Introduction

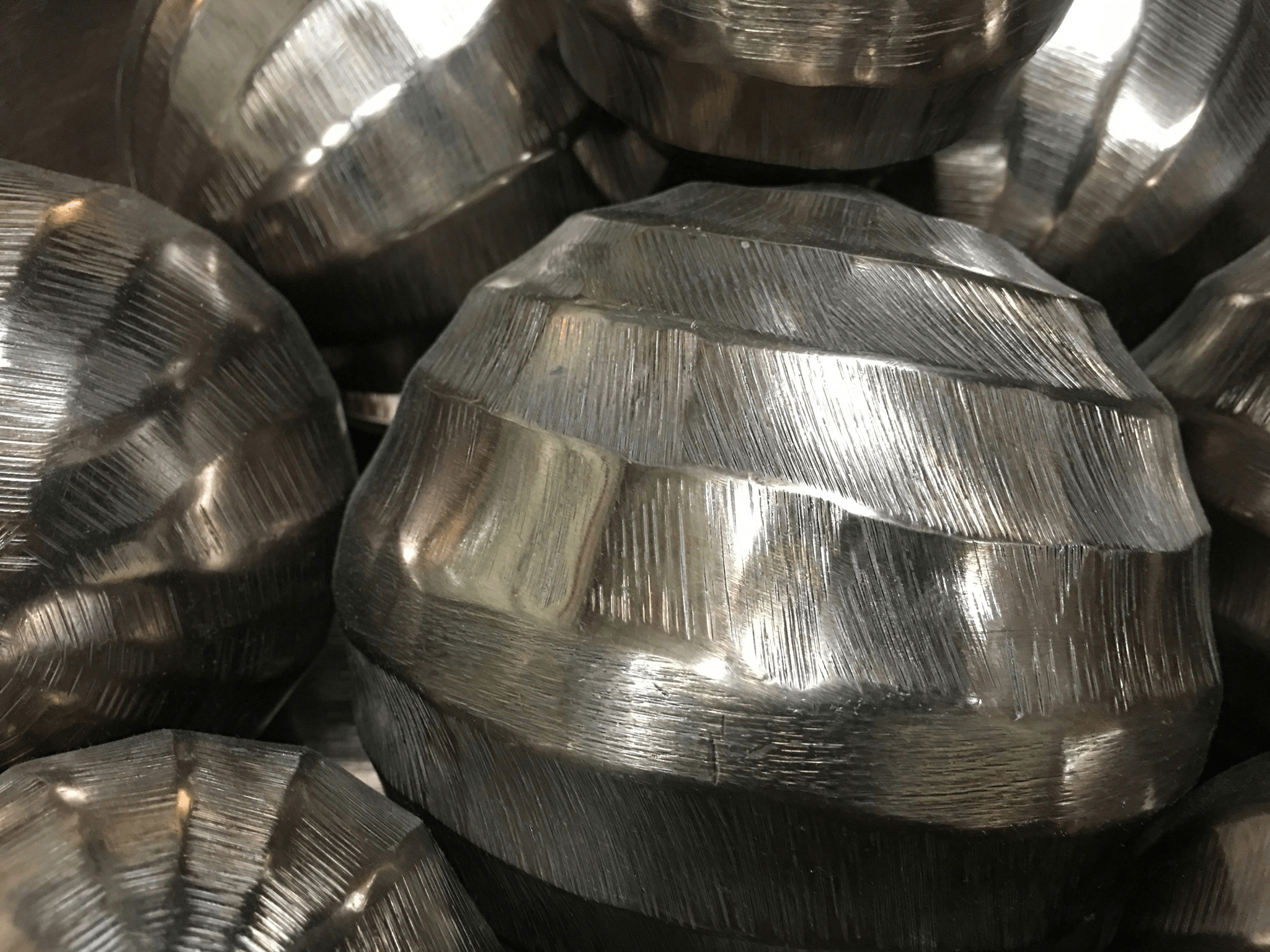

Aluminum Bronze Castings are a fascinating blend of metalworking artistry and engineering precision. These castings, known for their durability and corrosion resistance, have become a popular choice in various industries. Understanding the intricacies of Aluminum Bronze is essential to appreciate its applications and advantages fully.

Understanding Aluminum Bronze Castings

Aluminum Bronze is an alloy primarily composed of copper, aluminum, and other trace elements that enhance its properties. The unique composition provides Aluminum Bronze Castings with exceptional strength, making them suitable for demanding environments. Knowing what temperature aluminum bronze is poured at can significantly impact the final product's quality and performance.

