Introduction

Understanding Eye Bolts and Screw Eyes

Eye bolts are threaded fasteners with a looped head that allows for easy attachment of ropes or cables, while screw eyes serve a similar purpose but are designed to be screwed directly into a surface. Among the types of eye bolts for lifting, shouldered eye bolts stand out due to their unique design that provides added strength during heavy lifting tasks. Non-shouldered eye bolts offer versatility but may not have the same load-bearing capacity as their shouldered counterparts.

The Importance of Material Selection

Choosing the right material for your eye bolt is essential to ensure durability and reliability under load. Galvanized steel offers corrosion resistance, making it suitable for outdoor applications, while stainless steel provides even greater strength and resistance to rusting in harsh environments. Understanding the differences between materials can help you select the appropriate type—whether it’s a lifting shoulder eye bolt or a regular nut eye bolt—for your specific needs.

Applications of Eye Bolts in Various Industries

Eye bolts find widespread use across multiple sectors including construction, marine applications, electrical installations, and telecommunications. In construction sites, they facilitate rigging operations by securely anchoring loads during hoisting tasks; meanwhile, marine applications utilize them for securing equipment aboard vessels. With their versatility across industries—whether using shouldered or non-shouldered variants—eye bolts remain vital components in ensuring safe operations wherever heavy lifting is involved.

Types of Eye Bolts for Lifting

Shouldered Eye Bolt Overview

Shouldered eye bolts are designed with a shoulder that provides additional support when lifting loads. This shoulder helps distribute the weight more evenly, which is essential for preventing failure during heavy lifts. The shouldered eye bolt capacity is typically higher than that of non-shouldered varieties, making them an excellent choice for demanding applications.

The lifting shoulder eye bolt can be used in various environments, including construction sites and industrial settings. Their robust design allows them to handle significant stress while maintaining structural integrity. When consulting a shoulder eye bolt capacity chart, you’ll often find impressive ratings that highlight their reliability.

Non Shouldered Eye Bolt Characteristics

Non-shouldered eye bolts offer a simpler design without the added support feature found in their shouldered counterparts. These types of eye bolts are generally lighter and easier to install but may not provide the same level of stability under heavy loads. While they have their place in lighter applications, understanding their limitations is key to ensuring safe lifting practices.

For those looking to use a non shouldered eye bolt effectively, it's important to consider factors like load direction and angle during installation. Misalignment can lead to increased wear or even catastrophic failure if not properly accounted for. Thus, while they may be suitable for certain tasks, always refer back to safety guidelines when using this type.

Regular Nut Eye Bolt Features

Regular nut eye bolts are perhaps the most commonly recognized type within this category and are known for their versatility across different applications. These bolts feature a threaded shaft that allows them to be secured with a nut on one end while providing an attachment point on the other side via its looped head—perfect for connecting chains or ropes securely.

One major advantage of regular nut eye bolts is their ease of use; they can be quickly fastened or unfastened as needed without specialized tools or equipment. However, just like with any other types of eye bolts for lifting, it’s essential to check their load ratings before putting them into service—especially if you’re working near maximum capacity limits! Regular inspections will also help prevent accidents stemming from wear over time.

Capacity Considerations

When it comes to lifting heavy loads, understanding the capacity of different types of eye bolts is crucial. Among these, shouldered eye bolts stand out for their ability to handle significant weight due to their design and construction. In this section, we’ll delve into the shouldered eye bolt capacity, analyze shoulder eye bolt capacity charts, and discuss various factors that influence lifting capacity.

Shouldered Eye Bolt Capacity Explained

Shouldered eye bolts are engineered with a shoulder that provides additional support during lifting operations. This feature allows them to distribute weight more evenly, which can significantly enhance their load-bearing capabilities compared to non-shouldered eye bolts. For those looking for reliable lifting solutions, understanding shouldered eye bolt capacity is essential; these bolts often come with specific ratings that indicate the maximum load they can safely handle.

The shouldered design not only improves stability but also minimizes the risk of bending or breaking under stress. When selecting a shouldered eye bolt for your project, always refer to the manufacturer's specifications regarding its lifting capacities. Remember, using a properly rated shouldered eye bolt can make all the difference in ensuring safety during heavy lifts.

