Introduction

In the realm of modern telecommunications, OPGW hardware fittings play a pivotal role in ensuring the integrity and efficiency of fiber optic lines. These fittings are not merely accessories; they are essential components that support the structure and functionality of optical fiber optic systems. As demand for high-speed internet and reliable communication continues to surge, understanding the importance of these fittings becomes crucial for both manufacturers and users alike.

Importance of OPGW Hardware Fittings

OPGW hardware fittings serve as the backbone for any fiber optic installation, providing necessary support while safeguarding delicate fiber cable from environmental hazards. By effectively managing tension and strain on optical to optical cable systems, these fittings help maintain optimal performance over time. Their significance cannot be overstated; without robust hardware fittings, even the most advanced fiber optic technology could falter under pressure.

Overview of Fiber Optic Technology

Fiber optic technology has revolutionized data transmission by utilizing light to carry information through thin strands of glass or plastic known as optical fibers. This method allows for faster speeds and greater bandwidth compared to traditional copper wiring, making it a preferred choice for modern networks. As we delve deeper into this topic, it's essential to recognize how fiber optic fibers function within a broader infrastructure that includes OPGW hardware fittings.

Spark Fittings: A Quick Introduction

Among various solutions available in the market, Spark Fittings stands out with its innovative approach to OPGW hardware fittings tailored specifically for fiber optics applications. These products not only enhance the durability of installations but also offer customization options that cater to diverse project needs. With a commitment to quality assurance in manufacturing processes, Spark Fittings has established itself as a reliable partner in optimizing optical systems across industries.

