Introduction

These unsung heroes ensure that electricity travels safely and efficiently across vast distances, preventing short circuits and maintaining system integrity. Understanding the different types of insulators, such as porcelain insulators and glass insulators, is essential for anyone interested in the world of power transmission.

Understanding Power Line Insulators

Powerline insulators are vital components that separate electrical conductors from their supporting structures, like power poles or towers. They prevent unwanted flow of current to the ground while allowing safe transmission of electricity through overhead lines. Without these essential devices, our modern electric grid would be fraught with risks and inefficiencies.

Importance of Insulator Types

The type of insulator used can significantly affect performance, durability, and safety in various conditions. Porcelain electrical insulators have been a staple in the industry for decades due to their robustness and reliability; however, newer options like composite materials are gaining traction for their resilience against harsh weather conditions. Choosing the right type of powerline insulator is not just about preference; it's about ensuring long-term operational success.

Overview of Usage and Applications

Powerline insulators find applications in various settings—from rural areas with wooden poles to urban environments featuring high-voltage transmission lines. Their usage extends beyond simply supporting wires; they also play a critical role in minimizing maintenance costs and enhancing overall system reliability. With options like glass insulators for sale becoming more prevalent, utilities are increasingly exploring innovative solutions tailored to their specific needs.

The Basics of Powerline Insulators

Powerline insulators are essential components in the electrical transmission and distribution system. They serve to support and isolate conductors from the ground or other structures, ensuring safety and efficiency in power delivery. Understanding the basics of these insulators is crucial for anyone involved in electrical engineering or utility services.

What Are Powerline Insulators

Powerline insulators are devices designed to prevent electrical current from unintentionally flowing to the ground or other conductive materials. Typically mounted on power poles, these insulators keep power line conductors suspended at a safe distance, preventing short circuits and ensuring reliable electricity supply. Various types of powerline insulators include porcelain electrical insulators, glass insulators, and composite options, each tailored for specific applications.

Key Functions and Features

The primary function of powerline insulators is to provide electrical insulation while supporting heavy conductors under various environmental conditions. They must withstand mechanical stress from wind loads, ice accumulation, and thermal expansion without breaking down electrically or physically. Key features include high dielectric strength, resistance to moisture absorption, and durability against weathering effects—crucial attributes that ensure long-lasting performance in all climates.

Common Materials Used

Common materials used in making powerline insulators include porcelain, glass, and composite substances like polymer blends. Porcelain insulator options are favored for their excellent dielectric properties and mechanical strength; however, glass insulators have gained popularity due to their transparency that allows for easier inspection of potential damage. Composite materials offer advantages like lighter weight and better performance in severe weather conditions—making them increasingly popular among utilities looking for modern solutions.

Exploring Porcelain Insulators

Porcelain insulators have long been a staple in the world of powerline insulators, owing to their remarkable durability and reliability. These robust components play a crucial role in ensuring the safe transmission of electricity over vast distances. With their unique properties, porcelain electrical insulators stand out among different types of insulators used today.

