Introduction

Understanding PG Clamps Essentials

So, what is a PG clamp? At its core, a Parallel Groove Clamp (PG clamp) is designed to connect two conductors securely, allowing for efficient power transmission. These clamps are essential in maintaining the integrity of electrical systems, particularly in high-voltage environments where reliability is paramount.

The Importance of Choosing the Right PG Clamp

Choosing the right PG clamp can make all the difference between a successful installation and potential failures down the line. With various options available, understanding what is PG in electrical terms helps you select clamps that meet your specific needs. The wrong choice could lead to increased resistance or even catastrophic failures, making informed decisions critical.

Exploring Parallel Groove Clamp Benefits

The benefits of using Parallel Groove Clamps are numerous and impactful, especially when considering their role in transmission lines. Not only do they provide excellent mechanical strength and durability, but they also facilitate easy installation and maintenance. Additionally, exploring PG clamp uses can reveal their versatility across different sectors within electrical engineering—truly a must-have component!

What is a PG Clamp?

When diving into the world of electrical engineering, one might stumble upon the term PG clamp. So, what is a PG clamp? It’s a specialized device primarily used to connect two conductors together securely. These clamps are designed to ensure electrical continuity and mechanical strength, making them vital in various applications, especially in power distribution and transmission lines.

Definition and Functionality

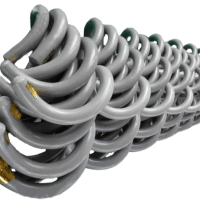

A PG clamp, or Parallel Groove Clamp, serves as an essential component that connects conductors while maintaining their alignment. Its design allows for a secure grip on the wires without causing damage, which is crucial in high-voltage environments. The functionality of a PG clamp extends beyond mere connection; it also ensures that electrical resistance remains low, promoting efficient power flow.

