Introduction

In the world of electrical engineering, transformer bushings play a pivotal role in ensuring the efficiency and safety of power systems. These components are crucial for facilitating the passage of high voltage electricity while maintaining insulation integrity, thus protecting both the equipment and personnel involved. Understanding transformer bushings is essential for anyone looking to navigate the complexities of high voltage applications.

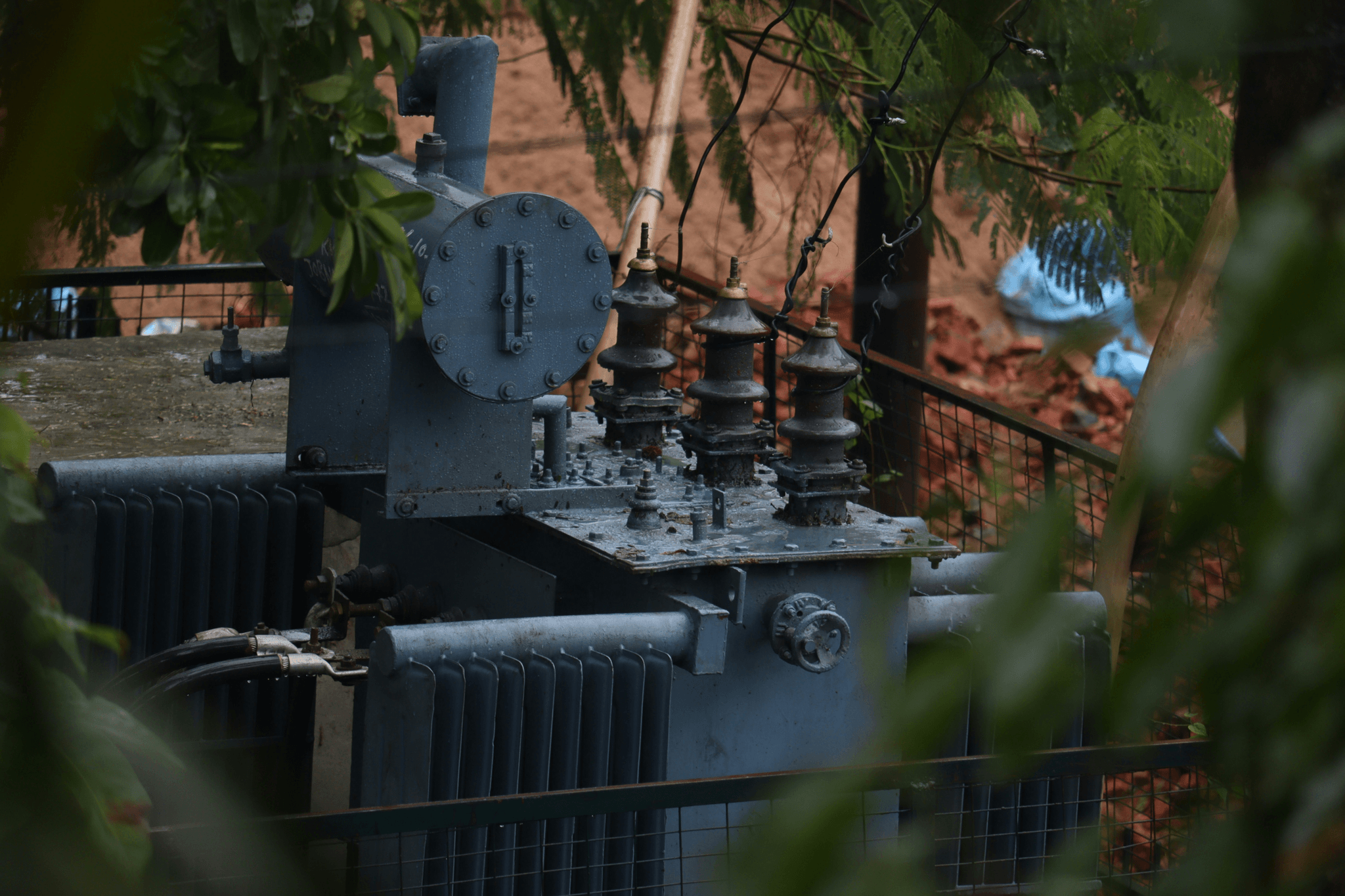

Understanding Transformer Bushings

A bushing transformer serves as a vital interface between high voltage conductors and grounded equipment, allowing electrical energy to flow safely and efficiently. It essentially acts as an insulator that prevents electrical leakage while providing a pathway for current to enter or exit a transformer for power distribution. In essence, these bushings are more than just passive components; they are integral to maintaining system reliability in both current transformers and voltage transformers.

