Introduction

In the rapidly evolving world of manufacturing, the rise of automated wire bending machines has revolutionized how industries approach wire forming. These advanced bending machines, particularly CNC wire bender machines, have significantly enhanced productivity and precision in creating complex wire shapes. As manufacturers seek to streamline their operations, understanding the capabilities of these cutting-edge tools becomes essential.

The Rise of Automated Wire Bending Machines

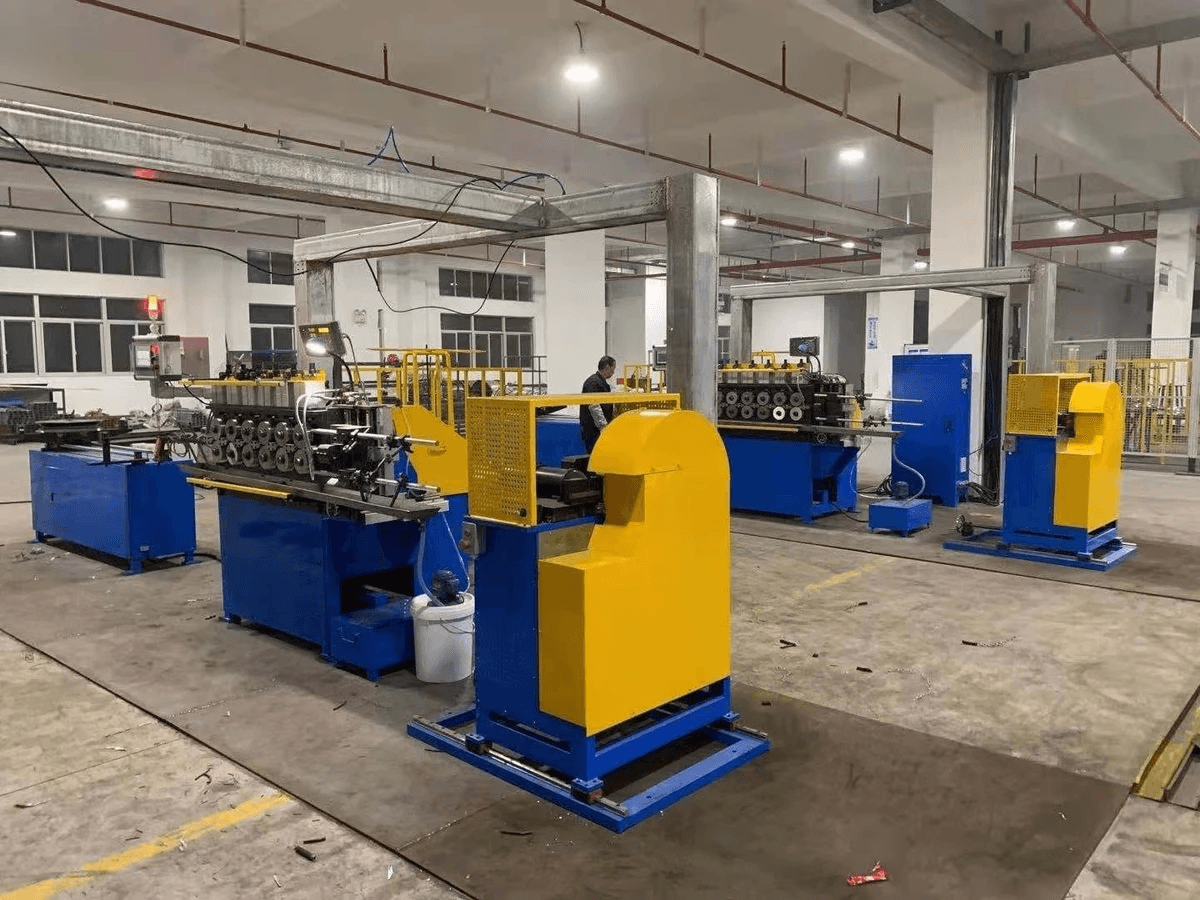

The demand for efficient and accurate bending equipment has skyrocketed as industries strive for higher output and lower costs. Automated wire bending machines have emerged as a game-changer, providing unparalleled speed and consistency compared to traditional methods. With innovations in technology, a CNC bending machine can now execute intricate designs that were once labor-intensive and time-consuming.

