Introduction

Aluminum bronze is a remarkable alloy that combines the best properties of aluminum and copper, making it a standout choice in various industries. With its unique characteristics, such as exceptional corrosion resistance and high strength, aluminum bronze components are increasingly becoming the go-to material for demanding applications. This introduction explores why Aluminum Bronze Castings are favored in metal casting and how they outperform other materials.

The Unique Properties of Aluminum Bronze

Aluminum bronze boasts a distinctive blend of properties that set it apart from traditional bronzes. Its notable corrosion resistance allows it to thrive in harsh environments, particularly where moisture and saltwater exposure are prevalent. Additionally, the strength and durability of aluminum bronze components make them ideal for applications requiring longevity and reliability.

Applications of Aluminum Bronze in Various Industries

The versatility of aluminum bronze is evident across numerous sectors, including marine, aerospace, and electrical industries. In marine hardware, aluminum bronze castings play a crucial role due to their ability to withstand the corrosive nature of seawater while maintaining structural integrity. Similarly, in aerospace applications, these alloys offer lightweight yet strong solutions for components that demand high performance under extreme conditions.

Why Choose Aluminum Bronze for Metal Casting

Choosing aluminum bronze for metal casting presents numerous advantages that enhance both product quality and performance. The excellent casting characteristics allow for intricate designs while ensuring minimal defects during production—important factors when creating reliable aluminum bronze components. Moreover, with innovations in Bronze/Aluminum castings technology continually emerging, manufacturers can produce even more efficient and effective products tailored to specific industry needs.

Understanding Aluminum Bronze

Aluminum bronze is a fascinating material that has won over many industries due to its unique properties and versatility. This alloy, primarily made from copper, aluminum, and small amounts of other elements, exhibits remarkable characteristics that make it an ideal choice for various applications. By delving into the composition and alloys of aluminum bronze, we can better appreciate why it stands out among other materials.

Composition and Alloys

The composition of aluminum bronze typically consists of 60-90% copper, 5-12% aluminum, and traces of iron, nickel, or manganese to enhance specific properties. This blend creates an aluminum bronze component that is not only strong but also highly resistant to corrosion. Different alloys exist within the aluminum bronze family; for instance, C95400 is known for its excellent wear resistance while C95500 offers superior strength—both are popular choices in Aluminum Bronze Castings.

Properties of Aluminum Bronze

When it comes to properties, aluminum bronze boasts impressive attributes such as high strength-to-weight ratio and exceptional corrosion resistance. These qualities make it particularly suitable for demanding environments like marine applications where exposure to saltwater can be detrimental to other metals. Additionally, the low friction coefficient of this alloy enhances its performance in wear-prone applications—making Aluminum Bronze for Metal Casting a preferred option in various industries.

Comparison with Other Bronze Alloys

In comparison with other bronze alloys like tin or silicon bronzes, aluminum bronze shines brightly due to its superior mechanical properties and resistance to galling. While tin bronzes may offer good machinability and silicon bronzes excel in casting fluidity, neither matches the overall durability found in aluminum-based formulations. Furthermore, when evaluating cost-effectiveness alongside performance metrics in Bronze/Aluminum Castings versus traditional bronzes or even brass alternatives, it's clear that aluminum bronze components deliver outstanding value without compromising quality.

Advantages of Aluminum Bronze Castings

Aluminum Bronze Castings are celebrated for their remarkable advantages, making them a popular choice in various industries. With unique properties that stand out among other materials, these castings offer a blend of strength, durability, and resistance to harsh conditions. This section will delve into the specific benefits that make aluminum bronze components indispensable.

Corrosion Resistance and Durability

One of the standout features of aluminum bronze is its exceptional corrosion resistance. This property is particularly beneficial in environments exposed to moisture and saltwater, such as marine applications; aluminum bronze components can withstand these conditions without succumbing to rust or degradation. The durability of Aluminum Bronze Castings ensures longevity, reducing the need for frequent replacements and maintenance.

Moreover, the inherent toughness of aluminum bronze contributes to its ability to endure mechanical stress and wear over time. This makes it an ideal choice for applications where reliability is paramount. When considering Bronze/Aluminum Castings for your projects, you can trust that they will maintain their integrity even in challenging environments.

Strength and Wear Resistance

Aluminum bronze boasts impressive strength characteristics that set it apart from many other alloys. The combination of copper with aluminum enhances its tensile strength, making it suitable for heavy-duty applications where traditional metals might falter. Additionally, this alloy exhibits excellent wear resistance; therefore, components made from Aluminum Bronze for Metal Casting can withstand friction better than many alternatives.