Understanding OPGW Hardware Fittings

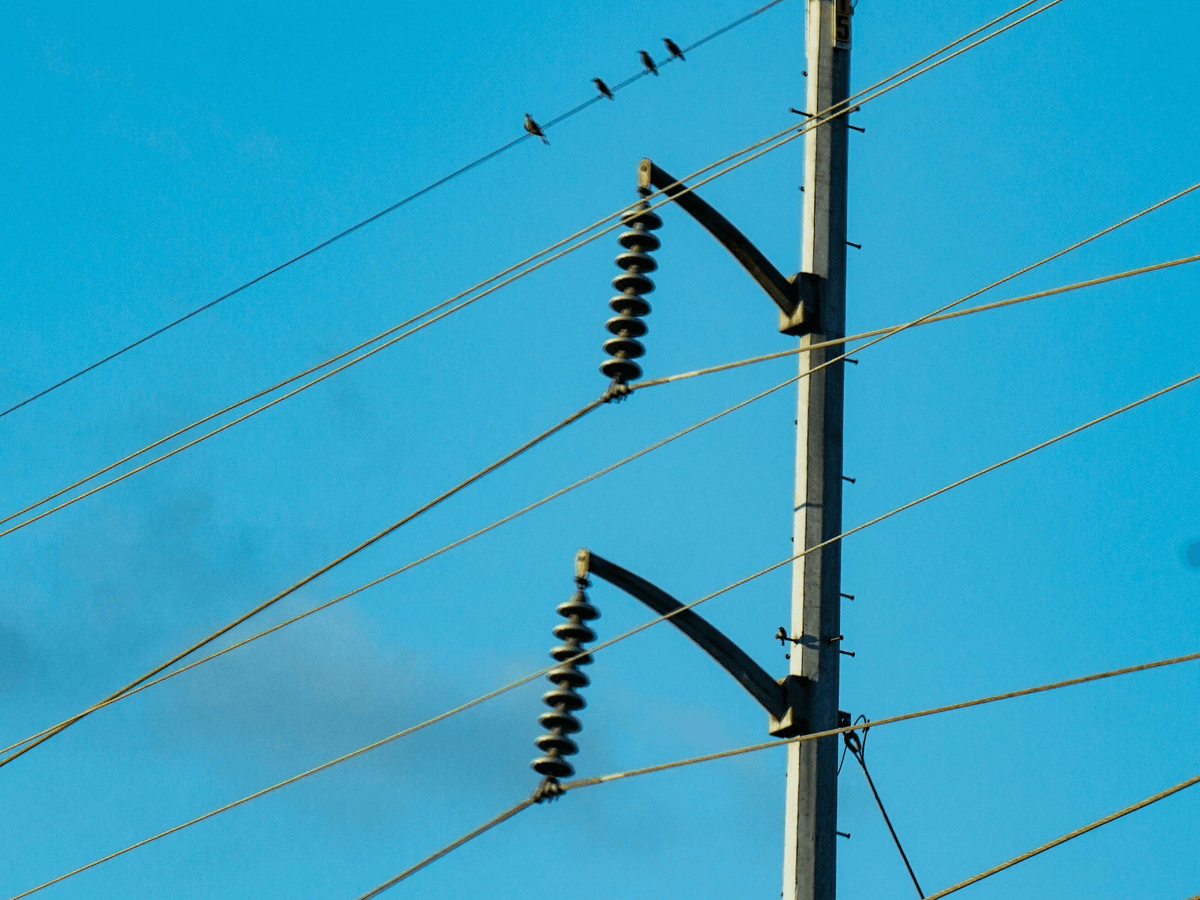

These fittings are specifically designed for Optical Ground Wire (OPGW) systems, which combine the functionalities of ground wire and optical fiber cables. By integrating these two technologies, OPGW provides not only protection against electrical surges but also facilitates high-speed data transmission through fiber optic fibers.

Definition and Functionality

OPGW hardware fittings refer to specialized components that support and protect optical fiber optic cables integrated within overhead power lines. Their primary functionality lies in securing the cable while allowing for flexibility during installation and maintenance. By using various fittings like tension clamps, suspension clamps, and splice closures, OPGW systems maintain optimal performance in both electrical grounding and data transmission.

Components of OPGW Systems

An OPGW system comprises several critical components that work together seamlessly to deliver reliable service. The main elements include the optical fiber optic cable itself, tension clamps for securing the cable to poles or towers, splice closures for protecting joints between fibers, and suspension clamps that help distribute weight evenly across the line. Each of these components is vital for ensuring that both the ground wire function and optical capabilities of the system operate without interruption.

Benefits of Using OPGW

Utilizing OPGW hardware fittings brings a plethora of benefits to telecommunications infrastructure. First off, they provide significant protection against environmental factors such as lightning strikes or wind-induced vibrations thanks to their dual-purpose design as both grounding wires and carriers for optical signals. Additionally, by incorporating fiber optic technology into existing power lines, companies can enhance their network capacity without needing extensive new installations—making it a cost-effective solution for modern communication needs.

Types of OPGW Hardware Fittings

When it comes to the world of fiber optic technology, understanding the various types of OPGW hardware fittings is crucial for ensuring a robust and efficient installation. These fittings are not just accessories; they play vital roles in supporting and protecting the fiber optic line, which is essential for maintaining high-performance optical communication. Let's dive into some key types of OPGW hardware fittings that every installer should be familiar with.

