Introduction

In the world of electrical engineering, transformer bushings play a pivotal role in ensuring the safe and efficient operation of high-voltage equipment. Without a solid understanding of these components, one might overlook their significance in power systems. So, what is a high-voltage bushing? It’s essential to explore this question and others to fully appreciate how these devices contribute to the broader landscape of electrical components.

Understanding Transformer Bushings

Transformer bushings are specialized insulators that facilitate the connection between high voltage conductors and various electrical equipment, such as transformers and switchgear. These bushings help maintain insulation integrity while allowing electrical flow, essentially acting as a bridge between the energized parts and grounded structures. By understanding their design and functionality, we can appreciate why high voltage bushings are critical for maintaining system reliability.

Importance of High Voltage Bushings

High voltage bushings are crucial for several reasons: they provide electrical insulation, support mechanical loads, and ensure safety by preventing arcing or short circuits. Their ability to withstand extreme conditions makes them indispensable in power transmission systems where reliability is non-negotiable. Furthermore, knowing which type of bushing is most commonly used in a high-voltage transformer can guide maintenance practices to prolong equipment life.

Overview of Electrical Components

Electrical systems comprise various components working together seamlessly; among these are transformers, switchgear, circuit breakers, and more—all interconnected through vital elements like high voltage bushings. Each component serves a unique purpose while contributing to overall efficiency and safety within the system. Additionally, understanding what does the bushing do on a voltage transformer helps clarify its role in ensuring that energy flows smoothly under varying operational conditions.

What is a High-Voltage Bushing?

High-voltage bushings are critical components within electrical systems, particularly in transformers, where they serve as the interface between the transformer and external electrical circuits. These specialized devices allow high voltage conductors to pass through grounded barriers while maintaining insulation and safety standards. Essentially, they play a pivotal role in ensuring the safe and efficient operation of high-voltage equipment.

Definition and Purpose

So, what is a high-voltage bushing? At its core, it is an insulated device that allows electrical conductors to enter or exit a transformer without compromising insulation integrity. The primary purpose of a bushing is to provide a pathway for electricity while ensuring that surrounding structures remain insulated from the high voltages involved, thereby preventing dangerous electrical arcs or faults.

The importance of bushings cannot be overstated; they not only facilitate the flow of electricity but also protect sensitive components from environmental factors such as moisture and dust. With their robust design, high-voltage bushings ensure that transformers can operate safely under extreme conditions without risking damage to internal parts or creating hazards for maintenance personnel.

Key Materials Used

When discussing high-voltage bushings, it's essential to highlight the materials used in their construction. Commonly utilized materials include porcelain, composite polymers, and oil-filled insulations—each selected for their unique insulating properties and mechanical strength. Porcelain has been long favored for its excellent dielectric strength and durability against environmental stressors.

Composite materials are gaining traction due to their lightweight nature and resistance to cracking under thermal cycling; they often outperform traditional materials in harsh conditions. Oil-filled bushings utilize insulating oil to enhance performance by providing superior dielectric properties while dissipating heat generated during operation effectively.

Applications in Power Systems

High-voltage bushings find applications across various segments of power systems beyond just transformers; they're also critical components in switchgear setups as well as circuit breakers. In these contexts, they help maintain system integrity by ensuring that electricity flows smoothly while minimizing risks associated with voltage spikes or failures.

Moreover, understanding which type of bushing is most commonly used in a high-voltage transformer can guide engineers in selecting appropriate components for new installations or upgrades. Regular testing methods are vital here; what are the different high-voltage tests conducted on bushings? They typically include insulation resistance tests, power factor tests, and capacitance measurements—all aimed at ensuring reliability over time.

In summary, high-voltage bushings serve essential roles across various applications within power systems by providing safe pathways for electrical currents while safeguarding against potential hazards. Their material composition enhances performance characteristics tailored for specific operational environments—making them indispensable in modern electrical engineering practices.

