Introduction

These clamp tools play a vital role in ensuring the reliability and efficiency of power distribution systems, making them indispensable in various applications. Whether you're dealing with long clamps for overhead lines or specialized clamp pliers for intricate tasks, understanding the essentials of hotline clamps can significantly enhance your operational capabilities.

The Essentials of Hot Line Clamps

Hotline clamps are designed to connect conductors while live, allowing maintenance work to proceed without interrupting power supply. These robust line clamps come in various designs and sizes, tailored to meet specific electrical requirements while ensuring maximum safety during use. With features like high conductivity materials and secure grips, hotline clamps provide the reliability needed for critical operations.

Importance of Selecting the Right Clamp

Choosing the right clamp is crucial not just for performance but also for safety in high-voltage environments. The wrong clamp can lead to inefficiencies or even dangerous situations, making it imperative to understand which type best fits your needs—whether you need long clamps for extensive spans or more compact options for tight spaces. A well-selected clamp ensures that your work is both effective and safe, protecting both personnel and equipment.

Overview of Applications for Hotline Clamps

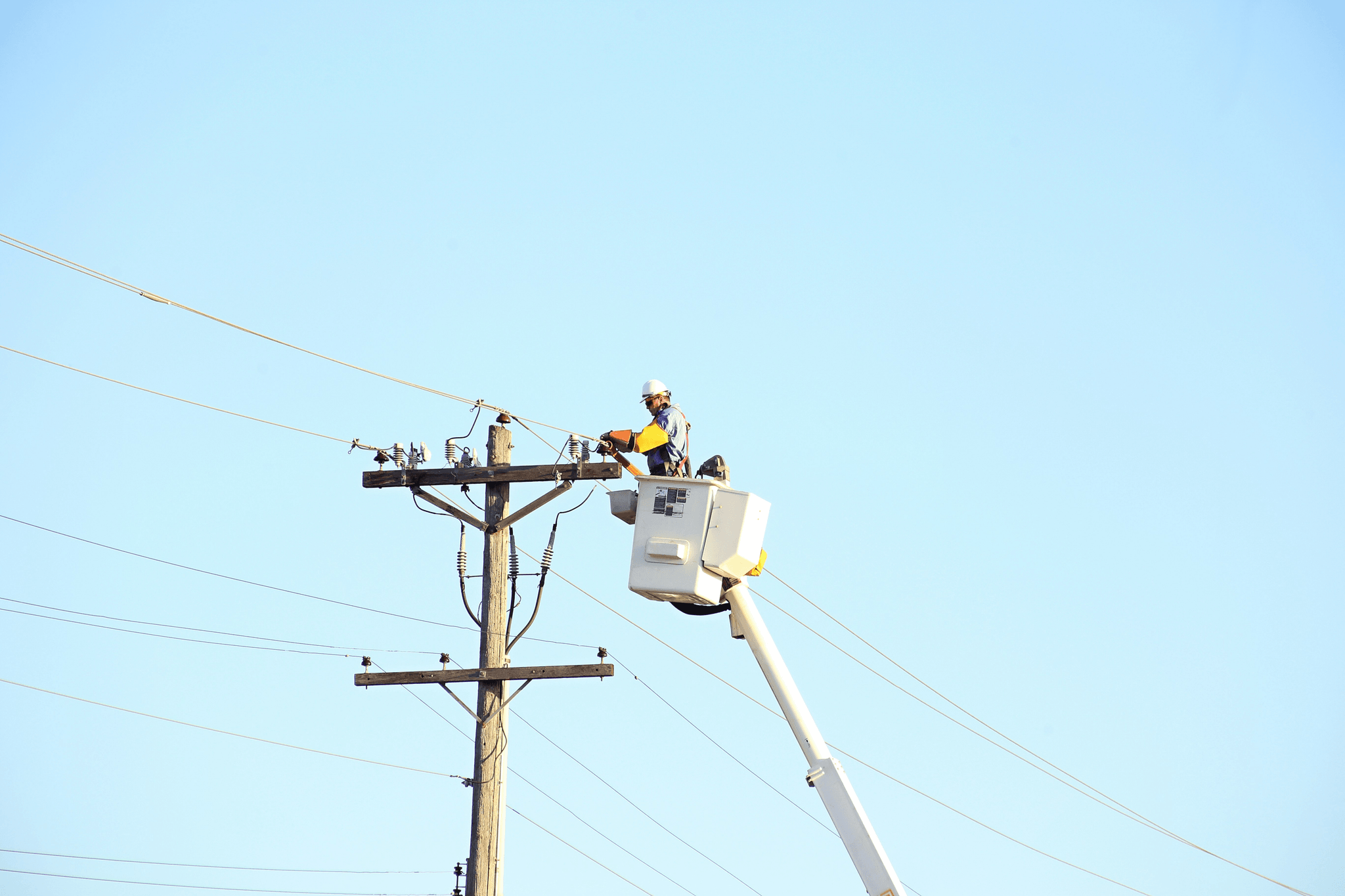

Hotline clamps find their applications across various sectors including electrical distribution systems, railway electrification projects, and routine maintenance tasks on power lines. They enable technicians to perform necessary repairs without taking down entire systems or shutting off power—a significant advantage in today’s fast-paced energy landscape. From utility companies to railway operators, understanding how these clampers tools function can streamline operations and improve overall service delivery.

