Introduction

Why Material Choice Matters in Transmission Lines

Material selection in transmission lines affects everything from durability to maintenance requirements. Opting for materials with superior corrosion resistance can significantly reduce the frequency of repairs and replacements, ultimately saving money in the long run. With increasing demands on power infrastructure, understanding which materials perform best is essential for ensuring reliability and efficiency.

Understanding Stainless Steel’s Properties

Stainless steel is renowned for its impressive mechanical properties, including high tensile strength and excellent corrosion resistance. These characteristics make it an ideal candidate for applications in overhead line fittings where exposure to harsh weather conditions is common. Additionally, stainless steel's inherent ability to resist rust and degradation raises an important question: is stainless steel corrosion resistant? The answer is a resounding yes, making it a preferred choice among cable accessories suppliers.

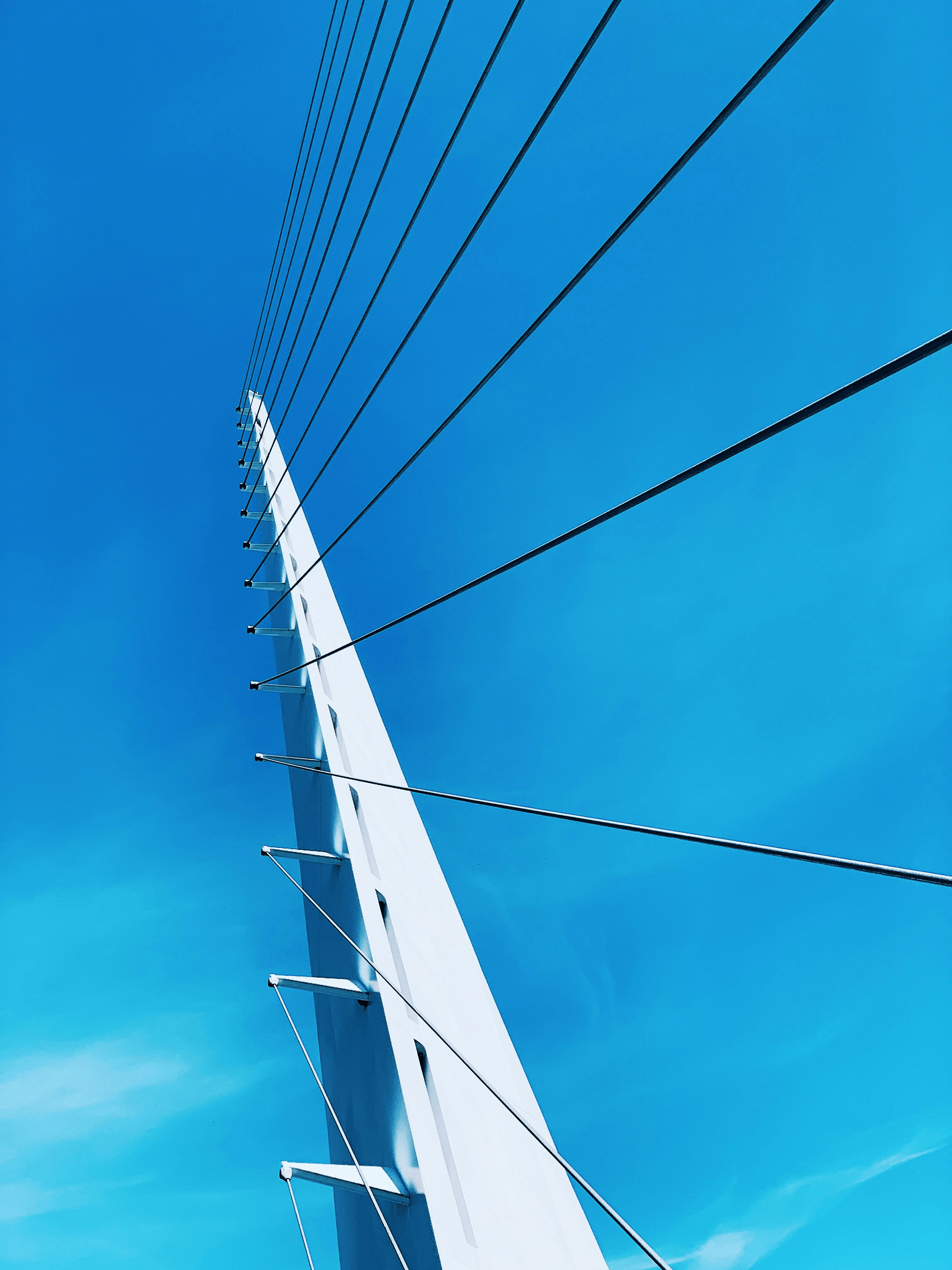

Evaluating Stainless Steel for Overhead Lines

When evaluating stainless steel for overhead lines, several factors come into play—including its performance under load and compatibility with existing systems like suspension clamps and strain clamps. Its mechanical strength ensures that components remain intact even under significant stress or adverse conditions. Moreover, as industries continue to innovate in power transmission solutions, the role of stainless steel becomes increasingly vital in enhancing the longevity and reliability of electrical infrastructure.

The Corrosion Resistance of Stainless Steel

When it comes to overhead lines, corrosion resistance is a non-negotiable quality that can make or break the longevity of the installation. Stainless steel stands out in this regard, thanks to its unique properties that keep it performing well even in harsh environments. Understanding why stainless steel is corrosion resistant helps us appreciate its role in Overhead Line Fitting applications and how it enhances the durability of strain clamps and suspension clamps.

What Makes Stainless Steel Corrosion Resistant

The secret sauce behind stainless steel's impressive corrosion resistance lies in its alloy composition, particularly the presence of chromium. This element forms a thin, protective oxide layer on the surface that acts as a barrier against moisture and corrosive agents. In essence, when you ask is stainless steel corrosion resistant? remember that it's not just about the material itself; it's about how it reacts with its environment to prevent rust and degradation over time.

Moreover, this protective layer can self-heal if damaged, which means that even minor scratches won’t lead to catastrophic failure like they might with other materials. This property is especially crucial for overhead lines where exposure to elements is constant, making stainless steel an ideal choice for components like strain clamps and suspension clamps designed to hold everything together securely. The result? A reliable solution for cable accessories suppliers looking to provide long-lasting products.