Common Types of Bushings in Transformers

When it comes to high voltage bushings, understanding the common types available is crucial for ensuring optimal performance and safety in transformers. Each type of bushing has its unique characteristics and applications, making it essential to choose the right one based on specific needs. This section will delve into the differences between porcelain and composite bushings, explore oil-filled bushings, and compare them with air insulated options.

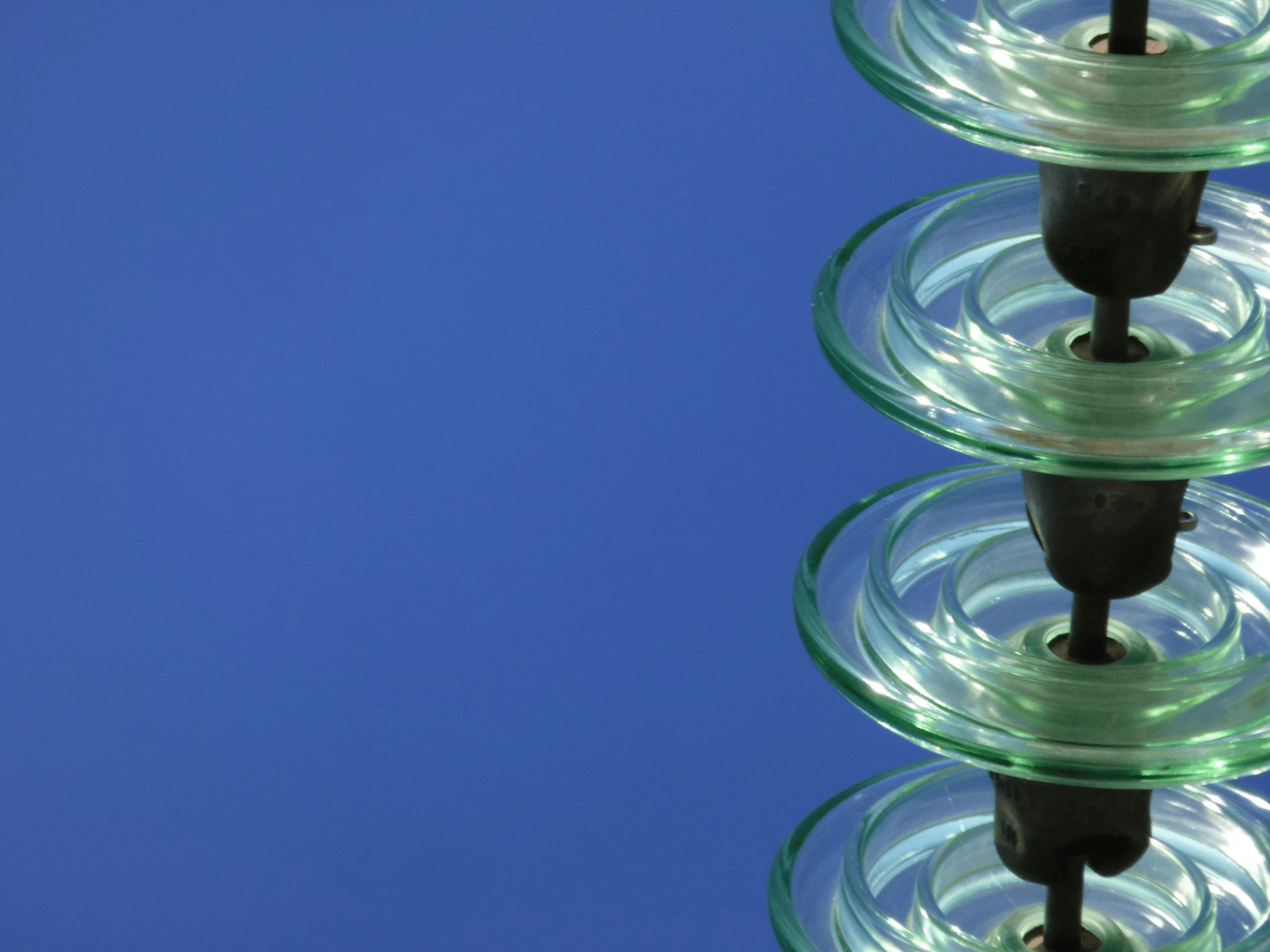

Porcelain vs. Composite Bushings

Porcelain bushings have long been a staple in high voltage applications due to their impressive dielectric strength and durability against environmental factors. These traditional high voltage bushings are often preferred for their ability to withstand extreme temperatures and resist moisture ingress. On the other hand, composite bushings offer a modern alternative with lightweight materials that provide enhanced resistance to vandalism and mechanical stress while still delivering excellent electrical performance.

So, which type of bushing is most commonly used in a high-voltage transformer? While porcelain remains prevalent due to its proven track record, composite bushings are gaining traction thanks to advancements in material technology that improve their reliability and efficiency. Ultimately, the choice between porcelain and composite depends on specific operational conditions and environmental considerations.

