Introduction

In the realm of electrical engineering, understanding electrical insulator materials is not just a technical necessity; it's essential for ensuring safety and efficiency in electric power distribution. These materials serve as barriers that prevent the unwanted flow of electricity, protecting both infrastructure and individuals from potential hazards. Whether it's in high voltage transformers or everyday wiring systems, the choice of electrical insulation material can make all the difference in performance and reliability.

Understanding Electrical Insulator Materials

Electrical insulator materials are designed to resist the flow of electric current, which makes them vital for various applications within electrical power systems. The best electrical insulator materials are characterized by their ability to withstand high voltages without breaking down, thereby maintaining system integrity. From glass to ceramics and polymers, each type of insulator material offers unique properties that cater to different operational requirements.

Importance in Electric Power Distribution

The significance of these materials becomes particularly apparent in electric power distribution networks where they play a crucial role in maintaining system stability and safety. High voltage transformers rely heavily on effective electrical insulation material to function correctly while minimizing energy loss and preventing short circuits. Inadequate insulation can lead to catastrophic failures, making the selection of appropriate insulator materials critical for reliable electric power delivery.

Overview of Insulator Material Types

Glass insulators are known for their durability and resistance to environmental factors; ceramic options offer excellent dielectric properties; while polymer insulators provide flexibility and lightweight solutions ideal for modern applications. Understanding these options helps engineers select the best electrical insulator materials tailored to their needs.

Common Types of Electrical Insulator Materials

Understanding the different types available can help in selecting the best electrical insulator materials for various applications, particularly in high voltage transformers and electrical power systems. This section explores three common types: glass, ceramic, and polymer insulators.