How Spark Fittings Leads the Way

Leading the charge in this technological advancement is Spark Fittings, a company renowned for its commitment to innovation in wire forming solutions. By integrating state-of-the-art features into their products, Spark Fittings ensures that their wire bending equipment meets the diverse needs of modern manufacturing processes. Their focus on quality and performance positions them at the forefront of the industry, setting a benchmark for others to follow.

Understanding Wire Forming Technology

To appreciate the significance of automated solutions like CNC wire bender machines, it’s crucial to grasp the fundamentals of wire forming technology. This encompasses various processes used to manipulate metal wires into desired shapes through bending and twisting techniques. Understanding these principles not only highlights the importance of effective machinery but also underscores how advancements in this field contribute to overall manufacturing efficiency.

What is a CNC Wire Bender Machine?

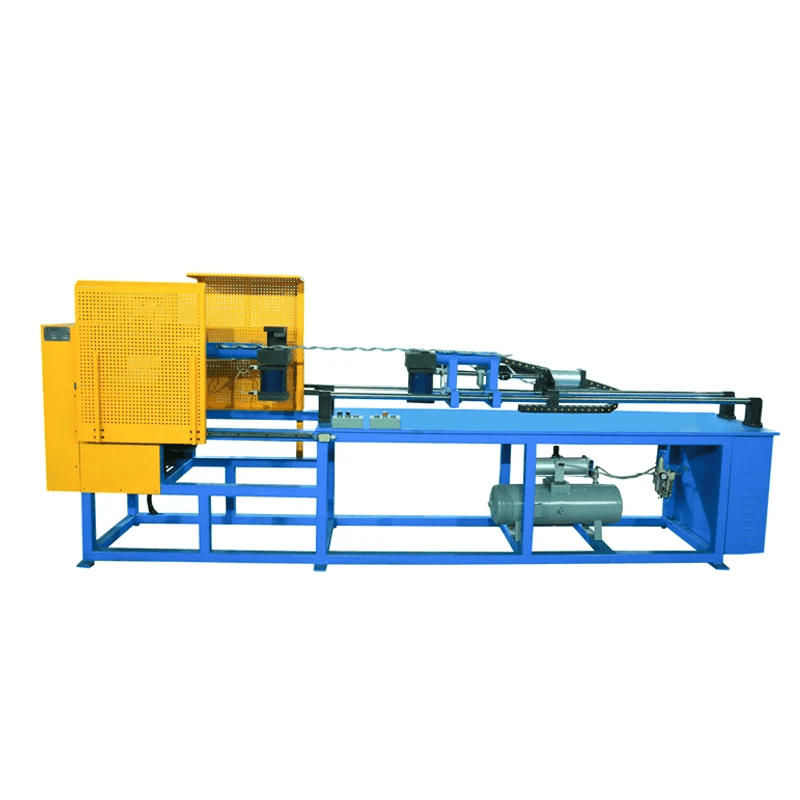

The CNC wire bender machine is revolutionizing the way manufacturers approach wire forming and bending tasks. Unlike traditional bending machines that rely heavily on manual input, this sophisticated piece of equipment utilizes computer numerical control (CNC) to execute precise bends and shapes in wire. This technological advancement not only enhances productivity but also significantly reduces the margin for error, making it a game-changer in the industry.

Definition and Functionality

A CNC bending machine is defined as an automated tool that shapes wire into specified forms through programmed instructions. The functionality of a CNC wire bender involves translating digital designs into physical products, allowing manufacturers to create intricate shapes with remarkable accuracy. This level of precision is particularly crucial for industries where exact specifications are non-negotiable, such as automotive and aerospace manufacturing.

Key Features of CNC Bending Machines

CNC bending machines come equipped with several key features designed to optimize performance and usability. One prominent feature is the user-friendly interface that allows operators to easily input designs and monitor the bending process in real-time. Additionally, these machines often include advanced safety measures, automatic material feeding systems, and high-speed operation capabilities—all of which contribute to efficient production cycles compared to conventional wire bending equipment.

Benefits for Manufacturers

The benefits of utilizing a CNC wire bender machine are manifold for manufacturers looking to enhance their operations. First off, the automation provided by these machines leads to increased efficiency; fewer manual interventions mean faster turnaround times on projects. Furthermore, consistency in product quality improves significantly due to the machine's ability to replicate complex bends without variation—an essential factor when scaling up production or meeting strict regulations.

