Introduction

In the rapidly evolving world of telecommunications, ADSS hardware fittings play a pivotal role in ensuring the reliability and efficiency of fiber optic lines. These specialized components are essential for supporting fiber optic cables, providing stability and protection against environmental factors that could compromise performance. Understanding the significance of these fittings not only enhances the longevity of fiber optic installations but also underscores their importance in modern communication infrastructure.

The Significance of ADSS Hardware Fittings

ADSS hardware fittings are crucial for maintaining the integrity of fiber optic wire cable systems, particularly in areas susceptible to high winds or other challenging conditions. By securely anchoring and protecting fiberglass optic cables, these fittings prevent damage and signal loss, ensuring uninterrupted service. Their significance is amplified as more industries transition to fiber optics for faster data transmission and improved connectivity.

Understanding Fiber Optic Solutions

Fiber optic solutions have revolutionized how we transmit information, utilizing light signals to achieve unparalleled speeds and bandwidth compared to traditional copper wiring. The core components of these systems include fiber cable optics that carry data over long distances with minimal attenuation. As businesses increasingly rely on robust fiber optic networks, understanding the nuances of each element—especially ADSS hardware fittings—becomes essential for optimal performance.

Overview of China’s Leading Manufacturers

China has emerged as a powerhouse in manufacturing ADSS hardware fittings, producing a wide array of products that meet global standards for quality and reliability. With numerous manufacturers competing in this space, it’s vital to evaluate their offerings based on innovation, durability, and compliance with international regulations. This overview will highlight key players who are setting benchmarks in the industry while providing insights into their product lines tailored for various applications involving fiber optic cables.

