Introduction

Choosing the right insulator isn't just a matter of preference; it can significantly affect performance and safety. The function of the insulator goes beyond mere support; it acts as a barrier against electrical hazards while also withstanding environmental conditions. This makes knowing what is the function of the insulator essential for effective transmission line management.

To navigate this complex landscape, it's important to familiarize oneself with the types of insulators available. There are 3 types of insulators—pin, suspension, and strain—that cater to different needs within transmission lines. Each type offers unique advantages and applications, which we'll explore further as we delve into their specific roles in enhancing electrical safety and performance.

Understanding Insulators in Transmission Line

When it comes to the infrastructure of electrical transmission, insulators play a pivotal role. They are essential components that help maintain the integrity and safety of transmission lines. But what exactly are the insulators used in transmission lines, and how do they function?

What are the insulators used in transmission lines?

Insulators in transmission lines are materials designed to prevent unwanted flow of electricity from conductors to other structures or the ground. The most common types of insulators include porcelain, glass, and composite materials, each serving specific needs based on environmental conditions and voltage levels. These three types of insulators have been widely adopted due to their durability and effectiveness in various climates.

What is the function of the insulator?

The primary function of an insulator is to provide electrical isolation between conductive parts and their surroundings, ensuring that electricity travels safely along its intended path. Insulators support power lines while preventing short circuits or electrical faults that could lead to outages or hazards. By maintaining this separation, they also minimize energy loss during transmission, enhancing overall system efficiency.

How do insulators protect against electrical hazards?

Insulators protect against electrical hazards by acting as barriers that prevent accidental contact with live wires or conductive surfaces. This protective feature is crucial for personnel safety as well as for safeguarding equipment from damage due to surges or faults in the system. Additionally, effective insulation helps reduce risks related to weather conditions such as lightning strikes or heavy winds, which can exacerbate potential dangers associated with high-voltage systems.

Types of Insulators and Their Applications

When it comes to insulators in transmission lines, understanding the various types is crucial for ensuring safe and efficient electrical distribution. There are three primary types of insulators: pin insulators, suspension insulators, and strain insulators. Each type serves a specific purpose and is designed to meet different transmission needs.

