Introduction

In the world of electric power transmission, transmission insulators play a crucial role in ensuring that electricity travels efficiently and safely across vast distances. These unsung heroes of the electrical grid are essential for maintaining the integrity of power lines, preventing short circuits, and minimizing energy loss. Understanding their function helps us appreciate how they contribute to the reliability of our power utilities.

Understanding the Role of Insulators

Transmission insulators serve as barriers that prevent unwanted electrical currents from escaping into the environment, thus facilitating the safe transmission of electricity along power lines. They are designed to withstand high voltages while providing mechanical support to conductors, ensuring that they remain securely suspended above the ground. By doing so, these insulators protect both infrastructure and personnel from potential electrical hazards.

Importance of Transmission Line Insulators

The importance of transmission line insulators cannot be overstated; they are vital for maintaining the efficiency and safety of our electric power transmission systems. Without reliable power line insulators, we would face an increased risk of outages due to electrical faults or environmental factors such as wind and rain. As a key component in power utility operations, these insulators help ensure that electricity is delivered smoothly from generation sources to consumers.

Overview of Electric Power Transmission

Electric power transmission involves transporting electricity from generation facilities to substations and ultimately to end users via an intricate network of cables and infrastructure. This process relies heavily on high-voltage transmission lines equipped with various types of transmission line insulators designed for specific applications and environments. As technology advances, understanding how these components work together will be essential for optimizing our energy systems for future demands.

What Are Transmission Insulators?

Transmission insulators are vital components in the intricate web of electric power transmission. They serve as barriers that prevent the unwanted flow of electricity, ensuring that power travels efficiently along transmission lines. By isolating conductors from supporting structures, these insulators help maintain safety and reliability in the transmission of electricity.

Definition and Function

At their core, transmission insulators are designed to support high-voltage conductors while preventing electrical leakage to the ground or surrounding structures. They act as non-conductive materials that withstand environmental stresses and electrical forces, ensuring that the flow of electricity remains uninterrupted. In essence, their primary function is to facilitate safe and efficient electric power transmission by keeping conductors securely in place.

Types of Transmission Insulators

There are several types of transmission line insulators, each with unique characteristics suited for various applications within power utilities. The most common types include porcelain insulators, glass insulators, and polymer insulators. Each type has its advantages; for instance, porcelain is known for its durability, while polymer offers lightweight properties ideal for modern installations.

Importance in Power Utilities

In power utilities, the role of transmission insulators cannot be overstated—they ensure reliable service while minimizing maintenance costs associated with failures or damages. High-quality transmission line insulators contribute to the overall efficiency of electric power transmission systems by reducing energy losses caused by leakage currents. Moreover, they enhance safety protocols by preventing short circuits and protecting both infrastructure and personnel involved in managing power lines.

Porcelain Insulators: The Classic Choice

When it comes to transmission insulators, porcelain has long been regarded as a classic choice in the realm of electric power transmission. Known for their impressive durability and strength, porcelain insulators have stood the test of time, proving essential in ensuring the reliability of power line insulators. Their robust nature makes them particularly suited for high-stress environments, where they play a pivotal role in the transmission of electricity.

Durability and Strength

Porcelain insulators are crafted from a dense ceramic material that offers superior durability compared to many other types of transmission line insulators. This strength allows them to withstand harsh environmental conditions—think extreme temperatures, heavy winds, and even ice accumulation—without compromising performance. Moreover, their resistance to mechanical stress ensures that these power utility components can endure years of service without significant wear or degradation.

Performance in High Voltage Applications

In high voltage applications, the performance of porcelain insulators is nothing short of remarkable. Their ability to maintain electrical integrity under pressure makes them ideal for situations where electric power transmission demands reliability and safety. Withstanding voltages that could easily break down lesser materials, porcelain insulators are often used in critical infrastructure projects where failure is not an option.

Popular Usage in Power Lines

Porcelain insulators have become synonymous with traditional power line configurations due to their widespread popularity among utilities across the globe. You’ll find them adorning countless transmission lines that crisscross our landscapes, silently supporting the vital work of transmitting electricity from generation sources to end-users. Their proven track record has solidified their status as a go-to option for power utility companies looking for dependable solutions in electric power transmission.