Understanding Hotline Clamps

Hotline clamps are essential tools in the electrical industry, designed to connect and support live wires safely. These clamp tools allow technicians to perform maintenance and repairs on power lines without shutting down the system, which is crucial for maintaining uninterrupted service. By understanding hotline clamps, users can make informed decisions about their applications and benefits.

What Are Hotline Clamps?

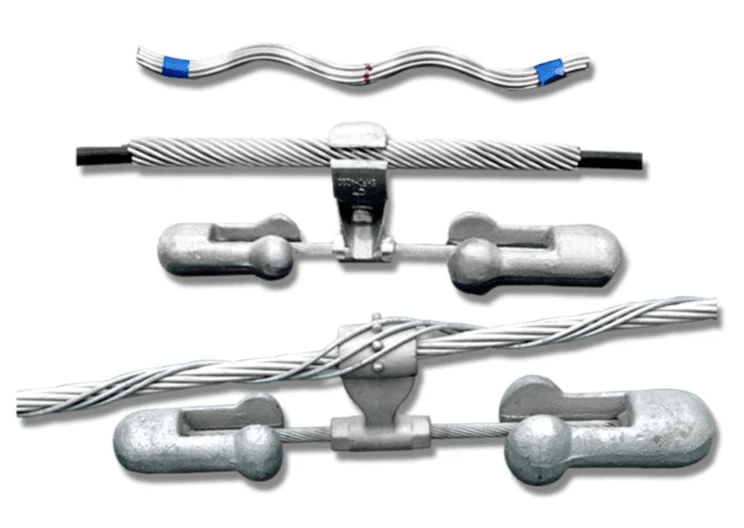

Hotline clamps are specialized devices used to grip electrical conductors securely while they remain energized. Typically made from durable materials, these clamps ensure a reliable connection that can withstand high voltage and environmental conditions. In essence, hotline clamps serve as a bridge between safety and functionality in electrical maintenance.

Key Features of Hotline Clamps

When selecting a hotline clamp, several key features should be considered to ensure optimal performance. First, the grip strength of the clamp is vital; it must hold conductors firmly without slipping or damaging them. Additionally, long clamps may offer extended reach for hard-to-access areas while ensuring that line clamps maintain their integrity under stress.

How Hotline Clamps Work

The operation of hotline clamps involves a simple yet effective mechanism that allows them to function safely around live wires. These clampers tool utilize a combination of pressure and design to secure themselves onto conductors without interrupting the flow of electricity. When applied correctly, these tools enable technicians to work efficiently on power lines while minimizing risks associated with electric shock or equipment failure.

Popular Applications of Hotline Clamps

Hotline clamps are versatile tools that play a crucial role in various sectors, especially where electrical systems are involved. Their ability to securely connect and support live electrical lines makes them indispensable in the industry. Let’s explore some of the most popular applications for these essential clamp tools.

Use in Electrical Distribution Systems

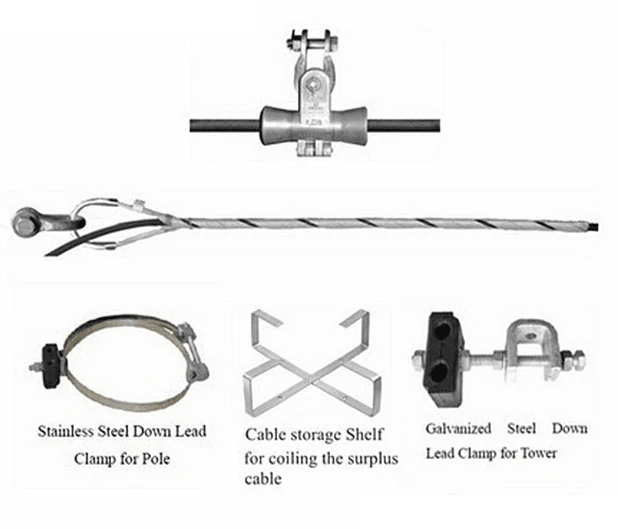

In electrical distribution systems, hotline clamps are vital for maintaining reliable connections between power lines and distribution networks. These clamps ensure that electricity flows smoothly while keeping safety at the forefront by allowing technicians to work on live wires without interrupting service. The use of long clamps helps accommodate different wire sizes and configurations, enhancing flexibility during installations or repairs.