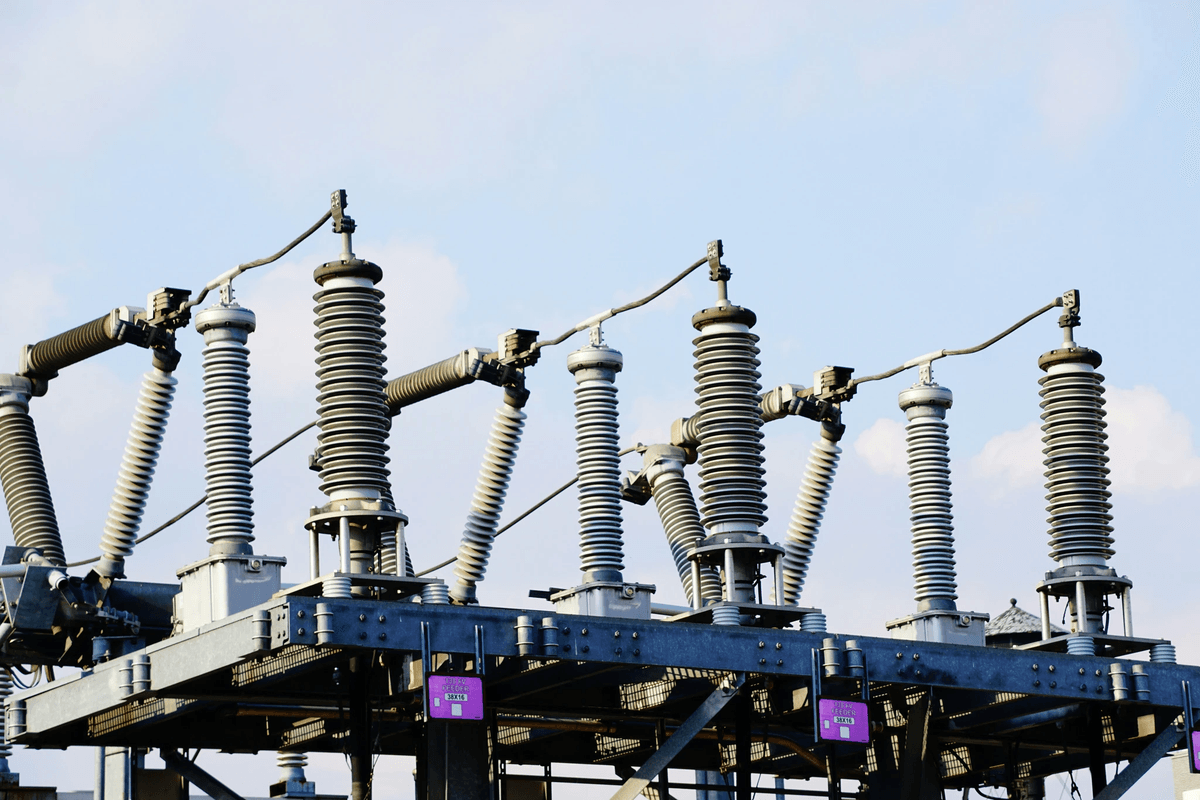

Overview of ADSS Hardware Fittings

ADSS (All-Dielectric Self-Supporting) hardware fittings play a pivotal role in the deployment and maintenance of fiber optic lines. These fittings are essential for securing and supporting fiber optic cables, ensuring they remain stable and functional in various environmental conditions. Without reliable ADSS hardware fittings, the integrity of fiber optic wire cable systems could be compromised, leading to potential service interruptions.

Importance in Fiber Optic Applications

In the realm of fiber optic applications, ADSS hardware fittings are indispensable components that enhance the performance and longevity of fiber optic cables. They provide necessary support and protection against mechanical stress, environmental factors, and physical damage. By using high-quality ADSS hardware fittings, operators can ensure that their fiber cable optic systems maintain optimal signal integrity over long distances.

Moreover, these fittings facilitate easier installation and maintenance processes for technicians working with fiberglass optic cable networks. The robust design of these fittings helps to minimize installation errors while maximizing efficiency on-site. Ultimately, the right ADSS hardware fittings contribute significantly to the overall reliability of a fiber optic network.

Key Types of Hardware Fittings

When it comes to ADSS hardware fittings, there is a diverse range designed specifically for various functions within a fiber optic line. Some key types include suspension clamps, tension clamps, splice closures, and anchor brackets—all tailored to meet specific needs in supporting or protecting fiber optic cables. Each type serves its unique purpose; for instance, suspension clamps hold cables securely while allowing them some degree of movement due to wind or thermal expansion.

Additionally, tension clamps are vital for maintaining proper tension on long spans between poles or towers where the fiber optic wire cable is strung up high above ground level. Splice closures protect critical connections between different sections of a fiberglass optic cable from environmental hazards like moisture or dust. Understanding these types helps users select the appropriate fitting for their specific application requirements.

Popular Materials Used

The materials used in manufacturing ADSS hardware fittings greatly influence their performance characteristics and durability in demanding environments. Commonly employed materials include aluminum alloys due to their lightweight yet strong properties that make them ideal for outdoor installations involving heavy-duty applications like fiber optics. These alloys resist corrosion while providing excellent structural support for any given project involving fiber cable optics.

Another popular material is stainless steel which offers superior resistance against rust and degradation over time—crucial for ensuring longevity in harsh conditions where moisture might be prevalent around the installation site. Additionally, some components may incorporate polymer materials that provide added flexibility without compromising strength or stability when installed alongside sensitive fibers within a fiberglass optical cable system.

Spotlight on Spark Fittings

When it comes to ADSS hardware fittings, Spark Fittings stands out as a beacon of expertise and innovation. With a strong focus on the needs of fiber optic applications, they have carved a niche for themselves in the competitive landscape of fiber optic solutions. Their commitment to quality and reliability makes them a trusted partner for projects involving fiber optic cable installations.

Expertise in ADSS Hardware Fittings

Spark Fittings has developed extensive knowledge in the realm of ADSS hardware fittings, ensuring that they meet the specific requirements of various fiber optic line applications. Their team is well-versed in both traditional and cutting-edge technologies, providing solutions that enhance the performance of fiber optic wire cable systems. This expertise translates into products designed for durability and efficiency, making them an essential player in the market.

With years of experience under their belt, Spark Fittings understands that each project is unique and may require tailored approaches to achieve optimal results. They offer comprehensive consultations to help clients choose the right components for their specific needs, whether it's for a long-haul transmission or urban infrastructure projects using fiberglass optic cable. This personalized service ensures that customers receive not just products but also valuable insights into effective installations.

Range of Customized Armor Rods

One of Spark Fittings' standout offerings is their range of customized armor rods designed specifically for protecting sensitive fiber cables from environmental stressors. These armor rods are crucial when it comes to extending the lifespan of fiber optic cable installations by providing essential support against mechanical damage and weather-related challenges. The ability to customize these fittings means that clients can select options tailored precisely to their operational conditions.