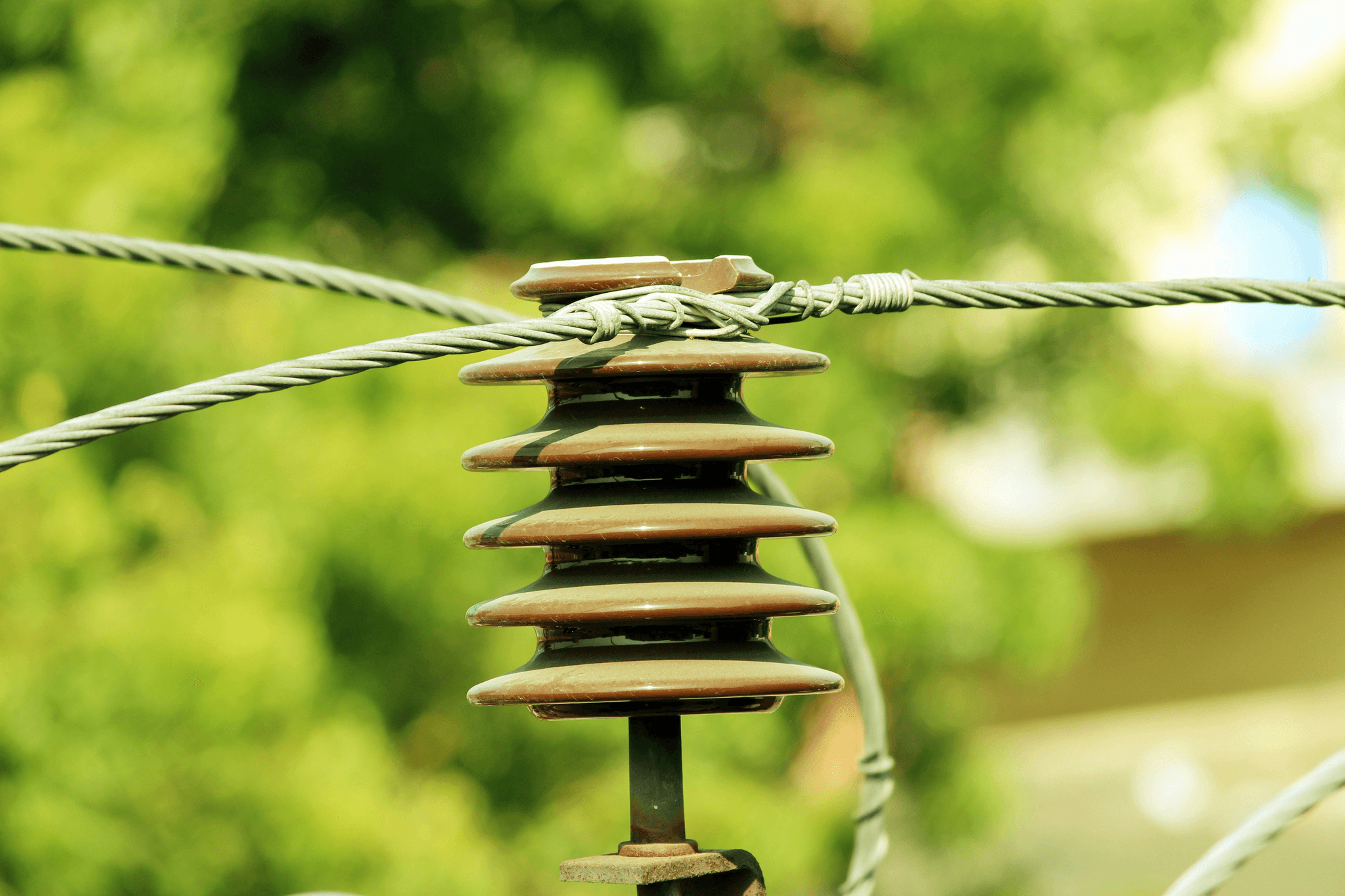

Characteristics of Porcelain Insulators

Porcelain insulators are primarily made from high-fired ceramic materials, which give them their characteristic strength and resistance to environmental factors. They are known for their smooth surface that minimizes the accumulation of dirt and moisture, enhancing their performance in various weather conditions. Additionally, porcelain electrical insulators exhibit excellent dielectric properties, making them ideal for high-voltage applications.

Advantages Over Other Types

One major advantage of porcelain insulators is their ability to withstand extreme temperatures and harsh environmental conditions without degrading or losing functionality. Unlike glass or composite alternatives, porcelain's robust structure offers superior mechanical strength and longevity, which translates into lower maintenance costs for utility companies. Furthermore, porcelain powerline insulators are less prone to breakage compared to glass insulators; thus, they provide a more reliable option for power pole installations.

