Introduction

In the world of telecommunications, OPGW (Optical Ground Wire) systems are crucial for ensuring reliable data transmission while also providing protection against lightning strikes. To achieve optimal performance, understanding the essentials of OPGW hardware is paramount. This includes familiarizing oneself with various fittings, such as the OPGW Tension Clamp and Preformed Dead End Fitting Clamp, which play significant roles in maintaining system integrity.

Understanding OPGW Hardware Essentials

OPGW hardware encompasses a range of components designed to support and protect the optical fibers within overhead power lines. These components must work together seamlessly to ensure that both mechanical stability and electrical conductivity are maintained. By grasping the fundamentals of OPGW hardware fittings, including their design and functionality, professionals can make informed decisions during installation and maintenance.

Importance of Proper Fitting Assemblies

Proper fitting assemblies are vital for the longevity and performance of OPGW systems. Incorrectly installed or unsuitable fittings can lead to premature failure, resulting in costly repairs and downtime. Utilizing the right components—like tension clamps or preformed dead end fittings—ensures that forces acting on the wire are properly managed, thereby enhancing overall system reliability.

Overview of OPGW Wire Size Chart

An essential tool for anyone working with OPGW systems is the OPGW wire size chart, which provides critical information about wire dimensions and specifications. This chart helps engineers determine appropriate wire sizes based on various factors such as tensile strength and environmental conditions. By referencing this chart when selecting components like tension clamps or dead end fittings, users can optimize their installations for safety and efficiency.

Introduction to OPGW Hardware

In the world of telecommunications and power distribution, Optical Ground Wire (OPGW) plays a pivotal role in ensuring efficient data transmission while simultaneously providing grounding for electrical systems. Understanding OPGW hardware is essential for any project involving this innovative technology. This section will delve into what OPGW is, its key components, and the vital role of spark fittings within these systems.

What is OPGW?

Optical Ground Wire (OPGW) is a dual-purpose cable that combines the functions of grounding and optical fiber communication. It typically consists of a central core made up of optical fibers surrounded by aluminum or steel wires that serve as both structural support and grounding elements. By integrating these functionalities, OPGW not only enhances communication capabilities but also protects electrical infrastructure from lightning strikes and other electrical surges.

Key Components of OPGW Systems

The effectiveness of an OPGW system relies on several key components working in harmony. These include the optical fibers themselves, which transmit data; the metallic outer layer that provides structural integrity; and various fittings that secure the cable to poles or towers, such as the OPGW Tension Clamp and Preformed Dead End Fitting Clamp. Each component plays a specific role in maintaining system reliability while ensuring optimal performance under varying environmental conditions.

Role of Spark Fittings in OPGW

Spark fittings are critical elements within an OPGW system designed to enhance safety and performance during installation and operation. These fittings ensure that connections are secure while facilitating proper grounding, which is especially important for preventing voltage surges from damaging sensitive equipment connected to the fiber optic lines. By utilizing spark fittings along with other essential components like the OPGW tension clamp, operators can maintain high-quality connections that withstand harsh weather conditions.

Types of OPGW Hardware Fittings

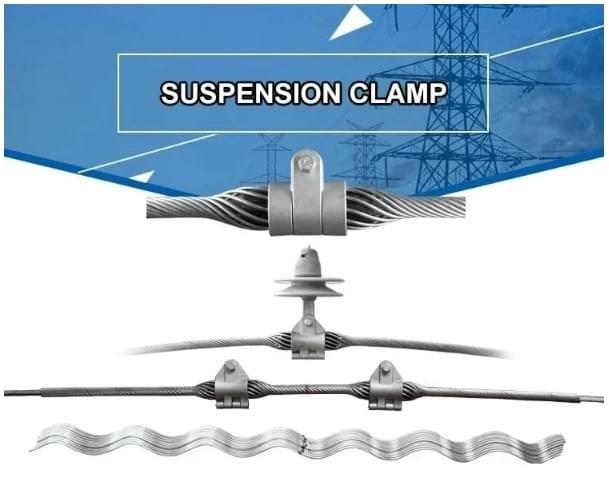

Overview of OPGW Hardware Fittings

OPGW hardware fittings are designed to secure and support optical ground wires in overhead power lines. These fittings include tension clamps, dead end clamps, and various connectors that facilitate effective installation and maintenance. The selection of appropriate fittings is often guided by factors such as the OPGW wire size chart, which helps determine compatibility based on wire specifications.