The versatility in design allows Spark Fittings to cater to various types of fiber cable optic systems, ensuring compatibility with different installation environments. Whether it's reinforcing overhead lines or securing underground networks, their armor rods offer unmatched reliability and performance across diverse applications. Clients appreciate this attention to detail as it significantly contributes to reducing maintenance costs over time.

Moreover, Spark's commitment to innovation means they continually refine their product offerings based on customer feedback and technological advancements within the industry. By staying ahead of trends in manufacturing processes, they can provide cutting-edge solutions that enhance the overall integrity of fiber optic wire cable systems while keeping costs competitive.

Innovations in Manufacturing Processes

Innovation is at the heart of what makes Spark Fittings a leader in ADSS hardware fittings production. They leverage advanced manufacturing techniques that not only streamline production but also ensure consistent quality across all products offered—particularly those related to fiber optics applications like fiberglass optic cable installations. Their state-of-the-art facilities are equipped with technology capable of producing precise components quickly without sacrificing quality.

Additionally, Spark embraces sustainable practices by integrating eco-friendly materials into their manufacturing processes whenever possible—an increasingly important factor for today’s environmentally conscious consumers looking at fiber optical solutions. This forward-thinking approach not only benefits clients but also contributes positively towards global sustainability efforts within industrial sectors reliant on high-performance materials.

By continuously investing in research and development alongside robust testing protocols, Spark ensures its product lineup remains at the forefront of industry standards—an assurance every client deserves when dealing with critical infrastructure like fiber optics systems requiring dependable ADSS hardware fittings.

Leading Manufacturers in China

China has emerged as a powerhouse in the production of ADSS hardware fittings, catering to the growing demand for reliable fiber optic solutions. With an extensive range of manufacturers, these companies specialize in various aspects of fiber optic cable technology, ensuring that they meet both domestic and international standards. Understanding who the key players are can help businesses make informed choices when selecting ADSS hardware fittings for their projects.

Top Players in the ADSS Market

Among the top players in China's ADSS market are well-established companies known for their innovation and quality. Notable names include Jiangsu Etern Company, which focuses on high-performance fiber optic wire cable systems, and Hangzhou Zhongke Optic-Electronic Company, recognized for its advanced manufacturing techniques. These manufacturers not only produce standard products but also offer customized solutions tailored to specific project requirements, making them leaders in the field.

Comparison of Product Offerings

When comparing product offerings from leading manufacturers, it's essential to consider factors like variety and material quality. Many suppliers provide a wide array of ADSS hardware fittings designed for different applications within fiber optic lines—ranging from armor rods to suspension clamps tailored for fiberglass optic cable installations. Additionally, examining whether these suppliers offer comprehensive support services can be crucial; after all, having access to expert advice can streamline installation processes and enhance overall project efficiency.

Supplier Reliability and Standards

Supplier reliability is paramount when sourcing ADSS hardware fittings; thus, evaluating certification and compliance with international standards is essential. Manufacturers that adhere to ISO certifications demonstrate a commitment to quality assurance that significantly boosts trust among customers looking for durable fiber cable optic solutions. Furthermore, those who consistently meet or exceed industry benchmarks not only ensure product longevity but also contribute positively to the integrity of fiber optic networks worldwide.

Quality Assurance and Certification

In the realm of ADSS hardware fittings, quality assurance and certification play pivotal roles in ensuring that these components meet the rigorous demands of fiber optic applications. As the reliance on fiber optic cable systems grows, so does the necessity for manufacturers to adhere to international standards that govern product safety, reliability, and performance. This section delves into these standards and their implications for both manufacturers and consumers.

International Standards for Hardware Fittings

International standards for hardware fittings are crucial in maintaining consistency across the industry, particularly for ADSS hardware fittings used in fiber optic lines. These standards cover various aspects such as material specifications, design criteria, testing methods, and performance benchmarks. Compliance with these regulations not only guarantees that products like fiberglass optic cable meet safety requirements but also ensures compatibility with other components in a fiber optic cable system.

Importance of Compliance in Manufacturing

Compliance with established international standards is essential for manufacturers producing ADSS hardware fittings because it directly impacts product quality and marketability. Non-compliance can lead to failures in critical applications, resulting in costly downtime or even catastrophic incidents along a fiber optic wire cable network. Thus, adherence to these regulations fosters a culture of accountability among manufacturers while enhancing their reputation within the industry.