Tension Clamps and Their Uses

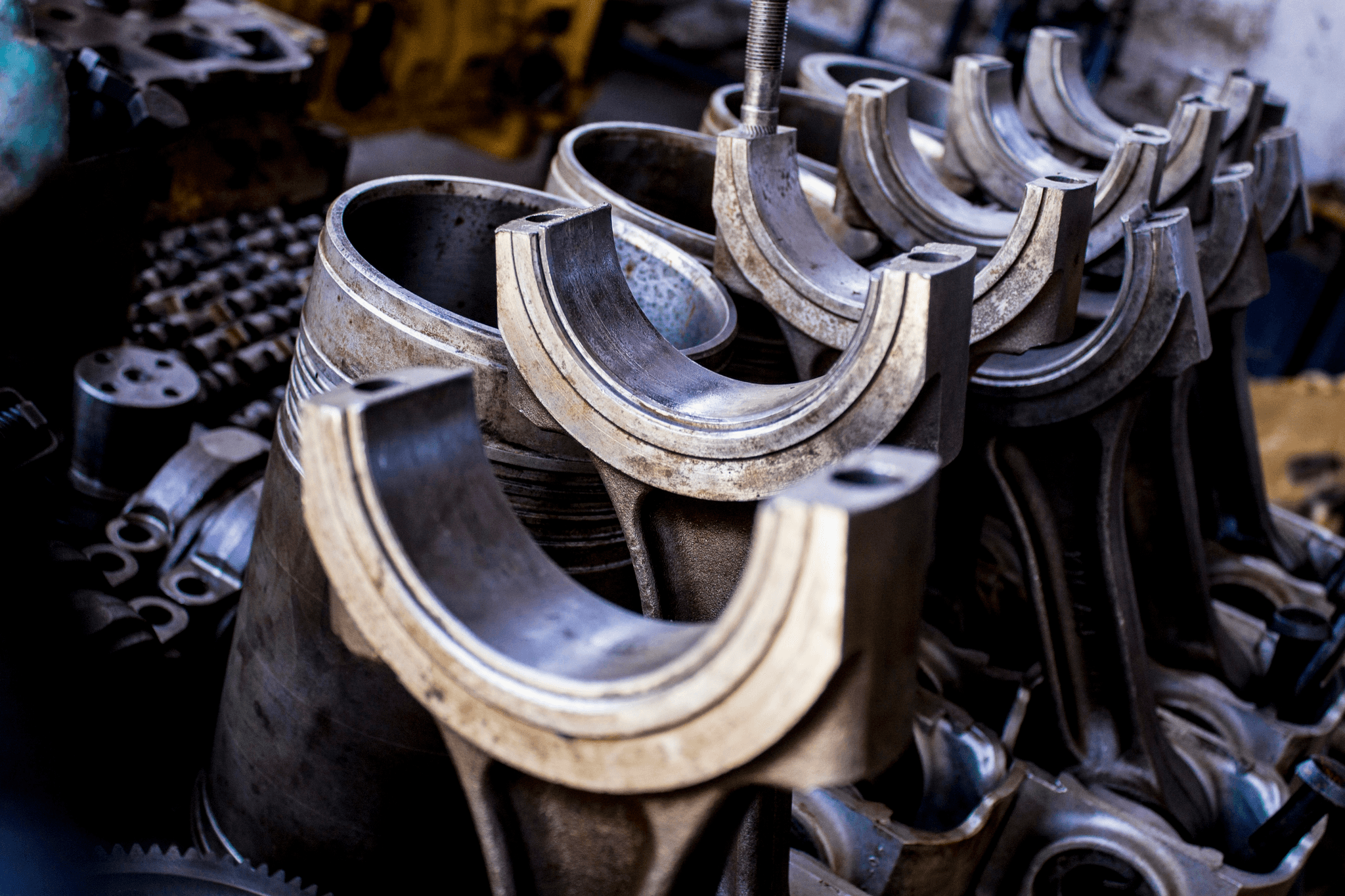

Tension clamps are indispensable components in any OPGW system, designed to secure the fiber optic cable under tension along its length. These clamps help maintain the integrity of the fiber optic fiber by preventing slippage and reducing stress on the cable during installation or adverse weather conditions. With their ability to withstand significant loads, tension clamps ensure that your optical to optical cable remains securely fastened, providing peace of mind for both installers and end-users.

In addition to their primary function of securing cables, tension clamps also play a role in managing ground wire connections effectively. Properly installed tension clamps can help prevent damage to both the fiber cable and associated ground wires during routine maintenance or unexpected environmental challenges. Thus, choosing the right type of tension clamp is crucial for optimizing performance across your entire OPGW system.

Splice Closures for Fiber Protection

Splice closures are another essential type of OPGW hardware fitting that serves as protective enclosures for spliced optical fibers within an overhead network. These closures safeguard critical connections from environmental factors such as moisture, dirt, and mechanical stress while enabling easy access for future maintenance or upgrades. By using splice closures specifically designed for fiber optic applications, you ensure that your optical fibers remain shielded from potential hazards throughout their operational lifespan.