Importance of Temperature in Casting

Temperature plays a critical role in the casting process, influencing everything from fluidity to solidification rates. For instance, understanding what temperature does aluminum-bronze melt can help manufacturers optimize their processes for better results. Achieving the right temperature ensures that Aluminum Bronze Castings retain their integrity and perform as intended under various conditions.

Applications of Aluminum Bronze Components

The versatility of Aluminum Bronze makes it ideal for numerous applications across different sectors like marine, aerospace, and electrical industries. Common uses include components for high voltage transformers where reliability is paramount due to harsh operating conditions. As we explore further into this guide, we will delve deeper into the specifics regarding temperatures involved—such as what is the temperature for casting aluminum—and how these factors contribute to successful projects involving Aluminum Bronze Castings.

What is Aluminum Bronze?

Aluminum bronze is a versatile and robust alloy primarily composed of copper, aluminum, and small amounts of other elements like iron and nickel. This unique combination results in a material that boasts excellent corrosion resistance, high strength, and impressive wear properties. Understanding the composition and properties of aluminum bronze castings helps industries leverage its advantages effectively.

Composition and Properties

The primary constituents of aluminum bronze include copper (typically 60-90%), aluminum (6-12%), with iron, nickel, or manganese added to enhance specific traits. The presence of aluminum not only contributes to the alloy's strength but also improves its resistance to oxidation and corrosion—making it ideal for harsh environments. In terms of physical properties, aluminum bronze exhibits good thermal conductivity, excellent machinability, and a melting point ranging from 950°C to 1050°C depending on the specific composition used.

Benefits of Using Aluminum Bronze

One significant benefit of using aluminum bronze castings is their exceptional durability under extreme conditions; they can withstand high temperatures without losing structural integrity. Additionally, their corrosion-resistant nature makes them suitable for marine applications where exposure to saltwater is inevitable. Furthermore, when considering what temperature does aluminum-bronze melt at—usually between 950°C to 1050°C—it becomes clear that this material can endure heat-intensive processes while maintaining its performance characteristics.

Common Industries and Applications

Aluminum bronze finds applications in various industries due to its unique properties; it's commonly utilized in marine hardware, valve components, pumps, and even aerospace applications where weight-to-strength ratios are crucial. Its resistance to wear makes it ideal for components that experience friction or abrasive environments such as gears or bearings. Moreover, understanding what temperature is aluminium bronze poured at during casting processes—typically around 1100°C—ensures optimal performance in these critical applications.

The Casting Process Explained

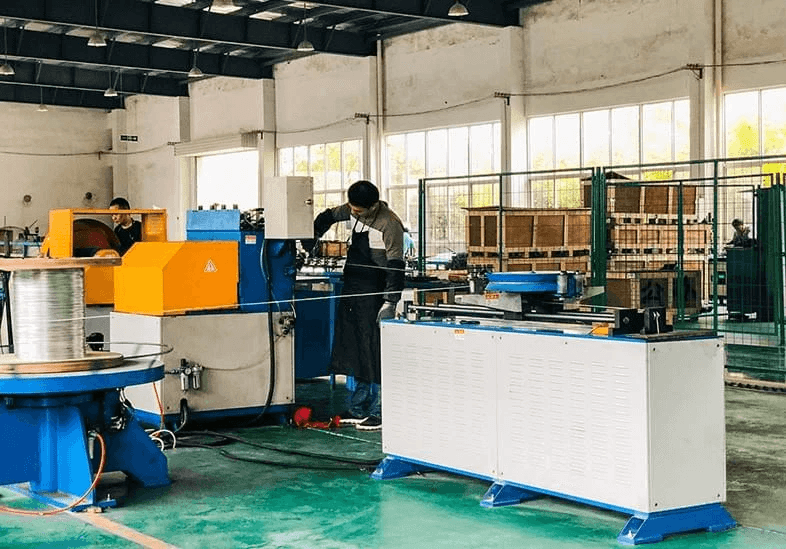

Casting aluminum bronze is a fascinating blend of art and science, where molten metal transforms into durable components. Understanding the casting process is essential for achieving high-quality Aluminum Bronze Castings that meet specific industry standards. This section will delve into key techniques, compare die-casting with sand casting, and highlight the critical role temperature plays in producing these exceptional materials.

Key Techniques for Aluminum Bronze Castings

One of the most popular methods is sand casting, which involves pouring molten metal into a mold made from sand. This technique allows for intricate designs and large-scale production, making it suitable for various applications in industries such as marine engineering and electrical components.