Characteristics of Oil-Filled Bushings

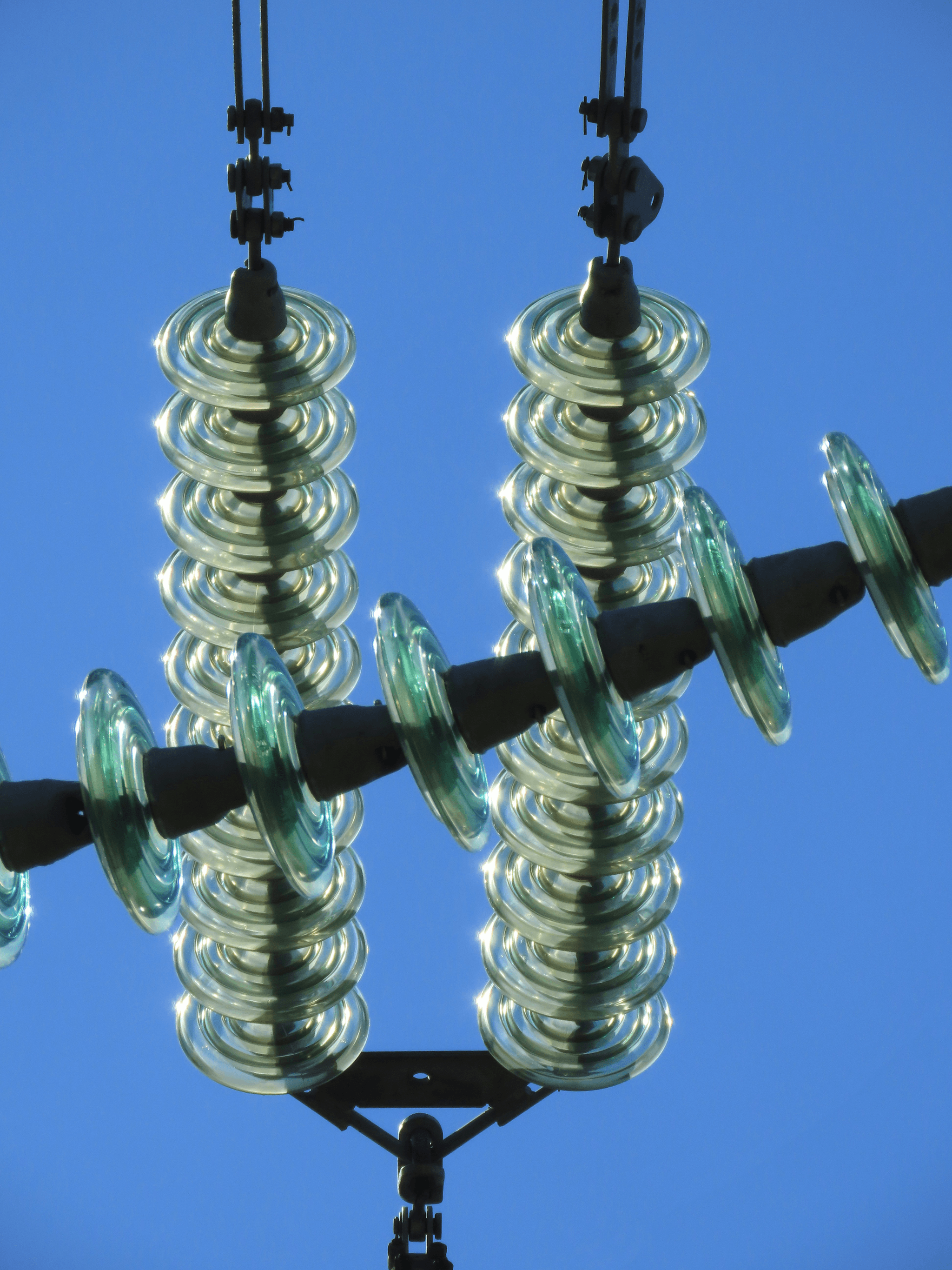

Oil-filled bushings stand out as another key player in the realm of high voltage bushings. These units utilize insulating oil to enhance electrical insulation while also providing cooling properties that help maintain optimal operating temperatures within transformers. The combination of oil with solid insulation materials allows these bushings to handle higher voltages effectively.

What does the bushing do on a voltage transformer? In essence, oil-filled bushings facilitate safe electrical connections between internal components and external circuits while ensuring minimal energy loss through effective insulation properties. Their design not only enhances performance but also plays a vital role in extending transformer lifespan by reducing thermal stress.

Comparison with Air Insulated Bushings

Air insulated bushings offer yet another option for high voltage applications; however, they differ significantly from their oil-filled counterparts. These types utilize air as an insulator rather than relying on liquid mediums like oil or solid materials like porcelain or composites. While air insulated designs can be lighter and easier to install, they may not provide the same level of insulation efficiency at extremely high voltages.

When considering different high-voltage tests conducted on bushings, it’s important to note that air insulated options can be more susceptible to environmental factors such as humidity or pollution compared to oil-filled or porcelain models. Therefore, regular inspections are vital for all types of electrical bushings for switchgear applications; this ensures that any potential issues are identified early before they escalate into significant problems affecting overall system performance.

The Role of Bushings in Voltage Transformers

High voltage bushings play a pivotal role in ensuring the safe and efficient operation of voltage transformers. These components serve as the interface between the transformer and its external electrical connections, facilitating not only the flow of electricity but also providing essential insulation to protect against high voltages. Understanding their functions is key to grasping how transformers operate within power systems.

