Introduction

In the ever-evolving landscape of telecommunications and power distribution, the role of specialized hardware cannot be overstated. Among these critical components are preformed dead end clamps, which play a vital role in securing overhead lines and ensuring the stability of fiber optic cables like ADSS and OPGW. Understanding these elements is essential for anyone involved in the installation or maintenance of modern communication infrastructures.

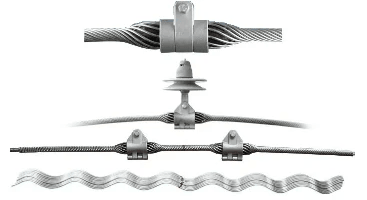

Understanding Preformed Dead End Clamps

Preformed dead end clamps are ingenious devices designed to provide secure anchoring for overhead lines, particularly in challenging environments. These clamps enhance cable stability by distributing mechanical loads evenly, which is crucial for maintaining system integrity over time. By utilizing a preformed dead end clamp, technicians can ensure that cables remain firmly in place, reducing the risk of sagging or damage caused by environmental factors.

Importance of ADSS and OPGW Fiber Cables

ADSS (All-Dielectric Self-Supporting) and OPGW (Optical Ground Wire) fiber cables represent significant advancements in telecommunications technology. Both types offer unique advantages; ADSS cables are lightweight yet durable, making them ideal for installation on existing utility poles without additional support structures. On the other hand, OPGW cables serve a dual purpose—they not only provide high-speed data transmission but also protect power lines from lightning strikes and electrical interference.

Overview of Spark Fittings’ Role

When it comes to ensuring reliability in cable installations, Spark Fittings stands out as a leader in providing quality solutions such as preformed dead end clamps and other related fittings. Their expertise extends to custom solutions tailored to meet specific project requirements while maintaining high-quality standards with materials like aluminum and galvanized steel. With an emphasis on innovation and performance, Spark Fittings plays a pivotal role in advancing the use of suspension clamps and dead end strain clamps across various applications.

The Basics of Preformed Dead End Clamps

When it comes to ensuring the reliability and stability of overhead lines, preformed dead end clamps play a pivotal role. These specialized fittings are designed to secure cables in place, preventing them from slipping or sagging under tension. By effectively managing the forces acting on cables, they provide an essential function in modern telecommunications infrastructure.

Definition and Functionality

A preformed dead end clamp is a device engineered to hold fiber optic cables firmly at their termination points in overhead lines. Unlike traditional clamps, which may require constant adjustments, these clamps are pre-shaped to fit the cable’s profile perfectly. Their unique design allows them to distribute stress evenly across the cable, thus enhancing its longevity and reliability.

The functionality of a dead end clamp extends beyond mere attachment; it actively contributes to the structural integrity of overhead systems. In essence, these clamps mitigate the risks associated with environmental factors such as wind or ice loading that can otherwise jeopardize cable performance. This makes them indispensable for maintaining optimal signal transmission in telecommunications networks.

How They Enhance Cable Stability

Preformed dead end clamps significantly enhance cable stability by providing consistent support throughout various weather conditions and mechanical stresses. Their ability to securely anchor cables helps prevent unwanted movement that could lead to damage or service interruptions. Additionally, by utilizing a design that minimizes stress concentrations, these clamps help prolong the lifespan of both ADSS and OPGW fiber cables.

In contrast to suspension clamps that allow for some degree of movement along the line, dead end strain clamps lock cables into place firmly. This distinction is crucial when considering system integrity; while suspension clamps offer flexibility for dynamic loads, dead end clamps ensure that static loads are managed effectively without risk of slippage or misalignment. Thus, they create a balanced approach where both flexibility and stability coexist in overhead installations.

Applications in Modern Telecommunications

The applications of preformed dead end clamps extend across various sectors within modern telecommunications infrastructure. From supporting ADSS (All-Dielectric Self-Supporting) fiber cables strung between utility poles to securing OPGW (Optical Ground Wire) installations on power lines, their versatility is unmatched. Moreover, their use is not limited solely to urban settings; rural installations also benefit from these robust fittings due to their ability to withstand harsh environmental conditions.

In addition to traditional telecommunications applications, preformed dead end clamps are increasingly utilized in renewable energy projects where fiber optics play a critical role in monitoring systems and data transmission. As technology evolves and demands for reliable communication increase, these fittings will continue being integral components in enhancing network resilience and performance across diverse applications.

Exploring ADSS Fiber Cables

ADSS (All-Dielectric Self-Supporting) fiber cables are a game-changer in the telecommunications industry, designed to be installed on existing power lines without the need for additional support structures. These cables are insulated and can withstand harsh environmental conditions, making them suitable for a variety of applications. Understanding ADSS technology is essential for anyone looking to enhance their communication networks effectively.

What is ADSS Cable?

ADSS cable is a type of fiber optic cable that features an all-dielectric construction, meaning it does not contain any conductive materials. This design allows it to be installed alongside electrical power lines without the risk of electrical interference, making it a preferred choice for many utility companies. The use of preformed dead end clamps in conjunction with ADSS cables ensures they remain securely attached to overhead lines while minimizing stress on the fibers themselves.