Applications in Power Transmission

Porcelain insulators are widely utilized in various applications within the power transmission sector due to their proven reliability and effectiveness. They can be found on overhead power lines as well as substations where they help support conductors while preventing electrical leakage to the ground. With ongoing advancements in design and manufacturing processes, these versatile components continue to play an essential role in modern energy distribution systems.

The Case for Glass Insulators

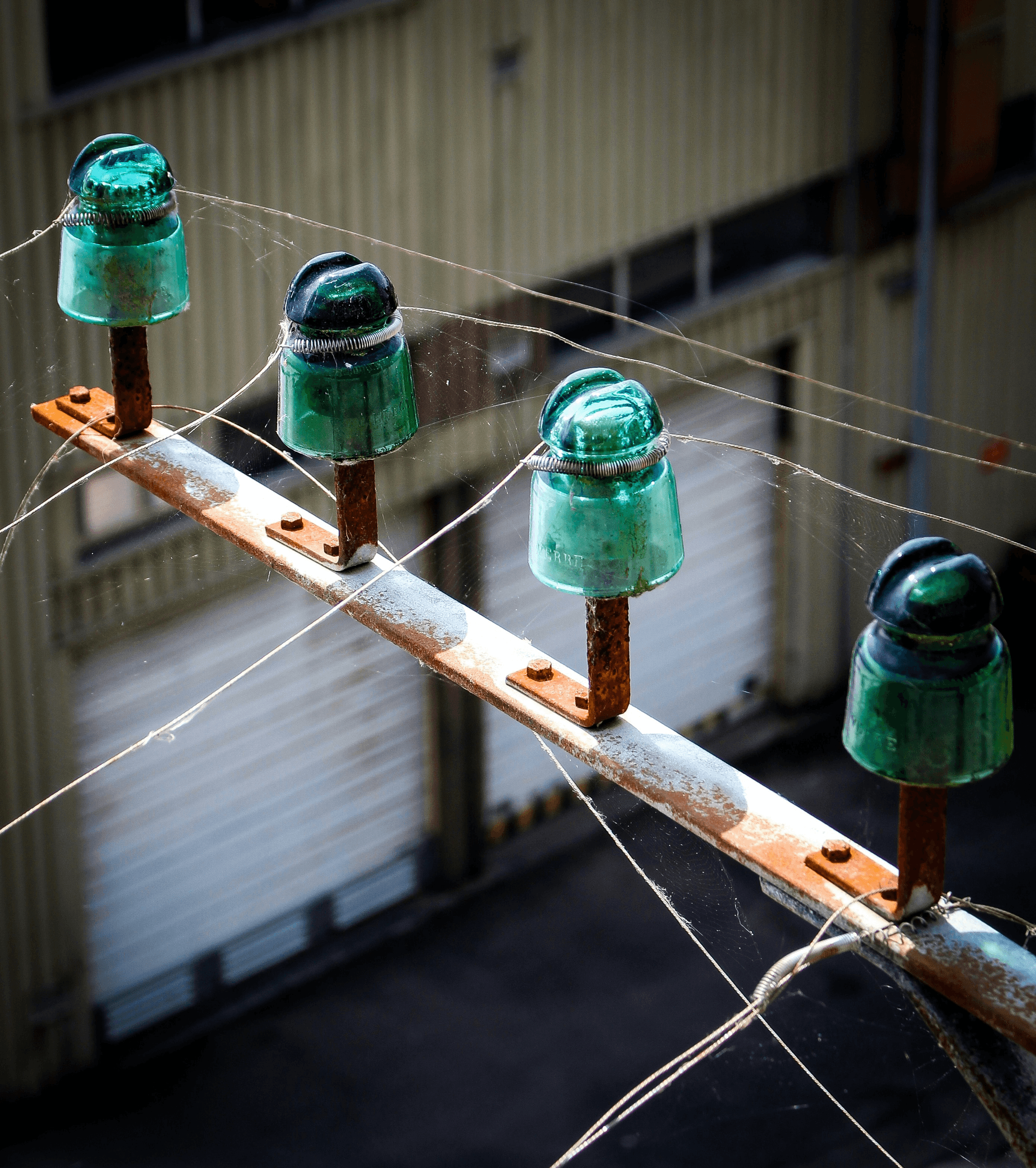

These transparent marvels have been around for over a century, proving their worth in various applications. Their durability and resistance to environmental factors make them a favored choice among utilities and power pole insulator manufacturers alike.