Types of Wire Bending Equipment

When it comes to wire forming, the market is teeming with various types of bending equipment that cater to different needs. Understanding these machines is crucial for any manufacturer looking to optimize their production processes. From CNC wire bender machines to more traditional setups, each type has its unique advantages and applications.

Overview of Common Bending Machines

Common bending machines include manual wire benders, CNC bending machines, and hybrid models that combine both functionalities. Manual wire benders are typically simpler and less expensive but require skilled operators for precise results. On the other hand, CNC wire bender machines automate the bending process, offering greater precision and efficiency—ideal for high-volume production runs.

The versatility of these bending machines allows manufacturers to work with various materials, including stainless steel, aluminum, and copper. Each machine type can handle different wire diameters and shapes, making it essential to choose the right equipment based on specific project requirements. With advancements in technology, many manufacturers are now leaning towards automated solutions for better output quality.

Comparing Manual vs. Automated Solutions

When comparing manual versus automated solutions in the realm of wire bending equipment, one must consider factors like efficiency and labor costs. Manual wire benders may have lower upfront costs but often result in higher labor expenses due to the need for skilled operators. In contrast, a CNC wire bender machine can significantly reduce labor costs while increasing throughput by automating repetitive tasks.

Automated solutions also offer enhanced precision compared to their manual counterparts; a minor error in manual bending can lead to costly reworks or scrap material. Furthermore, modern CNC bending machines come equipped with advanced software that simplifies programming complex bends and shapes—something that would take hours if done manually! In essence, while manual solutions still hold value in niche applications or smaller operations, automation is increasingly becoming the preferred choice among manufacturers.

Applications of Different Wire Benders

Different types of wire benders find applications across various industries such as automotive manufacturing, furniture design, electronics assembly, and more! For instance, a CNC bending machine is ideal for producing intricate components used in automotive parts where precision is paramount. Meanwhile, simpler bending machines might be sufficient for crafting basic furniture frames or decorative items.

The adaptability of these machines means they can produce everything from simple hooks to complex assemblies with multiple bends—all tailored to meet specific industry standards or customer specifications. Additionally, specialized equipment like twisted wire folding labeling machines has emerged from companies like Spark Fittings—demonstrating just how innovative this field has become! As industries continue evolving toward automation and customization demands grow stronger than ever before; investing in advanced wire forming technology will undoubtedly pay off.

Spark Fittings: Innovation in Wire Forming

In an industry where precision meets innovation, Spark Fittings stands out as a beacon of excellence in wire forming technology. With a commitment to pushing the boundaries of what is possible, this company has become synonymous with quality and efficiency in the realm of bending equipment. Their cutting-edge solutions are designed to meet the diverse needs of manufacturers, ensuring that every project is executed with unparalleled accuracy.

Introduction to Spark Fittings

Spark Fittings has carved its niche by specializing in advanced wire bending machines that cater to various industries. The company combines years of experience with modern technology to produce state-of-the-art CNC wire bender machines that redefine productivity standards. Their dedication to innovation allows them to offer versatile bending equipment that can adapt to any manufacturing process.

