Introduction

In the world of electrical power transmission lines, maintaining the integrity and reliability of overhead power systems is crucial. One essential component that plays a pivotal role in this process is the dead end clamp for transmission line, which secures conductors and ensures that they remain stable under various conditions. Understanding how these clamps function and their importance can dramatically impact the efficiency of electrical lines.

Understanding the Role of Dead End Clamps

Dead end clamps are specialized devices designed to anchor conductors at terminal points or changes in direction along a transmission line. Their primary function is to withstand mechanical loads while preventing any movement that could lead to wear or failure in electrical power transmission lines. Without these clamps, overhead power systems would be susceptible to damage from environmental factors such as wind, ice, and thermal expansion.

Importance of Quality in Electrical Components

High-quality materials ensure durability and resistance against corrosion, ultimately leading to fewer maintenance issues over time. Investing in superior electrical components not only enhances the reliability of a line of transmission but also contributes to cost-effectiveness by reducing long-term operational expenses.

Overview of Spark Fittings and Their Solutions

Spark Fittings stands out as a leader in clamp manufacturing, offering innovative solutions tailored for modern electrical needs. Specializing in products like dead end clamps for transmission lines and armor rods, Spark Fittings focuses on quality craftsmanship that meets industry standards. With a commitment to advancing technology in overhead power systems, they provide reliable products that enhance the overall performance of electrical power transmission lines.

What is a Dead End Clamp for Transmission Lines

This essential component secures conductors at the ends of spans, ensuring that they remain stable and secure under various conditions. Without these clamps, the reliability of overhead power systems would be significantly compromised.

Definition and Functionality

A dead end clamp for transmission line is designed specifically to anchor conductors at their termination points, preventing any unwanted movement or sagging. Its primary functionality lies in providing mechanical support and stability to the electrical line, especially when subjected to tension from wind or other environmental factors. By effectively distributing the load along the conductor, these clamps help maintain optimal performance in electrical power transmission lines.

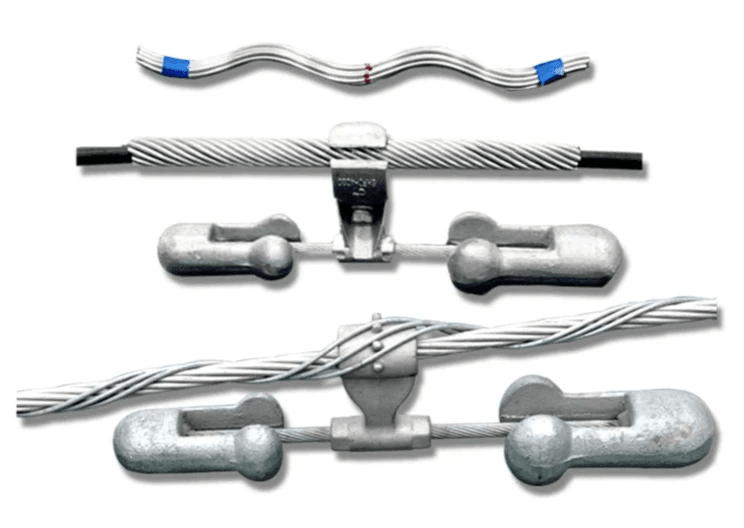

Types of Dead End Clamps

There are several types of dead end clamps available for different applications within overhead power systems. Common variants include bolted clamps, wedge clamps, and compression-type clamps, each tailored to meet specific requirements based on conductor size and material. Understanding these differences is key when selecting the right dead end clamp for transmission lines to ensure maximum efficiency and durability.

Applications in Electrical Power Transmission

Dead end clamps find their applications predominantly in overhead power lines where reliability is paramount. They are used extensively in both distribution and transmission networks to secure conductors at critical junctions or terminations. By ensuring that electrical lines remain firmly anchored, these clamps contribute significantly to the overall integrity of electrical power transmission systems across vast distances.

The Advantages of High-Quality Dead End Clamps

High-quality dead end clamps play an essential role in ensuring the reliability and longevity of electrical power transmission lines. These clamps are designed to securely hold conductors in place, especially at the ends of spans where tension is highest. By investing in superior dead end clamps for transmission lines, utilities can significantly enhance the overall performance and safety of their overhead power systems.

Enhancing Reliability in Transmission Lines

High-quality dead end clamps are engineered to withstand extreme weather conditions and mechanical stresses that can occur during operation. This means fewer failures and interruptions, leading to a more dependable line of transmission that serves communities without hiccups or outages.

Moreover, these clamps help maintain proper tension on the conductors, reducing sagging and potential damage over time. By ensuring that each component functions optimally, utilities can create a robust infrastructure capable of handling increased loads as demand grows. In essence, reliable dead end clamps are vital for maintaining the integrity of electrical lines across various terrains.

Prevention of Corrosion and Wear

High-quality dead end clamps are often treated with protective coatings or made from corrosion-resistant materials that extend their lifespan significantly. This prevention is crucial because once corrosion sets in on a clamp used in a transmission line, it can lead to catastrophic failures and costly repairs.