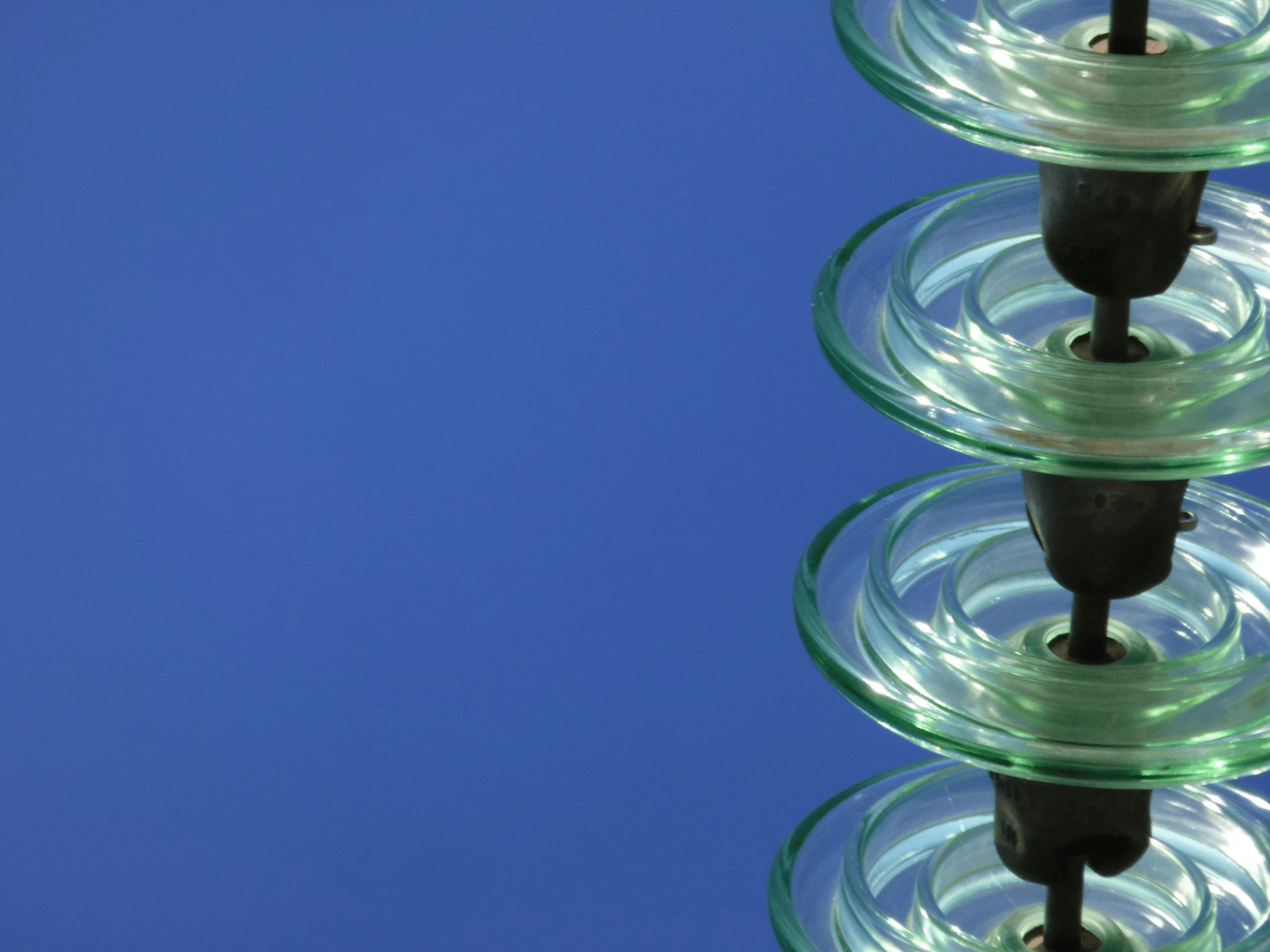

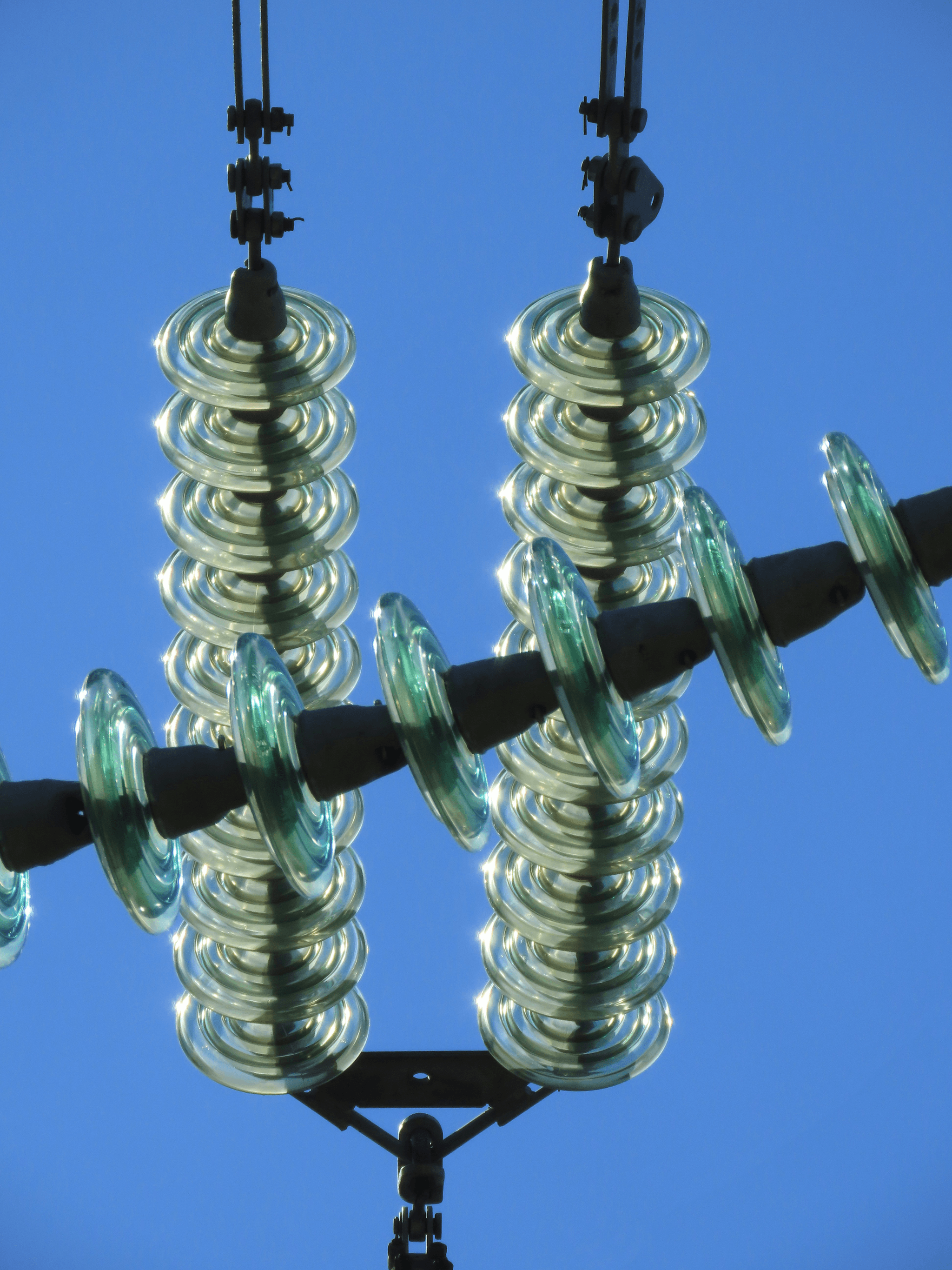

Glass Insulators

Glass insulators have been a staple in electrical infrastructure for decades, known for their excellent dielectric properties. These best electrical insulator materials are highly resistant to environmental factors such as UV radiation and moisture, making them ideal for outdoor applications in electric power distribution networks. Their transparency also allows for easy visual inspection, which is a significant advantage when maintaining high voltage transformers.

Despite their many benefits, glass insulators can be heavier than other options, which may pose challenges during installation or maintenance. However, their durability often outweighs these concerns; they can withstand extreme weather conditions while providing reliable insulation performance over time. As a result, they remain a popular choice among utilities striving for long-lasting solutions in their electrical insulation material inventory.

Ceramic Insulators

Ceramic insulators are another widely used type of electrical insulation material known for their robustness and thermal stability. Made from clay-based materials that are fired at high temperatures, these insulators excel in mechanical strength and can handle substantial loads without cracking or breaking under pressure—making them perfect candidates for high voltage transformer applications. Additionally, ceramic's natural resistance to corrosion ensures that these insulator materials maintain performance even in harsh environments.

