Introduction

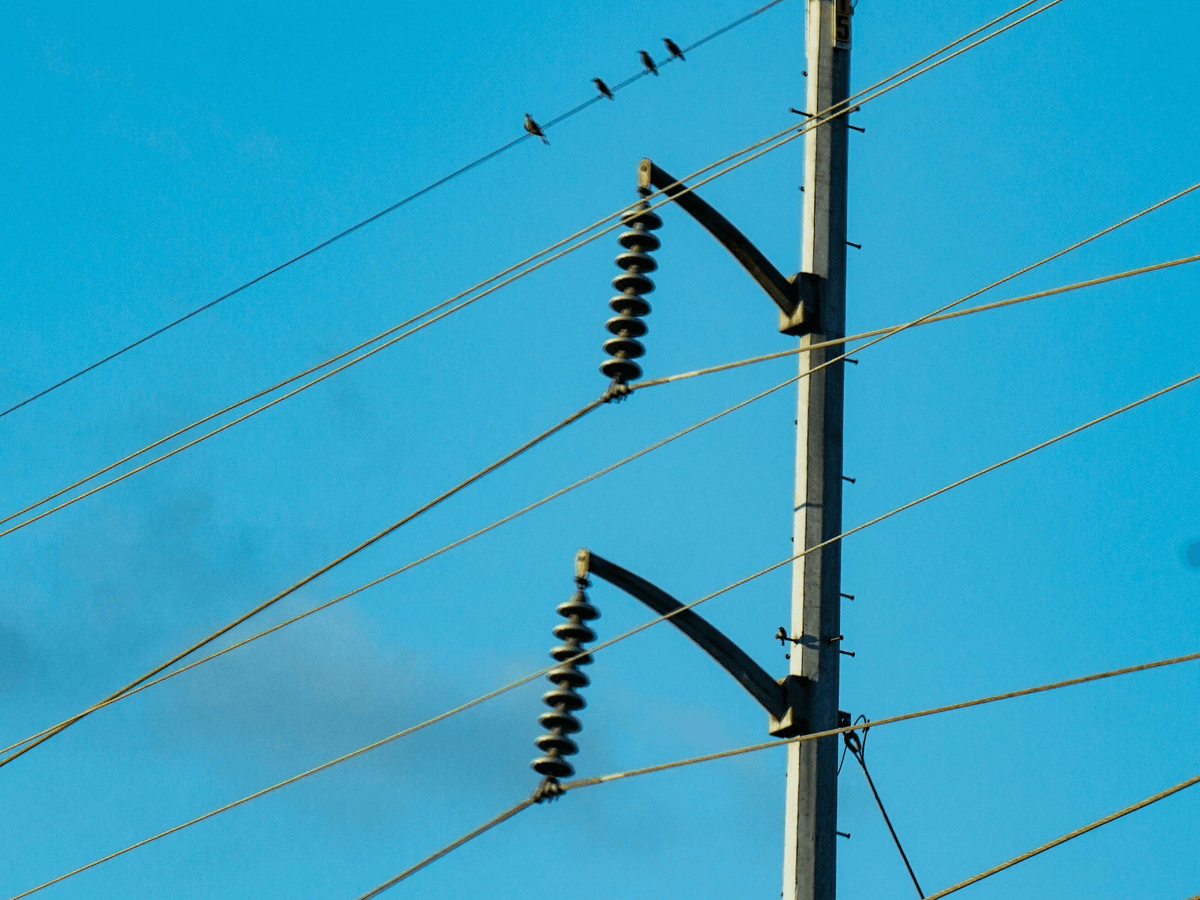

In the world of telecommunications, OPGW (Optical Ground Wire) plays a crucial role in enhancing connectivity and ensuring reliable communication. OPGW suspension clamps are essential components that support fiber optic lines, providing stability and protection for the delicate optical fiber cable housed within. Understanding these clamping clamps is vital for anyone involved in the installation or maintenance of fiber optic systems.

Understanding OPGW and Its Applications

OPGW combines the functions of grounding and communication into a single cable, making it an innovative solution for modern infrastructure. This dual-purpose design not only protects against lightning strikes but also facilitates high-speed data transfer through its embedded fiber optic lines. As industries increasingly rely on robust telecommunications networks, the adoption of OPGW continues to rise across various applications, from utility companies to telecommunication providers.