Shoulder Eye Bolt Capacity Chart Analysis

To navigate through the myriad options available in types of eye bolts for lifting, one must consult a shoulder eye bolt capacity chart effectively. These charts provide vital information about each bolt's rated load capacities based on size and material composition—key factors when making your selection. By analyzing this data carefully, you can determine which shouldered or regular nut eye bolt best suits your needs.

For instance, larger diameter shoulder eye bolts typically have higher load ratings than smaller ones; however, it's essential to consider not just size but also material strength when interpreting these charts. Each entry in a shoulder eye bolt capacity chart serves as a guidepost in your decision-making process—don’t overlook it! By ensuring you select an appropriate model based on this analysis, you mitigate risks associated with overloading.

Factors Influencing Lifting Capacity

Several factors influence the overall lifting capacity of any given type of eye bolt—be it a shouldered or non-shouldered design. First and foremost is the material used; stainless steel offers superior strength compared to other materials like carbon steel or plastic options commonly found in regular nut eye bolts. Additionally, environmental conditions such as temperature and exposure to corrosive elements can affect performance and longevity.

Another critical aspect is how an eye bolt is installed; improper installation techniques can drastically reduce its effective lifting capacity regardless of whether it's a shouldered or non-shouldered design. Always ensure proper alignment and secure fastening when utilizing any type of lifting hardware for optimal safety outcomes! Lastly, consider dynamic loads versus static loads; while some bolts may handle static weights well under ideal conditions, they might struggle under shifting forces during operation.

Material Matters

When it comes to eye bolts, the choice of material is pivotal in determining their performance and suitability for various applications. Two common materials used in manufacturing are galvanized steel and stainless steel, each offering distinct advantages and considerations. Understanding the differences between these materials can help you select the best option for your specific needs.

Galvanized vs. Stainless Steel Eye Bolts

Galvanized eye bolts are coated with a layer of zinc to protect against corrosion, making them ideal for outdoor or marine applications where moisture exposure is a concern. However, while they offer excellent rust resistance, they may not withstand high temperatures or harsh chemical environments as effectively as stainless steel options. On the other hand, stainless steel eye bolts boast superior strength and corrosion resistance without additional coatings, making them suitable for critical lifting tasks where durability is paramount.

When considering types of eye bolts for lifting, it's essential to evaluate whether you need the added protection of galvanized steel or if stainless steel's robust nature better suits your project. For instance, if you're using a shouldered eye bolt in a construction setting exposed to elements, galvanized might be your go-to choice; however, if you're working in an industrial facility with high-stress loads, a lifting shoulder eye bolt made from stainless steel could be more appropriate. Ultimately, both materials have their place in various industries depending on environmental factors and load requirements.

Choosing the Right Material for Your Needs

Selecting the right material involves understanding your project's specific demands—think about where you'll use these eye bolts and what kind of loads they'll support. If you're dealing with heavy lifting scenarios that require maximum strength without compromising safety standards, consider opting for regular nut eye bolts crafted from high-grade stainless steel due to their impressive shouldered eye bolt capacity. Conversely, if budget constraints are a significant factor but you still require decent performance under less extreme conditions, galvanized options may suffice.

It's also important to assess any potential exposure to corrosive substances or extreme temperatures when making your choice; this will guide you toward either galvanized or stainless options accordingly. Make sure to consult shoulder eye bolt capacity charts available from manufacturers—these charts provide valuable insights into load ratings based on material type and design features like shoulders or nuts that enhance stability during use. By aligning your selection process with these considerations, you'll ensure that you choose an eye bolt that meets both safety standards and operational efficiency.

Benefits of Using Spark Fittings Products

Spark Fittings offers an impressive range of quality products designed specifically for various industrial applications—including shouldered eye bolts tailored for heavy-duty lifting tasks! Their commitment to excellence means you can trust that each product meets stringent safety standards while providing optimal performance across different settings—from construction sites to marine environments where reliability is non-negotiable.

