Introduction

In the realm of electrical infrastructure, understanding overhead line hardware is crucial for ensuring reliable and efficient power distribution. Hardware and fittings for overhead lines serve as the backbone of any electrical system, facilitating connections and maintaining stability in various environmental conditions. From connectors for substations to specialized fittings for OPGW and ADSS cables, each component plays an integral role in the overall performance of the network.

Understanding Overhead Line Hardware

Overhead line hardware encompasses a wide range of components designed to support and protect electrical conductors. These include line fittings that connect cables to poles or towers, ensuring they remain secure under tension and environmental stress. A thorough understanding of these components allows engineers to select appropriate hardware that meets specific project requirements while maximizing safety and efficiency.

Importance of Quality Fittings

Poor-quality line fittings can lead to failures that disrupt service or even cause hazardous situations, making it essential to invest in durable materials and designs. By prioritizing quality fittings, utilities can maintain operational integrity while minimizing maintenance costs over time.

Key Components of Line Fittings

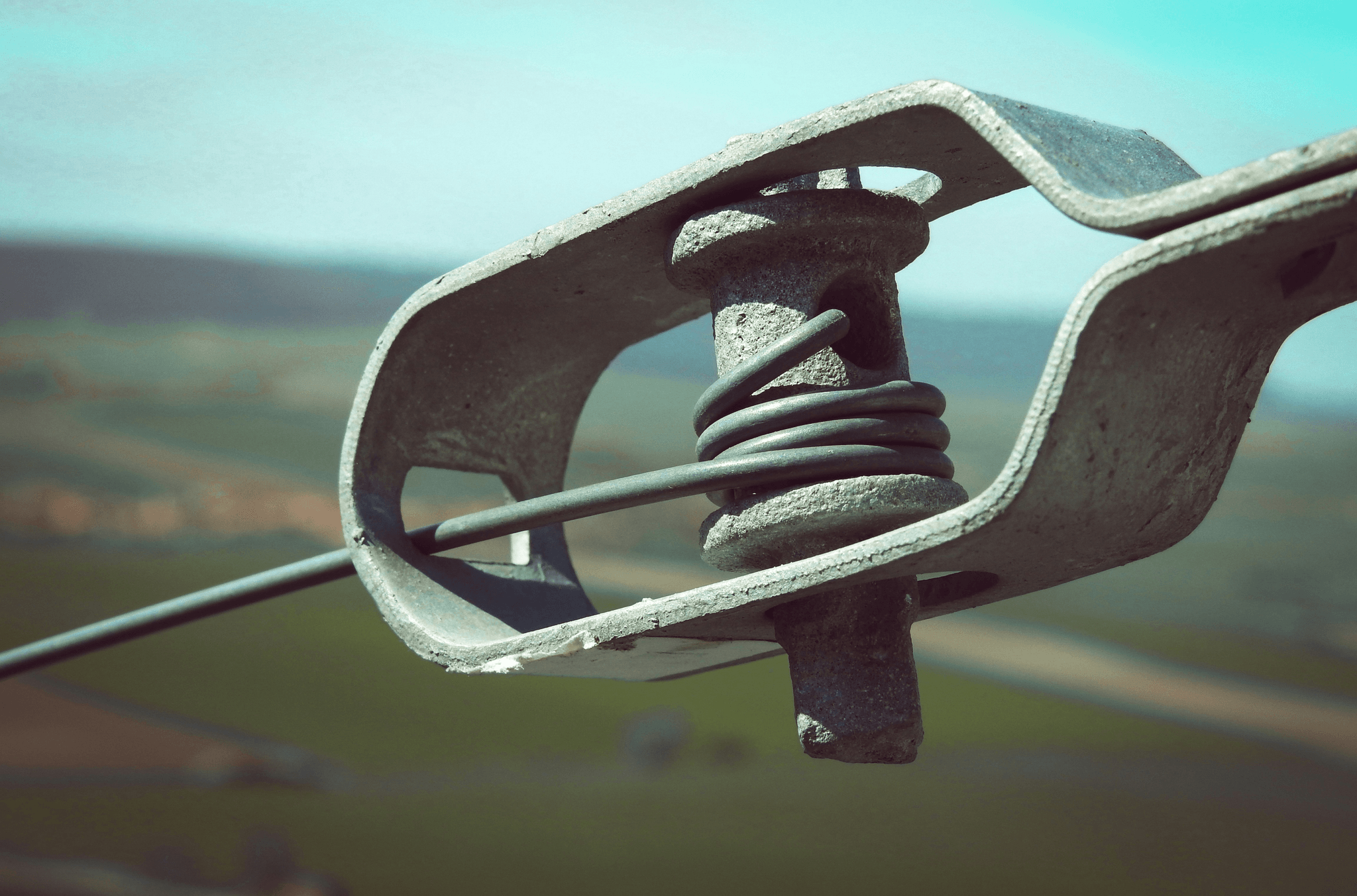

Line fittings consist of several key components that work together seamlessly to support overhead cables effectively. Among these are armour rods that protect conductors from abrasion, connectors for substation applications that facilitate safe energy transfer, and damping systems that minimize vibration-induced wear on cables. Understanding these components is vital for designing robust electrical networks capable of withstanding various operational challenges.

Overview of Hardware and Fittings for Overhead Lines

In the world of overhead lines, understanding the various hardware and fittings is essential for ensuring stability, safety, and efficiency. From connectors for substations to specialized fittings for OPGW and ADSS cables, each component plays a crucial role in maintaining the integrity of power transmission systems. This section delves into the types of fittings available, the importance of damping systems, and what makes quality line fittings stand out.

Types of Fittings for Overhead Cables

Overhead cables require a variety of fittings to ensure their proper installation and performance. Common types include suspension clamps, tension clamps, and dead-end fittings, each designed to handle specific loads while maintaining cable integrity. Moreover, these fittings are engineered to withstand environmental factors such as wind and ice loading—an essential consideration in regions prone to severe weather.