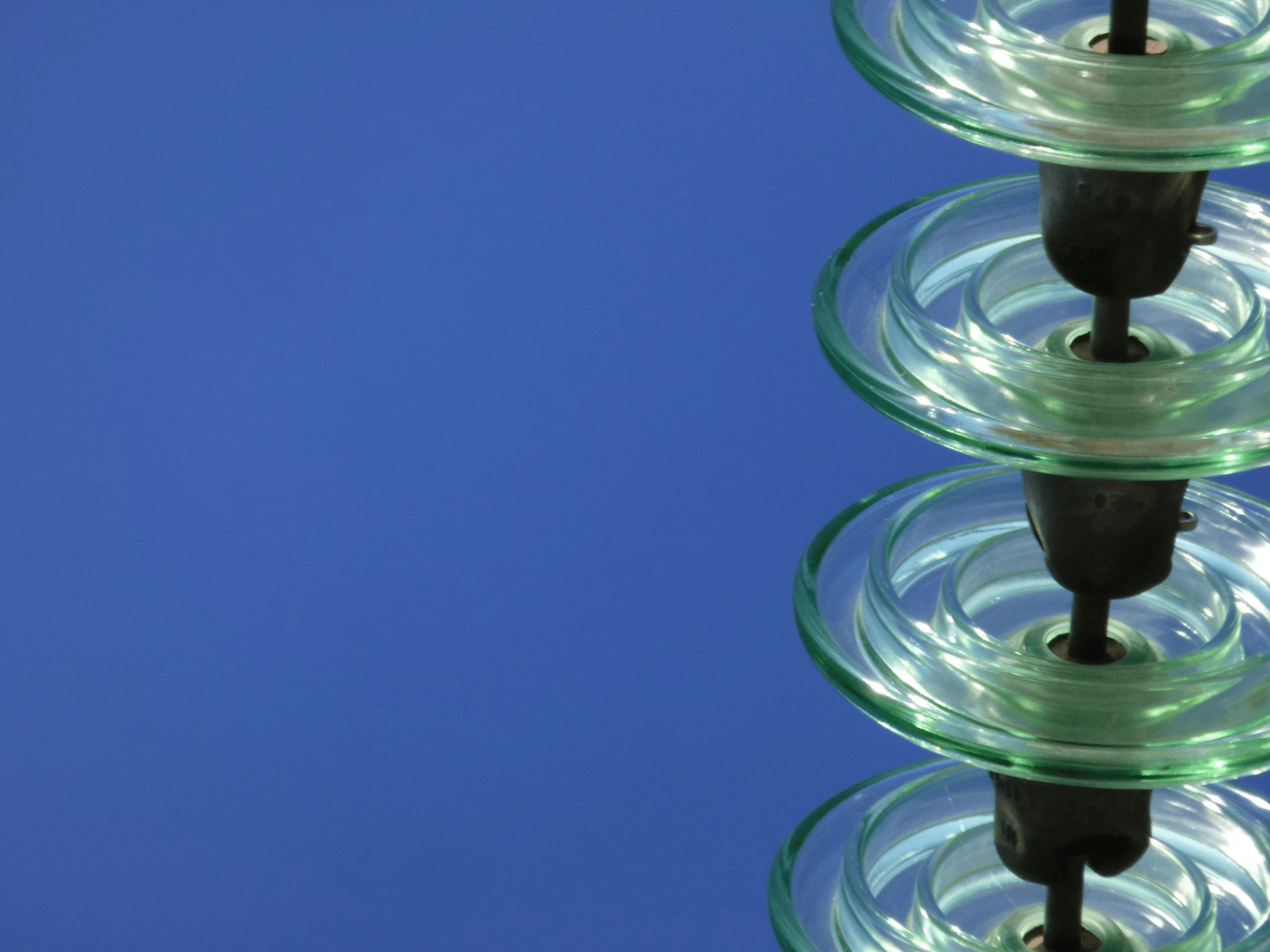

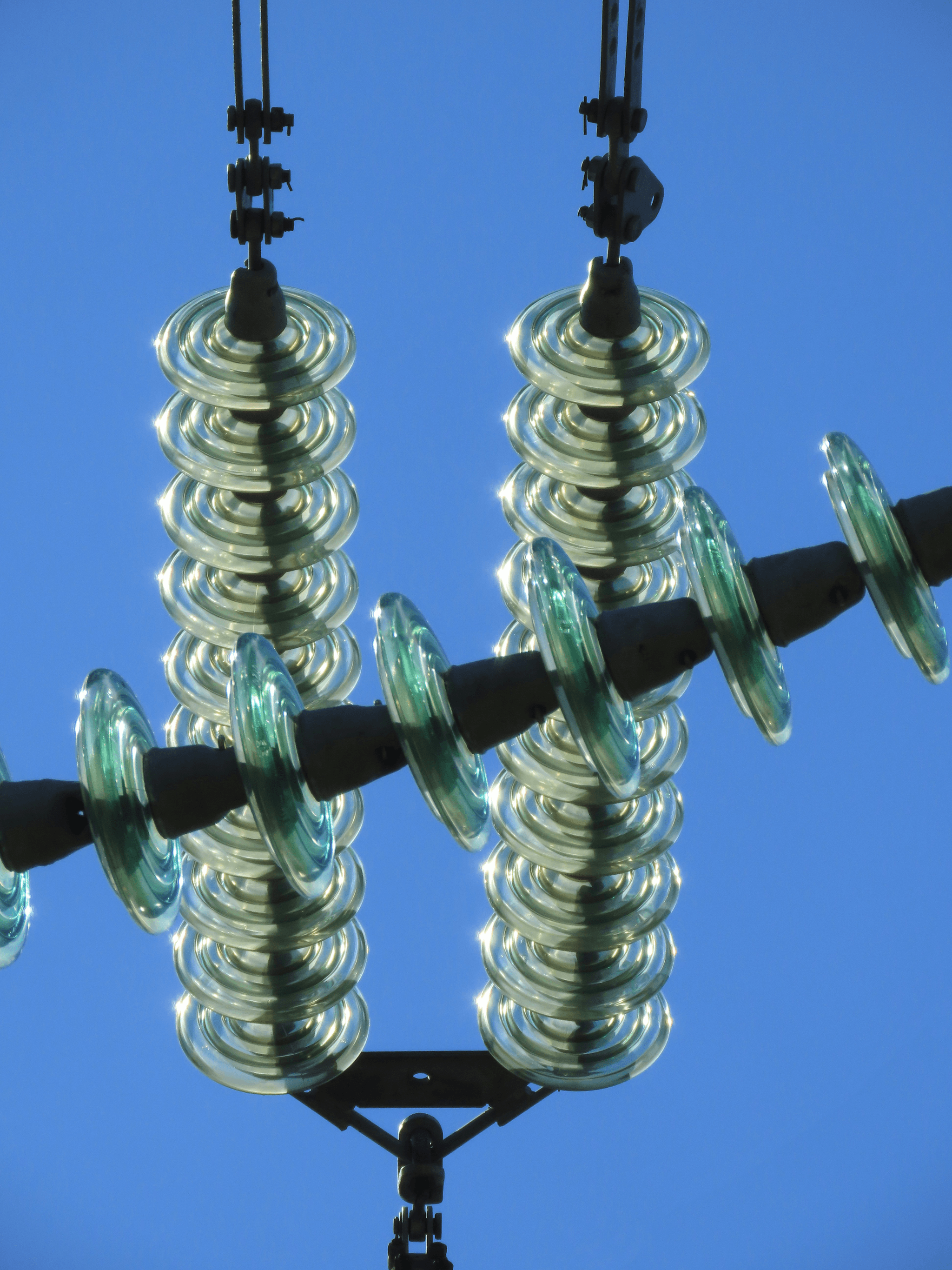

Glass Insulators: The Transparent Wonder

Glass insulators have long been a staple in the world of transmission line infrastructure, and for good reason. They offer a unique combination of durability, aesthetic appeal, and performance that makes them an excellent choice for power utilities. As electric power transmission continues to evolve, glass insulators remain relevant due to their remarkable attributes.

