Introduction

In the world of fasteners, PTFE washers stand out as a versatile and reliable choice for various applications. But what is a PTFE washer? Essentially, it is a type of washer made from polytetrafluoroethylene (PTFE), known for its exceptional chemical resistance and low friction properties. Understanding these characteristics is crucial when selecting materials for your projects, as the right choice can significantly impact performance and longevity.

Understanding PTFE Washers

PTFE washers are not just any ordinary washers; they offer unique benefits that set them apart from traditional options. These washers are particularly valued in environments where chemical exposure or extreme temperatures may compromise other materials. Their ability to withstand harsh conditions makes them an ideal alternative to spring washers, especially in applications requiring durability and stability.

Importance of Material Selection

The material you choose for your project can make all the difference between success and failure, especially when considering options like PTFE or nylon washers. Each material has its own set of advantages; for instance, while nylon washers might be lighter, PTFE offers superior temperature resistance and chemical compatibility. Additionally, understanding factors such as thickness—because yes, PTFE comes in various thicknesses—is essential to ensure you make the right selection that meets your specific needs.

Applications in Various Projects

From industrial machinery to automotive parts and even household DIY projects, the applications of PTFE washers are virtually limitless. Their robust nature allows them to perform well in demanding environments where other types might falter—like those pesky spring washers that sometimes just don’t cut it under pressure! Whether you're looking at load-bearing capacities or simply wondering how thick a PTFE washer should be for your job, knowing their versatility can help you make informed choices across multiple sectors.

What Are PTFE Washers?

PTFE washers are specialized components made from polytetrafluoroethylene (PTFE), a high-performance plastic known for its remarkable chemical resistance and low friction properties. They serve as essential elements in various mechanical and industrial applications, providing reliable sealing and insulation. But what is a PTFE washer? It's essentially a flat disc that can be used to distribute load, prevent leakage, or reduce wear between two surfaces.

Definition and Characteristics

At their core, PTFE washers are designed to withstand extreme temperatures and harsh chemicals, making them ideal for many demanding environments. Their unique molecular structure grants them excellent non-stick properties, which means they don't adhere to other materials easily—this is particularly useful when you need to remove or replace components without hassle. Additionally, the thickness of a PTFE washer can vary; common thicknesses range from 0.5 mm to several millimeters depending on the application requirements.

Benefits of Using PTFE Washers

One of the standout benefits of using PTFE washers is their superior chemical resistance; they can handle aggressive substances that would degrade other materials like nylon washers or traditional metal options. This characteristic makes them perfect for applications where exposure to solvents or corrosive liquids is inevitable. Moreover, PTFE washers excel in temperature tolerance—able to perform effectively in both high-heat scenarios and freezing conditions—making them versatile across numerous industries.

Additionally, many users wonder: what can I use instead of a spring washer? While spring washers provide tension and flexibility, PTFE washers offer unmatched stability without the risk of deformation under stress. This makes them an excellent alternative when consistent load distribution is necessary.