This resilience translates into lower operational costs due to reduced wear-and-tear on machinery and components. Industries reliant on high-performance materials—such as aerospace or manufacturing—often favor aluminum bronze because it meets stringent performance standards while providing peace of mind regarding component longevity. When you choose Bronze Casting solutions using this alloy, you're investing in quality that pays off over time.

Applications in Marine and Aerospace

The unique properties of aluminum bronze make it particularly advantageous in both marine and aerospace sectors. In marine environments, where exposure to seawater can wreak havoc on less resilient materials, aluminum bronze components are often used in shipbuilding hardware like propellers and valves due to their corrosion resistance and strength under pressure. Similarly, in aerospace applications where weight savings without compromising strength are critical, Aluminum Bronze Castings are increasingly utilized.

Furthermore, the versatility of this alloy allows engineers to innovate new designs while maintaining safety standards across various applications—from aircraft fittings to underwater equipment—showcasing its adaptability across demanding industries. As technology continues evolving within these fields, the role of aluminum bronze will likely expand even further as manufacturers seek reliable solutions for complex challenges.

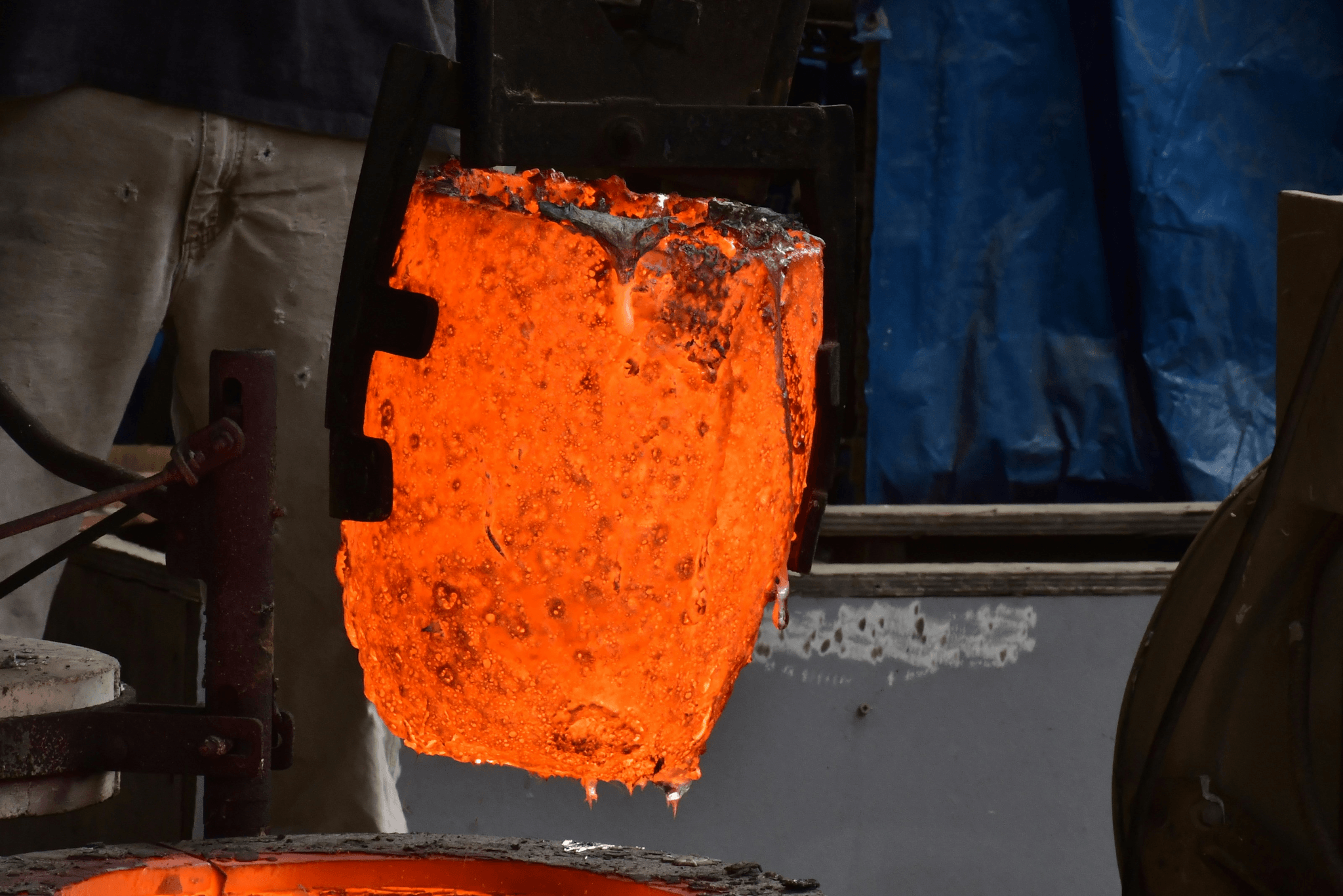

The Manufacturing Process of Aluminum Bronze

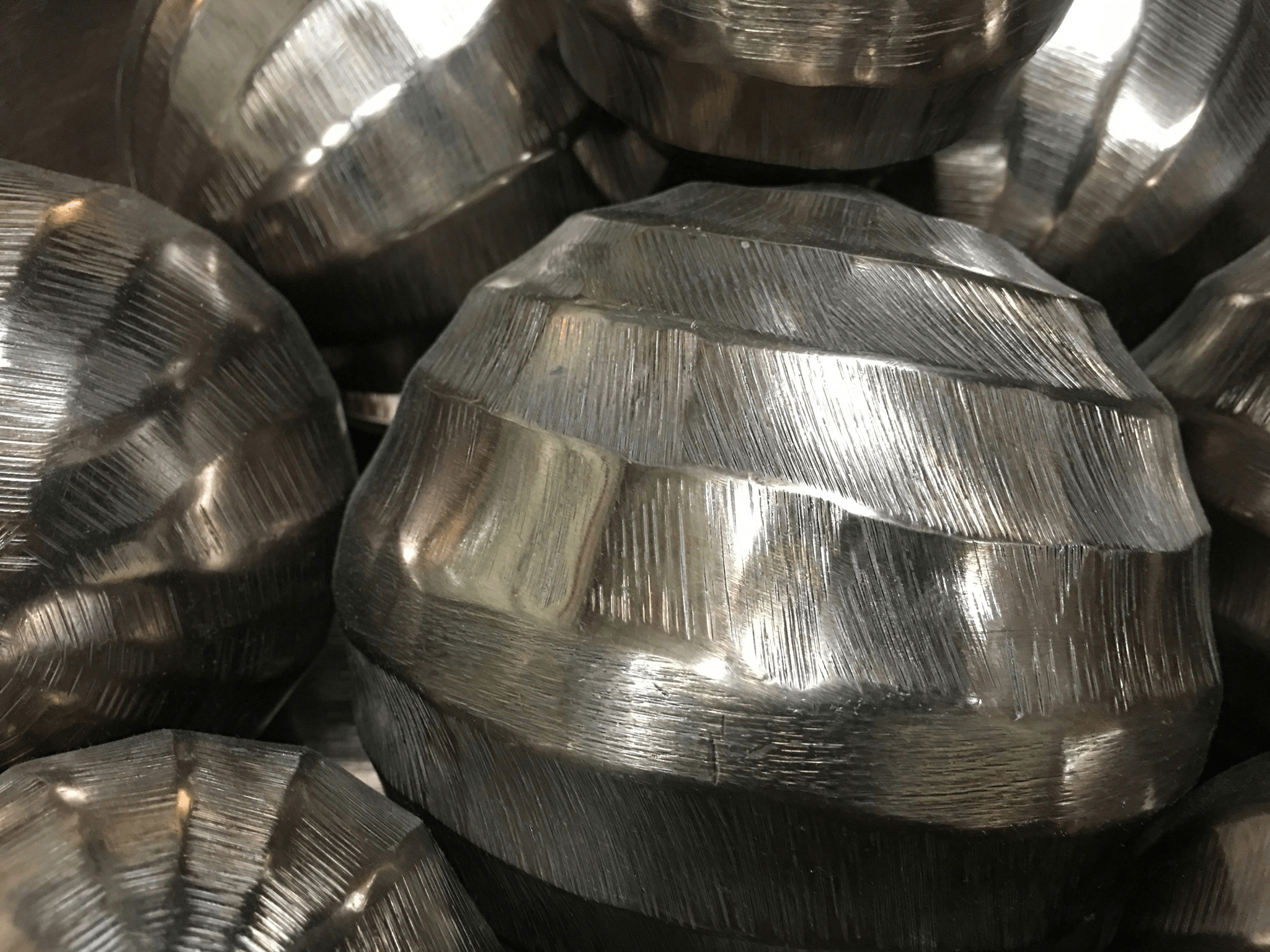

The manufacturing process of aluminum bronze is a fascinating journey that transforms raw materials into robust aluminum bronze components. The techniques employed in casting are crucial for achieving the desired properties and performance characteristics of these alloys. From the initial melting to the final finishing touches, each step is meticulously carried out to ensure high-quality Aluminum Bronze Castings.