Insulation and Safety Functions

One of the primary functions of high voltage bushings is their insulation capability, which is crucial for maintaining safety standards in electrical systems. They prevent electrical discharges that could lead to catastrophic failures or hazards, effectively isolating high-voltage conductors from grounded structures. This insulation ensures that any potential faults are contained, significantly reducing the risk of accidents associated with transformer operations.

Moreover, bushings are designed to withstand extreme environmental conditions, including temperature fluctuations and moisture exposure. This durability contributes to their safety function by ensuring that they maintain their insulating properties over time, even under stress. Thus, knowing what does the bushing do on a voltage transformer highlights its importance as a protective barrier in high-voltage applications.

How Bushings Facilitate Electrical Flow

High voltage bushings also play a critical role in facilitating electrical flow within transformers by providing a reliable path for current to travel between internal components and external circuits. They are engineered to minimize energy losses during this transmission process, which enhances overall system performance. When asking which type of bushing is most commonly used in a high-voltage transformer, it’s often found that oil-filled porcelain bushings dominate due to their excellent conductive properties.

Additionally, these bushings allow for thermal expansion and contraction without compromising performance or safety. The design incorporates features that accommodate movement while maintaining electrical integrity—an essential aspect when considering various operational conditions encountered by transformers. By understanding how bushings facilitate electrical flow, one can appreciate their integral role in maintaining efficient transformer functionality.