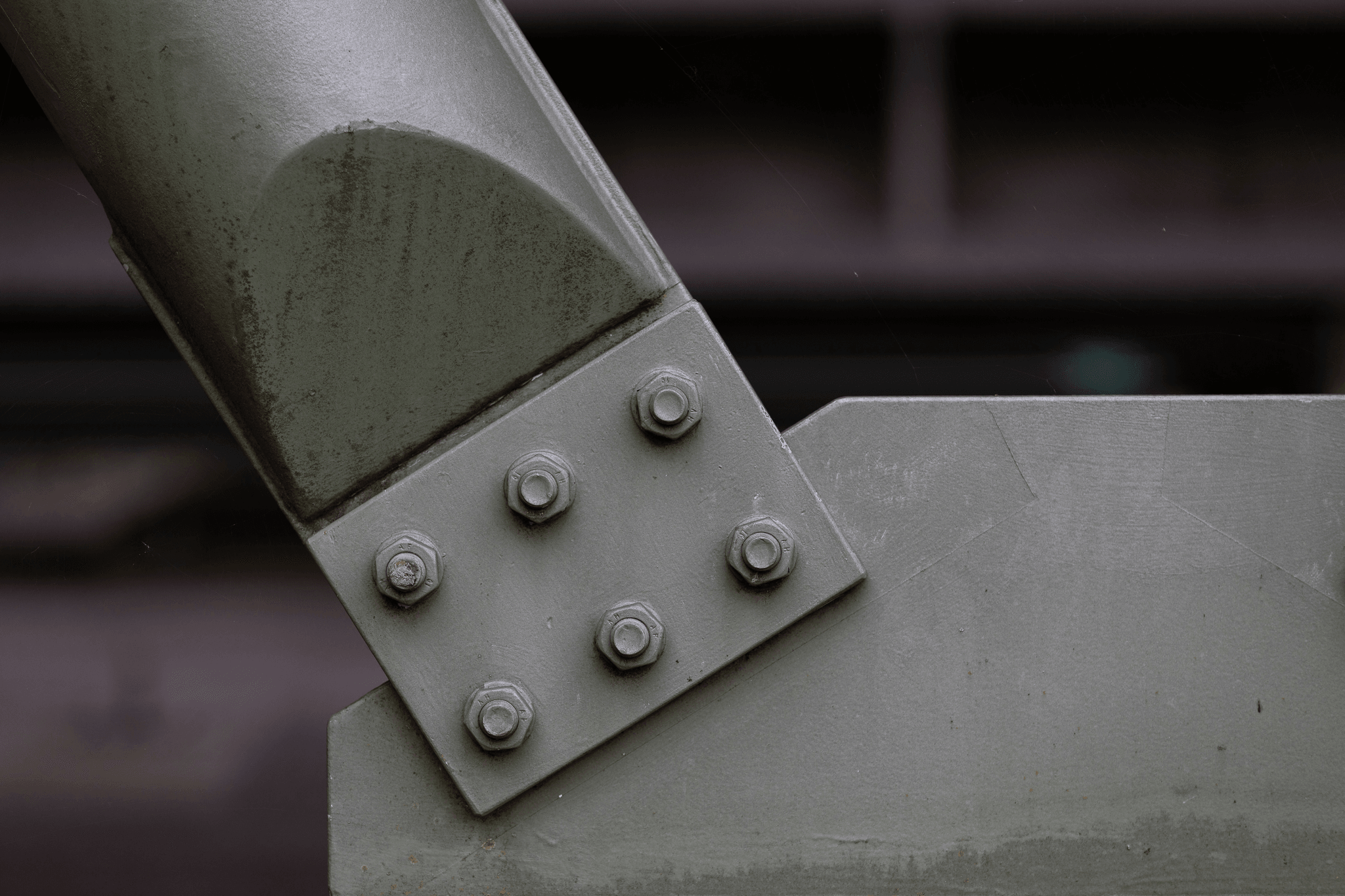

Key Features of PG Clamps

PG clamps come packed with features that make them highly effective in electrical applications. They are typically made from durable materials such as aluminum or copper alloy, ensuring longevity and resistance to corrosion. Additionally, many PG clamps are equipped with adjustable bolts for easy installation and maintenance; this adaptability makes them suitable for various conductor sizes.