Techniques for Aluminum Bronze Casting

When it comes to producing aluminum bronze components, various casting techniques are utilized, each with its unique advantages. Sand casting is one of the most common methods, allowing for intricate designs and large-scale production while maintaining cost-effectiveness. Another popular technique is investment casting, which offers superior surface finish and dimensional accuracy—ideal for precision applications in industries like aerospace and marine.

Moreover, pressure die casting has gained traction in recent years due to its efficiency and ability to produce complex shapes with minimal waste. Regardless of the method chosen, the focus remains on ensuring that every aluminum bronze component meets stringent quality standards while maximizing material properties. Ultimately, selecting the right casting technique can significantly influence both performance and longevity in applications requiring durable Bronze/Aluminum Castings.

Quality Control in Bronze/Aluminum Castings

Quality control is paramount when it comes to ensuring that aluminum bronze castings perform reliably under various conditions. Rigorous testing protocols are implemented throughout the manufacturing process, from raw material inspection to final product evaluation. This includes non-destructive testing methods such as ultrasonic testing and radiographic inspections that help identify any internal flaws or inconsistencies within the castings.

Additionally, chemical composition analysis ensures that each batch of Aluminum Bronze for Metal Casting meets specific alloy requirements, thereby enhancing performance characteristics like corrosion resistance and strength. By adhering to strict quality control measures, manufacturers can guarantee that their products will withstand demanding environments—whether they’re used in marine hardware or critical aerospace components.

Innovations in Casting Technology

The landscape of aluminum bronze manufacturing is continuously evolving thanks to innovations in casting technology that enhance efficiency and sustainability. One notable advancement is 3D printing technology; it allows for rapid prototyping of aluminum bronze components before full-scale production begins. This not only shortens lead times but also provides designers with unprecedented flexibility when creating complex geometries.

Furthermore, advancements in computer simulations enable manufacturers to predict how molten metal will flow during the casting process—minimizing defects like porosity or shrinkage before they occur. These innovations not only improve product quality but also reduce material waste associated with traditional Bronze Casting methods. As we look ahead, embracing these technological advancements will be key to optimizing production processes while meeting ever-increasing demands for high-performance aluminum bronze components.

Real-World Applications of Aluminum Bronze

Aluminum bronze is not just a shiny metal; it’s a powerhouse in various industries due to its remarkable properties. From electrical components to marine hardware, the versatility of aluminum bronze components is unmatched. This section delves into the significant applications of Aluminum Bronze Castings across different sectors.

