Introduction

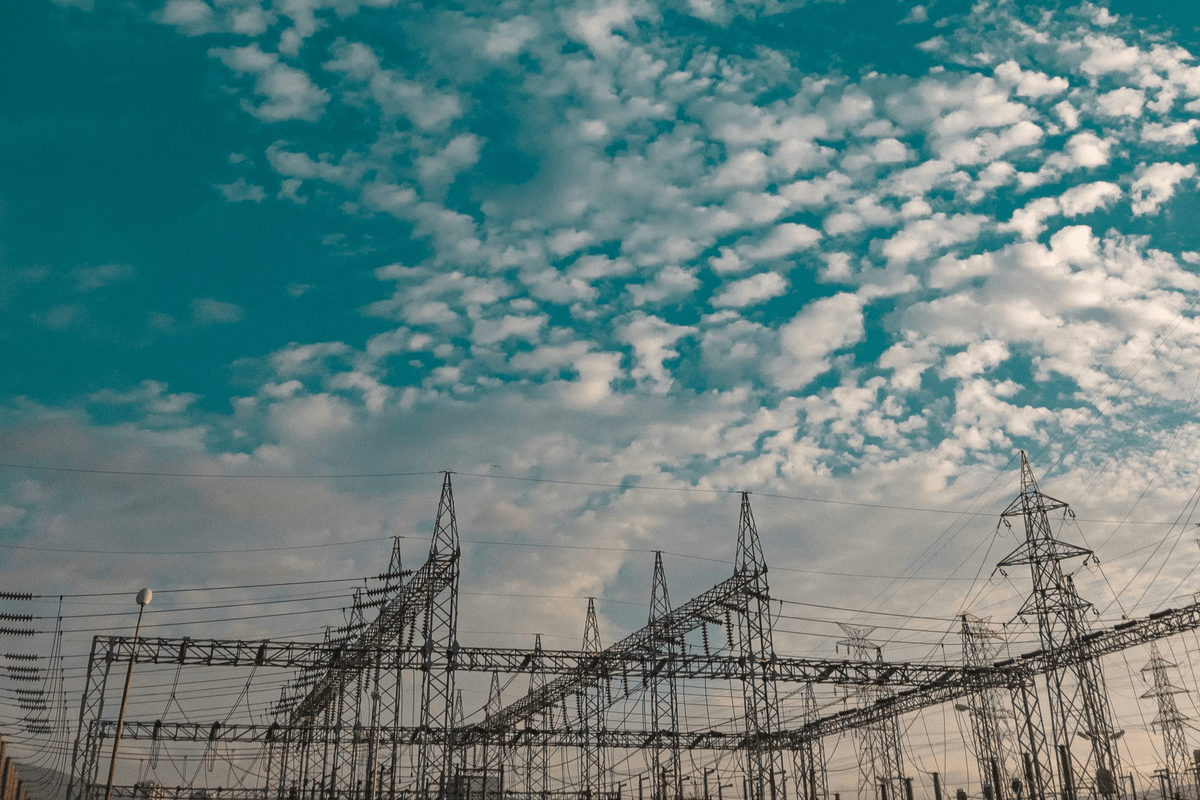

In the world of electrical and mechanical systems, suspension clamps play a pivotal role in ensuring stability and safety. These components are essential for securing transmission lines, preventing sagging or displacement that could lead to failures or accidents. Understanding the various types of suspension clamps and their applications is crucial for anyone involved in installation or maintenance.

Importance of Suspension Clamps

Suspension clamps are vital for maintaining the integrity of transmission lines, which carry electricity over vast distances. They provide support and allow for thermal expansion while minimizing stress on cables, thereby enhancing the overall reliability of the system. Without these clamps, issues such as cable breakage or misalignment could arise, leading to costly repairs and safety hazards.

Types of Suspension Clamps

There are several types of suspension clamps used in transmission lines, each designed for specific applications and load requirements. From standard suspension clamps to specialized C clamps in a transmission line setup, understanding their unique features can help ensure optimal performance. Knowing which clamp to use can make all the difference when it comes to functionality and durability.

Overview of Spark Fittings

Spark fittings are integral components that work alongside suspension clamps to facilitate secure mounting in transmission line systems. These fittings not only enhance stability but also contribute to the overall efficiency by reducing vibration and movement during operation. As technology advances, spark fittings continue to evolve, offering innovative solutions that cater to modern demands in transmission line mounting.