Benefits of ADSS Technology

The primary benefit of ADSS technology lies in its ability to provide high-speed data transmission over long distances while being resistant to environmental factors like moisture and temperature fluctuations. Unlike traditional cables that require extensive support systems, ADSS cables can be directly strung between poles or towers using a dead end clamp overhead line, simplifying installation processes and reducing costs. Moreover, their lightweight design means that fewer structural reinforcements are needed, allowing for easier upgrades and maintenance.

Common Use Cases and Installations

ADSS fiber cables are commonly used in urban areas where space is limited and existing infrastructure needs to be utilized efficiently. They are ideal for connecting remote locations or enhancing communication networks across cities without disrupting everyday operations. Typical installations include telecommunications backhaul links and smart grid applications where reliable data transfer is crucial; here, the use of dead end strain clamps ensures stability while suspension clamps maintain proper tension throughout the system.

OPGW Fiber Cables: A Closer Look

OPGW, or Optical Ground Wire, is a dual-purpose cable that combines both optical fibers for communication and a grounding function for electrical protection. This innovative technology allows utilities to utilize existing power line infrastructure while enhancing data transmission capabilities. By integrating fiber optics into the overhead lines, OPGW cables provide a reliable solution for modern telecommunications needs.

Defining OPGW Technology

At its core, OPGW technology consists of optical fibers encased in a protective aluminum or steel wire that also serves as a ground conductor. This unique design not only protects the fiber from environmental factors but also provides an essential grounding function for electrical systems. The versatility of OPGW allows it to be installed on new or existing overhead lines without disrupting service, making it an attractive option for utility companies.

Advantages Over Traditional Cables

When comparing OPGW to traditional cables, several advantages become apparent. Firstly, the integration of optical fibers directly into the grounding wire eliminates the need for separate installations, saving both time and resources. Additionally, OPGW cables are less susceptible to damage from external factors due to their robust construction and built-in protective features, ensuring greater system reliability.

Another key benefit lies in their ability to enhance communication capabilities without compromising safety—an important consideration when dealing with high-voltage power lines. The use of preformed dead end clamps with OPGW installations ensures secure connections that can withstand extreme weather conditions and mechanical stress. Furthermore, these clamps help maintain proper tension within the overhead line system while allowing for easy maintenance access.

Implementation in Power Lines

The implementation of OPGW fiber cables in power lines has revolutionized how utilities manage their networks and communicate with customers. By replacing traditional ground wires with OPGW technology, companies can streamline operations while providing enhanced data services simultaneously. This dual functionality creates an efficient setup where a single installation fulfills multiple roles—significantly reducing costs associated with separate infrastructure.

Moreover, utilizing preformed dead end clamps during installation ensures that both stability and integrity are maintained within the system throughout its lifespan. These dead end strain clamps play a crucial role by securing the cable at critical points along the overhead line while allowing flexibility during installation adjustments if needed. In comparison to suspension clamps used elsewhere in network setups, dead end clamps provide superior performance under tension loads commonly experienced by power lines.

In summary, implementing OPGW fiber cables not only boosts communication capabilities but also fortifies existing power line infrastructure against various challenges faced today—making it an essential component of modern telecommunications strategy.

The Role of Dead End Strain Clamps

Dead End strain clamps are vital components in overhead line systems, ensuring that cables remain securely anchored and stable under various conditions. These clamps are designed to withstand significant tension and environmental stresses, making them essential for maintaining the integrity of cable installations. By utilizing preformed dead end clamps, utility companies can enhance the reliability of their overhead lines while reducing maintenance needs.

Function in Overhead Lines

In overhead lines, the primary function of a Dead End clamp is to anchor the cable at its termination point, effectively preventing any unwanted movement or sagging. This is especially crucial in areas prone to high winds or heavy ice loads, where cable stability is paramount. The preformed dead end clamp achieves this by evenly distributing stress along the cable, reducing localized wear and tear.

Moreover, these clamps provide a secure attachment point for cables like ADSS and OPGW fiber cables, ensuring they remain in place during extreme weather events. The design of Dead End strain clamps allows for easy installation without compromising on strength or durability. With their robust construction and reliable performance, these clamps play a pivotal role in keeping telecommunications and power lines operational.

Comparing Dead End Clamp to Suspension Clamp

While both Dead End strain clamps and suspension clamps serve important functions in overhead line systems, they are designed for different purposes. A Dead End clamp is primarily used to terminate a cable at its endpoint while maintaining tension; conversely, a suspension clamp supports the weight of the cable along its run without applying tension at those points. Understanding these differences helps engineers choose the right component based on specific installation requirements.

Another key distinction lies in their design: while preformed dead end clamps focus on anchoring capabilities under load conditions, suspension clamps allow for flexible movement as needed due to thermal expansion or contraction of cables. This flexibility can be particularly beneficial when dealing with varying temperatures that affect line sagging over long spans. Thus, selecting between these two types hinges on understanding their unique roles within an overhead line system.