Key Features of Preformed Suspension Clamps

Preformed suspension clamps are engineered to securely hold OPGW cables while minimizing stress on the optical fibers inside. These clamping clamps provide excellent support by distributing weight evenly along the cable, reducing potential damage during installation or adverse weather conditions. Additionally, their durable construction ensures longevity and reliability for fiber optic lines exposed to harsh environmental factors.

The Role of Spark Fittings

Spark fittings play a pivotal role in optimizing the performance of OPGW suspension clamps by providing secure connections that enhance overall system integrity. These specialized fittings ensure that each component works harmoniously, allowing for seamless integration with fiberglass optic cables and other accessories. By choosing spark fittings tailored to specific needs, operators can significantly improve network performance while safeguarding their valuable investment in fiber optic technology.

What is an OPGW Suspension Clamp?

In the realm of optical fiber technology, the OPGW suspension clamp plays a pivotal role in ensuring the integrity and reliability of fiber optic lines. These clamping clamps are designed specifically for overhead applications, providing secure support for optical fiber cables (OFC) while allowing for thermal expansion and contraction. Understanding the definition and purpose of these clamps is essential for anyone involved in the installation or maintenance of fiber optic systems.

Definition and Purpose

An OPGW suspension clamp is a specialized device used to attach overhead optical fiber cables to poles or towers, preventing sagging and ensuring proper alignment. The primary purpose of these clamps is to provide mechanical support while minimizing stress on the cable itself, which can lead to damage if not properly secured. By effectively distributing weight and tension, these clamping clamps help maintain the longevity of both the optical fiber cable and its supporting infrastructure.

Advantages for Fiber Optic Lines

One of the significant advantages of using OPGW suspension clamps is their ability to protect delicate fiber optic lines from environmental stresses such as wind, ice, and temperature fluctuations. These clamps enable efficient installation by allowing for quick adjustments during setup without compromising cable integrity. Moreover, they contribute to improved network performance by ensuring that fibers remain properly aligned within their protective coverings, reducing signal loss over time.

Types of OPGW Suspension Clamps

There are various types of OPGW suspension clamps tailored to different applications within fiber optic installations. Some common types include standard suspension clamps designed for most overhead installations, as well as specialized models that accommodate unique environmental conditions or specific cable designs like fiberglass optic cables (FOC). Understanding these distinctions helps installers choose the right clamping solution for their specific needs while optimizing overall system performance.

The Importance of Material Selection

Selecting the right materials for OPGW suspension clamps is crucial for ensuring the longevity and performance of optical fiber cables. The choice of material affects not only the mechanical strength but also the resistance to environmental factors such as corrosion and wear. In this section, we’ll delve into why material selection is paramount in clamping clamps for fiber optic lines.

Choosing the Right Armor Rod Material

Materials such as fiberglass or high-strength aluminum are often preferred due to their lightweight yet robust nature, which helps support fiber optic lines effectively. Additionally, using high-quality materials ensures that clamping clamps maintain their integrity over time, reducing maintenance costs and enhancing overall network reliability.

Avoiding Corrosion: Aluminum vs. Galvanized Steel

Corrosion is a silent killer in the world of fiber optic cable installations, making it essential to choose materials wisely when selecting OPGW suspension clamps. Aluminum offers excellent resistance to corrosion but may not withstand heavy-duty applications as well as galvanized steel does under certain conditions. Understanding these nuances allows professionals to select either aluminum or galvanized steel based on specific project requirements while ensuring that their optical fiber cables remain protected in various environments.

Customizing Armor Rods with Spark Fittings

Customization plays a vital role in optimizing OPGW suspension clamp performance, especially when integrating spark fittings into armor rods. Spark fittings provide additional security and stability for fiber optic lines by adapting to various installation needs and environmental challenges. By customizing armor rods with spark fittings, users can enhance both functionality and durability while ensuring that their fiberglass optic cable installations meet industry standards.

Installation Best Practices

Properly preparing your optical fiber cable is crucial for ensuring a secure and effective installation. This step not only enhances the performance of your fiber optic line but also extends the lifespan of the clamping clamps used in the process.

Preparing Fiber Optic Cables for Clamping

Before diving into the installation, it's essential to prepare your fiber optic cables adequately. Start by inspecting the FO cable for any signs of damage or wear; this ensures that you’re working with a reliable product. Next, clean the ends of your fiberglass optic cable thoroughly to remove any dust or debris that could interfere with the clamping process.