Overview of the 3 types of insulators

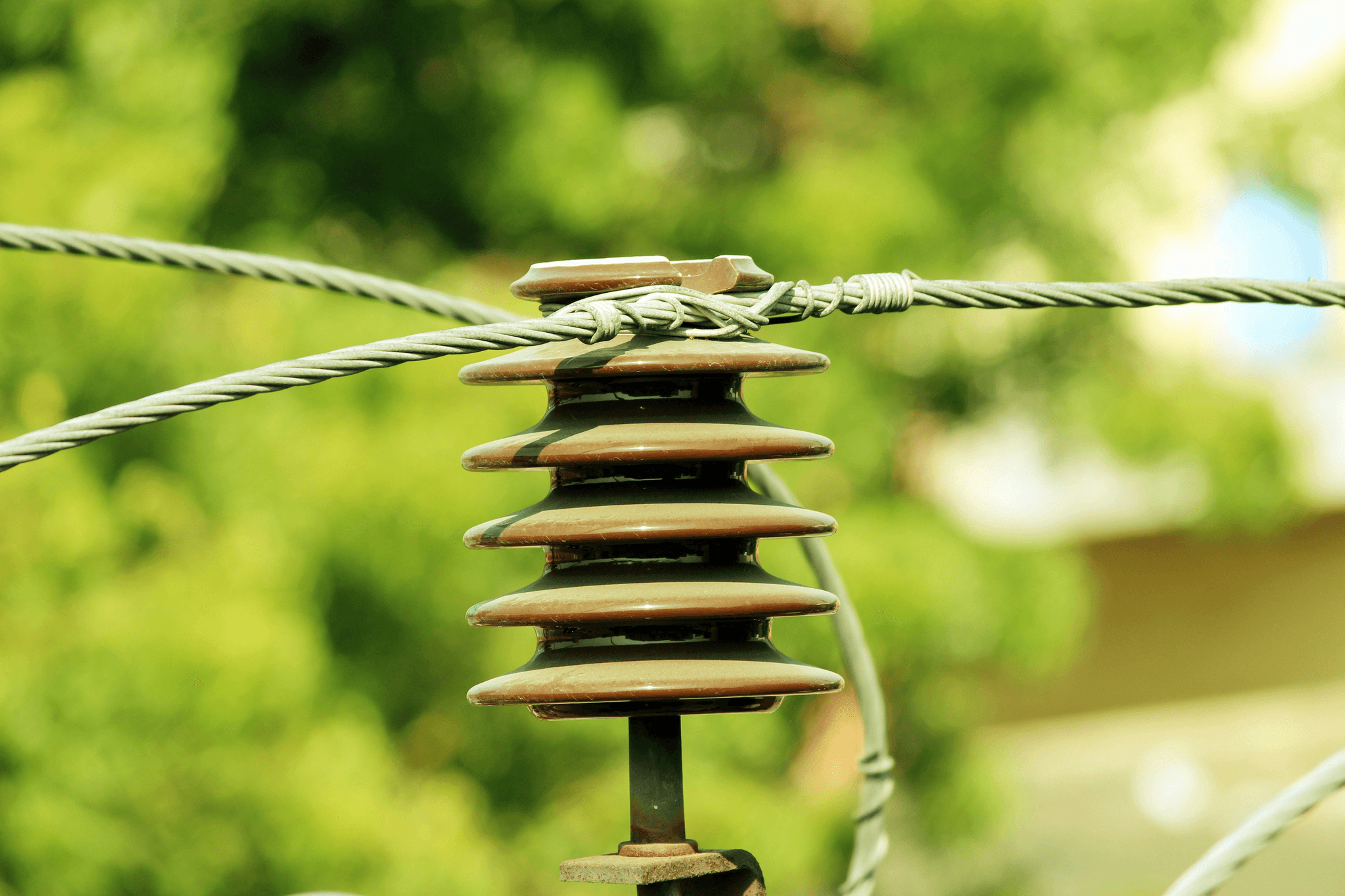

What are the insulators used in transmission lines? The answer lies in their design and application. Pin insulators are typically mounted directly on poles, holding conductors in place; suspension insulators hang from towers to support long spans between poles; while strain insulators are utilized where tension is required, such as at the ends of transmission lines or at angles. Each type plays a vital role in maintaining the integrity of electrical systems.