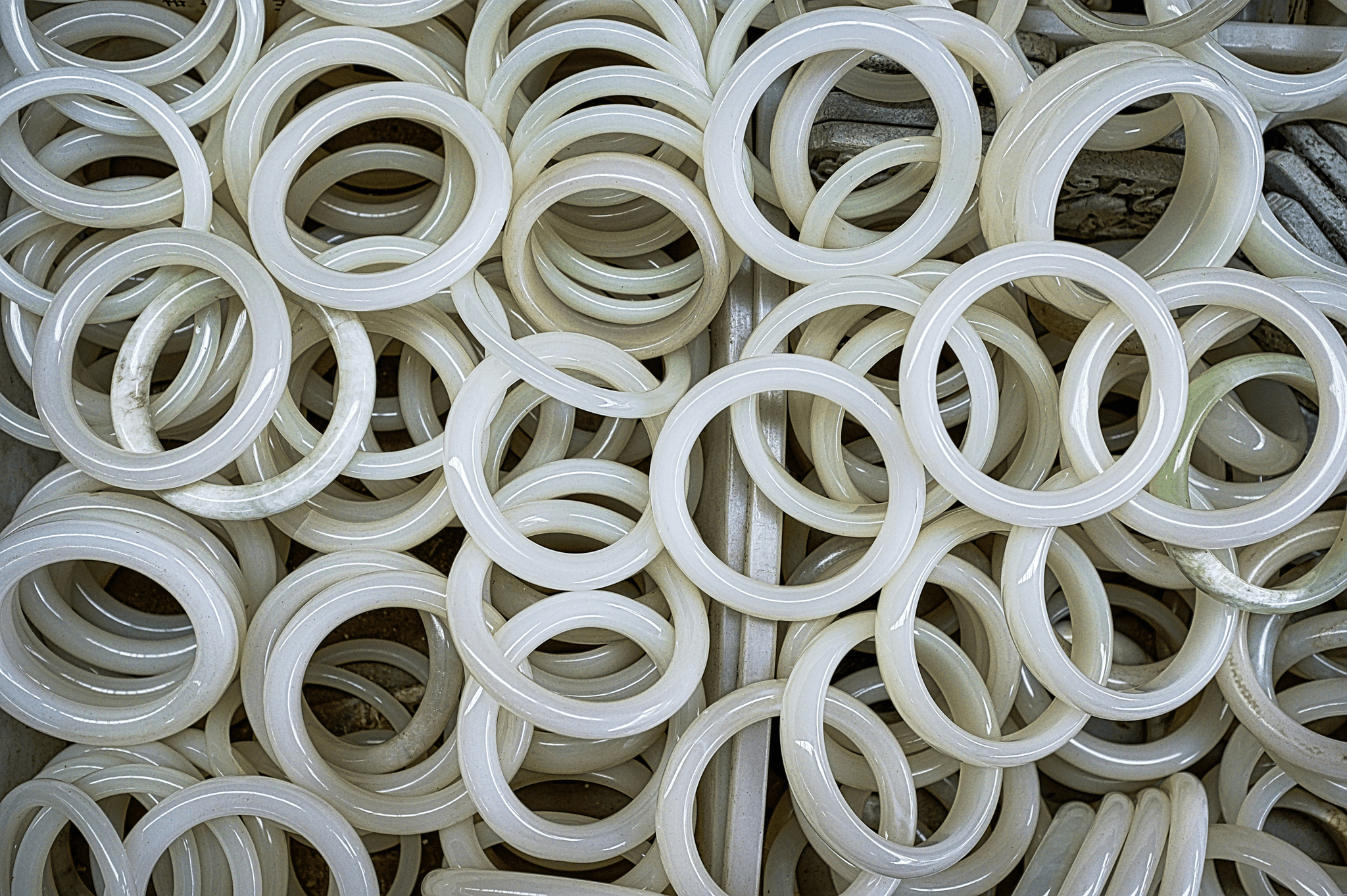

Common Types Available

Standard flat PTFE washers are most common but specialized versions like reinforced or filled variants exist for enhanced performance under specific conditions. Curious about how thick these come? The thicknesses do vary widely—typically ranging from 0.5 mm up to several millimeters—allowing users to select based on their particular needs.

As you explore your options further, you might ask: what's the difference between a spring washer and a normal washer compared with PTFE? While normal washers provide basic support against surface damage or loosening fasteners, spring washers add tension but may not suit all environments where chemical exposure occurs; that's where our trusty friend—the PTFE washer—shines bright!

Key Factors in Choosing PTFE Washers

When it comes to selecting the right PTFE washers for your project, there are several key factors to consider. Understanding these factors can help ensure that you choose the most suitable type of washer for your specific needs. Let's dive into temperature resistance, chemical compatibility, and load-bearing capacity—all crucial elements in the decision-making process.

Temperature Resistance Considerations

Temperature resistance is a vital factor when deciding on PTFE washers, especially if they will be exposed to extreme conditions. PTFE washers are known for their impressive thermal stability, able to withstand temperatures ranging from -200°C to +260°C. This makes them an excellent choice in applications where heat is a concern; however, it's essential to assess the specific temperature range of your project before making a final decision.

Moreover, if you're wondering What thicknesses does PTFE come in? keep in mind that thicker washers may offer better insulation against heat but could also affect flexibility and fit. Always consider how the washer's thickness relates to its ability to perform under varying temperatures. So when choosing PTFE washers, don't overlook temperature considerations—they can make or break your project's success!

Chemical Compatibility Overview

Chemical compatibility is another critical aspect when selecting PTFE washers for various applications. These washers are renowned for their resistance to a wide range of chemicals, making them ideal for industries like pharmaceuticals and food processing where contamination risks are high. However, not all chemicals interact with materials in the same way; therefore, it's essential to evaluate whether the specific substances involved will affect the integrity of your chosen PTFE washer.

If you're ever caught asking yourself What can I use instead of a spring washer? remember that while spring washers serve different purposes (like providing tension), PTFE washers excel in environments where chemical exposure is prevalent without compromising performance. By understanding chemical compatibility and selecting appropriate materials accordingly, you can avoid costly mistakes down the line.

Load Bearing Capacity and Thickness

Load-bearing capacity is crucial when determining which type of washer will best suit your needs—especially with heavy-duty applications where durability matters most! The thickness of a PTFE washer plays a significant role here; thicker options generally provide higher load-bearing capabilities than their thinner counterparts. If you've been pondering How thick is a PTFE washer? it's important to note that they typically come in various thicknesses depending on application requirements.