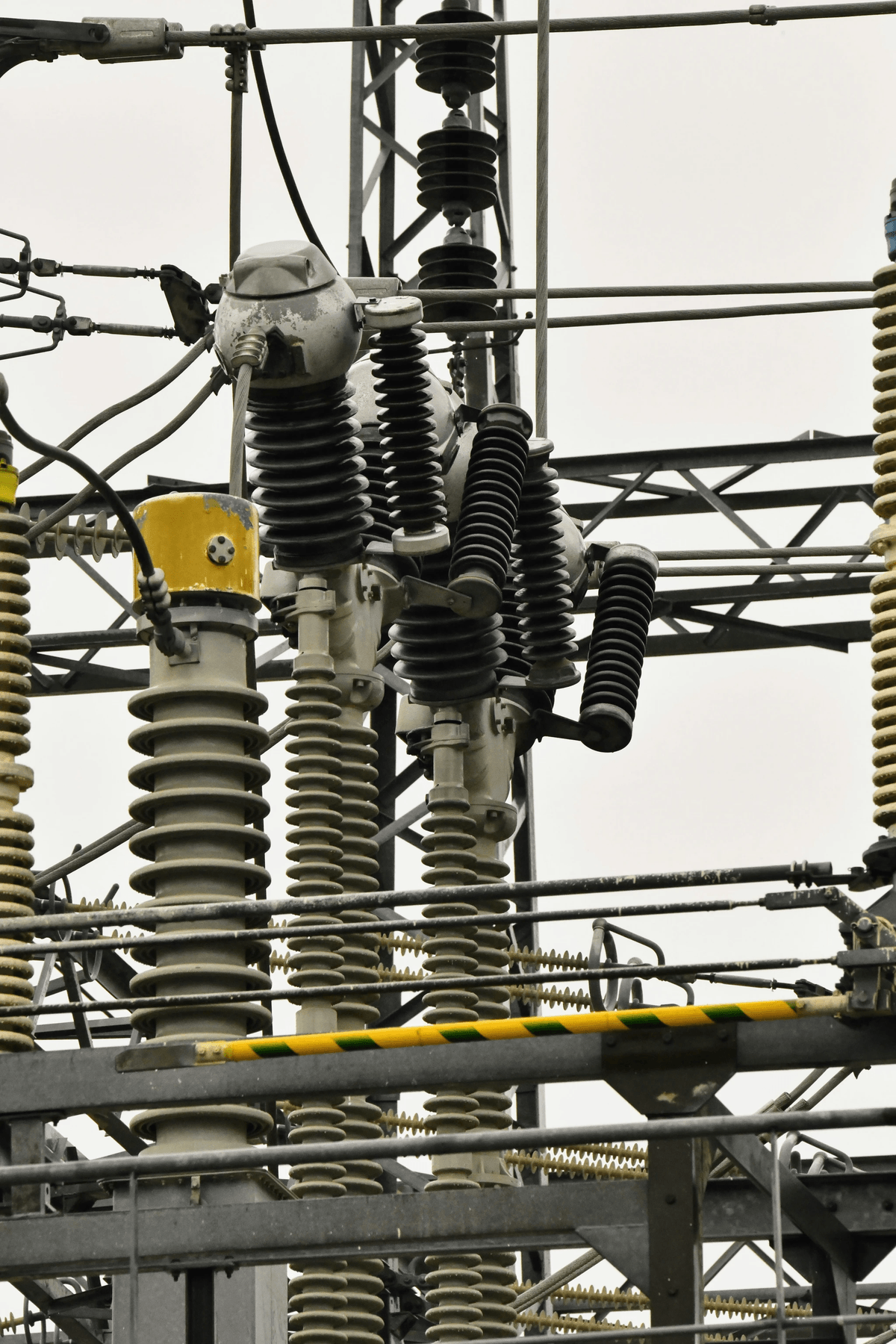

Applications in Electrical Engineering

The versatility of PG clamps shines through in their wide range of applications within electrical engineering. They are commonly used in overhead power lines where they provide secure connections between conductors like the popular Panther conductor. Furthermore, these clamps play an essential role in substations and other critical infrastructure by ensuring safe and reliable transmission of electricity across vast distances—truly showcasing the importance of understanding what is PG in electrical contexts!

What is PG in Electrical?

Explanation of PG in Electrical Terms

The term PG stands for Parallel Groove, which describes the design of these clamps that hold two conductors parallel to each other. What is a PG clamp? Essentially, it's a mechanical device that ensures a robust connection between conductors without compromising their integrity. This design allows for effective electrical conductivity while minimizing the risk of damage or overheating during operation.

Importance in Power Distribution

In power distribution networks, the importance of PG clamps cannot be overstated; they play a crucial role in maintaining system reliability and efficiency. Without proper connections facilitated by PG clamps, the risk of power loss and equipment failure increases significantly. Their ability to provide secure connections helps ensure that electricity flows smoothly from generation sources to end users.

Role in Transmission Lines

The role of PG clamps extends beyond mere connections; they are vital for ensuring safety and stability along transmission lines. PG clamp uses include supporting overhead lines and securing conductor joints against environmental factors such as wind and ice loads. By utilizing these clamps effectively, engineers can enhance the resilience of transmission systems while maintaining optimal performance levels.

Types of Clamps: G-Clamp vs. F Clamp

Distinguishing Features of G-Clamp and F Clamp

G-clamps are typically recognized by their C-shaped frame and a screw mechanism that allows for easy tightening. They provide a strong grip and are ideal for holding workpieces together during tasks like woodworking or metalworking. On the other hand, F clamps feature a more elongated shape with a sliding arm that can adjust to different widths, making them versatile for larger projects.

While both types of clamps can be used in similar scenarios, their design influences how they perform under various conditions. For instance, the G-clamp offers a more rigid hold due to its solid frame, while the F clamp allows for quick adjustments without sacrificing stability. When considering what is PG in electrical applications, knowing these distinctions becomes crucial as it affects how parallel groove clamps are utilized.

Common Uses for Each Type

G-clamps are commonly employed in workshops for securing materials while cutting or assembling them; they're particularly favored in woodworking where precision is vital. Their robust design makes them suitable for heavy-duty tasks where stability is paramount. Conversely, F clamps shine in situations requiring flexibility and rapid adjustments—think large-scale projects or assembly lines where multiple pieces need quick alignment.

In electrical engineering contexts, understanding what is a PG clamp becomes essential when discussing applications involving both types of clamps. While G-clamps might be used temporarily during setup phases, F clamps could be more beneficial during ongoing operations where adjustments are frequent—especially relevant when dealing with PG clamp uses in transmission lines.

How to Choose Between G-Clamp and F Clamp

Choosing between a G-clamp and an F clamp largely depends on your specific project requirements and workspace dynamics. If you're looking at heavy-duty applications that demand high stability without frequent adjustments—like those involving parallel groove clamps—a G-clamp may be your best bet. However, if your work involves varying sizes or requires rapid repositioning (think about instances related to PG clamp pricing), an F clamp could save you time and hassle.

Ultimately, consider factors such as material type, required pressure levels, and how often you'll need to make adjustments before making your choice between these two popular options. Knowing what is the price of PG clamp for panther conductor might also influence your decision if budget constraints come into play alongside functionality needs.