Differences between pin, suspension, and strain insulators

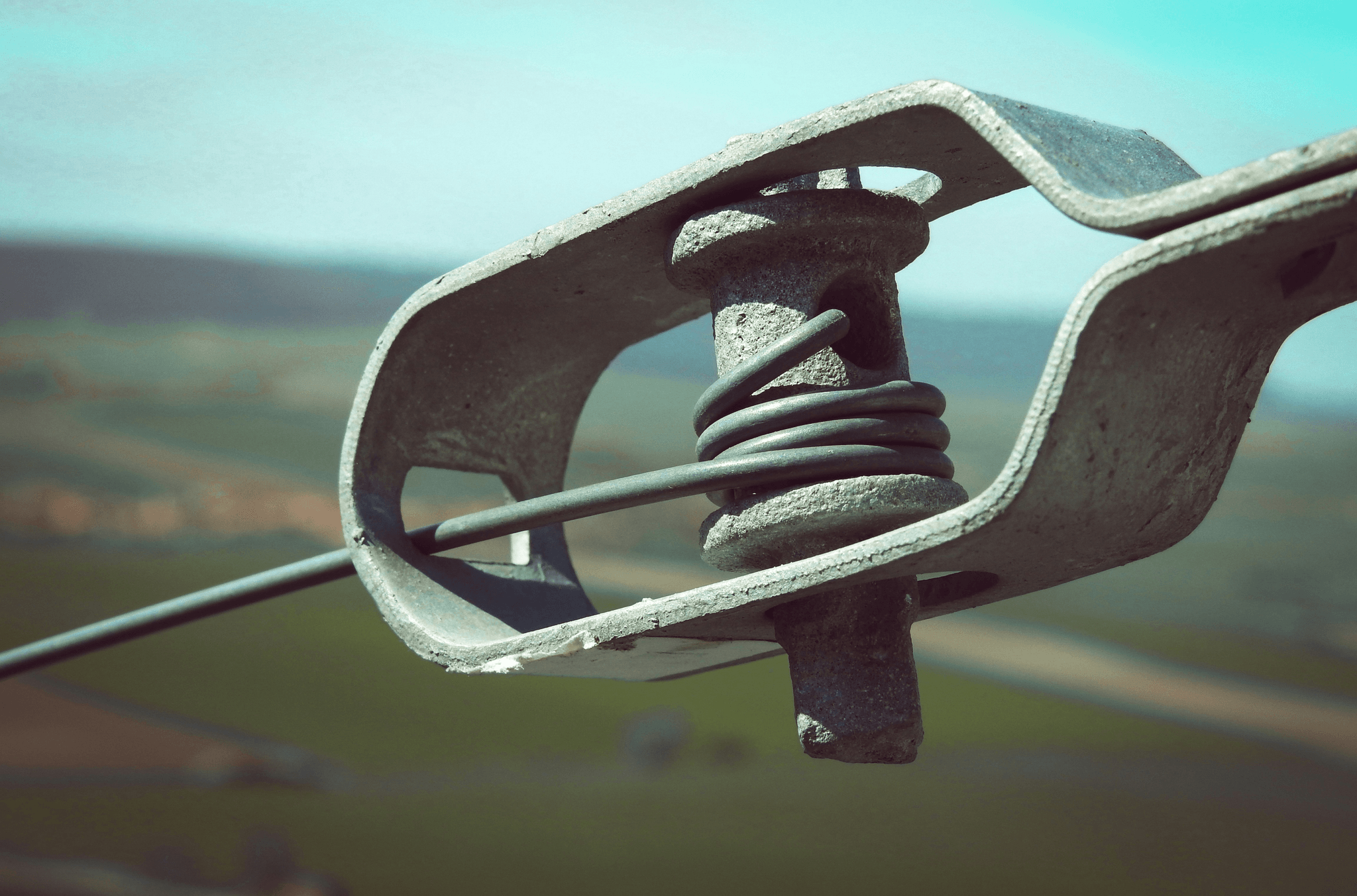

Now that we know about the 3 types of insulators, let’s dive into their differences. Pin insulators are generally more compact and suited for lower voltage applications; they connect directly to a pole with a single point attachment. In contrast, suspension insulators consist of multiple units connected together to form a longer chain, allowing them to bear heavier loads over longer distances. Strain insulators come into play when there's significant tension on the line—think of them as heavy-duty support structures that prevent sagging or breaking under stress.

Choosing the right type for various transmission needs

Choosing the right type for various transmission needs can be daunting but essential for optimal performance. Factors such as voltage levels, environmental conditions, and installation locations all influence which type of insulator is most suitable. For instance, if you're working with high-voltage lines across vast distances or rugged terrain, suspension or strain insulators may be your best bet due to their load-bearing capabilities while pin insulators could suffice for shorter spans or lower voltages.

Historical Context of Insulators

Understanding the historical context of insulators in transmission lines provides valuable insights into their development and significance. Initially, insulators were crucial for preventing electrical leakage and ensuring safety in early electrical systems. Their evolution reflects advancements in materials and technology, showcasing how these components have adapted to meet the growing demands of modern energy distribution.

What were insulators used for in the past?