When selecting fittings for overhead cables, it’s important to consider compatibility with armour rods that protect conductors from abrasion. Quality line fitting choices also enhance overall system reliability by minimizing wear on cables over time. Ultimately, choosing the right type of fitting can significantly impact both operational efficiency and maintenance costs.

Role of Damping Systems in Stability

Damping systems play an integral role in enhancing the stability of overhead lines by mitigating vibrations caused by wind or other external forces. These systems work by absorbing oscillations that could otherwise lead to fatigue failure in cables or hardware components like connectors for substations. By effectively dampening these movements, they help prolong the lifespan of both line fittings and conductors.

Moreover, a well-designed damping system can prevent resonance phenomena that may occur under certain conditions—keeping everything from railway electrical lines to standard overhead setups safe from potential damage. The integration of damping solutions into your hardware strategy not only improves performance but also boosts overall safety standards across installations.

Essential Features of Quality Line Fittings

When evaluating line fittings for overhead cables, several key features signal quality craftsmanship worth investing in. First off is material durability; high-quality materials resist corrosion and wear while standing up against harsh environmental conditions commonly faced by overhead installations. Furthermore, effective design should facilitate easy installation without compromising structural integrity or performance.

Another essential feature is compatibility with various cable types—including OPGW (Optical Ground Wire) and ADSS (All-Dielectric Self-Supporting) options—ensuring versatility across different projects. Lastly, reliable manufacturers often provide comprehensive testing data demonstrating their products' strength under real-world conditions—a crucial factor when considering safety implications associated with railway electrical lines or similar applications.

Armour Rods: Protecting Conductors

In the world of overhead lines, armour rods play a vital role in safeguarding conductors from wear and tear. These fittings are designed to absorb mechanical stress and protect the conductor's surface, ensuring longevity and reliability. By acting as a protective layer, armour rods contribute significantly to the overall performance of line fittings.