Another noteworthy technique is investment casting, which offers excellent surface finishes and dimensional accuracy. While both methods have their merits, the choice often depends on factors such as production volume and complexity of the part design. Regardless of the method chosen, understanding what temperature aluminum bronze is poured at is crucial to ensure that the metal flows smoothly into molds without defects.

Die-Casting versus Sand Casting

Die-casting and sand casting are two prominent techniques used in creating Aluminum Bronze Castings, each with its unique advantages. Die-casting utilizes high pressure to force molten metal into a steel mold, resulting in precise dimensions and a smooth finish—ideal for mass production runs where consistency is vital. However, this method may not be suitable for larger or more complex shapes due to mold limitations.

On the other hand, sand casting provides greater flexibility with design intricacies but may yield rougher finishes compared to die-casting. The choice between these methods often boils down to project requirements; understanding what temperature does bronze cast at Celsius can guide manufacturers in selecting the appropriate technique based on thermal properties during pouring and cooling phases. Ultimately, both processes can produce robust aluminum bronze components tailored for specific applications.

Importance of Temperature in Casting

Temperature plays a pivotal role in ensuring successful Aluminum Bronze Castings; it's not just about getting it hot enough but also maintaining optimal conditions throughout the process. Typically, aluminum bronze melts at around 950°C (1742°F), which means careful monitoring of temperatures during melting and pouring stages is essential to avoid defects like porosity or incomplete filling of molds.

Knowing what temperature aluminum bronze should be poured at ensures that it retains its fluidity while allowing proper setting once casted—too hot or too cold can lead to structural weaknesses or surface imperfections in finished products. Additionally, understanding what is the temperature for casting aluminum further emphasizes how crucial thermal management is across different metals involved in composite structures or multi-material assemblies.

Temperature Considerations in Aluminum Bronze Casting

Temperature plays a pivotal role in the process of Aluminum Bronze Castings, influencing not only the quality of the final product but also the efficiency of the casting process itself. Understanding what temperature is Aluminium bronze poured at is crucial for achieving optimal results. This section will explore key temperature considerations that impact aluminum bronze casting, including melting points and pouring temperatures.

What temperature is Aluminum bronze poured at?

When it comes to Aluminum Bronze Castings, pouring temperature is a critical factor that directly affects the integrity and performance of the cast component. Typically, Aluminum bronze is poured at temperatures ranging from 1,200°C to 1,300°C (2,192°F to 2,372°F). This high pouring temperature ensures that the alloy remains fluid enough to fill intricate molds and achieve precise details without compromising its mechanical properties.

Choosing an appropriate pouring temperature not only enhances mold filling but also minimizes defects such as porosity or cold shuts in the final product. Therefore, knowing what temperature is Aluminium bronze poured at can significantly impact production efficiency and material performance. In addition to this, it’s essential for manufacturers to monitor temperatures closely during casting operations for consistent results.

What is the temperature for casting aluminum?

While we are focusing on Aluminum Bronze Castings here, it's worth noting that aluminum itself has a different melting point which impacts its casting processes as well. The typical temperature for casting aluminum hovers around 660°C (1,220°F). This lower melting point compared to aluminum bronze allows for quicker setup times and reduced energy costs during production.

However, when comparing these two metals in terms of their respective casting processes, it’s important to remember that each metal requires specific handling techniques due to their differing thermal properties. Knowing what is the temperature for casting aluminum helps foundries optimize their operations when dealing with both metals simultaneously or sequentially in production lines.

What temperature does bronze cast at Celsius?

The term bronze encompasses various alloys; however, when discussing traditional copper-tin bronzes or even more specialized alloys like aluminum-bronze, understanding what temperature does bronze cast at Celsius becomes essential knowledge for any foundry operator. Generally speaking, most bronzes are cast between 1,050°C and 1,200°C (1,922°F - 2,192°F), depending on their composition.

For those particularly interested in Aluminum Bronze Castings specifically: while they might have slightly higher melting points than conventional bronzes due to their unique alloying elements—like aluminum—the general range still applies fairly well across different types of bronzes used in industry applications today. Thus knowing what temperature does bronze cast at Celsius can aid manufacturers in selecting appropriate materials based on desired characteristics.