Effects on Transformer Efficiency

The efficiency of a transformer can be significantly influenced by the quality and type of high voltage bushing used within its design. High-quality bushings reduce losses associated with dielectric heating and other inefficiencies that arise during operation; thus enhancing overall energy conservation within power systems. Regular assessments through different high-voltage tests conducted on bushings ensure they perform optimally.

Furthermore, poor-performing or damaged bushings can lead to increased operational costs due to wasted energy and potential downtimes caused by failures or maintenance issues. Therefore, understanding the effects on transformer efficiency underscores why regular inspections are vital—not just for safety but also for economic reasons linked with energy management strategies in modern power systems like Electrical Bushings for Switchgear applications.

High-Voltage Testing Methods for Bushings

High-voltage testing methods for bushings play a crucial role in ensuring the reliability and safety of electrical systems. These tests help identify potential issues before they lead to catastrophic failures, thus safeguarding both equipment and personnel. Understanding these methods is essential for anyone involved in the maintenance and operation of high-voltage transformers.

Routine Maintenance Tests

Routine maintenance tests are fundamental to assessing the health of high voltage bushings. These tests typically include insulation resistance measurements, power factor testing, and capacitance evaluations, which help determine if the bushing is functioning properly. Regularly performing these tests can catch early signs of wear and tear, allowing for timely interventions that prevent more significant problems down the line.

Among the common inquiries is What is a high-voltage bushing? Essentially, it's an insulated device that allows electrical conductors to pass through grounded barriers while maintaining safety standards. Routine maintenance helps ensure that these essential components continue to perform their vital functions without interruption.

Additionally, many organizations establish schedules for routine maintenance based on manufacturer recommendations or industry standards. By adhering to these guidelines, operators can ensure that their high voltage transformers remain efficient and safe over time.

Diagnostic Testing Techniques

When routine checks raise concerns or when a bushing exhibits abnormal behavior, diagnostic testing techniques come into play. These advanced methods include frequency response analysis (FRA) and time-domain reflectometry (TDR), which provide deeper insights into the condition of high voltage bushings. Such techniques can detect issues like moisture ingress or insulation degradation that might not be apparent through standard testing.

A common question arises: Which type of bushing is most commonly used in a high-voltage transformer? While various types exist—such as porcelain and composite—diagnostic testing helps identify which materials may be more susceptible to failure under specific conditions. This knowledge enables engineers to make informed decisions regarding maintenance strategies tailored to each unique situation.

The importance of employing diagnostic testing cannot be overstated; it provides a comprehensive view of a bushing's integrity over its operational life cycle. By utilizing these techniques effectively, operators can enhance system reliability while minimizing downtime due to unexpected failures.

Importance of Regular Inspections

Regular inspections are integral to maintaining the functionality of electrical bushings for switchgear and other applications within power systems. These inspections typically involve visual assessments alongside electrical performance evaluations, ensuring no external damage or internal faults compromise performance quality. The real question here is: What does the bushing do on a voltage transformer? It serves as both an insulator and conductor interface; hence its integrity directly impacts system performance.

Moreover, regular inspections help track changes in key parameters over time—offering invaluable data that can inform future maintenance decisions regarding high voltage bushings. This proactive approach not only enhances equipment longevity but also significantly contributes to overall electrical safety within substations and distribution networks.

In conclusion, understanding what constitutes effective inspection practices lays a solid foundation for robust operational protocols surrounding transformer care—ultimately leading toward improved efficiency in power delivery systems across industries.

Electrical Bushings for Switchgear

In the realm of electrical systems, high voltage bushings play a crucial role in switchgear applications. These components serve as insulators and conduits for electrical current, ensuring that power is transmitted safely and efficiently between various elements of the system. Understanding how these bushings function can help us appreciate their importance in maintaining reliable operations.