Understanding Transmission Line Clamps

Transmission line clamps are essential components in the world of electrical and mechanical engineering, providing stability and support to various transmission lines. They ensure that these lines remain securely fastened, preventing any unwanted movement or damage that could disrupt service. Understanding the functionality, materials, and applications of transmission line clamps is crucial for anyone involved in installation or maintenance.

Functionality of Transmission Line Clamps

The primary function of transmission line clamps is to hold and secure transmission lines in place, ensuring they operate efficiently without sagging or swaying. These clamps also help distribute the weight of the lines evenly across structures, reducing stress on individual components. Moreover, they play a vital role in minimizing vibrations caused by wind or operational factors, which can lead to wear and tear over time.

When we ask ourselves, What is the C clamp in a transmission line? we’re referring specifically to a type of clamp designed for this very purpose. C clamps are particularly effective at gripping cylindrical objects tightly while allowing for adjustments as needed during installation or maintenance tasks. This versatility makes them an invaluable tool for engineers working with various types of transmission lines.

Materials Used in Transmission Line Clamps

Transmission line clamps are typically made from robust materials designed to withstand harsh environmental conditions and mechanical stresses. Commonly used materials include stainless steel, aluminum alloys, and high-strength polymers that offer durability without compromising on weight. The choice of material can significantly impact the performance and longevity of these clamps; thus, selecting the right type is essential for any project involving transmission line mounting.

In addition to strength and durability, resistance to corrosion is another critical factor when choosing materials for transmission line clamps. For instance, stainless steel offers excellent resistance against rusting and degradation over time while maintaining structural integrity under extreme conditions. This durability ensures that even during adverse weather events or prolonged exposure to moisture—such as what might occur with a leaking cooler—transmission line clamps continue functioning effectively.

Common Applications

Transmission line clamps find their applications across various industries including telecommunications, electrical power distribution systems, and even transportation infrastructure projects like railways or highways where overhead cables are employed. In telecommunications networks specifically, these clamps help secure fiber optic cables that require precise alignment for optimal performance—a task made easier with reliable hardware like suspension clamps.

Moreover, you'll often see them used in power plants where high-voltage wires must be secured firmly while allowing some flexibility due to thermal expansion or contraction effects caused by temperature changes throughout the day. Understanding how serious a transmission cooler line leak can be emphasizes why using quality components like robust transmission line clamps is vital; leaks can lead not only to equipment failure but also significant safety hazards if left unchecked.

In summary, grasping how different types of transmission line clamps function along with their material composition enhances our understanding of their critical role within various applications across multiple sectors—ultimately ensuring smoother operations regardless if we're discussing coupling in transmission lines or how to install transmission line clips efficiently.

What is the C Clamp in a Transmission Line?

When delving into the world of transmission line clamps, one component that stands out for its utility is the C clamp. This essential fitting serves a critical role in securing various elements within transmission lines, ensuring stability and reliability in electrical and mechanical systems. Understanding what a C clamp is and how it functions can illuminate its importance in maintaining efficient transmission line operations.

Definition and Purpose

A C clamp in a transmission line is essentially a fastener designed to hold components together securely. Its distinctive C shape allows it to grip around pipes or bars, providing a stable connection that can withstand significant tension and environmental stressors. The primary purpose of these clamps is to ensure that transmission line components remain aligned and properly secured, preventing any unwanted movement that could lead to damage or failure.

Benefits of Using C Clamps

Firstly, they provide strong support for various components, which can significantly enhance overall system stability. Additionally, their ease of installation makes them an attractive choice for both professionals and DIY enthusiasts alike—no one wants to spend hours wrestling with complicated fittings! Lastly, the versatility of C clamps means they can be used across different types of transmission lines, making them an invaluable tool for anyone working with electrical or mechanical systems.

Installation Considerations

Installing a C clamp may seem straightforward, but there are several considerations to keep in mind for optimal performance. First off, ensure you select the right size clamp for your specific application; using an undersized or oversized clamp can lead to ineffective securing or even damage during operation. Furthermore, it's crucial to follow best practices when installing these clamps—over-tightening can cause unnecessary stress on both the clamp and the components it holds together. Finally, always double-check your work after installation; ensuring everything is secure will help prevent issues down the road.

How Serious is a Transmission Cooler Line Leak?