Spark Fittings: An Industry Leader

In the realm of Aluminum Bronze Castings, Spark Fittings stands out as a frontrunner, showcasing exceptional capabilities that cater to a diverse array of industries. With a commitment to quality and innovation, they specialize in producing components that meet the rigorous demands of high-performance applications. Their expertise in Aluminum Bronze Castings positions them as a trusted partner for businesses seeking reliable and durable solutions.

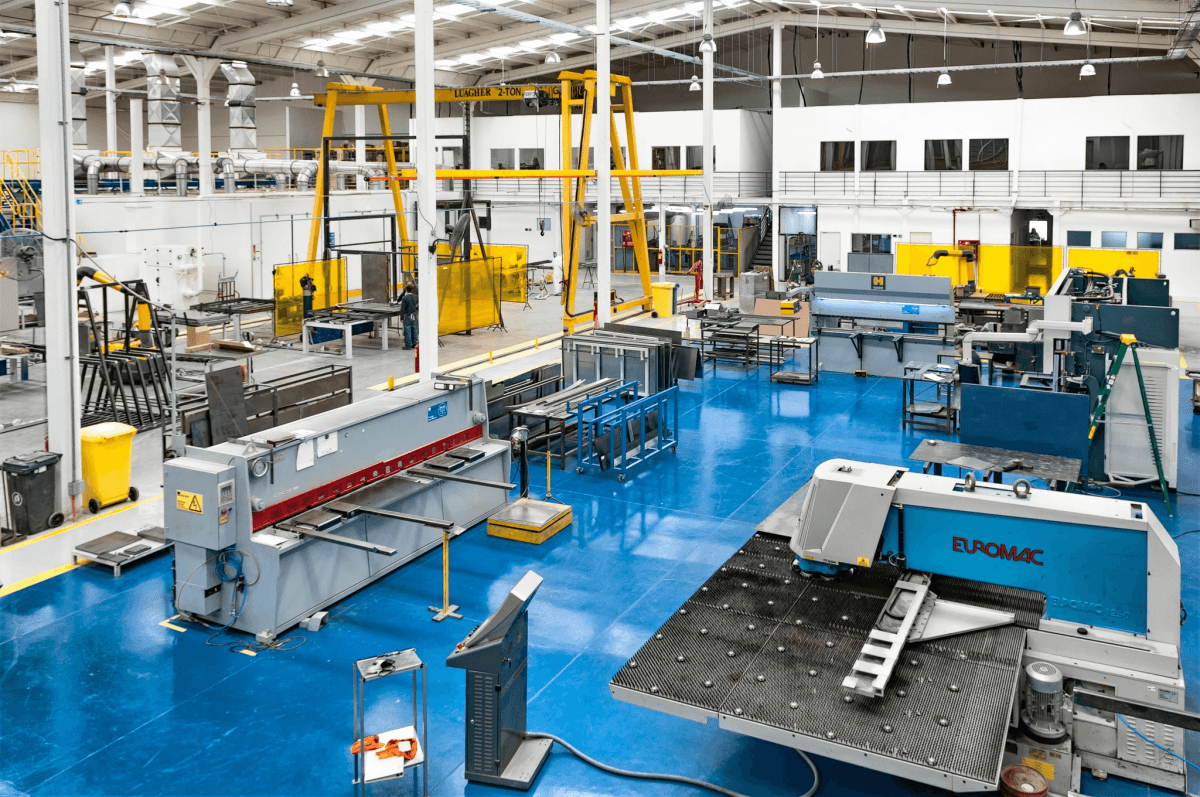

Overview of Spark Fittings' Capabilities

Spark Fittings boasts an impressive range of capabilities tailored specifically for Aluminum Bronze Castings. They employ advanced casting techniques to ensure precision and consistency in their products, addressing the unique requirements of various sectors. Their state-of-the-art facilities are equipped to handle large-scale production while maintaining stringent quality control measures, ensuring that every component meets industry standards.

Their Role in High Voltage Applications

When it comes to high voltage applications, Spark Fittings plays a pivotal role by providing specialized Aluminum Bronze components designed for safety and efficiency. The properties of aluminum bronze make it an ideal choice for electrical applications due to its excellent conductivity and resistance to corrosion. Understanding what temperature aluminum bronze is poured at is crucial; typically, it’s around 1,100°C (2,012°F), which ensures optimal performance under demanding conditions.

Custom Solutions for Aluminum Bronze Components

Spark Fittings excels in offering custom solutions tailored to specific client needs within the realm of Aluminum Bronze Castings. Whether it's designing unique fittings or creating specialized components for niche applications, their team collaborates closely with clients throughout the process. By understanding what temperature does bronze cast at Celsius—usually between 900°C (1,652°F) and 1,200°C (2,192°F)—they can fine-tune their processes to deliver top-notch products that exceed expectations.