One standout feature of Spark Fittings products is their comprehensive approach toward ensuring customer satisfaction through rigorous testing processes; this guarantees that every non-shouldered eye bolt or regular nut eye bolt delivers consistent results under pressure without compromising integrity over time! Additionally, using Spark Fittings means gaining access not only to premium materials but also expert guidance on choosing the right hardware tailored precisely for your needs—an invaluable resource when navigating complex projects requiring meticulous attention-to-detail regarding shouldered eye bolt capacity.

By investing in Spark Fittings products today, you're not just purchasing hardware; you're securing peace-of-mind knowing you've selected top-tier components designed explicitly with safety and functionality at heart!

Safety Protocols

When dealing with eye bolts, safety should always be your top priority. Understanding the specific characteristics of different types of eye bolts for lifting, such as shouldered eye bolts and non-shouldered eye bolts, is crucial for proper installation and use. By adhering to established safety protocols, you can ensure that your lifting operations are not only effective but also secure.

Best Practices for Eye Bolt Installation

Installing a shouldered eye bolt correctly is essential to maximize its lifting capacity and minimize risks. Always refer to the shoulder eye bolt capacity chart to select the appropriate size and type based on your load requirements. Additionally, ensure that you use the correct tools and follow manufacturer guidelines during installation to avoid any mishaps.

For non-shouldered eye bolts, it’s vital to check that they are installed in a manner that allows for optimal load distribution. This means avoiding any angles or positions that could lead to undue stress on the bolt itself. Remember that a regular nut eye bolt may require different considerations than its shouldered counterpart, so always approach each installation with an informed mindset.

Lastly, inspect all components before use; even minor wear can compromise safety. Ensure threads are clean and undamaged, and look out for signs of corrosion or fatigue in materials like galvanized steel versus stainless steel options. Following these best practices will not only enhance safety but also prolong the life of your hardware.

Common Mistakes to Avoid

When it comes to using shouldered eye bolts or any other types of eye bolts for lifting, some common mistakes can lead to unsafe conditions or equipment failure. One frequent error is overlooking the shoulder eye bolt capacity; using an undersized bolt can result in catastrophic failure under load stress. Always consult the shoulder eye bolt capacity chart before making selections.

Another mistake is neglecting proper alignment during installation; misalignment can cause uneven loading which increases the risk of bending or breaking a non-shouldered eye bolt. Ensuring that all components are aligned correctly will help distribute weight evenly across the hardware used in your application.

Moreover, many users forget about regular maintenance checks after installation—this oversight can lead to dangerous situations down the line. Regularly inspect both shouldered and non-shouldered designs for signs of wear or damage; this simple step can save lives and prevent costly equipment failures.

Ensuring Load Security

Ensuring load security when using a lifting shoulder eye bolt involves more than just selecting high-quality products—it requires diligence throughout every phase of operation as well! First off, always double-check connections before commencing any lift; this includes verifying that all fasteners are tightened properly according to specifications outlined by manufacturers.

Additionally, consider utilizing additional securing methods such as shackles or slings when appropriate; these accessories enhance stability during lifts involving heavy loads with regular nut eye bolts too! Furthermore, never exceed recommended weight limits outlined in either product manuals or charts—overloading leads directly back into potential disaster territory!

Lastly—and perhaps most importantly—train personnel involved in lift operations thoroughly so they understand how various types of eyes work together within rigging systems effectively! With comprehensive training coupled with strict adherence towards safe practices surrounding both installations & inspections alike – you’ll find peace-of-mind knowing everyone’s protected while achieving successful results!

Industry Applications

Eye bolts are versatile hardware components that find their place in various industries, each with unique requirements and challenges. From construction sites to marine applications and telecommunications, the use of eye bolts is critical for ensuring safety and efficiency in lifting and securing loads. Understanding the specific applications of shouldered eye bolts, non-shouldered eye bolts, and regular nut eye bolts can help you make informed choices for your projects.

Eye Bolts in Construction and Rigging

In the construction industry, shouldered eye bolts play a vital role in rigging operations where heavy lifting is involved. These types of eye bolts for lifting are often used to secure loads during hoisting or moving materials on-site. The shouldered eye bolt capacity is particularly crucial here; it ensures that these fittings can handle the weight they are subjected to without compromising safety.