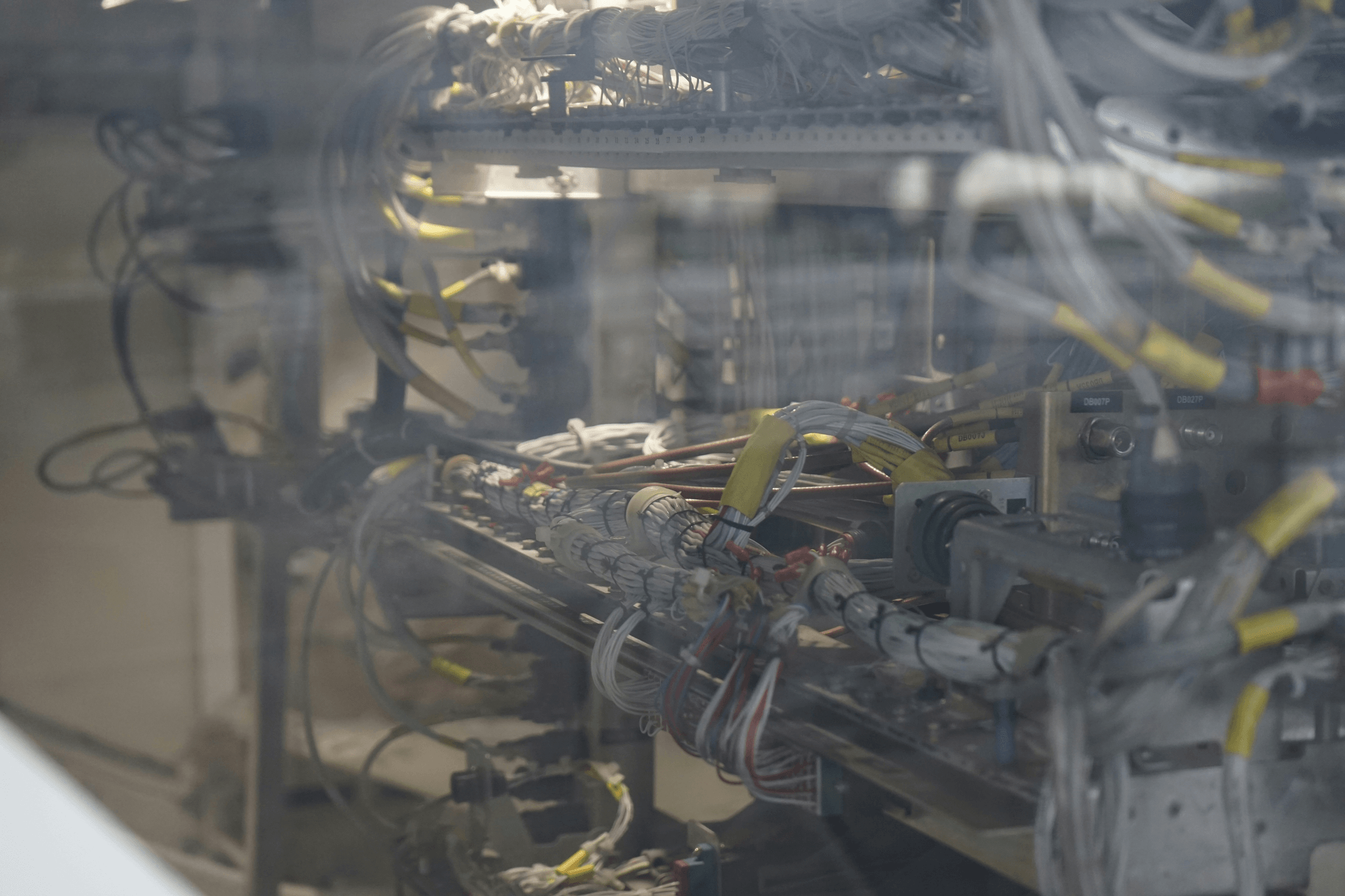

Twisted Wire Folding Labeling Machine Explained

One of the standout products from Spark Fittings is their Twisted Wire Folding Labeling Machine, an essential tool for manufacturers looking for efficiency and precision. This machine automates the labeling process for twisted wires, ensuring consistent quality while significantly reducing labor costs associated with manual labeling methods. The integration of this machine into production lines enhances workflow and demonstrates how automated solutions can revolutionize traditional wire forming practices.

Advantages of Spark Fittings Products

Choosing Spark Fittings products means opting for superior functionality and reliability in your wire bending equipment. Their CNC bending machines not only deliver exceptional performance but also offer user-friendly interfaces that simplify operation across various skill levels. With a focus on durability and innovation, Spark Fittings ensures that their products provide long-term value, making them a smart investment for any manufacturer looking to enhance their capabilities.

The Advantages of Automated Labeling

In the world of manufacturing, automated labeling has become a game-changer, especially when integrated with advanced bending equipment like the CNC wire bender machine. This technology not only streamlines production processes but also enhances overall efficiency across various applications. By leveraging automation, manufacturers can significantly reduce downtime and increase output without compromising quality.

Efficiency and Speed in Production

One of the most significant advantages of using a CNC wire bender machine is its ability to drastically improve efficiency and speed in production. Unlike manual methods that can be time-consuming and prone to errors, automated systems ensure that wire forming processes are executed swiftly and accurately. As a result, manufacturers can meet tight deadlines while maintaining high standards in their products.