Additionally, using both types strategically can enhance overall system performance—Dead End strain clamps secure critical junctions while suspension clamps maintain proper alignment throughout longer stretches of wire. Together they create a balanced approach that maximizes efficiency and minimizes wear over time.

How They Affect System Integrity

The integrity of an overhead line system heavily relies on components like preformed dead end clamps which ensure that cables remain firmly attached despite external forces such as wind or ice accumulation. When installed correctly, these Dead End strain clamps contribute significantly to reducing stress concentrations along cables—leading to longer service life and lower maintenance costs overall. Their ability to absorb shock loads helps prevent potential failures that could disrupt service delivery.

Moreover, by comparing them with suspension clamps—where improper use may lead either too much slack or excessive tension—it's clear how critical proper selection is for maintaining system integrity over time. A well-placed preformed dead end clamp can mean the difference between reliable operation and costly outages caused by equipment failure or damage from environmental factors.

In conclusion, understanding how these components interact within an infrastructure allows engineers not only to optimize designs but also predict future challenges more effectively—ultimately enhancing both performance longevity and safety standards across telecommunications networks.

Spark Fittings: Experts in the Field

When it comes to the world of telecommunications and power line installations, Spark Fittings stands out as a leader in providing innovative solutions. Their expertise in preformed dead end clamps and related fittings ensures that projects are executed with precision and reliability. With a commitment to quality and performance, Spark Fittings plays a crucial role in enhancing the integrity of overhead lines.

Custom Preformed Armor Rod Solutions

Spark Fittings specializes in custom preformed armor rod solutions designed to meet specific project needs. These rods are essential for supporting cables and maintaining their structural integrity, particularly when using a dead end clamp overhead line setup. By tailoring their products to client specifications, Spark Fittings ensures that each installation is optimized for performance, longevity, and safety.

The versatility of these armor rods allows them to be integrated seamlessly with various cable types, including ADSS and OPGW fiber cables. This customization not only enhances stability but also reduces the risk of cable damage during installation or adverse weather conditions. As such, using custom solutions from Spark Fittings can significantly improve overall system reliability.

Quality Materials Used: Aluminum and Galvanized Steel

The use of aluminum and galvanized steel ensures that these components can withstand harsh environmental conditions while maintaining their structural integrity over time. These materials are not only durable but also lightweight, which is crucial for minimizing strain on overhead lines.

Aluminum’s resistance to corrosion makes it an ideal choice for outdoor applications where exposure to moisture is inevitable. Meanwhile, galvanized steel provides added strength where necessary without compromising on weight considerations—making it perfect for both dead end strain clamps and suspension clamps alike. By utilizing these high-quality materials, Spark Fittings guarantees that their products will perform reliably throughout their lifespan.

Importance of Color Coding in Installation

Color coding is an often-overlooked aspect of installing preformed dead end clamps but plays a vital role in ensuring safety and efficiency on-site. By using distinct colors for different components such as dead end strain clamps or suspension clamps, technicians can quickly identify each part's function during installation or maintenance activities. This practice minimizes confusion and errors, leading to smoother operations overall.

Moreover, color coding helps streamline training processes for new employees who may be unfamiliar with various fittings used in overhead line systems. When every component is easily identifiable through color differentiation, learning becomes more intuitive—and safety increases as fewer mistakes occur during handling or installation phases. Ultimately, this simple yet effective strategy enhances both productivity and safety across all projects involving spark fittings.

Conclusion

In summary, preformed dead end clamps play a crucial role in the stability and reliability of overhead lines. These clamps not only secure cables effectively but also enhance the overall integrity of telecommunications systems. Understanding their functionality, along with ADSS and OPGW technologies, is essential for anyone involved in modern infrastructure.

Key Takeaways on Preformed Dead End Clamps

Preformed dead end clamps are indispensable components that ensure the safe and efficient operation of overhead lines. Their design allows for optimal load distribution, minimizing stress on cables while enhancing stability during adverse weather conditions. When comparing a Dead End clamp overhead line to other options like suspension clamps, it’s clear that these specialized fittings offer superior performance and durability.

Future Trends in ADSS and OPGW Technologies

The future of ADSS and OPGW technologies looks promising as advancements continue to emerge in materials science and engineering practices. We can expect innovations that enhance the efficiency of preformed dead end clamps, making them even more reliable for high-capacity installations. Additionally, as demand for fiber optic solutions grows, integrating smart technologies into these systems will likely become standard practice.

How Spark Fittings Stands Out in the Market

Spark Fittings has carved out a niche in the market by offering custom solutions tailored to meet specific client needs regarding preformed dead end clamps. Their commitment to quality materials such as aluminum and galvanized steel ensures longevity and performance under pressure—qualities essential for any Dead End strain clamp or suspension clamp application. With an emphasis on user-friendly installation practices, including effective color coding, Spark Fittings continues to lead the way in innovative fittings designed for tomorrow's challenges.