Benefits of Glass Insulators

Glass insulators offer a plethora of benefits that make them stand out in the realm of powerline insulators. Firstly, they boast exceptional electrical insulation properties, ensuring minimal leakage currents even under challenging conditions. Additionally, glass is inherently resistant to UV radiation and weathering, which means these insulators maintain their integrity over time without degrading like some porcelain electrical insulators.

Another significant advantage is their visibility; the transparent nature of glass allows for easy inspection for cracks or defects, which is crucial for maintenance teams monitoring power line infrastructure. Furthermore, glass insulators are less prone to breakage compared to porcelain options when subjected to mechanical stress or extreme weather conditions. This combination of strength and easy maintenance makes glass an attractive choice for many utility companies looking to optimize their power transmission systems.

Comparing Glass with Porcelain and Composite

When comparing glass insulators with porcelain and composite types, several factors come into play that can influence decision-making in the field of powerline insulation. While porcelain electrical insulators have long been recognized for their durability and mechanical strength, they can be more susceptible to moisture absorption which may lead to issues like flashover during rainy seasons. In contrast, glass does not absorb moisture and remains unaffected by environmental changes.

Composite insulators are often touted as the modern solution due to their lightweight design and resistance to pollution; however, they may not always provide the same level of mechanical strength as robust glass options or traditional porcelain designs. When considering longevity and overall performance in harsh environments, many utilities find that glass holds its own against both porcelain and composite alternatives—offering a balanced blend of performance characteristics suitable for various applications in power transmission.

Ultimately, choosing between these materials depends on specific project requirements; however, it's clear that each option has its unique advantages depending on the situation at hand.

Availability of Glass Insulators for Sale

For those interested in upgrading or expanding their infrastructure with high-quality products, there’s no shortage of options when it comes to finding glass insulators for sale on the market today. Various manufacturers specialize in providing a wide range of powerline insulator solutions tailored specifically for utility needs—ensuring that you can find exactly what you’re looking for without any hassle.

Additionally, online platforms have made sourcing these essential components easier than ever before; whether you’re searching through local suppliers or browsing global distributors specializing in electrical components like power pole insulators—you’ll likely discover competitive pricing along with detailed specifications on available products. This accessibility means that utilities can invest confidently in reliable insulation technology while keeping budgets intact.

In conclusion, while exploring your options among different types of powerline insulation materials is essential—glass stands out as an excellent choice due to its durability and ease-of-maintenance attributes paired with widespread availability from reputable sources eager to meet your needs.

Composite Insulators: The Modern Solution

In the ever-evolving world of powerline insulators, composite insulators have emerged as a leading choice for utilities seeking reliability and performance. These innovative insulators are crafted from a combination of materials, typically featuring a core made of fiberglass and an outer layer of polymer, which provides excellent electrical insulation properties. As technology advances, these modern solutions are becoming essential components in the infrastructure of power transmission.

What Are Composite Insulators?

Composite insulators are designed to offer superior performance compared to traditional porcelain electrical insulators and glass insulators. They consist of a lightweight, durable core that is encased in weather-resistant materials, making them ideal for various environmental conditions. Unlike their porcelain counterparts, which can be heavy and prone to breakage, composite power line insulators provide enhanced flexibility and resilience.