The Price of PG Clamp for Panther Conductor

When considering the price of a PG clamp for a Panther conductor, it’s essential to understand that various factors come into play. The cost can vary significantly based on material quality, brand reputation, and specific design features tailored for different applications. Additionally, market demand and regional availability can also influence pricing, making it crucial to shop around and compare options.

Factors Influencing PG Clamp Pricing

Several key factors influence the pricing of a PG clamp. First, the materials used in manufacturing play a significant role; clamps made from higher-grade metals or corrosion-resistant materials typically cost more than their standard counterparts. Furthermore, the complexity of design—such as whether the clamp is adjustable or includes additional safety features—can also bump up the price tag.

Another aspect to consider is the manufacturer’s reputation in producing high-quality parallel groove clamps. Established brands often charge a premium due to their reliability and performance history in electrical applications. Lastly, fluctuating raw material costs and shipping fees can impact overall pricing, so it's wise to keep these elements in mind when searching for “what is the price of PG clamp for Panther conductor?”

Cost Comparison with Other Types of Clamps

When comparing PG clamps with other types such as G-clamps and F-clamps, several distinctions arise that affect pricing structures. Typically, G-clamps are less expensive because they have simpler designs suited for lighter tasks; however, they lack the robustness required for heavy-duty electrical applications like those served by PG clamps. On the other hand, F-clamps may offer better grip but usually fall short when it comes to electrical conductivity and stability under high tension.

The investment in a quality PG clamp often pays off in terms of durability and safety features compared to cheaper alternatives that might compromise performance over time. Thus, while you might initially pay more upfront for a parallel groove clamp designed specifically for transmission lines, it's essential to weigh this against potential long-term savings related to maintenance and safety compliance.

Where to Buy PG Clamps

Finding reliable sources for purchasing PG clamps can be straightforward if you know where to look. Many electrical supply stores stock various types of clamps including parallel groove options tailored specifically for Panther conductors. Online marketplaces also provide an extensive selection with user reviews that can help gauge product quality.

Additionally, specialized electrical equipment suppliers often carry high-quality products designed explicitly for rigorous environments such as transmission lines—making them an ideal choice if you're seeking robust solutions like “PG Clamp uses” or understanding “what is a PG clamp?” before making your purchase decision.

PG Clamp Uses in Transmission Lines

Importance of PG Clamps in Electric Transmission

Understanding what a PG clamp is helps highlight its importance in electric transmission systems. These clamps are crucial for connecting overhead wires and ensuring they remain stable under various weather conditions and mechanical stresses. The reliability of power distribution heavily depends on these components, as they help prevent line failures that could lead to outages or hazardous situations.

Case Studies of PG Clamp Applications

Real-world applications provide compelling evidence of the effectiveness of PG clamps in transmission lines. For instance, during a recent upgrade on a major power grid, engineers utilized PG clamps extensively to enhance the stability of newly installed panther conductors. The results were impressive—reduced sagging and improved load distribution were noted, demonstrating how vital these clamps are in modern electrical infrastructure.

Benefits of Using PG Clamps for Safety

By providing a secure connection between conductors, these clamps minimize the risk of electrical faults that could lead to dangerous situations like short circuits or fires. Furthermore, their robust design ensures that even under extreme conditions—be it high winds or heavy ice build-up—the integrity remains intact, keeping both workers and communities safe.

Conclusion

In summary, selecting the right PG clamp is crucial for ensuring reliable and safe electrical connections. Understanding what a PG clamp is and its role in electrical systems can significantly impact the efficiency of power distribution. Moreover, knowing the differences between types of clamps, such as G-clamps and F clamps, can aid in making informed decisions based on specific project needs.

Key Takeaways on Choosing PG Clamps

It’s essential to understand what is PG in electrical contexts to ensure that your choice meets safety and performance standards. Additionally, comparing prices of PG clamps with other types can help you find the best value without compromising on quality.

Real-World Applications of PG Clamps

PG clamps are widely used in transmission lines due to their ability to securely connect conductors while minimizing electrical resistance. Their applications extend beyond just power distribution; they are also vital in various industrial settings where reliability is paramount. By examining case studies of PG clamp uses, one can appreciate their effectiveness in maintaining stable electric currents under various conditions.

How Spark Fittings Enhances Clamp Quality

Spark fittings play a significant role in enhancing the quality of parallel groove clamps by using superior materials and advanced manufacturing techniques. This ensures that each PG clamp not only meets but often exceeds industry standards for durability and performance. Consequently, investing in high-quality spark fittings for your PG clamps translates into safer operations and reduced maintenance costs over time.