When it comes to your vehicle's transmission system, a cooler line leak can be a significant issue that demands immediate attention. Understanding how serious a transmission cooler line leak can be is crucial for maintaining optimal performance and preventing further damage. This section will help you identify such leaks, explore the consequences of neglecting them, and highlight preventative measures to keep your transmission in top shape.

Identifying a Transmission Cooler Line Leak

Identifying a transmission cooler line leak is the first step in addressing this potentially damaging issue. Look for signs like fluid spots under your vehicle or noticeable drops in transmission fluid levels; these are clear indicators that something is amiss. Additionally, if you notice any unusual smells or smoke while driving, it's time to investigate further—this could mean that the fluid is leaking onto hot engine components.

Another telltale sign of a leak involves checking the condition of your transmission line clamps and connections; any corrosion or damage here could signal trouble ahead. If you're wondering what equipment is used in transmission line mounting, take note that proper clamps and fittings play an essential role in ensuring secure connections. Regular inspections can help catch leaks early before they escalate into more severe problems.

Consequences of Ignoring a Leak

Ignoring a transmission cooler line leak can lead to dire consequences for your vehicle's performance and longevity. As fluid levels drop due to leakage, your transmission may begin to overheat—resulting in costly repairs or even complete failure if left unchecked. Furthermore, low fluid levels can cause erratic shifting behaviors and reduce overall efficiency; nobody wants their car acting like it's auditioning for an action movie with dramatic gear changes!

In addition to mechanical issues, neglecting this problem could also result in environmental hazards as leaked fluids contaminate soil and water sources. The importance of coupling in transmission lines cannot be overstated here; faulty connections may worsen leaks over time if not properly secured with quality clamps like C clamps specifically designed for these applications. So don’t just sit back—take action before you find yourself stuck on the side of the road!

Preventative Measures

Taking preventative measures against potential leaks is key to maintaining the integrity of your vehicle’s transmission system. Regularly inspect all components involved—including those trusty suspension clamps—to ensure they are free from wear or damage that could lead to leaks down the road. Furthermore, always use high-quality equipment when mounting new lines; investing upfront will save you headaches later on.

Routine maintenance checks should include examining both the condition of your cooler lines and ensuring proper installation techniques are followed when installing new clips or fittings (here’s where knowing how to install transmission line clips comes into play). If you're unsure about any part of this process, don't hesitate to consult professionals who specialize in these systems—they'll have insights into what works best based on real-world experience!

Lastly, consider using protective sleeves around vulnerable areas where wear might occur over time due to friction or exposure elements; prevention truly is better than cure!

What is Coupling in Transmission Lines?

Coupling in transmission lines refers to the method of connecting two components or sections of a transmission system, allowing for the efficient transfer of power and signals. This connection is crucial for maintaining system integrity and performance, especially when using various types of transmission line clamps. Understanding coupling helps ensure that any installation, whether involving transmission line clips or other mounting equipment, is done correctly to avoid issues like leaks or poor signal quality.

Definition and Importance of Coupling

Coupling can be defined as the mechanism that links two systems together so they can work in harmony. In transmission lines, this connection is vital because it impacts how effectively power is transmitted from one point to another without significant losses. Proper coupling ensures that energy flows smoothly while minimizing disruptions caused by factors such as vibration or thermal expansion—issues often addressed by using appropriate suspension clamps.

Types of Coupling Used in Transmission Lines

There are several types of coupling used in transmission lines, each serving a unique purpose based on the specific requirements of the application. Common types include rigid couplings, flexible couplings, and universal joints; each type plays a significant role in maintaining alignment and accommodating movement within the system. Knowing what equipment is used in transmission line mounting can help you select the right coupling type for your project—ensuring that everything from C clamps to suspension clamps works seamlessly together.

Impact on Transmission Line Performance

The impact of coupling on transmission line performance cannot be overstated; it directly affects efficiency and reliability across various applications. Poorly designed or installed couplings can lead to increased resistance, energy loss, and even mechanical failure over time—similar to how neglecting a leak could spell disaster for your vehicle's transmission cooler line! By understanding what coupling means within this context—and considering factors like installation techniques for items such as how to install transmission line clips—you can significantly enhance overall performance and longevity.

Equipment Used in Transmission Line Mounting

When it comes to mounting equipment for transmission lines, a variety of tools and components are essential for ensuring stability and functionality. This equipment includes everything from transmission line clamps to specialized mounting brackets designed for secure attachment. Understanding the different types of equipment available is crucial for any technician or engineer involved in transmission line installation and maintenance.