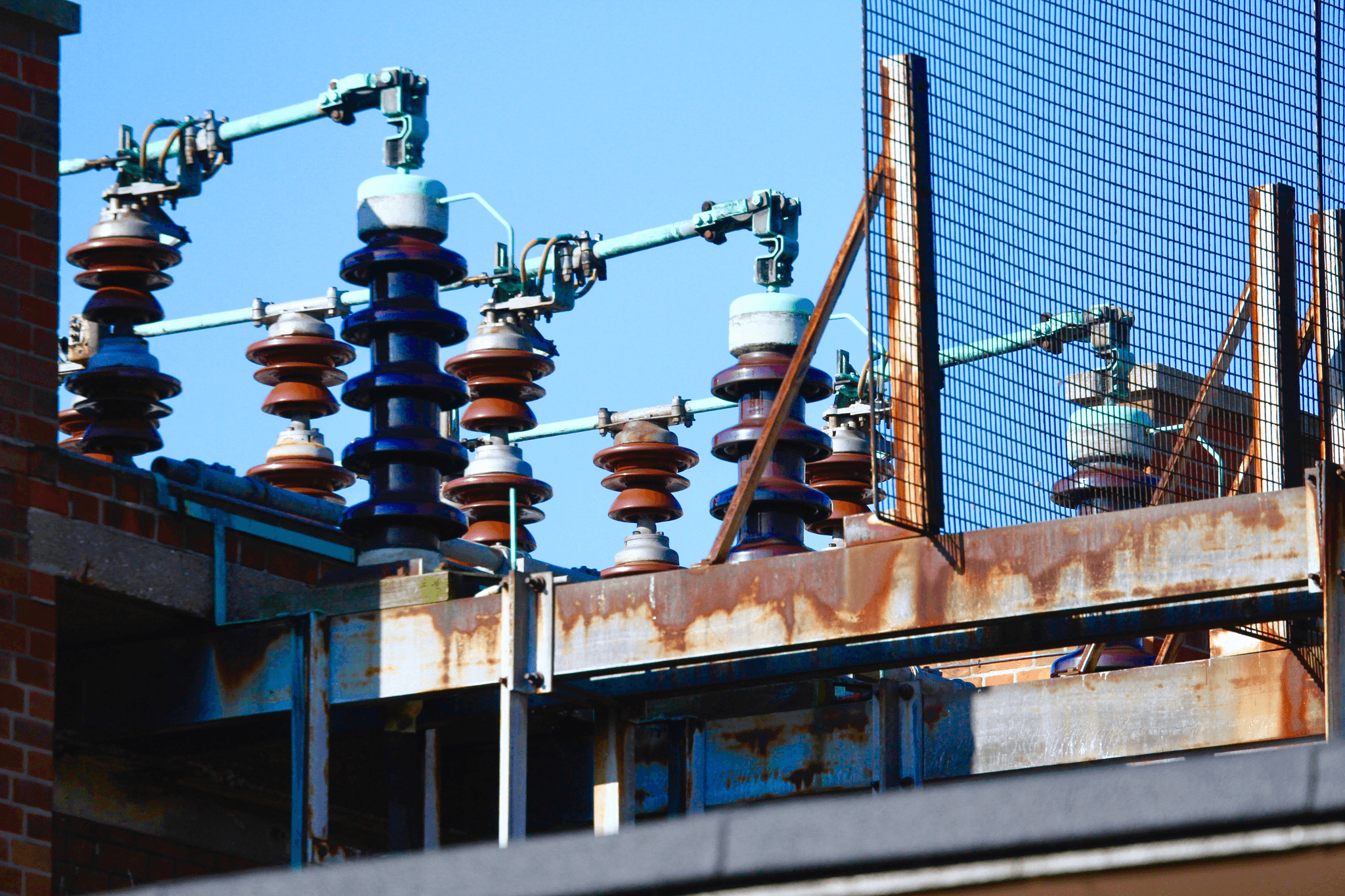

Overview of Switchgear Applications

Switchgear is integral to managing electricity flow in power distribution networks, and high voltage bushings are key players in this process. They connect circuit breakers, transformers, and other critical equipment while providing insulation against high voltages. Whether it’s in substations or industrial settings, these bushings are essential for ensuring that electricity moves smoothly without any hiccups.