Choosing the right OPGW hardware fittings is essential for minimizing stress on cables while maximizing their lifespan. Properly fitted components prevent damage caused by environmental factors or mechanical loads, ensuring reliable communication and grounding capabilities. By consulting the OPGW wire size chart during selection, installers can ensure that they are using components suited to their specific applications.

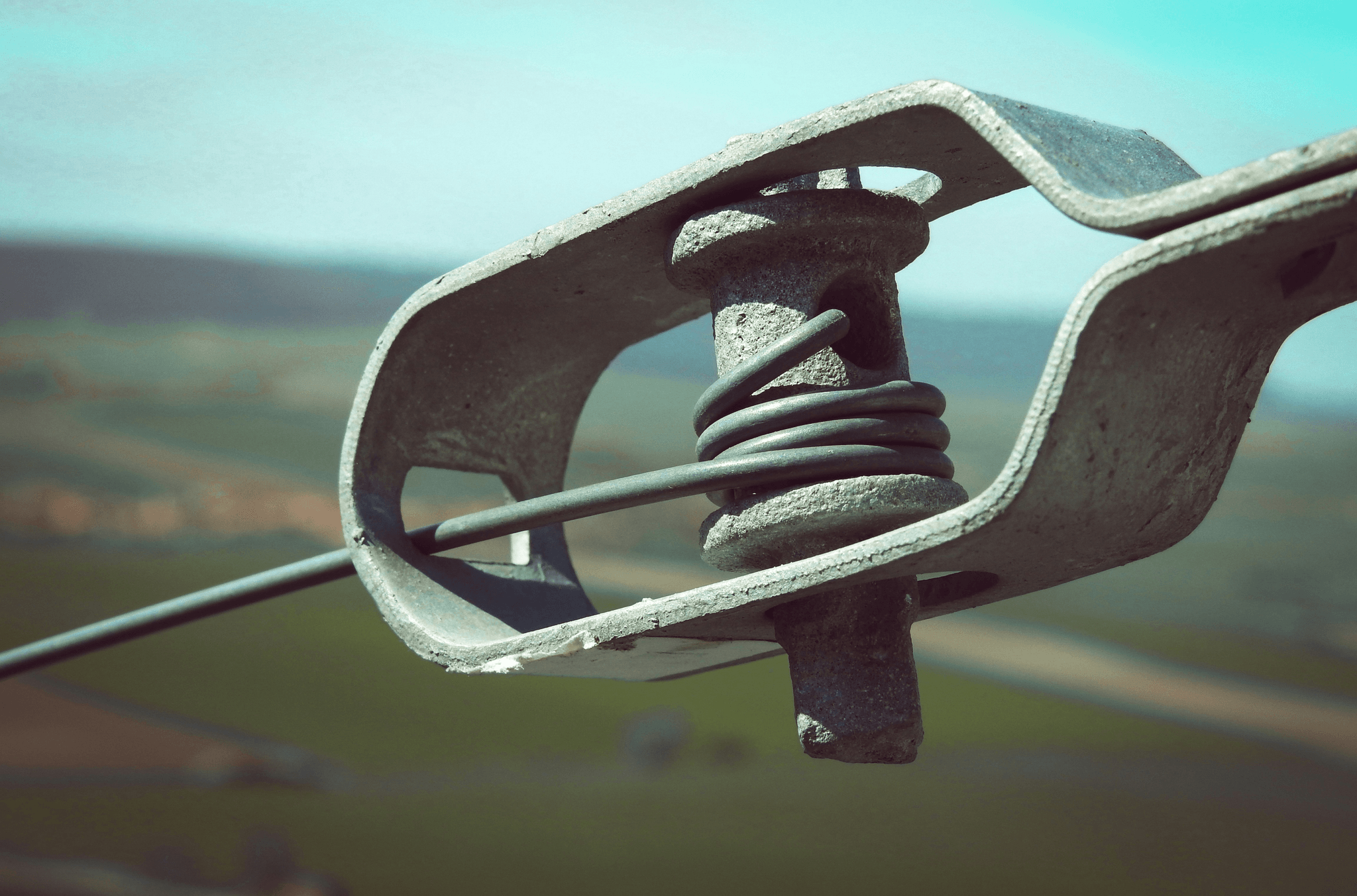

Spotlight on OPGW Tension Clamps

OPGW tension clamps are vital for maintaining proper tension in optical ground wires across spans between poles or towers. These clamps secure the wire while allowing for thermal expansion and contraction due to temperature fluctuations—an important factor in regions with extreme weather conditions. By utilizing tension clamps correctly, installers can significantly reduce the risk of sagging or snapping wires.

The choice of an appropriate OPGW tension clamp should align with both wire size and environmental considerations outlined in the OPGW wire size chart. This ensures that each clamp provides optimal grip without damaging the fiber optic elements within the cable itself. Additionally, these clamps come in various designs—such as wedge-type or bolt-type—to accommodate different installation scenarios.

Regular inspection and maintenance of tension clamps are also critical to ensure long-term reliability in any OPGW system. Over time, wear can occur due to weather exposure or mechanical stress; thus, keeping an eye on these components will help prevent unexpected failures down the line.

Significance of Preformed Dead End Fitting Clamps

Preformed dead end fitting clamps serve as essential components for terminating optical ground wires at poles or structures effectively. These specialized clamps distribute load evenly across a wider area than standard fittings, reducing localized stress points that could lead to cable failure over time. Their design allows for an easy installation process while ensuring a strong hold on high-tension lines.

In conjunction with utilizing an accurate OPGW wire size chart, selecting preformed dead end fitting clamps tailored to specific cable sizes ensures optimal performance under varying conditions—be it wind loads or ice accumulation during winter months. Such precision not only enhances safety but also contributes significantly to system longevity.