In the early days of electricity, insulators were primarily used to support overhead wires and prevent short circuits by keeping conductors separated from each other and from supporting structures. What were insulators used for? They played a pivotal role in maintaining the integrity of electrical systems, allowing for safer transmission of power over long distances. As technology advanced, these essential components became more sophisticated, paving the way for reliable electricity distribution.

Evolution of insulators from porcelain to composite materials

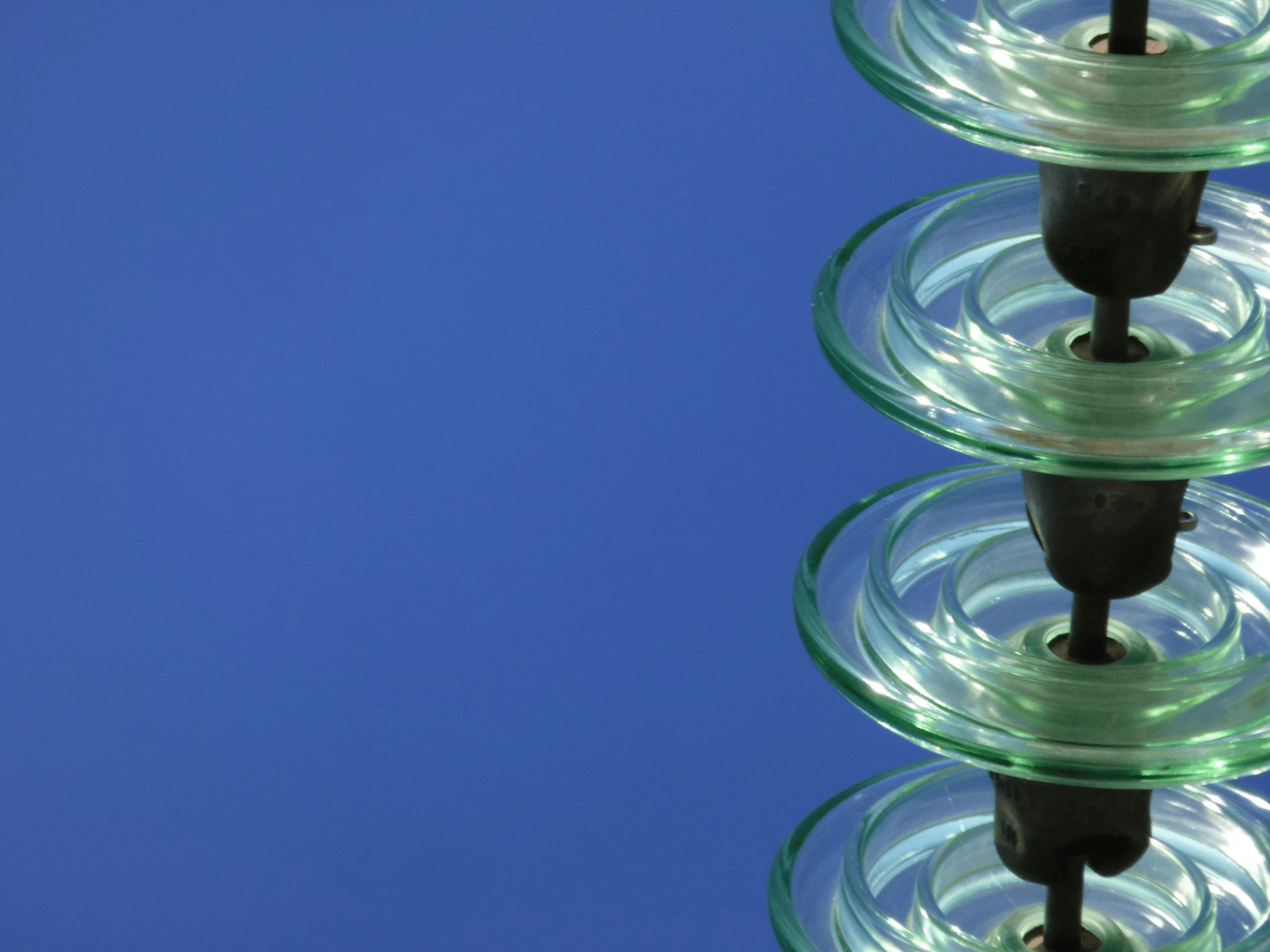

The journey from traditional porcelain to modern composite materials has transformed how we view insulators in transmission lines. Initially made from ceramics like porcelain, these insulators offered durability but had limitations regarding weight and susceptibility to breakage under stress or extreme weather conditions. The introduction of composite materials has revolutionized their design—lighter, more resilient, and better suited for various environmental challenges—showing that innovation can significantly enhance functionality while addressing previous shortcomings.

Key milestones in insulator technology

Several key milestones mark the evolution of types of insulators throughout history. The first major breakthrough came with the development of glass insulators in the late 19th century, which provided improved visibility and resistance to environmental factors compared to their ceramic counterparts. Later innovations included silicone rubber coatings that enhance performance against pollution and moisture—demonstrating that advancements in material science have been crucial for optimizing types of insulators used today.

Insulators and Conductors: A Dynamic Duo

When it comes to transmission lines, insulators and conductors work hand in hand like peanut butter and jelly. Insulators in transmission lines serve as the crucial barrier that keeps electrical energy flowing safely along the conductors while preventing unwanted leakage or short circuits. Understanding what are the insulators used in transmission lines is essential for anyone involved in electrical engineering or infrastructure development, as their interaction directly impacts performance and safety.

Exploring the interaction between insulators and conductors

The relationship between insulators and conductors is a fascinating dance of electricity, where each partner plays a vital role. Insulators are designed to withstand high voltages while ensuring that the current flows through the conductors without interruption or loss of energy. This synergy allows for efficient power distribution across vast distances, which is particularly important when considering what is the function of the insulator in maintaining system integrity.