One downside to ceramic insulators is their susceptibility to breakage if dropped or subjected to sudden impact; however, this risk is often mitigated through careful handling during installation. Furthermore, modern advancements have led to improved designs that enhance their overall durability while reducing weight—making them more user-friendly without compromising functionality. Overall, ceramic insulators continue to play a vital role in ensuring efficient electric power distribution systems across various sectors.

Polymer Insulators

Polymer insulators represent the latest innovation among electrical insulation materials and have gained popularity due to their lightweight nature and flexibility. Made from composite materials like silicone rubber or ethylene propylene diene monomer (EPDM), these modern alternatives offer exceptional resistance against pollution and moisture ingress—two common culprits that compromise traditional insulator performance over time in electric power distribution networks. Their lightweight characteristics make them easier to transport and install compared to heavier glass or ceramic options.

Moreover, polymer insulators boast impressive dielectric properties along with superior thermal stability—a combination that makes them suitable even for demanding applications such as electrified railways or renewable energy projects like wind farms and solar installations. As technology advances further into smart grids and interconnected systems requiring real-time monitoring capabilities within high voltage transformers' infrastructure, polymer-based solutions are likely to lead the charge toward more sustainable practices within the industry. With ongoing innovations enhancing both performance metrics and longevity prospects of these best electrical insulator materials—it's no wonder they're becoming increasingly prevalent across global markets.