Real-World Applications in Overhead Lines

Stainless steel has made significant strides in real-world applications involving overhead lines due to its remarkable corrosion resistance. Many utility companies have adopted stainless steel fittings for their overhead line systems because they require less frequent replacements compared to traditional materials like aluminum or plain carbon steel. For instance, when used in suspension clamps for overhead lines, stainless steel ensures a secure grip while resisting environmental wear and tear.

In coastal areas where saltwater exposure accelerates corrosion rates, using stainless steel fittings becomes even more critical for maintaining system integrity over time. By leveraging the benefits of stainless steel’s properties, cable accessories suppliers can offer solutions that not only meet but exceed industry standards for performance and durability under challenging conditions. This makes them a go-to choice for any project requiring reliable overhead line installations.

Comparing with Other Materials

When comparing stainless steel with other materials used in overhead line fittings—like aluminum or galvanized iron—it becomes clear why many engineers prefer this alloy. While aluminum is lightweight and cost-effective initially, it often falls short when it comes to long-term durability due to susceptibility to corrosion over time. Galvanized iron may offer some protection against rust but lacks the self-healing properties inherent in stainless steel.

Additionally, while both aluminum and galvanized iron may require more frequent maintenance or replacement due to their lower resilience against environmental factors, stainless steel stands tall as an investment worth making upfront—especially considering lifespan costs associated with Overhead Line Fitting components like strain clamps and suspension clamps. Ultimately, choosing stainless steel translates into fewer headaches down the road for cable accessories suppliers who prioritize reliability alongside performance.

Mechanical Strength and Durability

When it comes to overhead line construction, the mechanical strength and durability of materials play a pivotal role in ensuring reliability and safety. Stainless steel stands out in this regard due to its robust properties that enhance the performance of overhead line fittings and accessories. This section will delve into how stainless steel performs under load, its implications for overhead line fittings, and the long-term performance of strain clamps.

Assessing Strength under Load

Stainless steel is renowned for its impressive tensile strength, making it an ideal choice for applications that require resilience under heavy loads. When assessing whether stainless steel is corrosion resistant, one must also consider how it holds up structurally when subjected to environmental stresses such as wind or ice accumulation on overhead lines. This high strength-to-weight ratio ensures that suspension clamps can maintain their integrity even in challenging conditions, reducing the risk of failures.