Moreover, this interaction helps mitigate risks associated with electrical hazards by providing a physical barrier that prevents accidental contact with live wires. Without effective insulation, even minor environmental factors like moisture or pollution could lead to significant power outages or safety incidents. Thus, recognizing how types of insulators interact with conductors can help engineers design safer and more reliable transmission systems.

How insulators facilitate better electrical performance

Insulators play a pivotal role in enhancing electrical performance by minimizing energy loss during transmission. By preventing leakage currents, they ensure that nearly all of the generated electricity reaches its destination efficiently – an essential feature for modern power grids striving for sustainability and reliability. This efficiency also translates into cost savings over time since less energy wasted means lower operational expenses.

In addition to reducing losses, quality insulators improve system stability by providing consistent dielectric strength under varying environmental conditions such as temperature fluctuations and humidity levels. This adaptability is crucial when considering what are types of insulators best suited for specific applications within different geographical settings or climates. Ultimately, choosing appropriate insulator materials can significantly impact overall system performance.

Types of insulators and conductors used together

There are three main types of insulators commonly utilized in transmission lines: pin insulators, suspension insulators, and strain insulators – each tailored for specific roles within an electrical network. Pin insulators are typically employed on lower voltage lines where space constraints exist; meanwhile, suspension insulators cater to higher voltage applications by allowing longer spans between towers without compromising safety or functionality.

Strain insulators come into play where tension forces are at their peak—usually at dead ends or corners—ensuring that cables remain securely anchored despite external stresses such as wind loads or ice accumulation. Understanding these types of insulation options allows engineers to make informed decisions about which combinations will yield optimal results when paired with various conductor materials like aluminum or copper.

To wrap up this dynamic duo's exploration: knowing how different types of insulation work alongside conductors not only enhances operational efficiency but also bolsters safety measures across power distribution networks worldwide.

Innovations in Insulator Manufacturing

The world of insulators in transmission lines is undergoing a remarkable transformation, driven by technological advancements that enhance performance and safety. These innovations are not only improving the durability and effectiveness of insulators but also addressing the evolving demands of electrical infrastructure. As we delve into these advancements, it's essential to understand how they relate to the historical context and future potential of insulators.

