacements needed for cable line applications. Additionally, consider implementing an ongoing monitoring system that tracks vibrations along electrical lines; this data can inform timely interventions when issues arise.

It’s also beneficial to educate staff responsible for maintenance about proper care techniques—training them on how vibrations affect overhead power line efficiency will foster a proactive approach toward upkeep efforts. Lastly, always keep records of maintenance activities and any observed changes in performance; these logs will assist future troubleshooting efforts should problems arise unexpectedly down the line.

Conclusion

In summary, vibration dampers in transmission lines play a crucial role in enhancing the performance and longevity of power lines. By effectively mitigating vibrations caused by environmental factors and operational stresses, these devices contribute to the reliability and efficiency of high voltage power lines. As we have discussed, their benefits extend beyond mere maintenance; they are integral to ensuring seamless power transmission across overhead power lines and cable lines.

Summary of Vibration Damper Benefits

The advantages of utilizing a vibration damper in transmission line systems are manifold. They significantly reduce wear and tear on electrical line components, which can lead to costly repairs and downtime in power transmission systems. Furthermore, by minimizing vibrations, these dampers enhance overall system reliability, ensuring that electrical lines can operate efficiently under various conditions.

The Future of Vibration Dampers in Transmission Lines

Looking ahead, the future of vibration dampers in transmission lines appears promising as technology continues to evolve. Innovations aimed at improving the design and functionality of these devices will likely make them even more effective at handling the unique challenges posed by high voltage power lines. Additionally, with growing awareness about sustainability and energy efficiency, we can expect an increased emphasis on integrating advanced vibration dampers into new overhead power line projects.

Choosing Quality Products like Spark Fittings

Products like Spark Fittings offer tailored solutions that ensure compatibility with various specifications across electrical lines and cable lines alike. Investing in high-quality vibration dampers not only enhances performance but also contributes to long-term savings through reduced maintenance costs.