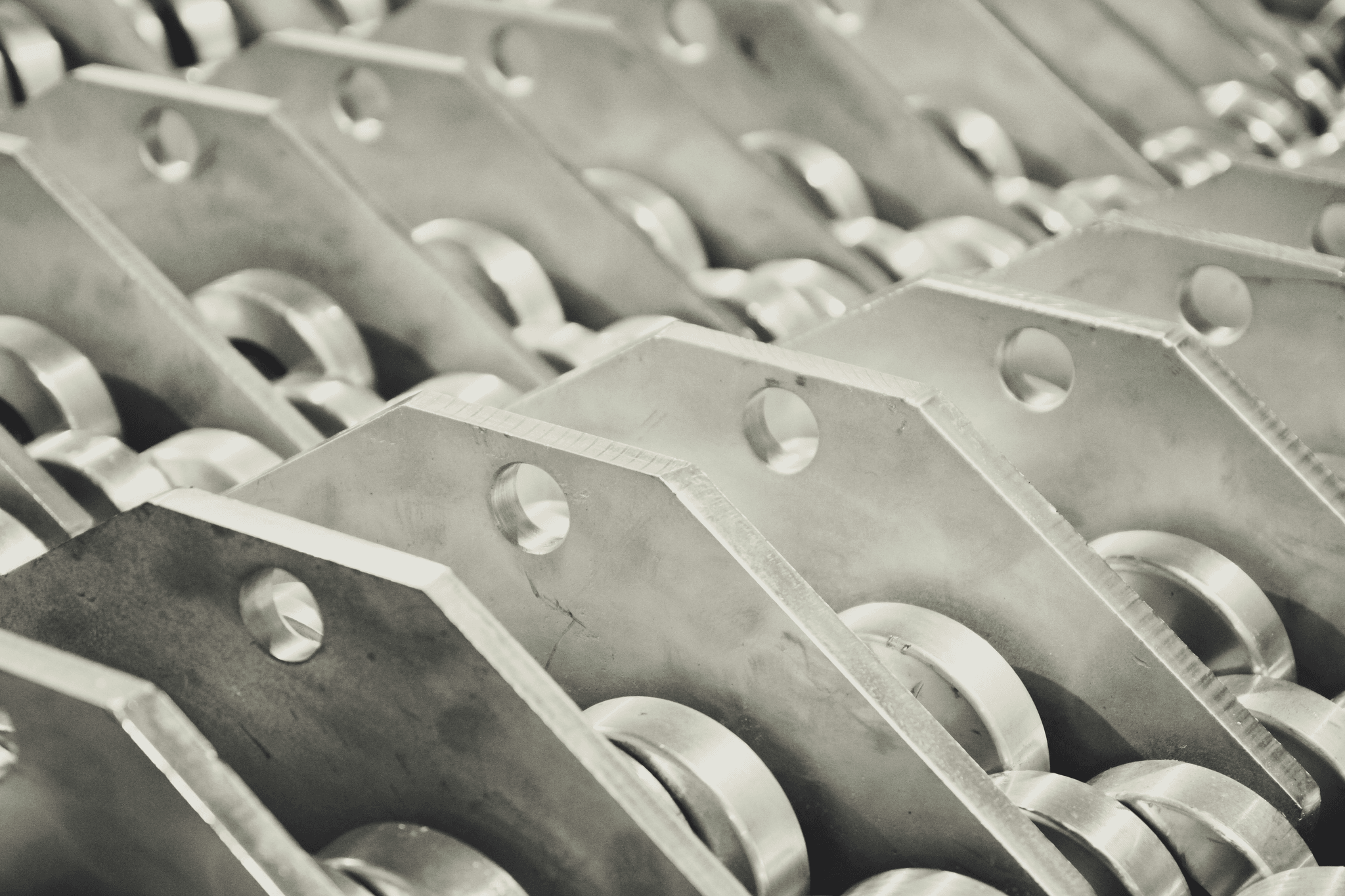

Use in Spark Fittings and Electrical Components

In the world of electrical engineering, aluminum bronze components shine brightly—quite literally! These alloys are often used in spark fittings and other electrical components due to their excellent conductivity and resistance to corrosion. The reliability of Bronze/Aluminum Castings ensures that these parts can withstand harsh environments without compromising performance, making them essential for long-lasting electrical systems.

Moreover, aluminum bronze's non-sparking nature makes it an ideal choice for applications in explosive atmospheres, providing an extra layer of safety. This characteristic is particularly crucial in industries such as oil and gas, where even the smallest spark could lead to catastrophic consequences. Thus, choosing aluminum bronze for metal casting not only enhances functionality but also prioritizes safety in critical applications.

Role in Marine Hardware and Shipbuilding

Its exceptional corrosion resistance makes it perfect for components exposed to seawater, ensuring longevity and durability even under the harshest marine conditions. From propellers to valves, Aluminum Bronze Castings are widely utilized because they can handle both saltwater's corrosive effects and mechanical stress.

Furthermore, the lightweight nature of aluminum bronze allows for more efficient fuel consumption when used in shipbuilding applications. This efficiency translates into cost savings over time—a win-win situation for shipbuilders looking to optimize performance while keeping budgets intact. As a result, aluminum bronze has become a staple material within the maritime industry.

Importance in Aerospace Components

In aerospace engineering, precision is paramount—and that's where aluminum bronze steps up to deliver exceptional results! The strength-to-weight ratio of this alloy makes it an invaluable resource for manufacturing aircraft components that require both durability and reduced weight. Aluminum Bronze Castings are utilized in various parts like landing gear bushings or structural elements where reliability under extreme conditions is non-negotiable.

Additionally, its ability to withstand high temperatures without losing structural integrity further solidifies its importance within the aerospace sector. This resilience contributes significantly to overall aircraft safety and performance during flight operations—a critical factor that cannot be overlooked by manufacturers or operators alike. Thus, incorporating aluminum bronze into aerospace component design not only enhances functionality but also supports innovation within this ever-evolving field.