The Importance of High Voltage Insulation

High voltage insulation is not merely an accessory; it is a necessity in any power transformer setup. Proper insulation ensures that electricity can travel at elevated voltages without risk of breakdown or failure, which could lead to catastrophic events like arcing or short circuits. Therefore, selecting appropriate materials and designs for high voltage applications is crucial, as they directly impact performance and safety standards.

Types of Transformer Bushings

Transformer bushings come in various types tailored to specific applications within power systems. Common varieties include porcelain-insulated bushings, resin-impregnated paper bushings, and composite materials designed for low voltage transformers as well as high voltage environments. Each type offers unique benefits depending on the operational demands placed on them, making it essential to choose wisely based on your specific needs in both current transformer and voltage transformer scenarios.

What is a Bushing Transformer?

A bushing transformer is a crucial component in electrical systems, especially in high voltage applications. It serves as an interface between the transformer and the external environment while providing insulation and support for high voltage conductors. Understanding its definition and functionality can help demystify its importance in power transformers.

Definition and Functionality

At its core, a bushing transformer is designed to allow electrical conductors to pass through grounded barriers without compromising safety or performance. It effectively isolates high voltage from lower voltage areas, ensuring that energy flows smoothly while minimizing risks of electrical discharge or failure. This functionality is vital for maintaining the integrity of power transformers, allowing them to operate efficiently within various power systems.

Components of a Bushing Transformer

Bushing transformers consist of several key components that work together to provide reliable performance under high voltage conditions. The primary elements include the insulating material, which prevents electrical leakage; the conductor that carries current; and various fittings that ensure structural stability and connection integrity. Each component must be carefully engineered to withstand not only the operational stresses but also environmental factors such as temperature fluctuations and humidity.

Applications in Power Systems

Bushing transformers are widely used across different sectors of power systems, particularly where high voltage transmission is necessary. They play an essential role in substations, allowing for safe connections between high voltage equipment and low voltage transformers or other devices within the network. Additionally, their use extends to current transformers and voltage transformers, where they facilitate accurate measurements essential for monitoring energy flow and system performance.

High Voltage Insulation Explained

High voltage insulation is a crucial aspect of transformer technology, particularly for bushing transformers and their role in power systems. The right insulation materials ensure that these transformers can handle the stress of high voltage without compromising safety or performance. Understanding how insulation works can help in selecting the appropriate transformer for power applications.

Insulation Materials Used

When it comes to high voltage applications, several materials stand out as the preferred choices for insulation in bushing transformers and other power transformers. Commonly used materials include silicone rubber, epoxy resins, and various types of paper impregnated with oil or synthetic fluids. Each of these materials has unique properties that make them suitable for different environments and requirements in high voltage scenarios.

Silicone rubber offers excellent resistance to environmental factors like moisture and UV radiation, making it a popular choice for outdoor installations. Epoxy resins provide strong mechanical strength and electrical insulation properties, while oil-impregnated paper is renowned for its longevity and reliability in transformer applications. Selecting the right insulation material is essential not only for performance but also for ensuring the lifespan of both current transformers and low voltage transformers.

How Insulation Affects Performance

Insulation plays a pivotal role in determining how effectively a bushing transformer operates under high voltage conditions. The quality of insulation affects not just energy efficiency but also thermal management within the transformer system. Poorly insulated components can lead to overheating, which may result in failures or even catastrophic accidents.

Moreover, effective insulation minimizes electrical losses by preventing leakage currents that could compromise overall system performance. This is especially critical when integrating with low voltage transformers where maintaining efficiency across different voltage levels is necessary. Thus, understanding how various types of insulation impact performance helps engineers design more robust power systems capable of handling diverse operational demands.

Safety Standards and Regulations

Safety standards governing high voltage applications are rigorous due to the potential hazards associated with electricity at such levels; this includes regulations specifically tailored for bushing transformers and other types of power transformers. Organizations like IEEE (Institute of Electrical and Electronics Engineers) set guidelines that manufacturers must adhere to ensure safety during operation and maintenance procedures. Compliance with these standards not only protects personnel but also safeguards equipment from damage.

In addition to industry standards, local regulations often dictate specific requirements regarding installation practices, testing methods, and maintenance schedules for high voltage equipment including current transformers and voltage transformers alike. Awareness of these regulations ensures that operators remain compliant while maximizing safety during day-to-day operations involving sensitive equipment like bushing transformers or any transformer designed to manage high voltages effectively.