How Certification Enhances Trust

Certification serves as a badge of honor for manufacturers of ADSS hardware fittings, signifying their commitment to quality and reliability within the competitive landscape of fiber optics. When clients see certified products, they gain confidence that they are investing in durable solutions tailored to withstand environmental challenges associated with fiber cable optic installations. Ultimately, this trust translates into long-term partnerships between suppliers and customers who prioritize high-quality fiber optic solutions.

Selecting the Right Supplier

Choosing the right supplier for ADSS hardware fittings is crucial for ensuring the reliability and performance of your fiber optic line. With numerous options available, it can be overwhelming to navigate through various manufacturers and their offerings. However, focusing on key factors can simplify your decision-making process and lead you to a supplier that meets your needs.

Key Factors for Consideration

When selecting a supplier for ADSS hardware fittings, start by considering their experience in the industry. A manufacturer with a solid track record in providing high-quality fiber optic solutions will likely understand the nuances of fiber optic cable requirements better than others. Additionally, assess their production capabilities; suppliers should have advanced technology and equipment to ensure that they can produce durable products suitable for your specific applications.

Another important factor is the range of products offered by potential suppliers. You want a partner who provides not only ADSS hardware fittings but also complementary items such as fiberglass optic cable and various connectors, which will streamline your procurement process. Lastly, consider geographic location; working with local suppliers might reduce shipping times and costs while facilitating easier communication.

Evaluating Product Quality and Price

Price is always a consideration when purchasing ADSS hardware fittings, but it shouldn't be the sole determinant in your decision-making process. While it may be tempting to go for the lowest price, remember that quality is paramount when working with fiber optic wire cable or any related components—subpar materials can lead to failures down the line. It's essential to compare product specifications and warranties offered by different manufacturers to ensure you're getting value for money.

Conducting thorough research on customer reviews can provide valuable insights into product quality as well as long-term performance of fiber optic cable solutions from various suppliers. Don't hesitate to request samples or test products before making large purchases; this allows you to gauge whether their offerings meet industry standards and your specific requirements effectively. Ultimately, finding a balance between price and quality will help you secure reliable ADSS hardware fittings without breaking the bank.

The Role of Customer Service

Exceptional customer service plays an integral role in fostering long-term relationships with suppliers of ADSS hardware fittings. A responsive team should be readily available to address inquiries about product specifications or availability—especially important when dealing with complex items like fiber cables optic or specialized armor rods designed for unique applications. Good communication ensures that any issues are resolved swiftly, minimizing disruptions in your operations.

Moreover, consider whether potential suppliers offer support after purchase—this includes installation guidance or troubleshooting assistance related to their fiber optic cable products. A supplier who stands behind their goods demonstrates confidence in their offerings while providing peace of mind that you won't face challenges alone after making a purchase decision. In today's competitive market, excellent customer service often sets apart leading manufacturers from those merely trying to fill orders.

Conclusion

In wrapping up our exploration of ADSS hardware fittings and their role in fiber optic solutions, it's clear that the future is bright for this sector. As demand for high-speed internet continues to surge, innovations in fiber optic cable technology will only enhance the capabilities of these fittings. The integration of advanced materials and manufacturing techniques promises to improve durability and performance, making ADSS hardware fittings essential for reliable fiber optic lines.

Future Trends in ADSS Hardware Fittings

Looking ahead, we can expect significant advancements in ADSS hardware fittings, driven by technological innovation and rising demand for efficient communication infrastructure. Manufacturers are likely to focus on developing more lightweight yet robust materi

als that can withstand harsh environmental conditions while maintaining optimal performance across various applications involving fiber optic wire cables. Additionally, smart technology integration may lead to the creation of self-monitoring systems within fiber optic cable installations, enhancing maintenance efficiency and reducing downtime.

Why Choose Chinese Manufacturers

They offer a wide array of products tailored to different needs at competitive prices without compromising on quality—ideal for projects requiring extensive use of fiber cable optics. Furthermore, these manufacturers are increasingly adhering to international standards, ensuring that their products meet global requirements while providing excellent customer service and support throughout the procurement process.

Ensuring Quality with Fiber Optic Solutions

Quality assurance is paramount when selecting ADSS hardware fittings for your fiber optic projects. Rigorously tested products not only ensure reliability but also enhance the overall integrity of your fiber optic cable installations—be it fiberglass optic cables or traditional varieties. By prioritizing suppliers who adhere to strict certification processes and international standards, you can trust that your investment in fiber optics will yield long-lasting results.