Overview of Mounting Equipment

Mounting equipment plays a pivotal role in the overall performance and reliability of transmission lines. Key components include transmission line clamps, brackets, insulators, and C clamps that hold the lines firmly in place while allowing for some flexibility under stress or environmental changes. Each piece of equipment is designed with specific functionalities; therefore, selecting the right combination is critical to avoid issues like sagging or misalignment.

Role of Spark Fittings in Mounting

Spark fittings are integral to the mounting process as they ensure secure connections between various components in a transmission line system. They provide electrical continuity while minimizing resistance, which can be particularly beneficial when dealing with high-voltage applications. Additionally, spark fittings help prevent arcing and other electrical hazards that could arise from improper connections, making them indispensable when considering what equipment is used in transmission line mounting.

Best Practices for Equipment Usage

To maximize efficiency and safety when using mounting equipment, adhering to best practices is essential. Always ensure that all components—especially transmission line clamps—are properly rated for their intended load; this can prevent unexpected failures down the line. Regular inspections should also be conducted to identify any wear or damage that might compromise performance; after all, ignoring issues could lead to serious problems like leaks or even structural failures.

How to Install Transmission Line Clips

Installing transmission line clips may seem daunting, but with the right approach, it can be a straightforward task. These clips are essential for securing transmission line clamps and ensuring that everything remains in place during operation. Whether you're dealing with C clamps or other types, understanding how to install them properly is crucial.

Step-by-Step Installation Guide

1. **Preparation**: Start by gathering all necessary tools and equipment used in transmission line mounting. Ensure that you have the correct size of transmission line clips for the clamps you’re working with, as this will make installation smoother.

2. **Positioning**: Identify where the clips need to be installed along the transmission lines. Proper positioning is vital; if you’re unsure, consult your vehicle's manual or specifications regarding what is coupling in transmission lines.

3. **Installation**: Secure each clip around the transmission line and fasten it tightly using your tools of choice. Make sure not to overtighten; this could lead to damage or leaks, especially if you're also considering how serious a transmission cooler line leak could be.

4. **Final Check**: After installation, give everything a thorough inspection to ensure that all clips are secure and that there are no loose ends left hanging around—literally!

By following these steps closely, you'll have successfully installed your transmission line clips without a hitch.

Common Mistakes to Avoid

One of the most common mistakes when installing transmission line clips is neglecting to check compatibility with existing components like C clamps in a transmission line setup. Using mismatched sizes can lead to improper fitment and potential leaks down the road—definitely something you'd want to avoid!

Another pitfall is failing to secure the lines properly; loose fittings can cause vibrations that wear out components faster than you'd expect, impacting coupling in transmission lines significantly over time. Always double-check your work before moving on!

Lastly, many people overlook proper torque specifications when tightening their clips and clamps; too tight can damage components while too loose may result in leaks or disconnections later on.

Conclusion

In wrapping up our exploration of transmission line clamps, it’s clear that these components play a crucial role in ensuring the reliability and efficiency of transmission systems. From understanding what the C clamp in a transmission line is to recognizing how serious a transmission cooler line leak can be, we’ve navigated through essential aspects of these fittings. Moreover, insights into coupling in transmission lines and the equipment used in transmission line mounting highlight the intricacies involved in maintaining optimal performance.

Key Takeaways on Suspension Clamps

Suspension clamps are vital for securing conductors and ensuring proper alignment within transmission lines. They come in various types to accommodate different applications, showcasing their versatility across industries. Understanding how to install transmission line clips correctly can prevent costly mistakes and enhance overall system integrity.

Future Trends in Transmission Line Technology

As technology evolves, so does the landscape of transmission line clamps and associated equipment. Innovations such as smart sensors integrated into mounting systems are on the horizon, promising enhanced monitoring capabilities for detecting issues like leaks or misalignments early on. Additionally, advancements in materials will likely lead to lighter yet stronger suspension clamps that improve performance while minimizing environmental impact.

Role of Spark Fittings in Innovation

Spark fittings are emerging as pivotal players in enhancing the efficiency of mounting equipment for transmission lines. Their design allows for quick installation while providing robust support to ensure stability under various conditions. As we move forward, spark fittings will continue to drive innovation by enabling more streamlined processes and improving safety standards across all applications involving suspension clamps.