Non-shouldered eye bolts also find their niche in construction, especially for lighter applications where load security is essential but extreme strength isn't required. Regular nut eye bolts serve as reliable options for general-purpose use when attaching cables or securing structures temporarily. Understanding the shoulder eye bolt capacity chart helps contractors select the right type of bolt based on weight requirements and project specifications.

Use in Marine Applications

Marine environments present unique challenges that demand robust solutions like shouldered eye bolts designed specifically for maritime conditions. The corrosion-resistant properties of galvanized or stainless steel materials make these types of eye bolts essential for securing boats, docks, and other marine equipment against harsh weather elements. The durability offered by these fittings ensures they withstand constant exposure to saltwater without deteriorating.

In addition to shouldered options, non-shouldered eye bolts are frequently used on vessels where space constraints limit the size of hardware components. Their lightweight design makes them ideal for quick installations while maintaining a strong hold on ropes or chains used during docking operations. For any marine application requiring reliability under duress, understanding shoulder eye bolt capacity is imperative to avoid accidents at sea.

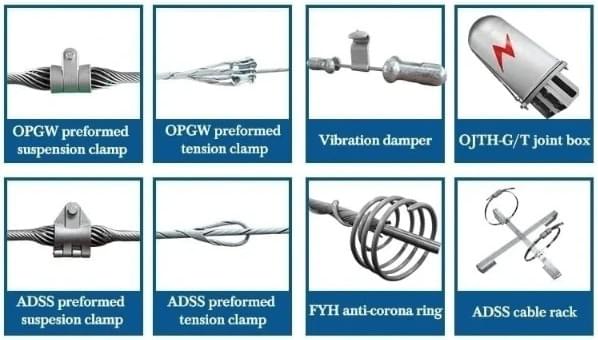

Eye Bolts for Electrical and Telecommunications

The electrical and telecommunications industries utilize regular nut eye bolts extensively when installing overhead lines or securing equipment at heights. These fittings provide a stable anchoring point that can withstand environmental stressors while supporting heavy cables or apparatuses without risk of failure. Non-shouldered variants offer flexibility in installation options where space might be limited but strength remains paramount.

Shouldered eye bolts come into play when dealing with heavier electrical loads or specialized telecommunications equipment that requires additional support during installation or maintenance operations. By consulting a shoulder eye bolt capacity chart before making selections, professionals ensure they choose appropriately rated hardware capable of bearing anticipated weights over time without compromising safety standards.

In conclusion, whether you're working on a construction site, navigating through marine tasks, or tackling electrical installations, understanding the various types of eye bolts available—like shouldered and non-shouldered options—will empower you to make safer choices tailored to your specific needs.

Conclusion

In conclusion, selecting the right eye bolt for your project is crucial for ensuring safety and efficiency in lifting operations. Whether you opt for a shouldered eye bolt, a non-shouldered eye bolt, or a regular nut eye bolt, understanding the specific requirements of your application will guide you in making an informed choice. Always refer to the shoulder eye bolt capacity chart to ensure that the selected type meets your load demands.

Choosing the Right Eye Bolt for Your Project

Shouldered eye bolts are often preferred for heavy-duty applications due to their superior lifting shoulder design that distributes weight more evenly. On the other hand, if you're dealing with lighter loads, a non-shouldered eye bolt or regular nut eye bolt might suffice and offer flexibility without compromising safety.

Maximizing Safety with Eye Bolts

Safety should always be at the forefront when using any lifting hardware, including shouldered and non-shouldered eye bolts. Proper installation techniques are vital; always ensure that you follow best practices to avoid common mistakes that could lead to accidents or equipment failure. Regular inspections of your lifting shoulder eye bolts can also help in maintaining load security and identifying wear before it becomes a serious issue.

The Future of Eye Bolt Innovations

As industries evolve, so does technology surrounding lifting equipment like shouldered eye bolts and their counterparts. Innovations in materials and designs promise even greater safety and efficiency in future applications of these essential tools. With ongoing research into advanced alloys and smart technology integration, we can expect significant improvements in both performance metrics and user experience regarding regular nut eye bolts and other types.