Once cleaned, make sure to measure and cut your optical fiber cable to the desired length according to project specifications. This step is vital because an improperly sized cable can lead to tension issues when using OPGW suspension clamps. Finally, ensure that all necessary tools and materials are on hand before beginning installation; this will streamline the process and reduce potential delays.

Step-by-Step Installation Guide

Installing OPGW suspension clamps may seem daunting at first, but breaking it down into manageable steps can simplify things significantly. Begin by positioning the OPGW suspension clamp at designated attachment points along your fiber optic line, ensuring it’s aligned correctly with other components such as poles or towers. Once in place, secure it using appropriate hardware while avoiding over-tightening; this can cause damage to both the clamp and FO cable.

Next, carefully insert your prepared optical fiber cable into each clamp's designated grooves or slots—this is where those preformed suspension clamps really shine! Make sure each section is snugly fitted without excessive pressure that could compromise signal integrity or physical stability. After securing all sections properly, conduct a thorough inspection before proceeding further; double-checking now can save you headaches later on.

Finally, once everything looks good and secure, test your setup by applying tension gradually while monitoring for any signs of stress on both clamping clamps and optical fibers alike. If everything holds up well under pressure, congratulations—you’ve successfully installed your OPGW suspension clamp!

Common Mistakes to Avoid

While installing OPGW suspension clamps may seem straightforward, there are several common pitfalls that can derail even seasoned professionals. One major mistake is neglecting proper measurements—always double-check lengths before cutting! An incorrect size could lead not only to improper tension but also potential damage during installation.

Another frequent error involves overlooking environmental conditions such as wind speed or temperature fluctuations during installation day; these factors can influence how tightly you should secure clamping clamps around your fiber optic line components. Additionally, be mindful of using incompatible materials when customizing armor rods with spark fittings—using mismatched metals can lead to corrosion over time!

Lastly, don’t forget about post-installation checks! Many people assume their work is done after securing everything in place but failing to conduct thorough inspections afterward may result in overlooked issues down the road—ensure reliability by being diligent throughout every phase of installation!

Innovations in OPGW Technology

The landscape of Optical Ground Wire (OPGW) technology is constantly evolving, driven by the need for improved efficiency and reliability in fiber optic lines. Innovations in design and materials are enhancing the performance of OPGW suspension clamps, making them more robust and adaptable to various environmental conditions. As we delve into these advancements, it's essential to recognize how they contribute to the overall effectiveness of fiber optic cable installations.

Advances in Suspension Clamp Design

Recent years have seen significant advancements in the design of OPGW suspension clamps, focusing on enhancing their durability and ease of installation. Modern clamping clamps are engineered with advanced materials that provide better resistance against harsh weather conditions, ensuring that fiber optic lines remain secure under extreme stress. Additionally, ergonomic designs are being implemented to simplify the installation process, reducing labor costs and time associated with setting up fiber optic cable systems.

These new designs also accommodate a wider range of optical fiber cables, including specialized fiberglass optic cable types that require unique handling characteristics. The integration of adjustable features allows for easy modifications during installation or maintenance, providing flexibility that was often lacking in older models. Thus, advancements in OPGW suspension clamp design not only contribute to improved performance but also enhance user experience throughout the lifecycle of the product.

Role of Spark Fittings in Industry Development

Spark fittings have emerged as a key player in the development of OPGW technology by providing customized solutions tailored to specific project requirements. These innovative fittings enhance the functionality of clamping clamps by ensuring optimal connectivity between components while maintaining the integrity of fiber optic lines. Their ability to facilitate seamless transitions between different types of cables further underscores their importance in modern installations.

Moreover, spark fittings are designed with a focus on minimizing signal loss and protecting against environmental factors that could compromise optical performance. This has made them indispensable for projects involving high-capacity fiber optic cable networks where reliability is paramount. As industry standards evolve, spark fittings continue to adapt, driving forward innovations that support efficient deployment and long-term sustainability within the telecommunications sector.

Future Trends in Optical Fiber Cable Accessories

Looking ahead, several trends are shaping the future landscape of optical fiber cable accessories like OPGW suspension clamps and related components. One prominent trend is the increasing emphasis on lightweight yet durable materials that can withstand environmental challenges without adding unnecessary weight to installations—this is particularly important for aerial applications where every gram counts!

Another significant trend is automation; as technology progresses, automated systems for monitoring and maintaining clamping clamps will likely become more prevalent—improving operational efficiency while reducing human error during installation or maintenance activities on fiber optic lines. Moreover, sustainability considerations will drive innovations focused on eco-friendly materials and manufacturing processes within this sector.