Additionally, wear from environmental factors such as wind or ice can weaken lower-quality materials quickly. Investing in superior clamps reduces maintenance needs and helps ensure that electrical power transmission lines remain functional even under harsh conditions. Ultimately, choosing high-quality options translates into less downtime and fewer emergency repairs down the road.

Cost-Effectiveness in Long-Term Operations

While high-quality dead end clamps may come with a higher upfront cost compared to lower-grade alternatives, they offer significant savings over time through enhanced durability and reduced maintenance needs. The long-term operational costs associated with frequent replacements or repairs due to inferior products can quickly add up—making quality a wise investment for any utility company managing electrical lines.

Furthermore, by minimizing failures caused by subpar components, companies can avoid costly outages that disrupt service for customers and damage reputations alike. High-performance dead end clamps contribute not only to operational efficiency but also positively impact customer satisfaction levels by providing consistent service delivery through reliable electrical power transmission lines.

In conclusion, opting for high-quality dead end clamps yields numerous advantages that extend beyond immediate performance benefits; they enhance reliability while preventing corrosion-related issues and ultimately prove cost-effective over time.

Spark Fittings: Pioneers in Clamp Manufacturing

When it comes to the world of electrical power transmission lines, Spark Fittings stands out as a leader in clamp manufacturing. With a commitment to quality and innovation, they focus on producing top-notch components that ensure the reliability of overhead power systems. Their expertise in creating durable solutions makes them a go-to choice for anyone involved in the line of transmission.

Overview of Spark Fittings

Spark Fittings has built a reputation for excellence in the manufacturing of electrical components, particularly dead end clamps for transmission lines. Founded with the goal of enhancing safety and efficiency in electrical line installations, they have continually evolved their product offerings to meet industry demands. Their dedication to research and development ensures that they remain at the forefront of technology, providing reliable solutions for electrical power transmission.

Specialization in Armor Rod Production

One area where Spark Fittings truly excels is armor rod production, which plays a vital role in protecting dead end clamps for transmission lines from wear and tear. These armor rods are designed to reinforce connections and improve overall durability within overhead power systems. By specializing in this critical component, Spark Fittings helps utility companies maintain efficient operations while minimizing downtime caused by equipment failure.

Innovations in Preformed Armor Rods

Spark Fittings has revolutionized the market with their innovative preformed armor rods designed specifically for use with various types of conductors found on electrical lines. These preformed rods offer superior protection against environmental factors such as corrosion and mechanical stress, ensuring longevity and reliability for transmission lines. By investing heavily in research and technology, Spark Fittings continues to lead the charge toward more effective solutions that enhance performance across all aspects of electrical power transmission.

Choosing the Right Armor Rod Material

Selecting the appropriate armor rod material is crucial for ensuring the performance and longevity of dead end clamps for transmission lines. The right choice can significantly affect the reliability of electrical power transmission lines, especially when subjected to various environmental conditions and mechanical stresses. This section will explore raw material options, the importance of matching materials, and how color coding aids in easy identification.

Raw Material Options: Aluminum and Steel

When it comes to armor rods, two primary materials dominate the market: aluminum and steel. Aluminum is lightweight, corrosion-resistant, and offers excellent conductivity, making it a popular choice for overhead power applications. On the other hand, steel provides superior strength and durability under high-stress conditions but may require additional protective coatings to prevent rusting on electrical lines.

Choosing between aluminum and steel depends on several factors, including environmental conditions, load requirements, and budget constraints. For instance, in coastal areas where saltwater exposure is prevalent, aluminum might be favored due to its resistance to corrosion. Meanwhile, in regions with heavy ice loads or extreme wind conditions on transmission lines, steel may be more suitable due to its strength.

Ultimately, understanding these raw material options can help ensure that your dead end clamp for transmission line applications meets both performance expectations and cost-effectiveness over time. It's essential to weigh these factors carefully before making a decision that could impact your overall electrical power transmission system.

Importance of Matching Conductor Materials

Matching armor rod materials with those of conductors is vital for maintaining system integrity in overhead power installations. When different metals are used together without proper consideration—such as an aluminum armor rod paired with a steel conductor—galvanic corrosion can occur. This unwanted reaction not only compromises the mechanical stability of your dead end clamp but also leads to premature failure in electrical connections.

Furthermore, compatibility ensures optimal conductivity within the entire line of transmission; mismatched materials can create resistance points that lead to energy losses or overheating issues over time. By ensuring that both conductor and armor rod are made from similar materials—like using aluminum with aluminum or steel with steel—you promote better synergy throughout your electrical line system.

In summary, taking the time to match conductor materials effectively enhances both safety and efficiency within electrical power transmission lines while maximizing the lifespan of components like dead end clamps.