When considering what is a high-voltage bushing?, it’s important to note that they come in various forms tailored to specific applications within switchgear. Some common types include porcelain and composite materials, which each have unique benefits depending on the environment they operate in. The choice of bushing impacts not only performance but also the longevity of the entire switchgear assembly.

How Bushings Enhance Performance

High voltage bushings enhance performance by minimizing energy losses during transmission and maintaining system integrity under varying load conditions. Their design allows them to withstand extreme electrical stress while providing excellent insulation properties—essentially acting as a barrier between live conductors and grounded structures. This capability ensures that operational efficiency remains high while also reducing maintenance costs over time.

Moreover, when we ask which type of bushing is most commonly used in a high-voltage transformer?, we often find that oil-filled porcelain bushings take center stage due to their durability and effectiveness at insulating against electrical breakdowns. By utilizing materials specifically designed for high voltage applications, these bushings ensure optimal performance across different environments—be it harsh weather or fluctuating temperatures.

Additionally, understanding what does the bushing do on a voltage transformer? reveals its dual role: facilitating electrical flow while providing critical safety features that prevent accidents from occurring during operation. The synergy between switchgear components and their respective bushings fosters an environment where electricity can be managed effectively without compromising safety or reliability.

Impact on Overall Electrical Safety

The impact of high voltage bushings on overall electrical safety cannot be overstated; they serve as vital safeguards against potential hazards associated with high voltage systems. Properly installed and maintained bushings protect both equipment and personnel from dangerous surges or faults that could lead to catastrophic failures or injuries. Regular inspections are essential to ensure these components remain functional over time.

In light of this need for vigilance, many professionals inquire about what are the different high-voltage tests conducted on bushings? These tests typically include capacitance measurements, insulation resistance checks, and power factor testing—all aimed at assessing the health of bushing components within switchgear systems. By proactively identifying issues before they escalate into serious problems, organizations can enhance their overall safety protocols significantly.

Ultimately, investing time into understanding Electrical Bushings for Switchgear pays off not just in terms of performance but also through improved safety outcomes across power distribution networks—ensuring everyone involved remains protected while keeping those lights shining bright!

Conclusion

In summary, high voltage bushings play a critical role in the functionality and safety of transformers and switchgear. They serve as the interface between the transformer and external electrical systems, ensuring that electrical energy is transmitted efficiently while maintaining insulation integrity. Understanding what is a high-voltage bushing? is essential for anyone involved in power systems, as these components are vital for operational reliability.

Key Functions of Transformer Bushings

The primary function of transformer bushings is to provide insulation and facilitate the transmission of electrical currents at high voltages safely. They not only protect against electrical arcing but also help maintain optimal performance by reducing losses during operation. Which type of bushing is most commonly used in a high-voltage transformer? Typically, porcelain or composite bushings are preferred due to their durability and effectiveness in various environmental conditions.

Importance of Regular Testing

Regular testing of high voltage bushings cannot be overstated; it’s essential for ensuring their longevity and reliability. What are the different high-voltage tests conducted on bushings? Routine maintenance tests such as capacitance measurements, power factor testing, and insulation resistance checks help identify potential issues before they escalate into costly failures. By prioritizing regular inspections, operators can enhance safety measures while extending the life cycle of their equipment.

Future Trends in Bushing Technology

The future of bushing technology looks promising with advancements aimed at improving performance and efficiency further. Innovations such as smart sensors integrated into high voltage bushings will allow for real-time monitoring and predictive maintenance capabilities that can revolutionize how we approach transformer upkeep. As we continue to explore Electrical Bushings for Switchgear applications, sustainability and enhanced materials will likely drive future developments within this critical component field.