Moreover, preformed dead end fitting clamps are known for their resistance against corrosion and environmental degradation—factors that can severely impact traditional metal components over time. This resilience makes them a popular choice among utility companies looking for reliable solutions when installing new lines or upgrading existing infrastructure.

The Importance of the OPGW Wire Size Chart

This chart provides critical information that helps engineers and technicians determine the appropriate wire size for various applications, ensuring optimal performance and safety. Understanding how to read and utilize this chart can prevent costly mistakes and improve the longevity of your OPGW hardware fittings.

How to Use the OPGW Wire Size Chart

Using the OPGW wire size chart is straightforward, but it requires a bit of attention to detail. Start by identifying your specific application requirements, such as load capacity, environmental conditions, and installation height. Once you have these parameters in mind, locate the corresponding wire size on the chart that meets or exceeds these requirements—this will guide you in choosing the right OPGW tension clamp or preformed dead end fitting clamp for your project.

The beauty of this chart lies in its ability to simplify complex engineering decisions into easy-to-understand guidelines. It includes various factors such as tensile strength and weight that are crucial for selecting compatible fittings. By adhering to this guide, you ensure that your installation remains stable under different conditions while maximizing performance.

Factors Affecting Wire Size Selection

Several factors come into play when selecting wire size from the OPGW wire size chart, each influencing both safety and efficiency. First off, environmental conditions like wind load, ice accumulation, and temperature fluctuations can significantly affect wire tension and overall performance; thus requiring careful consideration during selection. Additionally, installation height plays a crucial role; higher installations often demand thicker wires due to increased tension from gravity.