Moreover, the integration of bending machines into production lines allows for continuous operation without the need for frequent breaks or adjustments. This seamless workflow means that businesses can handle larger orders with ease, ultimately leading to increased profitability. In an industry where time is money, adopting automated labeling through advanced wire bending equipment is a no-brainer.

Precision and Consistency in Labeling

Precision is paramount when it comes to labeling products; any deviation can lead to costly mistakes or misbranding issues. Automated labeling systems integrated with CNC bending machines deliver unparalleled accuracy that manual methods simply cannot match. This consistency ensures that every label adheres perfectly to specifications, enhancing brand integrity and customer satisfaction.

Furthermore, these automated systems eliminate human error by standardizing processes across all operations involving wire forming and labeling tasks. With precise measurements being maintained throughout each cycle of the bending machine’s operations, manufacturers can trust that their output will meet exact requirements every time. The end result? A flawless product presentation that speaks volumes about quality control.

Boosting Productivity with Automation

The integration of automation into manufacturing processes significantly boosts productivity levels by allowing machines to work around the clock without fatigue—a feat no human worker could achieve! With state-of-the-art wire bending equipment handling complex tasks efficiently, staff members are freed up to focus on higher-level operations or maintenance duties instead of mundane tasks like manual labeling.

Additionally, automated systems provide real-time data analytics that help identify bottlenecks or inefficiencies within production lines featuring CNC wire bender machines or other bending equipment. By addressing these issues proactively, manufacturers can optimize workflows even further—creating a cycle of continuous improvement that's hard to beat! Ultimately, embracing automation not only enhances productivity but also fosters innovation within manufacturing environments.

Integration and Usability of Bending Equipment

In today's fast-paced manufacturing environment, the integration and usability of bending equipment like CNC wire bender machines are crucial. Manufacturers need solutions that can seamlessly fit into their existing production lines without causing disruptions. The versatility of modern bending machines allows for smooth integration, making it easier than ever to adopt advanced wire forming technologies.

Ease of Integration with Existing Lines

One of the standout features of contemporary bending equipment is its ability to be integrated effortlessly with existing setups. Whether you’re upgrading an old bending machine or introducing a new CNC bending machine, manufacturers can expect minimal downtime during installation. This adaptability not only enhances productivity but also ensures that teams can quickly return to their regular workflow without missing a beat.

User-Friendly Touchscreen Controls

Navigating the complexities of a wire bending machine has never been easier thanks to user-friendly touchscreen controls. These intuitive interfaces allow operators to manage the CNC wire bender machine with just a few taps, reducing training time significantly. With clear visual displays and straightforward options, even those new to wire forming can operate sophisticated bending equipment confidently.

Customization for Diverse Manufacturing Needs

Every manufacturer has unique requirements, and that's where the customization capabilities of modern wire bending machines come into play. From adjusting settings for different materials to programming specific bend angles, these machines can be tailored to meet diverse production needs effectively. This level of customization ensures that every manufacturer can maximize their efficiency and output while using cutting-edge wire bending equipment designed specifically for their operations.

Conclusion

In the ever-evolving landscape of manufacturing, the future of wire bending is brimming with promise and innovation. The emergence of advanced technologies, particularly in CNC wire bender machines, is revolutionizing how businesses approach wire forming and production processes. As industries continue to embrace automation, the potential for increased efficiency and quality in bending equipment is boundless.

Unlocking the Future of Wire Bending

The future of wire bending lies in harnessing the capabilities of cutting-edge CNC bending machines that offer unparalleled precision and speed. With advancements in technology, modern bending machines can produce intricate designs with minimal human intervention, paving the way for more complex applications. This shift not only streamlines production but also enhances product quality—essential elements for staying competitive in today’s market.

Why Choose Spark Fittings for Your Needs

When it comes to selecting a provider for your wire bending equipment needs, Spark Fittings stands out as a leader in innovation and reliability. Their range of products includes state-of-the-art CNC wire bender machines designed to meet diverse manufacturing demands while ensuring exceptional performance. Choosing Spark Fittings means investing in high-quality solutions that not only boost productivity but also simplify integration into existing workflows.

The Impact of Automation on Manufacturing

The impact of automation on manufacturing cannot be overstated; it has transformed how industries operate and compete globally. Automated systems like wire bending machines significantly reduce production times while increasing accuracy and consistency across batches. As manufacturers increasingly adopt these technologies, they unlock new levels of productivity that drive growth and profitability.