Technological advancements in insulator production

Recent years have seen significant technological advancements in the production of insulators used in transmission lines. Modern manufacturing techniques, such as injection molding and advanced composite materials, have allowed for the creation of lighter yet stronger insulators that can withstand harsh environmental conditions. These improvements not only enhance the function of the insulator but also reduce maintenance costs and prolong service life, which is vital for ensuring reliable electricity delivery.

Moreover, automation and precision engineering have revolutionized how these components are produced. Enhanced quality control measures ensure that each piece meets stringent safety standards, thus reinforcing their role as protective barriers against electrical hazards. The integration of smart technologies into manufacturing processes is also paving the way for customized solutions tailored to specific applications within various types of insulators.

Spark Fittings and their role in the industry

Spark fittings play a pivotal role in enhancing the reliability of insulators used in transmission lines by providing secure connections between conductors and their supporting structures. These fittings are designed to minimize arcing—a common issue that can lead to electrical failures or outages—by ensuring a stable electrical connection under varying load conditions. By effectively managing this risk, spark fittings contribute significantly to overall system safety.

Furthermore, spark fittings come in various designs tailored for different types of insulators and applications within transmission networks. Their compatibility with pin, suspension, and strain insulators allows engineers to optimize performance based on specific requirements like voltage levels or environmental factors. As innovations continue to emerge within this niche area, spark fittings are becoming increasingly sophisticated, further solidifying their importance in maintaining efficient power distribution systems.

Future trends in insulator design and materials

Looking ahead, several key trends are shaping the future design and materials used for types of insulators found in transmission lines. One prominent direction is towards sustainable materials that reduce environmental impact while maintaining high performance standards; biodegradable composites may soon become a reality as manufacturers prioritize eco-friendly practices. This shift reflects growing awareness about climate change impacts on infrastructure resilience.

Additionally, advances in nanotechnology could lead to more efficient insulating properties at reduced weights—an exciting prospect for both overhead line construction and long-distance power transmission projects alike! With ongoing research focused on enhancing dielectric strength while minimizing bulkiness or fragility issues typical with traditional materials like porcelain or glass, we may see entirely new classes of high-performance insulators emerging soon.

As innovations continue apace across all facets related specifically to what are types of insulators?, it’s clear that staying informed about these developments will be essential for professionals involved with electrical systems management moving forward.

Conclusion

As we wrap up our exploration of insulators in transmission lines, it’s clear that these components play a pivotal role in ensuring the safe and efficient transmission of electricity. From understanding what are the insulators used in transmission lines to their various functions, it becomes evident that choosing the right type is crucial for any electrical infrastructure. With three main types of insulators—pin, suspension, and strain—each with its unique applications, there's plenty to consider when making decisions about your electrical systems.

Key Takeaways on Insulators in Transmission Lines

Insulators in transmission lines serve as a barrier between conductive materials and the environment, preventing unwanted electrical flow and ensuring safety. What is the function of the insulator? Primarily, they support conductors while isolating them from physical structures like poles or towers. Understanding what are types of insulators can help engineers optimize their designs for different environmental conditions and load requirements.

The Impact of Insulators on Electrical Safety

By effectively managing electrical stress, these components help mitigate risks associated with power surges or faults. Additionally, knowing what were insulators used for historically highlights their evolution into today's advanced materials that enhance safety standards across the industry.

Next Steps for Choosing Insulators Effectively

When selecting insulators for your project, consider factors like environmental conditions, mechanical stresses, and voltage levels to determine which types of insulators will best suit your needs. Familiarity with types of insulators and conductors can aid in creating a harmonious system where each component complements the other effectively. Lastly, keeping an eye on innovations in manufacturing will ensure you’re equipped with cutting-edge technology that maximizes performance while maintaining safety.