Another key factor is electrical loading; higher electrical loads necessitate larger diameter wires to minimize resistance loss over long distances. The choice between different types of fittings—like OPGW tension clamps or preformed dead end fitting clamps—also hinges on selected wire sizes since compatibility ensures structural integrity throughout its lifespan. Failing to account for these factors can lead to premature wear or even catastrophic failures down the line.

Real-World Applications of Wire Size

The real-world applications of proper wire sizing using the OPGW wire size chart are vast and varied across industries—from telecommunications to power distribution networks. For instance, in telecommunications setups where high bandwidth is essential, using an appropriate wire size ensures minimal signal degradation over distance while allowing for necessary flexibility during installation with compatible hardware fittings like tension clamps or dead end clamps.

In power distribution networks where reliability is paramount, correctly sized wires help manage electrical loads effectively while minimizing risks associated with overheating or failure under extreme weather conditions—an all-too-common scenario if improper sizing occurs! Furthermore, industries focused on renewable energy sources benefit greatly from optimized designs that rely heavily on accurate sizing charts; they ensure efficient energy transmission across expansive distances without loss.

By understanding how crucial proper sizing is through real-world examples—and leveraging tools like the OPGW wire size chart—you’re not just ensuring compliance but also enhancing operational efficiency across diverse applications.

Installation Guidelines for OPGW Fittings

Installing OPGW fittings requires attention to detail and adherence to best practices to ensure optimal performance. Proper installation not only enhances the longevity of the system but also mitigates potential issues that could arise from improper fitting assemblies. By following a structured approach, you can confidently navigate the complexities of OPGW hardware fittings.

Step-by-Step Installation Process

The first step in the installation process is to consult the OPGW wire size chart, which provides essential information on selecting appropriate fittings based on wire dimensions. Begin by securing all necessary tools and materials, including OPGW tension clamps and preformed dead end fitting clamps, ensuring that everything is within reach. Next, carefully position the OPGW cable, making sure it aligns with your planned installation layout before proceeding with attaching fittings.

Once the cable is positioned correctly, install the tension clamps by sliding them onto the cable and tightening them according to manufacturer specifications—this ensures a secure grip without damaging the fiber optic core within the cable. After securing tension clamps, it's time to install preformed dead end fitting clamps; these are crucial for providing stability at termination points or where additional support is needed along spans. Finally, double-check all connections and fittings against your initial plan before conducting a final inspection of your work.

Common Installation Mistakes to Avoid

One common mistake during installation is neglecting to reference the OPGW wire size chart before selecting hardware fittings; this can lead to mismatched components that compromise system integrity. Another frequent error involves over-tightening tension clamps or preformed dead end fitting clamps; while it may seem like a good idea for security, excessive force can damage both cables and connectors alike. Additionally, failing to ensure proper alignment during installation can result in undue stress on cables over time.

It's also easy to overlook environmental factors such as temperature fluctuations or exposure to moisture when installing OPGW hardware fittings; these elements can significantly impact performance if not accounted for properly. Make sure you're working in conditions that comply with recommended guidelines and always verify that all components are rated for their intended environment—this includes checking compatibility with local weather conditions! Lastly, always remember that patience pays off; rushing through installations often leads to mistakes that could have easily been avoided.

Ensuring Longevity of OPGW Assemblies

To maximize longevity in your OPGW assemblies, regular maintenance checks are essential after initial installation—this includes inspecting all fittings for signs of wear or corrosion over time. Utilizing quality materials such as high-grade aluminum or stainless steel for your tension clamps and preformed dead end fitting clamps will greatly enhance durability against environmental stresses while ensuring compatibility with various wire sizes from your chosen opgw wire size chart. Additionally, applying protective coatings where necessary can further shield against elements like UV radiation and moisture ingress.

Another important factor in prolonging assembly life is adhering strictly to manufacturer guidelines during both installation and maintenance processes; this ensures you’re using each component as intended without risking premature failure due to misuse or misapplication of products designed specifically for certain types of cables or environments! Furthermore, keeping an organized inventory of spare parts allows quick replacements when needed without compromising overall system functionality during outages caused by unexpected failures.