Moreover, the design of hotline clamps allows for quick attachment and detachment, making them ideal for dynamic environments where speed is crucial. Whether you’re dealing with overhead lines or underground cabling, line clamps provide the necessary support to keep operations running efficiently. With their robust construction, these clampers tool can withstand harsh weather conditions and heavy loads typical in electrical distribution systems.

Role in Maintenance of Power Lines

Technicians often rely on clamp pliers to secure connections while performing inspections or repairs on energized lines. This capability allows maintenance crews to address issues without de-energizing sections of the grid, thus minimizing downtime and improving service reliability.

Additionally, using hotline clamps reduces the risk associated with working near live wires by providing a stable grip on cables during maintenance tasks. This ensures safety for workers while they perform their duties high above ground or in challenging environments. The durability of these long clamps means they can handle repeated use over time without compromising performance or safety standards.

Significance in Railways and Electrification

Hotline clamps also find significant applications within railways and electrification projects where overhead catenary systems are utilized. These line clamps help secure contact wires that supply power to trains while ensuring safe operation even under high voltage conditions. By providing reliable connections between various components of the electrification system, hotline clamps contribute directly to operational efficiency.

Moreover, when installing new railway electrification infrastructure, using clamp tools simplifies the process by allowing quick adjustments as needed during setup or modifications later on. The ability to easily attach or detach components saves valuable time during installation phases where precision is critical—after all, every second counts when it comes to transport! In this context, choosing the right clampers tool is paramount for successful project execution.

The Best Materials for Hotline Clamps

Common Materials Used in Clamp Manufacturing

Hotline clamps are typically made from a variety of materials including aluminum, copper, and stainless steel. Aluminum is lightweight yet strong, making it an excellent choice for long clamps that require easy handling without sacrificing durability. Copper is highly conductive, often used in electrical applications where efficient power transfer is essential, while stainless steel offers superior corrosion resistance and strength for harsh environments.

In addition to these metals, some manufacturers incorporate polymer composites into their designs to enhance insulation properties and reduce weight further. These composite materials can be particularly beneficial when working with live wires or in wet conditions where electrical safety is paramount. Ultimately, the choice of material will depend on the specific requirements of your application and environment.

Comparing Durability and Performance

When comparing durability and performance among different materials for hotline clamps, it's essential to consider factors such as tensile strength, resistance to environmental stressors, and conductivity. For instance, aluminum clamps may be more prone to wear over time compared to stainless steel options but offer significant advantages in weight reduction that can enhance ease of use with clamp pliers or other clamp tools.

Stainless steel clamps excel in environments exposed to moisture or chemicals due to their rust-resistant properties; however, they may be less conductive than copper alternatives when it comes to electrical applications like line clamps. Each material has its strengths and weaknesses; thus understanding these nuances helps ensure you select the right clampers tool for your specific task.

Choosing the Right Material for Your Needs

Selecting the right material for your hotline clamp involves assessing both your application requirements and environmental conditions you'll face during use. If you're working primarily with high-voltage lines where conductivity is critical, opting for copper or aluminum would likely serve you best due to their excellent electrical properties. On the other hand, if corrosion resistance is a priority—say you're near saltwater or chemical exposure—stainless steel long clamps might be your go-to option.

Moreover, consider how often you'll need to maneuver these tools; lighter materials like aluminum could make repetitive tasks less strenuous on your body while still providing adequate support during operations involving heavy-duty line clamps or maintenance work on power lines. Ultimately, weighing these factors will guide you toward making a smart investment that pays off over time in terms of performance and reliability.

Selecting the Right Hotline Clamp

Choosing the right hotline clamp is crucial for ensuring safety and efficiency in electrical work. With so many varieties of clamps available, it’s easy to feel overwhelmed by options that might not be suitable for your needs. By considering certain factors, measuring properly, and avoiding common pitfalls, you can make an informed decision that enhances your operations.

Factors to Consider for Clamp Selection

When selecting a hotline clamp, several factors come into play that can significantly impact performance. First off, consider the current rating; different clamps are designed to handle varying levels of electrical load, so matching this with your specific requirements is essential. Additionally, think about the size and type of line you’ll be working with—long clamps may be necessary for larger cables or specific applications in power distribution.

Another critical factor is the environment where the clamp will be used; if you’re working in harsh weather conditions or corrosive environments, opt for materials that resist wear and tear. The ease of use is also important; some clamp tools are designed for quick application while others may require more effort. Lastly, don’t forget about compliance with industry standards—ensuring your chosen clamp meets safety regulations can save you from future headaches.