Performance Characteristics

Dielectric Strength and Breakdown Voltage

Dielectric strength refers to the ability of an electrical insulator to withstand electric fields without breaking down, which is essential for high voltage transformers. The higher the dielectric strength, the more effective the insulator material will be in preventing electrical breakdown, ensuring safety in electric power distribution systems. For optimal performance in electrical insulation material, engineers often look for materials that boast high breakdown voltages to minimize risks associated with short circuits or equipment failure.

Thermal Stability and Weather Resistance

Thermal stability is a critical factor when evaluating the best electrical insulator materials because they often operate under varying temperature conditions. Insulators must resist degradation from heat while also being resilient against environmental factors like moisture or UV exposure—key components of weather resistance. This combination ensures that insulator materials can maintain their integrity over time, particularly in demanding applications such as electrified railways or outdoor installations.

Mechanical Strength and Durability

Mechanical strength plays a vital role in determining how well electrical insulators can handle physical stresses such as wind loads or impacts from falling debris. Durable insulator materials are designed to withstand these challenges without compromising their insulating properties, which is essential for long-term reliability in electric power distribution systems. Ultimately, selecting robust electrical insulation material contributes significantly to reducing maintenance costs and enhancing system longevity in high voltage transformer applications.

Applications in Electrical Infrastructure

Electrical insulators play a crucial role in various applications within electrical infrastructure, ensuring the safe and efficient distribution of electric power. From high voltage transformers to electrified railways, the choice of the best electrical insulator materials can significantly impact performance and reliability. Understanding these applications helps highlight the importance of selecting appropriate electrical insulation materials.

Use in High Voltage Transformers

High voltage transformers are essential for stepping up or down voltage levels in electric power distribution systems. The use of robust electrical insulators within these transformers is critical, as they must withstand significant electrical stress while maintaining dielectric strength. Insulator materials like ceramic and polymer composites are often favored for their ability to handle high voltages without compromising safety or efficiency.

In addition to their electrical properties, the best electrical insulator materials used in high voltage transformers must also exhibit thermal stability and weather resistance. This is particularly important since transformers often operate under varying environmental conditions that could impact their performance over time. By incorporating advanced insulator materials, manufacturers can enhance transformer longevity and reduce maintenance costs.

Moreover, innovations in design have led to smarter high voltage transformers equipped with monitoring capabilities that can detect potential failures before they occur. These advancements not only improve operational efficiency but also ensure that the chosen electrical insulation material plays a vital role in safeguarding against unexpected breakdowns.

Role in Electrical Power Distribution

The role of electrical insulators in power distribution systems cannot be overstated; they provide critical support for overhead lines and substations while preventing short circuits and ensuring safety. High-quality insulator materials help maintain system integrity by effectively isolating conductors from each other and from grounded structures. This isolation is essential for minimizing energy losses during electric power transmission.

In modern electric power distribution networks, choosing the best electrical insulator materials can lead to improved reliability and reduced downtime due to faults or failures. For instance, glass insulators are known for their excellent durability under adverse weather conditions, making them suitable for long-term outdoor applications where exposure to elements is inevitable. Similarly, polymer-based insulators offer lightweight solutions that facilitate easier installation without sacrificing performance.

Furthermore, as renewable energy sources become more integrated into existing grids, there’s an increasing need for adaptable insulation solutions capable of handling fluctuating loads efficiently. By investing in advanced electrical insulation material technologies tailored for modern challenges, utilities can enhance overall system performance while ensuring safety across diverse applications.