The design of splice closures varies depending on specific application needs; some are made with features that allow them to accommodate multiple splices while others focus on single-fiber applications. Regardless of design specifics, all splice closures aim to maintain optimal performance levels by minimizing signal loss in every connection point along your fiber cable network. This attention to detail is what makes these fittings indispensable when working with sensitive optical components.

Suspension Clamps and Their Importance

Suspension clamps serve a unique purpose within an OPGW installation by supporting the weight of overhead cables while allowing them adequate space to expand or contract due to temperature fluctuations or other external factors. Proper use of suspension clamps helps maintain alignment between multiple strands in a bundled fiber optic line without causing undue strain on individual cables—critical when dealing with sensitive optical fibers where even minor misalignments can lead to signal degradation.

These fittings also contribute significantly towards enhancing overall system reliability by distributing weight evenly across multiple points along poles or towers where cables are anchored down securely using ground wires attached via suspension clamps themselves. By understanding how suspension clamps work together with other types of OPGW hardware fittings like tension clamps and splice closures, installers can create an integrated approach that maximizes both performance and longevity throughout their projects.

The Role of Spark Fittings

When it comes to OPGW hardware fittings, Spark Fittings stands out as a key player in the fiber optic industry. Their products are designed to enhance the performance and reliability of fiber optic lines, ensuring that optical to optical cable connections remain seamless and efficient. With a commitment to quality and innovation, Spark Fittings has carved a niche for itself in the realm of fiber cable solutions.

Overview of Spark Fittings Products

Spark Fittings offers a diverse range of products tailored specifically for OPGW systems. These include tension clamps, splice closures, and suspension clamps that cater to various needs within the fiber optic realm. Each product is meticulously designed to support the unique demands of installing and maintaining optical fiber optic networks while ensuring durability against environmental challenges.

Customization Options for Armor Rods

One standout feature of Spark Fittings is their extensive customization options for armor rods used in OPGW hardware fittings. Customers can select from different materials, sizes, and designs, allowing them to tailor solutions that fit their specific requirements perfectly. This level of customization not only enhances compatibility with existing ground wire setups but also optimizes performance across various installations.

Quality Assurance in Manufacturing

Quality assurance is at the forefront of Spark Fittings' manufacturing process for OPGW hardware fittings. Each product undergoes rigorous testing to ensure it meets high standards before it reaches customers' hands, providing peace of mind when integrating into fiber optic systems. By prioritizing quality control at every stage—from sourcing materials like aluminum or steel to final assembly—Spark ensures that its fittings can withstand the test of time in demanding environments.

Selecting the Right Armor Rod Material

When it comes to OPGW hardware fittings, the choice of armor rod material is crucial for the integrity and longevity of your fiber optic line. The right material not only ensures optimal performance but also affects the overall reliability of the optical fiber optic system. Understanding material compatibility can save you from costly repairs and downtime in the future.

Importance of Material Compatibility

Material compatibility is essential in OPGW hardware fittings because different materials react differently under various environmental conditions. For example, using a steel armor rod where aluminum is required can lead to corrosion issues, compromising the durability of your fiber cable. Ensuring that your armor rod matches the specifications for your optical to optical cable will enhance performance and extend lifespan.

Choosing Between Aluminum and Steel

When selecting between aluminum and steel for your armor rods, consider factors like weight, strength, and environmental exposure. Aluminum is lighter and resistant to corrosion, making it a popular choice for many fiber optic installations; however, steel offers superior strength and durability in harsher conditions. Ultimately, your decision should be based on specific project requirements and local environmental factors affecting your fiber optic system.

Understanding Color Codes for Identification

Color coding plays a vital role in identifying different types of armor rods used in OPGW hardware fittings. Each color corresponds to specific materials or properties that help technicians quickly determine compatibility with existing components in a fiber optic installation. Familiarizing yourself with these color codes can streamline maintenance processes and ensure that you are using the correct materials for your optical fiber systems.