While some might wonder Which is better: PTFE or nylon washers?, keep this factor in mind: nylon offers good strength but may not withstand harsh chemicals as effectively as PTFE does. Therefore, evaluating both load-bearing capacity and material properties ensures you select the right option tailored specifically for your project's demands!

Applications of PTFE Washers

PTFE washers are incredibly versatile components that find their way into a plethora of applications across various industries. Their unique properties, such as chemical resistance and temperature stability, make them indispensable in many projects. Understanding where PTFE washers can be applied is essential for anyone looking to enhance the efficiency and durability of their operations.

Industrial Uses and Projects

In industrial settings, PTFE washers are often employed in high-performance environments where traditional materials might fail. These washers excel in applications involving corrosive chemicals or extreme temperatures, making them ideal for manufacturing plants and chemical processing facilities. When you ask, What is a PTFE washer? you'll discover they provide reliable sealing solutions that prevent leaks and ensure operational safety.

Additionally, industries often face the question: What can I use instead of a spring washer? In many cases, PTFE washers serve as a superior alternative due to their non-compressible nature and resistance to wear over time. This makes them suitable for heavy machinery where load-bearing capacity is crucial; after all, how thick is a PTFE washer? They come in various thicknesses to meet specific needs while maintaining structural integrity under pressure.

Automotive and Aerospace Applications

The automotive and aerospace sectors heavily rely on PTFE washers due to their lightweight yet robust characteristics. These industries demand components that can withstand harsh conditions without compromising safety or performance. So when pondering which is better—PTFE or nylon washers—the answer often leans towards PTFE because it offers superior thermal stability, reducing the risk of failure during critical operations.

In aerospace applications specifically, the requirements for precision are paramount; thus, understanding what thicknesses PTFE comes in becomes vital for engineers designing aircraft systems. From fuel lines to hydraulic systems, these washers play an integral role in ensuring everything runs smoothly under pressure. Moreover, when comparing a spring washer versus a normal washer within these contexts, it's evident that the unique properties of PTFE make it an ideal choice for high-stakes environments.

Household and DIY Projects

Even outside industrial settings, PTFE washers have carved out a niche in household repairs and DIY projects. Homeowners often utilize these versatile components when dealing with plumbing issues or appliance repairs where water exposure could lead to corrosion over time. The question What is the difference between a spring washer and a normal washer? becomes relevant here; while spring washers offer tensioning capabilities, PTFE provides unmatched sealing performance without rusting or degrading.

DIY enthusiasts also appreciate how easy it is to source different thicknesses of PTFE—after all, knowing what thicknesses does PTFE come in allows you to choose precisely what you need for your project at hand! Whether you're fixing leaky faucets or assembling outdoor furniture that will face the elements year-round, using quality PTFE washers ensures durability without compromise on style or functionality.

How to Source Quality PTFE Washers

When sourcing quality PTFE washers, it's crucial to consider the reputation of the manufacturers you choose. Not all PTFE washers are created equal, and selecting a reliable supplier can make all the difference in your projects. You want to ensure that the PTFE washers you purchase meet industry standards and are suitable for your specific applications.

Reputable Manufacturers to Consider

Several reputable manufacturers specialize in producing high-quality PTFE washers. Companies like Parker Hannifin and Saint-Gobain have established themselves as leaders in this field, providing durable products that stand up to rigorous use. When asking yourself, What is a PTFE washer? remember that these brands offer extensive catalogs featuring various thicknesses and types designed for different environments.

It’s also wise to check for customer reviews and testimonials when evaluating potential suppliers of PTFE washers. A manufacturer with a solid track record will often have satisfied clients who can vouch for their products' performance under stress. Additionally, consider local suppliers who may provide faster shipping times and personalized service tailored to your needs.

Importance of Certifications and Testing

Certifications play a vital role in ensuring that the PTFE washers you purchase meet safety and quality standards. Look for products that have been tested by recognized organizations; this ensures they can withstand temperature extremes, chemical exposure, and mechanical stress without failure. The question Which is better: PTFE or nylon washers? often comes down to these certifications since they indicate reliability in demanding applications.

Testing is another critical aspect; reputable manufacturers will conduct thorough testing on their products before releasing them into the market. This includes assessments of load-bearing capacity, thickness variations (which brings us back to “How thick is a PTFE washer?”), and performance under various conditions. By prioritizing certified products from tested sources, you can avoid costly mistakes down the line.