Insulator Materials for Electrified Railways

Electrified railways rely on effective insulating technology to ensure safe operation while maximizing efficiency during transit operations. The application of specialized insulator materials allows trains to draw electricity from overhead lines without risking contact with conductive elements that could lead to accidents or service interruptions. Thus, selecting appropriate electrical insulation material becomes paramount when designing railway infrastructure.

Among various options available today, composite polymer insulators have gained popularity due to their lightweight properties combined with exceptional mechanical strength—ideal characteristics needed along railway lines where weight savings translate directly into improved train speeds and reduced energy consumption per journey taken by passengers or freight alike! Furthermore, these innovative designs often come with enhanced weather resistance features suitable for diverse climates encountered across different regions worldwide.

As electrified rail systems continue evolving towards greater sustainability goals through electrification efforts aimed at reducing carbon emissions associated with traditional diesel-powered alternatives; investing in cutting-edge technologies around best electrical insulator materials will remain key drivers behind achieving such ambitions efficiently while maintaining safety standards throughout operations!

Innovations in Insulator Technologies

The world of electrical insulation is rapidly evolving, driven by the need for enhanced performance and reliability in electric power distribution systems. Innovations in insulator technologies are not only improving efficiency but also ensuring that electrical transformers and other components can withstand the rigors of modern demands. This section explores some of the most exciting advancements in insulator materials that are shaping the future of electrical power.

Advances in Composite Insulator Materials

Composite insulator materials have emerged as a game-changer in the realm of electrical insulation, offering a unique blend of properties that enhance performance. These materials combine the best features of traditional insulators while addressing their limitations, making them ideal for high voltage transformers and other critical applications. With superior dielectric strength, lightweight characteristics, and resistance to environmental degradation, composite insulators are quickly becoming a preferred choice for electric power distribution networks.

Moreover, these advanced materials can be tailored to meet specific operational requirements, enabling engineers to design systems that maximize efficiency while minimizing maintenance costs. The flexibility offered by composite insulators allows for innovative designs that can withstand extreme weather conditions and mechanical stress without compromising safety or reliability. As industries continue to seek out the best electrical insulator materials available, composite options are leading the charge toward more resilient electrical infrastructure.

Enhanced Coatings for Increased Longevity

In addition to advances in material composition, enhanced coatings have significantly contributed to extending the lifespan of electrical insulation material used today. These protective layers serve as barriers against moisture, pollution, and UV radiation—common threats that can lead to premature failure in traditional insulators. By applying specialized coatings designed for durability and resistance to environmental factors, manufacturers ensure that their products remain effective over time.

These innovations not only improve longevity but also reduce maintenance requirements associated with conventional insulation systems. With lower upkeep needs, utilities can focus on optimizing their electric power distribution without worrying about frequent replacements or repairs caused by degraded insulators. Thus, investing in high-quality coatings is crucial when selecting the best electrical insulator materials for any application involving electrical transformers or similar equipment.

Smart Insulators with Monitoring Capabilities

The rise of smart technology has reached even the world of electrical insulation through smart insulators equipped with monitoring capabilities. These cutting-edge devices integrate sensors into traditional or composite insulating structures to provide real-time data on performance metrics such as temperature fluctuations and potential faults within an electric power distribution system. This proactive approach enables operators to identify issues before they escalate into costly failures or outages.

Smart insulators represent a significant leap forward from passive solutions by allowing continuous assessment of their condition throughout their lifecycle. This data-driven insight empowers utility companies to make informed decisions regarding maintenance schedules and resource allocation—ultimately enhancing system reliability while optimizing operational costs associated with managing high voltage transformers and related equipment. As we embrace this technological evolution within our infrastructures, smart insulating solutions will undoubtedly play an essential role in achieving greater efficiency across all domains involving electrical power.

Leading Manufacturers and Suppliers

In the realm of electrical insulator materials, a handful of manufacturers stand out for their quality and innovation. The choices made by utility companies and infrastructure developers can significantly influence the performance of electric power distribution systems. Selecting the best electrical insulator materials is crucial for ensuring reliability in high voltage transformers and other electrical applications.