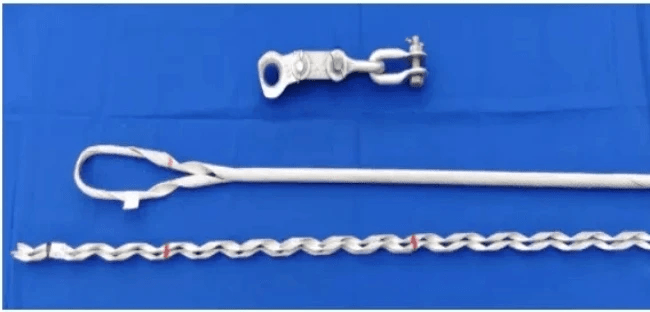

Understanding the Color Code for Easy Identification

Navigating through various armor rod options doesn’t have to be daunting; color coding simplifies this process significantly! Most manufacturers employ a standardized color code system that allows users to quickly identify specific attributes such as size or material type at a glance when selecting components like dead end clamps for transmission lines. This visual aid streamlines installation processes by reducing mistakes caused by misidentification.

For example, you might find that blue indicates an aluminum rod while red signifies a steel variant; knowing these codes helps ensure you select compatible parts efficiently during installation or maintenance tasks on overhead power systems. Additionally, adhering strictly to this color-coded identification fosters consistency across projects involving multiple installations or repairs on different electrical lines.

Overall, understanding this simple yet effective coding system not only saves time but also safeguards against costly errors when working with critical components like dead end clamps in electrical power transmission systems.

Installation Best Practices for Dead End Clamps

When it comes to ensuring the reliability of your electrical power transmission lines, proper installation of dead end clamps is crucial. A well-installed dead end clamp for transmission line not only secures the overhead power lines but also enhances their longevity and performance. In this section, we’ll explore a detailed step-by-step installation guide, common pitfalls to avoid, and tips for maintaining the integrity of your electrical line.

Step-by-Step Installation Guide

Installing a dead end clamp for transmission line requires precision and care to ensure that it functions effectively. Begin by selecting the appropriate clamp size based on the diameter of your conductor; this is essential for achieving a secure fit. Next, prepare the area by clearing any debris or obstacles around the installation site, ensuring you have ample space to work safely.

Once you have everything ready, position the dead end clamp around the conductor and tighten it according to manufacturer specifications—typically using a torque wrench for accuracy. It's important to check that all components are aligned correctly before finalizing your installation; misalignment can lead to unnecessary strain on your electrical power transmission lines over time. Finally, perform a thorough inspection after installation to confirm that everything is securely fastened and functioning as intended.

Common Mistakes to Avoid

Even seasoned professionals can make mistakes during the installation of dead end clamps for transmission lines, so it's vital to be aware of common errors that can compromise safety and efficiency. One frequent oversight is neglecting to match the clamp's specifications with those of the conductor; using an ill-fitting clamp can lead to premature wear or failure in overhead power systems. Always consult product guidelines before proceeding with installation.

Another mistake often made is failing to adequately torque bolts when securing clamps; under-torqued bolts may loosen over time while over-torqued bolts can damage components or lead to breakage in electrical lines. Additionally, overlooking environmental factors such as temperature fluctuations or exposure to moisture can adversely affect performance—ensure that materials used are suitable for local conditions. By being mindful of these pitfalls, you’ll enhance both safety and durability in your line of transmission.

Ensuring Longevity of Electrical Lines

To guarantee that your electrical power transmission lines remain operational over many years, regular maintenance checks should be integrated into your routine practices after installing dead end clamps. Periodically inspect all fittings and connections for signs of wear or corrosion; early detection allows you to address issues before they escalate into costly repairs or outages in overhead power systems.

Furthermore, consider implementing protective measures such as weather-resistant coatings on metal components; this simple step can significantly reduce corrosion risks associated with environmental exposure over time. Lastly, keep detailed records of inspections and maintenance performed on each segment of your electrical line; this documentation will aid in tracking patterns that might indicate underlying issues needing attention.

Conclusion

In summary, understanding the role of dead end clamps for transmission lines is crucial for ensuring the reliability and efficiency of electrical power transmission. These components not only secure conductors but also enhance the overall integrity of overhead power systems. By choosing high-quality dead end clamps, operators can significantly reduce maintenance costs and increase system longevity.

Key Takeaways on Dead End Clamps

Dead end clamps are essential for maintaining the stability and functionality of electrical lines, particularly in overhead power applications. They come in various types, tailored to meet specific requirements based on conductor materials and environmental conditions. Proper selection and installation of these clamps can prevent costly failures in transmission lines, making them a vital component in any electrical power transmission strategy.

The Impact of Quality on Electrical Transmission

The quality of components like dead end clamps directly influences the performance and safety of electrical power transmission lines. High-quality materials resist corrosion and wear, ensuring that the line of transmission remains intact even under harsh conditions. Ultimately, investing in superior products leads to enhanced reliability and reduced operational costs over time.

Why Spark Fittings Should Be Your Go-To Supplier

Their specialization in armor rod production ensures that customers receive innovative solutions tailored to their needs. With a commitment to quality and customer satisfaction, Spark Fittings is undoubtedly your best choice for reliable electrical line components.