Exploring Spark Fittings' PTFE Products

One notable option when searching for quality PTFE washers is Spark Fittings' product line. Known for their innovative designs, Spark Fittings offers an impressive range of thicknesses—perfect if you're wondering about What thicknesses does PTFE come in? Their commitment to quality ensures that every washer meets stringent industry standards while also being customizable according to specific project needs.

If you're still pondering alternatives like spring washers (and asking yourself What can I use instead of a spring washer?), it's worth exploring how Spark Fittings’ offerings stack up against traditional options in terms of durability and versatility. They provide detailed specifications on each product's capabilities so you can make informed decisions based on your project requirements—whether industrial or DIY-related!

By focusing on reputable sources like Spark Fittings for your next set of PTFE washers, you'll not only enhance your project's reliability but also gain peace of mind knowing you've made an informed choice.

Customization Options for PTFE Washers

CNC Machining Capabilities Explained

CNC (Computer Numerical Control) machining has revolutionized the production of PTFE washers by allowing for precise and intricate designs that were once difficult to achieve. This technology enables manufacturers to create custom shapes, sizes, and thicknesses of PTFE washers that cater specifically to your needs. So if you're wondering, What thicknesses does PTFE come in? the answer is quite flexible; CNC machining can produce washers in a variety of thicknesses tailored to your specifications.

Moreover, CNC machining ensures consistency and accuracy across large production runs, making it an ideal choice for industrial applications where uniformity is crucial. Unlike traditional methods that may introduce variability, CNC machining guarantees that each washer meets exacting standards—perfect if you’re considering alternatives like spring washers or need a specific fit. Whether you require a simple design or a complex configuration, CNC technology makes it possible with ease.

Reinforcements and Fillers Overview

To further enhance the performance of PTFE washers, manufacturers often incorporate reinforcements and fillers into the material mix. These additives can improve properties such as strength, wear resistance, and thermal stability—making them suitable for demanding environments where standard PTFE might fall short. If you’re comparing options like “Which is better: PTFE or nylon washers?” consider how fillers can elevate the capabilities of PTFE beyond what nylon offers.

Common fillers include glass fibers and carbon compounds which not only increase tensile strength but also help in reducing friction during operation. This means that when you choose customized PTFE washers with reinforcements, you're investing in components designed for longevity and reliability under stress—critical factors in both industrial settings and everyday DIY projects alike. The versatility offered by these enhancements makes them appealing across various sectors.

Tailoring Washers for Specific Needs

Customization goes beyond just size; it encompasses tailoring the entire design of your PTFE washer based on specific application requirements. For instance, if you're working on an automotive project requiring high-temperature resistance or chemical compatibility—key features of what makes a good washer—you can specify those needs upfront during manufacturing discussions. This ensures that your custom washer performs optimally under its intended conditions.

Additionally, understanding how thick a PTFE washer should be based on load-bearing capacity is essential when customizing these components. Each project might demand different specifications depending on factors like pressure exerted or environmental conditions faced during use—a crucial consideration when pondering alternatives like spring washers versus standard ones! Ultimately, having the ability to customize allows users to achieve exactly what they need without compromise.

Conclusion

In summary, choosing the right PTFE washers for your project can significantly impact its success and durability. Whether you’re pondering “What is a PTFE washer?” or weighing options between different materials, understanding their unique properties and applications will guide you in making an informed decision. With a variety of thicknesses available, including those that answer the question “How thick is a PTFE washer?”, you can tailor your selection to meet specific project demands.

Making the Right Choice for Your Project

When selecting PTFE washers, consider factors such as temperature resistance and chemical compatibility to ensure optimal performance in your application. If you're contemplating alternatives, you might ask yourself, “What can I use instead of a spring washer?” While spring washers provide elasticity, PTFE washers offer superior chemical resistance and thermal stability. Understanding the difference between a spring washer and a normal washer can also clarify why PTFE might be the better choice for certain environments.

The Future of PTFE Washers in Innovation

The landscape of material science is ever-evolving, with ongoing research into enhancing the properties of PTFE washers for even greater performance. Innovations in manufacturing techniques are leading to more efficient production processes and custom options tailored to individual needs—further broadening their applications across industries like automotive and aerospace. As we explore “Which is better: PTFE or nylon washers?”, it’s clear that each material has its niche; however, advancements in PTFE technology could solidify its place as a preferred choice in many future projects.

Essential Tips for Successful Usage

To maximize the effectiveness of your chosen PTFE washers, ensure they are sourced from reputable manufacturers who adhere to industry standards and testing protocols. Familiarize yourself with common thicknesses available—after all, knowing “What thicknesses does PTFE come in?” will help you select the right fit for your needs. Finally, always keep an eye on installation practices; proper placement can prevent issues down the line and enhance longevity.