Moreover, stainless steel's ability to resist deformation under stress means that overhead line fittings remain secure over time without requiring frequent adjustments or replacements. A thorough evaluation reveals that stainless steel not only meets but often exceeds industry standards for mechanical strength, making it a preferred material among cable accessories suppliers. This reliability translates into fewer disruptions in power transmission due to structural failures.

Impact on Overhead Line Fitting

The choice of material significantly impacts the effectiveness of overhead line fittings, with stainless steel providing distinct advantages over traditional materials like aluminum or carbon steel. Since these fittings are crucial for connecting various components within an overhead line system, their durability directly affects overall performance and safety. The inherent toughness of stainless steel ensures that suspension clamps maintain their grip on cables even under varying loads.

Furthermore, when evaluating if stainless steel is corrosion resistant, it becomes clear that this characteristic complements its mechanical strength by preventing degradation over time—something that's particularly important in harsh environments where exposure to moisture and pollutants is common. As a result, using stainless steel for overhead line fitting not only enhances structural integrity but also minimizes maintenance requirements—an appealing proposition for cable accessory suppliers looking to optimize product offerings.

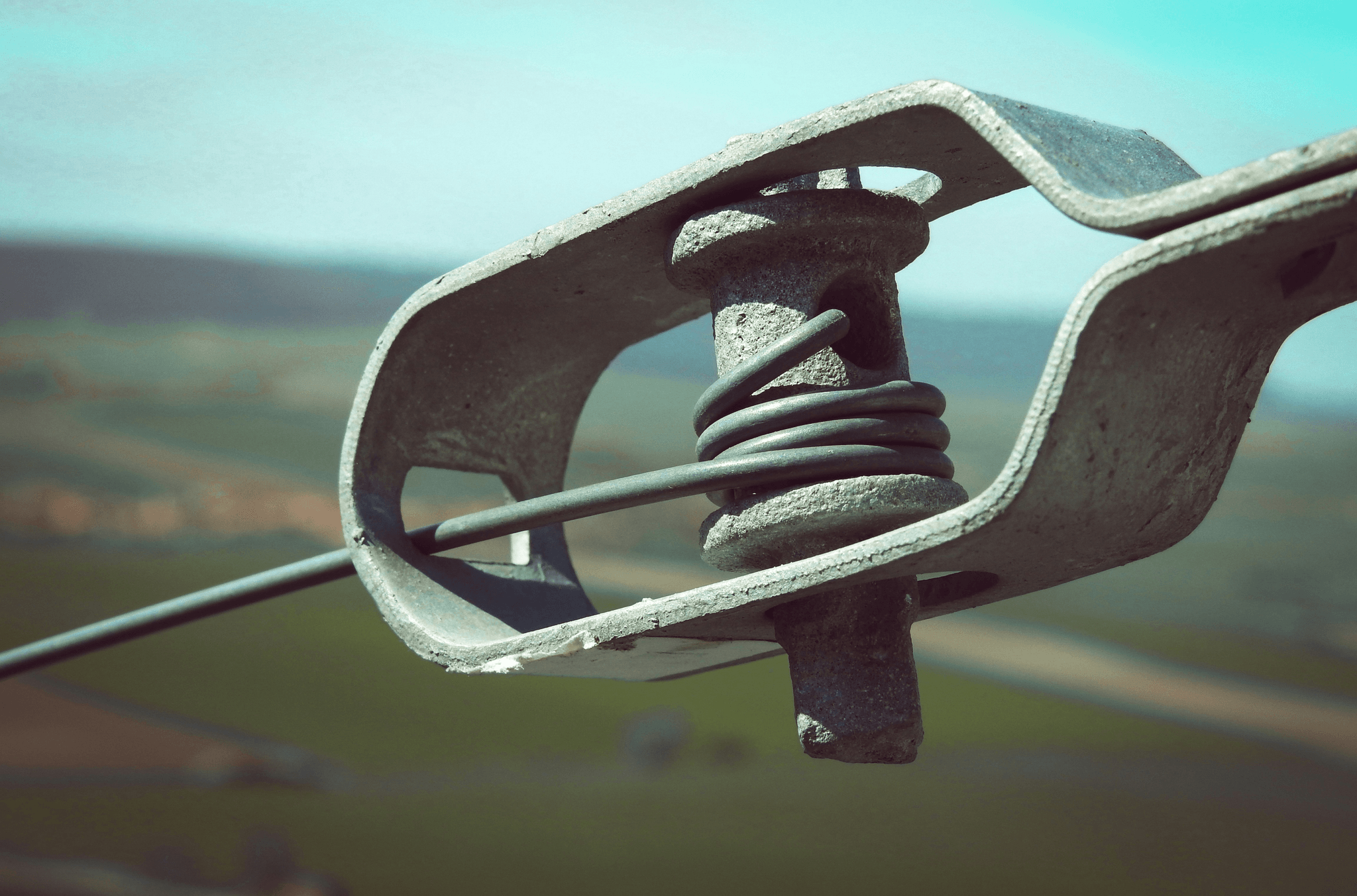

Long-Term Performance of Strain Clamps

Strain clamps play a vital role in supporting cables while accommodating thermal expansion and contraction caused by temperature fluctuations. The long-term performance of these clamps hinges on their ability to withstand mechanical stress without succumbing to fatigue—a feat at which stainless steel excels remarkably well due to its high endurance limits. In practical terms, this means fewer replacements and lower maintenance costs associated with strain clamps made from stainless steel.

Additionally, since many professionals often ask if stainless steel is corrosion resistant when considering materials for strain clamps, it's essential to highlight that this resistance extends the lifespan of these components significantly compared to those made from lesser materials prone to rusting or degradation over time. Consequently, engineers can confidently recommend stainless-steel strain clamps as reliable solutions within any power transmission framework—ultimately benefiting both operators and consumers alike.

Cost-Effectiveness Over Time

When evaluating materials for overhead lines, cost-effectiveness is a crucial factor for both utilities and cable accessories suppliers. Stainless steel, known for its durability and long lifespan, often presents a more economical option over time despite higher initial costs. Understanding the financial implications of choosing stainless steel can help in making informed decisions that benefit both the bottom line and operational efficiency.