Lastly, fostering an environment where ongoing training regarding best practices around handling OPGW hardware fittings becomes standard practice among team members will also contribute significantly towards achieving long-lasting assembly installations! By emphasizing careful handling techniques alongside diligent monitoring schedules post-installation phases—your systems will thrive well into their operational lifespan!

Testing and Quality Assurance for OPGW Hardware

The stakes are high, as any failure in OPGW systems can lead to significant operational disruptions and costly repairs. Ensuring that every component, from the OPGW tension clamp to the preformed dead end fitting clamp, meets stringent standards is essential for maintaining system integrity.

Importance of Rigorous Testing

Rigorous testing serves as a critical line of defense against potential failures in OPGW hardware fittings. Each component must undergo various stress tests to simulate real-world conditions, ensuring they can withstand environmental factors like wind, ice, and temperature fluctuations. This level of scrutiny helps identify weaknesses before they become issues in the field, safeguarding both infrastructure and investment.

Moreover, consistent testing reinforces compliance with industry regulations and standards, which are designed to protect both utility providers and consumers alike. By adhering to these protocols, manufacturers can assure clients that their products will perform as expected over time. In essence, rigorous testing is not just about passing; it’s about delivering peace of mind.

Quality Standards in OPGW Production

Quality standards play an indispensable role in the production of OPGW hardware fittings. These standards ensure that each component—whether it be an OPGW tension clamp or a preformed dead end fitting clamp—is manufactured under strict guidelines that dictate material quality and performance benchmarks. Adhering to such standards minimizes variability in product performance across different batches.

Manufacturers often align their processes with international quality certifications such as ISO 9001 or specific industry guidelines tailored for electrical components. This alignment not only boosts consumer confidence but also paves the way for smoother regulatory approvals during installation projects. Ultimately, high-quality production leads to long-lasting installations that require less maintenance over time.

Role of Spark Fittings in Quality Assurance

Spark fittings are pivotal when it comes to quality assurance within the realm of OPGW systems. These specialized connectors are designed not only for optimal electrical conductivity but also for mechanical strength—ensuring that connections remain secure under various conditions encountered by overhead lines. Their inclusion in quality assurance measures elevates overall system reliability.

Additionally, spark fittings undergo their own set of rigorous tests before they can be deemed fit for use alongside components like tension clamps and dead-end fittings on the OPGW wire size chart. This ensures compatibility across different types of hardware while providing additional layers of protection against electrical faults or mechanical failures during operation. As such, spark fittings serve as a linchpin between quality assurance processes and effective operational performance.

Conclusion

In wrapping up our exploration of OPGW hardware, it's clear that understanding the nuances of these systems is crucial for anyone involved in installation and maintenance. From the vital role of the OPGW wire size chart to the significance of various fittings like the OPGW tension clamp and preformed dead end fitting clamp, every element plays a part in ensuring reliable performance. As we look to the future, staying informed about advancements in technology will help us adapt and improve our practices.

Key Takeaways on OPGW Hardware

OPGW hardware is not just a collection of components; it's an integrated system designed for optimal performance. The OPGW wire size chart serves as an essential tool for selecting appropriate wire sizes based on specific project requirements, ensuring safety and efficiency. Additionally, understanding fittings such as the OPGW tension clamp and preformed dead end fitting clamp can dramatically enhance installation quality and longevity.

Best Practices for Fitting Assemblies

When it comes to assembling fittings like those found in OPGW hardware, best practices are paramount. Always refer to the OPGW wire size chart before making selections to ensure compatibility with your specific cable type and project specifications. Furthermore, proper installation techniques should be employed with each fitting assembly—especially with critical components like the OPGW tension clamp—to avoid common pitfalls that could lead to premature wear or failure.

Future Trends in OPGW Technology

As technology evolves, so too does the landscape of OPGW hardware fittings. We can expect innovations that enhance both performance and ease of installation while maintaining robust standards outlined by industry guidelines. Moreover, advancements in materials used for items such as preformed dead end fitting clamps may lead to lighter yet stronger options that improve overall system efficiency.