Benefits of Glass Insulators

One of the standout benefits of glass insulators is their impressive electrical performance; they provide excellent insulation properties that help ensure the safe transmission of electricity across long distances. Unlike some traditional materials, glass does not degrade over time, which means these transmission line insulators can maintain their effectiveness for decades without significant maintenance. Additionally, their transparency allows for easy visual inspection, enabling power utility workers to quickly identify any potential issues.

Resistance to Environmental Factors

When it comes to environmental resilience, glass insulators shine bright—literally! They are highly resistant to moisture and pollution, making them ideal for use in various climates and settings where other materials might falter. This resistance not only enhances the longevity of these transmission line insulators but also ensures reliable performance in the face of harsh weather conditions or environmental challenges.

Applications in Electric Power Transmission

Glass insulators have found their niche in numerous applications within electric power transmission systems. From high-voltage power lines snaking across rural landscapes to urban substations bustling with energy transfer, these versatile components play a crucial role in ensuring efficient electricity flow. Their ability to withstand extreme conditions makes them particularly valuable for power utilities aiming to maintain reliability while minimizing outages caused by equipment failure.

Polymer Insulators: The Modern Marvel

In the ever-evolving world of electric power transmission, polymer insulators have emerged as a modern marvel, revolutionizing the landscape of transmission line technology. Unlike traditional insulators made from porcelain or glass, polymer insulators offer a range of benefits that make them increasingly popular among power utilities. Their unique composition allows for enhanced performance in various environmental conditions, making them an ideal choice for many high-voltage applications.

Advantages Over Traditional Insulators

One of the standout advantages of polymer insulators is their superior resistance to environmental stressors such as pollution and moisture. Unlike porcelain or glass transmission line insulators, which can suffer from surface degradation over time, polymer materials maintain their integrity and performance even in harsh conditions. This resilience not only prolongs the lifespan of these insulators but also reduces maintenance costs for power utilities, ultimately leading to more efficient electric power transmission.

Moreover, polymer insulators are designed to be hydrophobic, which means they repel water rather than allowing it to pool on their surfaces. This characteristic significantly decreases the risk of electrical tracking and flashover incidents—two common issues that can disrupt the transmission of electricity across power lines. When it comes to reliability and safety in high-voltage environments, polymer insulators are proving to be a game-changer for the industry.

Lightweight and High Performance

Another compelling feature of polymer insulators is their lightweight nature compared to traditional options like porcelain and glass. This reduced weight translates into easier handling during installation and maintenance processes on transmission lines, allowing utility workers to operate more efficiently without sacrificing safety or performance standards. The lightweight design also means that less structural support is needed on towers and poles, leading to potential savings in construction costs for new power utility projects.

In terms of performance, polymer insulators excel at maintaining electrical stability under varying temperatures and weather conditions. Their ability to withstand extreme heat or cold without compromising functionality makes them an attractive option for diverse geographic locations where temperature fluctuations are common during different seasons. This adaptability ensures that electric power transmission remains uninterrupted regardless of external factors.

Adoption in Power Utility Projects

The adoption rate of polymer insulators among power utilities has surged in recent years as organizations seek innovative solutions that align with modern infrastructure needs. Many utilities have begun replacing outdated porcelain or glass options with advanced polymer technology on new projects due to its numerous benefits—particularly its resilience against environmental challenges faced by transmission line systems today. As more companies recognize the value these modern marvels bring, we can expect widespread implementation across electric power transmission networks globally.

Furthermore, industry trends indicate a growing preference for sustainable materials within energy sectors; this aligns perfectly with the use of eco-friendly polymers used in manufacturing these advanced transmission line insulators. By choosing polymers over traditional materials like glass or porcelain, utilities not only enhance operational efficiency but also contribute positively toward reducing their carbon footprint—a win-win situation! With ongoing advancements in material science and engineering techniques focused on improving insulation properties further still ahead lies exciting potential for even greater adoption rates amongst forward-thinking power utility companies.