How to Measure for Proper Fit

Measuring correctly ensures that your hotline clamp fits snugly without causing damage to the line or compromising performance. Start by measuring the diameter of the cable; this measurement will guide you toward selecting a clamp that accommodates it well without being too loose or overly tight. Use a caliper or a measuring tape specifically designed for wires to get an accurate reading.

Once you've got your diameter measurement down pat, consider how much surface area contact is required between your line clamps and cable insulation—this affects conductivity and heat dissipation during operation. Remember also to account for any additional thickness due to insulation layers when making your measurements. Proper fit isn’t just about size; it's about achieving optimal functionality while minimizing risks during installation.

Common Mistakes to Avoid

Even seasoned professionals can stumble when selecting hotline clamps if they aren’t careful! One common mistake is assuming all clamps are created equal; different models serve various purposes based on material composition and design features like grip strength and load capacity—always double-check specifications before purchasing!

Another misstep involves neglecting environmental factors; using standard clamps in extreme weather conditions could lead them to fail when you need them most—opt for specialized long clamps if needed! Lastly, don’t overlook maintenance requirements; some clampers tools require regular checks and upkeep while others offer low-maintenance solutions suitable for busy environments.

Top Manufacturers of Hotline Clamps

Spotlight on Spark Fittings

Spark Fittings has established itself as a leader in the hotline clamp industry, known for its innovative designs and high-quality products. Their line clamps are engineered to withstand harsh conditions while maintaining excellent conductivity and safety standards. With a focus on durability and ease of use, their clamp plier options are particularly popular among professionals who require reliable tools for maintenance tasks.

One standout feature of Spark Fittings is their commitment to customer satisfaction; they provide extensive support and resources for users navigating the selection process. Their long clamps are especially favored in electrical distribution systems where robust performance is essential. If you’re looking for a dependable hotline clamp solution, Spark Fittings should be at the top of your list.

Other Notable Brands in the Industry

While Spark Fittings shines brightly in the world of hotline clamps, several other brands deserve mention as well. Companies like Thomas & Betts and 3M have made significant contributions to the industry with their own unique offerings in clamp tools and accessories. These manufacturers have developed specialized line clamps that cater to various sectors such as railways, power lines maintenance, and more.

Moreover, brands like Panduit focus on creating innovative solutions that enhance efficiency during installation or repairs involving long clamps or other types of clampers tool. Each brand brings its strengths to the table—whether it's cutting-edge technology or user-friendly designs—making it essential to explore multiple options before making a decision.

Evaluating Manufacturer Reputation

Choosing the right manufacturer goes beyond just looking at product specifications; evaluating their reputation is equally important when selecting hotline clamps or any related equipment. Start by checking customer reviews and testimonials; real-world experiences can provide valuable insights into product reliability and performance over time. Additionally, consider how long a company has been in business—established companies often have proven track records that can instill confidence.

Another factor worth investigating is whether manufacturers adhere to industry standards and certifications; this ensures that their products meet safety regulations necessary for effective operation in demanding environments. Engaging with professional forums or networks can also yield recommendations from experienced users who understand which clamp tools perform best under specific conditions. Ultimately, taking these steps will help you make an informed choice when selecting your next set of hotline clamps.

Conclusion

In wrapping up our exploration of hotline clamps, it's essential to highlight their key features that make them indispensable in various applications. These clamp tools are designed for safety and efficiency, ensuring reliable connections during electrical work. With a variety of line clamps available, selecting the right clamp plier can significantly impact your project's success.

Recap of Key Hotline Clamp Features

Hotline clamps come equipped with several standout features that enhance their usability and effectiveness. They are crafted from durable materials, ensuring they withstand harsh environmental conditions while maintaining optimal performance. Additionally, long clamps often provide superior grip and stability, making them ideal for high-voltage applications where safety is paramount.

Long-Term Benefits of Proper Selection

Choosing the right hotline clamp has lasting benefits that extend beyond immediate use; it can save time and money in the long run. A well-selected clamp tool minimizes the risk of equipment failure or accidents during maintenance tasks on power lines or railways. Furthermore, investing in quality clamps long ensures longevity and reliability, reducing the need for frequent replacements or repairs.

Next Steps for Implementing Hotline Clamps

To effectively implement hotline clamps into your operations, start by assessing your specific needs based on the application at hand. Measure carefully to ensure a proper fit when selecting your clampers tool; this will help avoid common mistakes that could lead to inefficiencies or hazards. Finally, consider reaching out to reputable manufacturers like Spark Fittings to explore options tailored to your requirements.