Spark Fittings and Its Offerings

Spark Fittings has established itself as a key player in providing top-tier electrical insulation material solutions. They offer a diverse range of products, including glass, ceramic, and polymer insulators tailored for various applications in electric power distribution. Their commitment to quality ensures that customers receive the best electrical insulator materials that not only meet but exceed industry standards.

With an emphasis on durability and performance, Spark Fittings continuously innovates its product line to include advanced features such as enhanced weather resistance and thermal stability. This makes their offerings particularly appealing for use in challenging environments, including those faced by electrical transformers operating under extreme conditions. Customers often find that investing in Spark Fittings' products translates into long-term savings due to reduced maintenance needs and improved system reliability.

Other Key Players in the Industry

While Spark Fittings is a notable name, several other manufacturers contribute significantly to the landscape of electrical insulation materials. Companies like Siemens, ABB, and General Electric are recognized for their extensive portfolios that include cutting-edge insulator technologies designed for high voltage applications. These organizations focus on research and development to create innovative solutions that enhance the efficiency of electric power distribution networks globally.

Additionally, emerging players are making waves with unique offerings such as composite insulators that combine different materials for superior performance characteristics. The competition among these manufacturers drives continuous improvement across the industry, ensuring that utilities have access to some of the best electrical insulator materials available today. As a result, selecting an appropriate supplier becomes pivotal for companies looking to optimize their infrastructure investments.

Impact of Quality on Electrical Insulation Material Selection

The quality of electrical insulation material directly impacts system performance, safety, and longevity—especially when it comes to high voltage transformers used in electric power distribution systems. Choosing inferior products can lead to premature failures or costly outages; thus, it’s essential for stakeholders to prioritize quality when selecting insulator materials. High-quality options not only provide better dielectric strength but also enhance mechanical resilience against environmental stressors.

Investing in reliable electrical insulation material ensures compliance with regulatory standards while minimizing risks associated with equipment failure or accidents caused by poor insulation properties. Furthermore, well-manufactured components often come with warranties or service agreements that add value over time through assurance against defects or operational issues. Ultimately, understanding how quality influences performance helps decision-makers choose wisely among various options available on the market today.

Conclusion

In the realm of electric power distribution, selecting the best electrical insulator materials is crucial for ensuring safety and efficiency. The right electrical insulation material not only enhances system reliability but also mitigates risks associated with high voltage transformers and other critical infrastructure components. With a variety of insulator materials available, understanding their unique properties can help engineers make informed decisions tailored to specific applications.

Choosing the Right Electrical Insulator Materials

When it comes to choosing the best electrical insulator materials, several factors come into play, including dielectric strength, thermal stability, and mechanical durability. Each application demands a different set of characteristics; for instance, glass insulators are favored for their superior dielectric properties in high voltage environments, while polymer insulators offer lightweight alternatives with impressive weather resistance. By carefully evaluating these parameters against operational requirements in electric power distribution systems, one can confidently select the ideal electrical insulation material that meets both performance and safety standards.

Trends Shaping the Future of Insulation

The landscape of electrical insulation is evolving rapidly due to technological advancements and increasing demand for sustainable solutions. Innovations such as composite insulator materials are gaining traction because they combine lightweight benefits with enhanced mechanical strength—ideal for modern high voltage transformers. Furthermore, smart insulators equipped with monitoring capabilities are emerging as game-changers in maintaining system integrity by providing real-time data on performance and potential failures in electrical power systems.

Final Thoughts on Insulator Material Selection

In conclusion, choosing the right electrical insulator is not just about meeting current standards; it's about anticipating future challenges within electric power distribution networks. As trends continue to evolve towards more resilient and intelligent solutions, staying informed about new developments will be key for engineers and decision-makers alike. Ultimately, investing time in understanding various insulator materials ensures that we achieve optimal performance while safeguarding our critical infrastructure from potential disruptions.