Advantages in Severe Weather Conditions

One of the standout benefits of composite insulators is their remarkable ability to withstand severe weather conditions that often challenge other types like porcelain or glass insulators. Their lightweight design means they can endure high winds without compromising structural integrity, while their hydrophobic properties help prevent water accumulation that can lead to flashovers. This resilience not only enhances safety but also reduces maintenance costs for utilities operating in harsh climates.

Rising Popularity Among Utilities

The rising popularity of composite power pole insulators among utility companies speaks volumes about their effectiveness and efficiency in modern applications. As more utilities recognize the advantages offered by these innovative solutions—such as reduced weight and improved durability—they are increasingly replacing traditional porcelain electrical insulators with composites in new installations and upgrades alike. With growing demand for reliable infrastructure that can handle extreme conditions, it's no wonder that composite insulators are becoming the go-to choice for many power providers.

Innovations from Spark Fittings

In the ever-evolving world of powerline insulators, Spark Fittings stands out as a beacon of innovation. Their commitment to advancing manufacturing technologies has significantly impacted the production of various types of insulators, including porcelain electrical insulators and composite options. As utilities seek more reliable and efficient solutions for their power pole insulators, Spark Fittings has risen to the occasion with state-of-the-art equipment and processes.

Equipment for Manufacturing Insulators

The machinery used in the manufacturing of powerline insulators is crucial to ensuring quality and durability. Spark Fittings employs cutting-edge technology that enhances precision in creating porcelain insulator designs, allowing for better performance under stress and environmental challenges. This level of automation not only boosts productivity but also reduces waste, making it a win-win for both manufacturers and consumers.

The Role of Spark Fittings in the Industry

Spark Fittings plays a pivotal role in shaping industry standards for powerline insulators through its innovative practices. By focusing on research and development, they have introduced new materials that enhance the resilience of glass insulators while maintaining affordability—making glass insulators for sale more accessible than ever before. Their influence extends beyond production; they actively engage with utility companies to understand their needs, ensuring that products like porcelain electrical insulators meet real-world demands.

Enhancing Quality in Power Pole Insulators

Quality is paramount when it comes to power pole insulators; after all, these components are responsible for maintaining safety and efficiency in our electrical grids. Thanks to innovations from Spark Fittings, advancements such as improved glazing techniques in porcelain electrical insulators have dramatically increased their lifespan and resistance to environmental factors. As a result, utilities can trust that their investments in powerline insulation will pay off over time with reduced maintenance costs and enhanced reliability.

Conclusion

In the world of powerline insulators, understanding the different types available is crucial for effective power transmission. From porcelain insulators, known for their durability and reliability, to innovative composite options that thrive in harsh weather conditions, each type has its unique attributes and applications. With glass insulators for sale also making a comeback due to their aesthetic appeal and performance characteristics, it’s clear that there's a broad spectrum of choices for utilities and engineers alike.

Summary of Insulator Types

Porcelain electrical insulators have long been the standard due to their excellent insulating properties and resistance to environmental factors. Glass insulators offer transparency in terms of condition monitoring while also being lightweight and durable. Meanwhile, composite power line insulators are becoming increasingly popular among utility companies thanks to their ability to withstand severe weather conditions without compromising performance.

The Importance of Choosing Wisely

Selecting the right type of power pole insulators is not merely a matter of preference; it directly impacts safety, efficiency, and longevity in power transmission systems. Each type—whether it's porcelain, glass, or composite—comes with its own set of advantages that can significantly influence operational costs and maintenance schedules over time. Therefore, making an informed choice based on specific application needs is essential for ensuring reliable service.

Future Trends in Insulator Technology

Looking ahead, advancements in materials science are likely to lead to even more efficient designs for powerline insulators that can better withstand environmental challenges while reducing costs. Innovations such as smart insulator technology could provide real-time data on performance metrics, allowing utilities to optimize maintenance schedules proactively. As we embrace these future trends in insulator technology, the importance of selecting the right type will only grow more critical as we strive for safer and more efficient energy solutions.