Case Studies: Successful Aluminum Bronze Projects

Aluminum bronze castings have proven their worth in various demanding applications, showcasing their strength and versatility. This section delves into specific case studies that highlight the effectiveness of aluminum bronze components in high voltage environments, GIS systems, and innovative solutions tailored to unique challenges. Through these examples, we will see how temperature considerations play a crucial role in optimizing performance.

High Voltage Transformer Components

High voltage transformers are critical for efficient power transmission, and aluminum bronze castings have emerged as a preferred material due to their excellent conductivity and resistance to corrosion. These components are typically poured at temperatures around 1,200°C to 1,300°C (2,192°F to 2,372°F), which is essential for ensuring the integrity of the casting process. The question often arises: What temperature does aluminum-bronze melt? Generally, it melts at approximately 1,050°C (1,922°F), making it suitable for high-stress applications where reliability is paramount.

The use of aluminum bronze in transformer components has led to improved performance metrics and longer operational lifespans. By maintaining optimal temperatures during casting—specifically ensuring that the alloy is poured at the right temperature—manufacturers can achieve superior mechanical properties and enhanced electrical conductivity. This careful attention to detail not only boosts efficiency but also reduces maintenance costs over time.

GIS and Termination Applications

Gas Insulated Switchgear (GIS) systems rely heavily on robust materials that can withstand harsh environmental conditions while maintaining electrical integrity. Aluminum bronze castings are ideal for termination applications due to their high resistance to wear and tear as well as their ability to operate effectively under extreme temperatures. When considering what temperature is aluminum bronze poured at for these applications, it's crucial to note that precise control during casting ensures optimal results.

In GIS installations, components made from aluminum bronze exhibit remarkable durability against electrical arcing and thermal stress. The casting process must be closely monitored; if the pouring temperature deviates from the recommended range—typically between 1,200°C and 1,300°C—it could compromise component integrity. Thus understanding what temperature does bronze cast at Celsius becomes vital for manufacturers aiming for excellence in this sector.

Innovative Solutions with Aluminum Bronze

Innovation thrives on materials that can adapt and perform under challenging conditions—and aluminum bronze certainly fits this bill! Companies have developed custom solutions utilizing aluminum bronze castings in a variety of industries ranging from marine applications to aerospace engineering. The versatility of this alloy allows engineers to design components that withstand both physical stresses and corrosive environments while being mindful of what is the temperature for casting aluminum during production.

One fascinating example involves creating specialized marine fittings designed specifically for underwater use where saltwater corrosion poses significant risks. By pouring these fittings at an ideal temperature range—ensuring they are neither too hot nor too cold—manufacturers maximize durability without sacrificing performance or structural integrity over time. Moreover, understanding what temperature does aluminum-bronze melt aids engineers in crafting innovative designs with confidence.

Conclusion

In the ever-evolving landscape of manufacturing, Aluminum Bronze Castings stand out for their durability and versatility. As industries strive for innovation and efficiency, the demand for high-quality aluminum bronze components is likely to grow. With advancements in casting techniques and temperature management, the future of aluminum bronze manufacturing looks bright.

The Future of Aluminum Bronze Manufacturing

The future of Aluminum Bronze Castings is promising, driven by technological advancements in casting processes and materials science. Manufacturers are increasingly focused on optimizing what temperature aluminum bronze is poured at to enhance product quality and performance characteristics. Innovations in temperature control during the melting process will play a crucial role in determining what temperature does aluminum-bronze melt, ensuring consistent results across various applications.

Why Choose Aluminum Bronze for Custom Parts

Choosing Aluminum Bronze Castings for custom parts offers numerous advantages that make it a go-to material in many industries. Its excellent corrosion resistance and mechanical properties make it ideal for applications requiring durability under extreme conditions. Additionally, understanding what is the temperature for casting aluminum can help manufacturers achieve optimal results when working with this versatile alloy.

Partnering with Experts Like Spark Fittings

When it comes to sourcing high-quality Aluminum Bronze Castings, partnering with industry leaders like Spark Fittings can make all the difference. Their expertise ensures that every aspect of production adheres to stringent quality standards while optimizing processes such as determining what temperature does bronze cast at Celsius during fabrication. With custom solutions tailored to specific needs, Spark Fittings stands out as a reliable partner in delivering top-notch aluminum bronze components.