Initial Costs vs. Lifespan

While the upfront costs of stainless steel components may be higher than those made from traditional materials, it’s essential to consider the lifespan of these products. Stainless steel's resilience means that overhead line fittings made from this material typically require replacement far less frequently than alternatives, thereby reducing long-term expenses significantly. Investing in high-quality stainless steel strain clamps or suspension clamps for overhead lines can yield substantial savings over the years due to their extended service life.

Maintenance Needs for Stainless Steel

One of the standout features of stainless steel is its corrosion resistance; it requires minimal maintenance compared to other materials used in overhead lines. This property drastically reduces labor costs associated with inspections and repairs, making it an attractive choice for cable accessories suppliers who want to offer reliable solutions without ongoing maintenance headaches. By choosing stainless steel fittings, operators can focus their resources on other critical areas rather than worrying about frequent upkeep.

Economic Benefits for Cable Accessories Suppliers

For cable accessories suppliers, recommending stainless steel products not only enhances their credibility but also aligns with industry trends favoring sustainable and efficient solutions. The economic benefits are twofold: suppliers can charge a premium upfront while also ensuring customer satisfaction through reduced failure rates and longevity of products like strain clamps and suspension clamps designed specifically for overhead lines. Ultimately, promoting stainless steel options positions suppliers as leaders in innovation while providing clients with cost-effective solutions that stand the test of time.

Installation and Ease of Use

How Stainless Steel Fits into Existing Systems

Stainless steel's versatility allows for easy integration with traditional overhead line fittings, ensuring that projects can proceed without unnecessary delays. The material's standardized dimensions mean that suspension clamps for overhead lines can be manufactured to match existing hardware specifications perfectly. This streamlined compatibility not only simplifies installation but also minimizes the risk of errors during assembly.

Suspension Clamps for Overhead Lines: A Practical Guide

When selecting suspension clamps for overhead lines, it's essential to consider both functionality and durability. Stainless steel suspension clamps are designed to withstand various environmental factors while maintaining structural integrity under load. These clamps offer robust support, ensuring that strain clamps hold cables securely in place, even under challenging conditions.