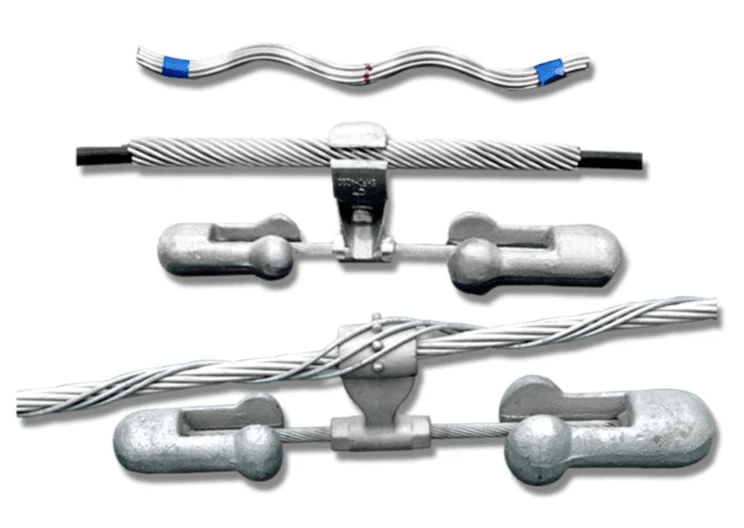

The Role of Spark Fittings

When it comes to high voltage applications, spark fittings play a crucial role in ensuring reliability and safety. They are designed to protect transformer components from electrical discharges that can occur under high voltage conditions. Understanding their function is essential for anyone involved with bushing transformers and power transformers.

Overview of Spark Fittings

Spark fittings are specialized components used in high voltage systems to prevent arcing and electrical faults. These fittings provide a barrier that directs electrical discharges safely away from sensitive parts of the transformer for power applications. Essentially, they act as the unsung heroes of voltage transformers, safeguarding against potential damage that could lead to catastrophic failures.

In bushing transformers, spark fittings are particularly important because they help maintain insulation integrity while managing the intense stresses associated with high voltage operations. Without these fittings, even minor electrical surges could escalate into significant issues, jeopardizing both equipment and safety protocols. Thus, their role in maintaining operational efficiency cannot be overstated.

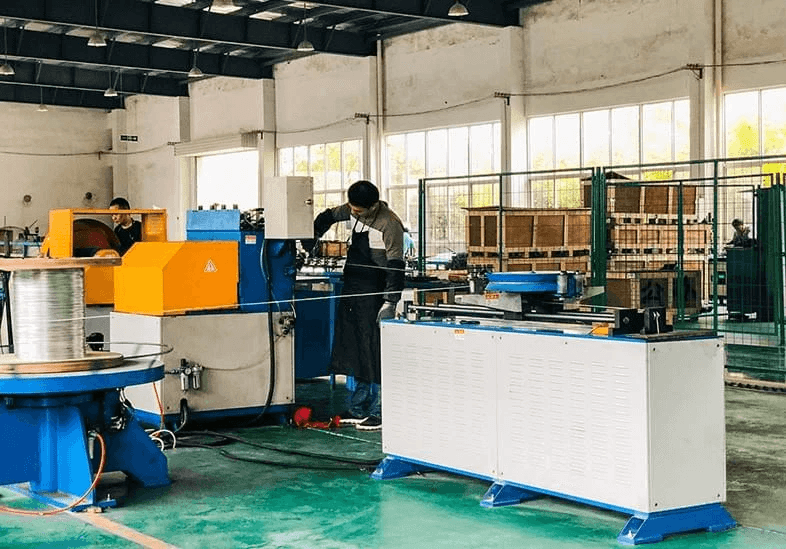

Manufacturing Equipment for Transformer Parts

The manufacturing process for spark fittings involves precision engineering and advanced technology to ensure that each component meets stringent quality standards. Equipment used in this process includes CNC machines, molding tools, and testing apparatus designed specifically for high voltage applications like current transformers and low voltage transformers alike. This sophisticated machinery ensures that every spark fitting is produced with the utmost accuracy.

Moreover, manufacturers must adhere to rigorous guidelines when fabricating these parts to guarantee their effectiveness in real-world scenarios involving power transformers and bushing transformers. Quality control measures throughout production help catch any defects early on so that only reliable components make it into the market. Consequently, investing in top-notch manufacturing equipment is vital for producing durable spark fittings essential for safe operation.

Importance of Quality in High Voltage Applications

In the world of high voltage systems, quality cannot be compromised—especially when dealing with components like spark fittings that protect critical infrastructure such as bushing transformers or other types of power transformer setups. Inferior quality can lead to premature failures or dangerous situations where arcing occurs unexpectedly due to weak connections or flawed materials used in production.

Choosing reputable manufacturers who prioritize quality ensures that all components meet industry standards necessary for safe operation within various applications—from current transformer scenarios down to low voltage transformer integrations within larger systems. Ultimately, investing in quality spark fittings translates into enhanced performance longevity across all aspects of high voltage technology—making them an indispensable part of any effective power system strategy.

Current Transformers vs. Voltage Transformers

In the realm of power systems, understanding the distinctions between current transformers and voltage transformers is crucial for effective energy management. Both types of transformers play vital roles in monitoring and controlling electrical systems, but they serve different purposes. A bushing transformer often incorporates these elements, enhancing high voltage applications and ensuring optimal performance.