In summary, innovations within OPGW technology are paving new paths for enhanced network performance through improved designs and smart integrations like spark fittings—ensuring our optical infrastructure remains robust well into the future.

Quality Assurance in OPGW Components

When it comes to OPGW suspension clamps, quality assurance is paramount. These components play a critical role in supporting optical fiber cables, ensuring that they remain secure and functional under various environmental conditions. Rigorous testing and adherence to industry standards are essential for maintaining the integrity of fiber optic lines.

Testing and Standards for Clamping Clamps

Testing clamping clamps is vital to ensure their performance and reliability. Industry standards dictate that these components must withstand significant mechanical stress while maintaining their ability to protect the delicate fiber optic cable within. Regular assessments, including tensile strength tests and environmental exposure evaluations, help ensure that the OPGW suspension clamp can endure harsh conditions without compromising the integrity of the fo cable.

Moreover, compliance with international standards guarantees that clamping clamps meet specific safety requirements, reducing the risk of failure during operation. Manufacturers often conduct these tests in controlled environments, simulating real-world conditions to evaluate how well their products perform over time. As technology advances, new testing methods will continue to enhance our understanding of how best to safeguard fiber optic lines.

Importance of Choosing Reputable Suppliers

Selecting reputable suppliers for your OPGW suspension clamps is crucial for ensuring quality and reliability. Established suppliers typically have a proven track record of producing high-quality products that meet rigorous testing standards. By investing in clamping clamps from trusted sources, you can mitigate risks associated with subpar materials that may lead to premature failures or costly repairs on your fiber optic cable installations.

Additionally, reputable suppliers often provide comprehensive documentation regarding their manufacturing processes and quality control measures. This transparency allows you to make informed decisions about which clamping clamps will best suit your needs while ensuring compatibility with various optical fiber cables or fiberglass optic cables in use today. The long-term performance of your installations significantly depends on choosing reliable partners in this industry.

How Spark Fittings Ensures Reliability

Spark fittings are designed with an emphasis on reliability and performance in mind when it comes to OPGW components like suspension clamps. By incorporating advanced engineering techniques into their designs, Spark Fittings ensures that every product meets stringent quality benchmarks before reaching customers' hands. Their commitment to innovation means they continuously refine their offerings based on feedback from users across various sectors utilizing optical fiber lines.

Furthermore, Spark Fittings conducts extensive testing on all its products—including clamping clamps—to guarantee durability under extreme conditions such as high winds or temperature fluctuations common in outdoor settings where fo cables are deployed extensively. This dedication not only enhances the longevity of each component but also instills confidence among users who rely heavily on these systems for seamless connectivity.

In conclusion, prioritizing quality assurance when selecting OPGW suspension clamps is essential for safeguarding your optical fiber infrastructure's longevity and performance—especially when choosing suppliers like Spark Fittings known for delivering reliable solutions tailored specifically for modern applications involving fiber optic technology.

Conclusion

In summary, the integration of OPGW (Optical Ground Wire) technology into telecommunications has revolutionized the way we enhance network performance. By implementing high-quality OPGW suspension clamps, operators can ensure that their optical fiber cables remain secure and functional, even in challenging environmental conditions. This not only boosts the reliability of fiber optic lines but also maximizes the potential of these advanced communication systems.

Enhancing Network Performance with OPGW

The use of OPGW suspension clamps is pivotal in maintaining the integrity and efficiency of fiber optic lines. These clamping clamps are designed to support and protect FO cables, ensuring minimal stress on the fibers during installation and throughout their operational life. Enhanced network performance is achieved through effective strain relief provided by these clamps, which helps prevent damage to delicate optical fibers.

Choosing Spark Fittings for Custom Solutions

When it comes to optimizing your installation, selecting spark fittings for your OPGW suspension clamp setup can make a significant difference. These fittings provide tailored solutions that cater to specific project needs, ensuring compatibility with various types of fiber optic cable configurations. By investing in custom solutions using spark fittings, you can address unique challenges presented by different environments while enhancing overall system reliability.

Final Thoughts on OPGW Suspension Clamps

In conclusion, OPGW suspension clamps play an essential role in safeguarding fiber optic cables from external stresses and environmental factors that could compromise their functionality. With advancements in design and material selection, these clamping clamps have become more reliable than ever before. As technology continues to evolve, embracing innovations like spark fittings will be crucial for those looking to future-proof their optical fiber installations.