The Role of Spark Fittings in Insulator Systems

In the intricate world of electric power transmission, spark fittings play a pivotal role in ensuring that transmission insulators function optimally. These specialized components are designed to facilitate the efficient installation of power line insulators, enhancing their overall performance and reliability. By understanding their significance, we can appreciate how spark fittings contribute to the seamless transmission of electricity across vast distances.

Equipment for Efficient Installation

When it comes to installing transmission line insulators, having the right equipment is crucial. Spark fittings serve as essential tools that simplify the installation process, allowing technicians to secure insulators quickly and effectively. This efficiency not only saves time but also reduces labor costs for power utilities while ensuring that each component is properly aligned for optimal performance.

Moreover, these fittings are designed to accommodate various types of insulators used in electric power transmission systems. Their versatility means they can be employed with porcelain, glass, or polymer insulators, making them a valuable asset for any power utility project. Ultimately, using spark fittings enhances operational efficiency and ensures that all components work harmoniously together.

Enhancing Insulator Performance

The performance of transmission line insulators can significantly impact the reliability and safety of electric power transmission systems. Spark fittings enhance this performance by providing a secure connection that minimizes electrical leakage and potential failures during operation. This ensures that the integrity of the entire system is maintained while reducing maintenance costs for power utilities.

Additionally, these fittings contribute to better load distribution across the insulator system, which is particularly important under high voltage conditions typical in modern electric grids. By optimizing how forces are transmitted through the setup, spark fittings help prevent premature wear or damage to both insulators and associated hardware. This proactive approach not only extends the lifespan of transmission line components but also enhances overall system resilience.

Supporting the Transmission of Electricity

Spark fittings play a crucial role in supporting the efficient transmission of electricity from generation facilities to end-users via robust networks of power line insulators. By ensuring proper installation and enhancing overall performance, these components help maintain stable voltage levels throughout the grid infrastructure. Consequently, they enable utilities to deliver reliable service while minimizing outages caused by equipment failures.

Furthermore, as demand for electricity continues to rise globally, having effective spark fitting solutions becomes increasingly important for modernizing existing infrastructure or developing new projects within power utility sectors. The right combination of spark fittings with high-quality transmission line insulators ensures that systems can handle increased loads without compromising safety or efficiency standards. In this way, they are indispensable in meeting future energy demands while maintaining grid stability.

Conclusion

In conclusion, transmission insulators play a pivotal role in the landscape of electric power transmission, ensuring that the flow of electricity remains uninterrupted and efficient. As technology evolves, so do the materials and methods used in the production of these essential components. Understanding future trends in transmission insulators will help power utilities adapt to new challenges and enhance their infrastructure.

Future Trends in Transmission Insulators

Looking ahead, we see several exciting trends shaping the world of transmission line insulators. Innovations such as smart insulators equipped with sensors are on the rise, allowing for real-time monitoring and maintenance alerts to prevent failures before they happen. Additionally, environmentally friendly materials are gaining traction as power utilities aim to reduce their carbon footprint while maintaining high standards for electric power transmission.

The Importance of Quality in Power Utilities

Quality is non-negotiable when it comes to power line insulators; after all, they are critical for ensuring reliable electricity delivery. Poor-quality transmission insulators can lead to outages or even catastrophic failures, which can be costly both financially and operationally for power utilities. By investing in high-quality materials and manufacturing processes, utility companies can safeguard their infrastructure and ensure a steady transmission of electricity.

Choosing the Right Insulator for Your Needs

When it comes time to select transmission line insulators, it's essential to consider various factors such as environmental conditions, voltage levels, and specific application requirements. Each type—be it porcelain, glass, or polymer—has its unique advantages suitable for different scenarios within electric power transmission systems. Ultimately, making an informed choice will not only enhance performance but also contribute to long-term reliability within your power utility operations.