Key Differences and Uses

Current transformers (CTs) are designed to measure alternating current (AC) by producing a reduced current proportional to the input current, making them essential for protective relaying and metering in high voltage systems. On the other hand, voltage transformers (VTs) focus on measuring voltage levels by stepping down high voltages to a manageable level for monitoring and control purposes. While both are integral components of power transformer setups, their specific uses can dictate which type is necessary based on system requirements.

The choice between a current transformer and a voltage transformer often hinges on the application at hand; for instance, CTs are ideal for load monitoring while VTs excel in voltage regulation tasks. Understanding these key differences ensures that engineers select the appropriate equipment to maintain system efficiency and safety in high-voltage environments.

Selection Criteria for Power Transformers

When selecting a power transformer, several criteria come into play to ensure it meets operational needs effectively. Factors such as rated power capacity, insulation class, environmental conditions, and compatibility with existing low voltage transformers must be carefully considered during this process. Additionally, understanding whether a bushing transformer or other types of transformers best suit your specific application can significantly affect performance outcomes.

Another important consideration is the transformer's ability to handle peak loads without compromising safety standards or operational integrity in high-voltage scenarios. This involves evaluating specifications such as impedance ratings and thermal characteristics that directly impact how well the transformer integrates into an overall electrical system.

Integrating with Low Voltage Transformers

Integrating high-voltage transformers with low-voltage transformers is essential for creating efficient energy distribution networks that cater to various applications across industries. This integration allows seamless transition from high voltage levels down to usable levels suitable for commercial or residential use without sacrificing performance or safety standards associated with bushing transformers.

Effective integration requires careful planning around load characteristics and potential fault conditions within the electrical system; mismatched specifications can lead to inefficiencies or even catastrophic failures if not addressed properly. Therefore, when designing an electrical network incorporating both current transformers and voltage transformers alongside low-voltage counterparts, meticulous attention must be paid to each component's role within the broader framework of power management.

Maintenance and Lifespan of Bushings

Maintaining transformer bushings is crucial for ensuring the longevity and efficiency of a bushing transformer. These components are designed to withstand high voltage, but over time, wear and tear can compromise their functionality. Regular maintenance not only extends the lifespan of these critical parts but also enhances the overall performance of power transformers.

Signs of Wear and Tear

Identifying signs of wear and tear in transformer bushings is essential for preventing catastrophic failures in high voltage applications. Common indicators include oil leakage, cracks in the porcelain or composite materials, and changes in capacitance readings during testing. Additionally, if a bushing transformer exhibits unusual sounds or vibrations during operation, it may signal underlying issues that require immediate attention.

Best Practices for Maintenance

To keep your voltage transformers operating at peak performance, adhering to best practices for maintenance is key. Regular inspections should be conducted to identify any early signs of damage or degradation; this includes checking insulation resistance and monitoring temperature variations. Moreover, using qualified personnel for maintenance tasks ensures that both current transformers and low voltage transformers receive expert care tailored to their specific needs.

Replacement and Upgrade Options

When bushings show significant wear or fail testing standards, replacement becomes necessary to maintain system integrity in high voltage environments. Upgrading to newer technologies can also enhance performance; modern bushing designs often incorporate better insulation materials that provide improved durability against environmental factors. Ultimately, selecting the right manufacturer for your power transformer parts ensures you receive quality components that meet industry standards while providing long-lasting service.

Conclusion

In wrapping up our exploration of transformer technology, it's clear that the future holds exciting advancements for bushing transformers and their applications. As power systems evolve, the demand for high voltage solutions will continue to rise, pushing manufacturers to innovate and enhance their products. The integration of cutting-edge materials and smart technologies will redefine how we think about voltage high applications in the energy sector.

The Future of Transformer Technology

Looking ahead, the future of transformer technology is poised for remarkable growth as renewable energy sources become more prevalent. Bushing transformers will play a critical role in facilitating this transition by ensuring efficient power transmission at high voltages. Innovations such as smart grid technology and real-time monitoring systems will further enhance the reliability and performance of power transformers.

Innovations in High Voltage Solutions

Innovations in high voltage solutions are not just limited to bushing transformers; they encompass a wide range of technologies aimed at improving efficiency and safety in power systems. For instance, new insulation materials are being developed that can withstand extreme conditions while maintaining optimal performance levels in current transformers and voltage transformers alike. These advancements ensure that low voltage transformers can seamlessly integrate with existing infrastructures while meeting stringent safety standards.

Choosing the Right Manufacturer for Transformers

A reputable manufacturer will not only provide durable products but also offer comprehensive support throughout the lifecycle of your power transformer system. By considering factors such as industry experience, customer reviews, and adherence to safety regulations, you can make an informed choice that ensures long-term reliability in high voltage applications.