Challenges and Solutions in Aluminum Bronze Casting

Aluminum Bronze Castings, while celebrated for their remarkable properties, do face several challenges during the casting process. Issues such as porosity, shrinkage, and surface defects can undermine the integrity of aluminum bronze components. Understanding these common pitfalls is essential for manufacturers looking to optimize their production methods and ensure high-quality Bronze/Aluminum Castings.

Addressing Common Issues in Bronze Casting

Porosity is a frequent concern in Bronze Casting that can lead to weakened structures and reduced performance of aluminum bronze components. This defect often arises from gas entrapment during the solidification process or from moisture in the mold material. To combat this, manufacturers must maintain strict control over environmental conditions and utilize degassing techniques to minimize gas formation.

Shrinkage is another challenge that can affect the final quality of Aluminum Bronze Castings. As the molten metal cools and solidifies, it contracts, potentially leading to voids or misalignments in the finished product. Employing proper gating systems and optimizing cooling rates are effective strategies to mitigate shrinkage issues during casting.

Surface defects such as roughness or inclusions can also mar the appearance and functionality of aluminum bronze components. These imperfections not only detract from aesthetic appeal but may also compromise mechanical properties. Regular inspections and adopting advanced mold materials can help reduce these surface-related problems.

Techniques for Improving Casting Quality

To enhance the quality of Aluminum Bronze for Metal Casting, several innovative techniques have emerged within the industry. One effective method is utilizing advanced simulation software that allows engineers to visualize fluid flow patterns within molds before actual casting begins. This predictive capability helps identify potential problem areas early in the design phase.

Another promising approach involves refining alloy compositions through metallurgical processes to improve fluidity during casting while maintaining strength after solidification. By adjusting elements like nickel or iron content, manufacturers can produce more robust aluminum bronze components with fewer defects.

Lastly, implementing rigorous quality control measures throughout production ensures that each stage—from melting to finishing—is monitored closely for adherence to specifications. Regular testing of both raw materials and finished products guarantees that only top-notch Aluminum Bronze Castings make it out of production facilities.

Future Trends in Aluminum Bronze for Metal Casting

Looking ahead, there are exciting trends on the horizon for aluminum bronze casting technologies that promise improved efficiency and sustainability. The rise of additive manufacturing techniques could revolutionize how we create complex shapes with aluminum bronze components while minimizing waste—a win-win scenario for both manufacturers and environmental advocates alike.

Moreover, advancements in recycling technologies will likely play a significant role in enhancing sustainability within the industry by enabling more efficient reuse of scrap metal from previous castings. This not only reduces costs but also aligns with global initiatives toward greener manufacturing practices.

Finally, ongoing research into hybrid materials may lead to new alloy formulations combining aluminum bronze with other metals or polymers, expanding their applications even further across industries like aerospace or marine hardware manufacturing—where performance is paramount but weight savings are equally crucial.

Conclusion

In wrapping up our exploration of aluminum bronze, it’s clear that this remarkable material offers numerous advantages across a variety of applications. From its impressive corrosion resistance to its strength and durability, aluminum bronze components have solidified their position as a preferred choice in industries ranging from marine to aerospace. As we look ahead, the continued innovation in Aluminum Bronze Castings will undoubtedly enhance their utility and performance even further.

Key Benefits of Aluminum Bronze Components

Aluminum bronze components are celebrated for their outstanding properties, which include exceptional corrosion resistance and high strength-to-weight ratios. These characteristics make them particularly suitable for demanding environments where traditional materials might fail. Moreover, the versatility of Bronze/Aluminum Castings allows for tailored solutions that meet specific industry needs, making them an invaluable asset in manufacturing.

Choosing the Right Aluminum Bronze Supplier

When selecting a supplier for your aluminum bronze needs, it’s essential to consider factors such as quality assurance processes and technical expertise in Bronze Casting techniques. A reliable supplier should provide comprehensive information on the composition and properties of their Aluminum Bronze for Metal Casting products, ensuring they meet your project requirements. Additionally, establishing a strong partnership with a knowledgeable supplier can lead to better support and innovations tailored to your unique applications.

The Future of Aluminum Bronze in Manufacturing

The future looks bright for aluminum bronze as advancements in casting technology continue to evolve. Innovations aimed at improving production efficiency and casting quality are paving the way for even more applications within various industries. As demand grows for robust materials capable of withstanding harsh conditions, aluminum bronze components will likely play an increasingly vital role in manufacturing processes worldwide.