Installation Best Practices for OPGW Fittings

When it comes to installing OPGW hardware fittings, preparation is key. A well-thought-out plan ensures that the installation of the fiber optic line goes smoothly, minimizing potential issues down the road. This stage involves assessing the site conditions, understanding the specific requirements of your optical fiber optic system, and gathering all necessary materials and tools.

Preparation and Planning

Before diving into installation, take time to map out your approach. Start by reviewing technical specifications for your fiber optic cable and OPGW hardware fittings; knowing these details helps in determining what components are needed for a successful setup. Additionally, consider factors like weather conditions and site accessibility; these can greatly influence both safety and efficiency during installation.

Once you have a solid plan in place, ensure that everyone involved understands their roles and responsibilities. Clear communication about the installation sequence will help avoid confusion when handling critical components like tension clamps or splice closures for fiber protection. Lastly, do not forget to conduct a risk assessment to mitigate any potential hazards associated with working on or near electrical lines.

Tools and Equipment Required

Having the right tools is paramount when installing OPGW hardware fittings; they ensure that everything from tension clamps to suspension clamps is secure and functional. Essential tools include cable cutters, crimping tools, torque wrenches, and appropriate safety gear such as gloves and helmets. Additionally, specialized equipment like splice trays may be required to protect your optical fiber during installation.

Don't overlook basic equipment such as ladders or scaffolding if you're working at heights; safety should always come first! Also consider having spare parts on hand—because nothing derails an installation project faster than finding out you’re missing a fitting or two mid-job. By being well-prepared with both tools and materials, you'll set yourself up for a seamless installation process.

Step-by-Step Installation Guide

Now that you've prepared thoroughly with planning and gathered all necessary tools, it’s time to get down to business! Begin by carefully laying out your optical fiber optic line along its designated path while ensuring minimal tension on the cable itself—this helps prevent damage during installation. Next up is attaching the OPGW hardware fittings: start with tension clamps at specified intervals according to manufacturer guidelines.

Following this step involves securing splice closures for fiber protection; make sure they are installed correctly so that moisture doesn’t compromise your precious optical fibers over time! Once everything is secured tightly using torque wrenches (don’t skip this step!), proceed with attaching suspension clamps where needed—these play an essential role in supporting both weight and stability of your entire fiber cable setup.

Finally, double-check all connections before energizing any ground wire systems associated with your OPGW configuration; this ensures everything operates smoothly without unexpected hiccups later on! With careful execution of each step in this guide underpinned by quality assurance practices from Spark Fittings’ manufacturing processes—your new optical network will be set up flawlessly!

Conclusion

In wrapping up our exploration of OPGW hardware fittings, it is essential to recognize their pivotal role in the realm of fiber optic technology. These fittings not only facilitate the secure installation of fiber optic lines but also enhance the overall performance and longevity of optical systems. As we look toward the future, understanding the nuances and benefits of these components will be crucial for anyone involved in fiber optic projects.

Key Takeaways on OPGW Hardware Fittings

OPGW hardware fittings are indispensable for any successful fiber optic installation, providing critical support and protection for fiber cables. The various types of fittings, such as tension clamps and splice closures, ensure that optical to optical cable connections remain secure and efficient throughout their lifespan. Moreover, selecting the right materials and adhering to best practices during installation can significantly impact the reliability of your fiber optic systems.

The Future of Fiber Optic Technology

The future of fiber optic technology is incredibly promising, with advancements continually pushing the boundaries of speed and connectivity. As more industries embrace high-speed internet demands, OPGW hardware fittings will play a vital role in supporting this growth by ensuring robust infrastructure for both communication and power transmission lines. Innovations in materials and design will further enhance how we utilize optical fibers, paving the way for even more efficient systems.

Final Thoughts on Spark Fittings' Role

Their commitment to manufacturing excellence ensures that each component contributes effectively to maintaining integrity within your fiber optic network. By investing in high-quality spark fittings, you not only enhance your system's performance but also support a sustainable approach to deploying cutting-edge fiber technology.