Advantages in Installation Efficiency

One of the primary advantages of using stainless steel in overhead line applications is the efficiency gained during installation. The lightweight nature of stainless steel components allows for easier handling and quicker setup times compared to heavier alternatives. Additionally, reduced maintenance needs mean that once installed, these systems remain reliable over time, freeing up resources for other projects.

Industry Perspectives and Innovations

The landscape of overhead line construction is evolving rapidly, driven by the need for more efficient and durable materials. As energy demands increase, utilities are exploring innovative solutions to enhance the longevity and reliability of their infrastructure. This shift has led to a growing interest in materials like stainless steel, particularly in applications such as Overhead Line Fitting and suspension clamps.

Trends in Overhead Line Construction

One prominent trend is the increasing focus on sustainability and resilience in power transmission systems. Utilities are now prioritizing materials that not only perform well under load but also resist environmental challenges, which raises the question: is stainless steel corrosion resistant? The answer is a resounding yes, making it an attractive option for overhead lines that face harsh weather conditions.

Moreover, advancements in technology have allowed manufacturers to develop improved strain clamps and suspension clamps that optimize performance while reducing material waste. These innovations are not just about meeting current demands; they also set the stage for future developments in power transmission systems where durability and efficiency reign supreme.

Innovations from Spark Fittings

Spark Fittings has been at the forefront of introducing cutting-edge solutions tailored specifically for overhead line applications. Their latest designs incorporate stainless steel components known for their exceptional corrosion resistance, ensuring that installations remain reliable over time. By focusing on high-quality Overhead Line Fitting options, they provide cable accessories suppliers with products that stand out in a competitive market.

Additionally, Spark Fittings has developed advanced strain clamp technologies that enhance mechanical strength without compromising weight or ease of installation. These innovations reflect an industry-wide shift towards smarter design practices that prioritize both functionality and user-friendliness—an essential consideration when selecting suspension clamps for overhead lines.

Future of Stainless Steel in Power Transmission

Looking ahead, the role of stainless steel in power transmission appears brighter than ever. With ongoing research into enhancing its properties further—such as improving tensile strength while maintaining its corrosion-resistant qualities—stainless steel could become even more integral to overhead line construction strategies. The question remains: how will this material reshape our current understanding of what makes effective cable accessories?

As utilities adopt more sustainable practices and seek long-term cost-effectiveness, we can expect increased reliance on stainless steel solutions across various applications—from strain clamps to suspension systems. Ultimately, embracing these advancements will not only benefit suppliers but also contribute significantly to building resilient energy infrastructures capable of supporting tomorrow's needs.

Conclusion

As we wrap up our exploration of stainless steel in overhead line applications, it’s clear that material choice is paramount for ensuring durability and performance. Stainless steel stands out as a reliable option, particularly when considering its corrosion resistance and mechanical strength. Furthermore, its compatibility with existing systems makes it an attractive choice for cable accessories suppliers looking to enhance their offerings.

Key Takeaways on Material Suitability

When evaluating materials for overhead line fittings, stainless steel consistently proves its worth due to its exceptional properties. Not only is stainless steel corrosion resistant—making it ideal for various environmental conditions—but it also boasts impressive mechanical strength that can withstand significant loads. This combination ensures that strain clamps and suspension clamps maintain their integrity over time, providing peace of mind for those involved in power transmission projects.

The Long-Term Benefits of Stainless Steel

Investing in stainless steel translates to long-term benefits that far outweigh initial costs. Its inherent durability means reduced maintenance needs over time, allowing cable accessories suppliers to focus on quality rather than frequent replacements or repairs. Additionally, the longevity of stainless steel components—like suspension clamps for overhead lines—ultimately leads to cost savings and improved operational efficiency in power transmission systems.

Final Thoughts on Power Transmission Solutions

In conclusion, the future of power transmission solutions looks bright with the integration of stainless steel into overhead line construction. As industry trends shift towards more resilient materials, understanding whether stainless steel is corrosion resistant becomes crucial for making informed decisions. By choosing high-quality materials like stainless steel for strain clamps and suspension clamps, stakeholders can ensure reliable and efficient power delivery while contributing positively to sustainable practices in the energy sector.