Functionality of Armour Rods

Armour rods serve multiple functions that enhance the durability of overhead cables. Primarily, they provide mechanical protection against abrasion and environmental factors, which can lead to premature failure of conductors. Additionally, these fittings help maintain the integrity of electrical connections by preventing damage during installation or adverse weather conditions.

Spark Fittings' Role in Production

Spark fittings are essential components in the production process of armour rods, ensuring that each fitting meets stringent quality standards. These connectors for substations help facilitate a smooth transition between different hardware and fittings for overhead lines, enhancing overall system performance. By integrating spark fittings into their design, manufacturers ensure that armour rods can withstand electrical surges while protecting conductors effectively.

Benefits of Using Quality Armour Rods

Investing in quality armour rods yields numerous benefits for any overhead line project. High-quality fittings not only extend the lifespan of conductors but also improve operational efficiency by minimizing maintenance needs over time. Furthermore, using reliable hardware enhances safety across various applications—including those related to railway electrical lines—by reducing the risk of failures and outages.

Connectors for Substation Applications

Connectors play a pivotal role in the functionality of substations, acting as the bridge between various components of electrical systems. These connectors are not just simple fittings; they are essential for maintaining electrical efficiency and ensuring that power flows smoothly from one point to another. When considering hardware and fittings for overhead lines, the choice of connectors can significantly impact overall system performance.

Importance in Electrical Efficiency

Electrical efficiency is paramount in substation applications, where even minor losses can lead to significant operational costs over time. Quality connectors ensure minimal resistance and heat generation, which is crucial for maintaining optimal energy transfer. Inadequate or poorly designed line fittings can lead to inefficiencies that compromise both performance and safety, making it essential to invest in high-quality connectors.

Common Types of Connectors

There are several types of connectors commonly used in substation applications, each designed for specific tasks. For instance, compression connectors provide a secure connection by compressing the conductor against a metal surface, while bolted connectors offer flexibility through mechanical fastening methods. Additionally, specialized designs exist for fittings for OPGW and ADSS cables to accommodate their unique characteristics while ensuring reliability.

Best Practices for Installation

Installing connectors correctly is vital to maximize their effectiveness and longevity within substation environments. Best practices include ensuring proper torque specifications during installation to avoid loose connections that could cause arcing or overheating.

Specialized Fittings for OPGW and ADSS

When it comes to overhead line hardware, specialized fittings for Optical Ground Wire (OPGW) and All-Dielectric Self-Supporting (ADSS) cables play a crucial role in ensuring optimal performance and reliability. These cables are not just ordinary conductors; they serve dual purposes, combining electrical transmission with fiber optic communication. As such, the fittings designed for these cables must meet specific requirements that cater to both their physical properties and operational demands.

Key Characteristics of OPGW and ADSS

OPGW cables are unique because they integrate optical fibers within an aluminum or steel wire structure, providing both grounding and communication capabilities. On the other hand, ADSS cables are entirely non-metallic, allowing them to be installed in environments where electrical interference is a concern. Both types of cables require line fittings that can handle varying levels of tension while also accommodating thermal expansion and contraction—factors that can significantly affect the integrity of overhead lines.

Types of Fittings Specific to These Cables

Fittings for OPGW and ADSS include tension clamps, suspension clamps, and armor rods tailored specifically for the unique characteristics of these cables. Tension clamps secure the cable firmly while allowing flexibility during installation—essential for maintaining cable integrity under load conditions. Additionally, suspension clamps help distribute weight evenly along the cable run, minimizing stress points that could lead to failure over time; this is particularly important when considering damping systems that mitigate vibrations caused by wind or movement.

Ensuring Safety and Reliability

Ensuring safety and reliability in fittings for OPGW and ADSS involves rigorous testing standards that assess their performance under various environmental conditions. Quality control measures are vital; only high-grade materials should be used to manufacture these line fittings to withstand harsh weather elements while providing long-lasting service life. Moreover, regular inspections should be conducted post-installation to identify any potential issues early on—after all, when it comes to overhead lines, a stitch in time saves nine!

Fittings for Railway Electrical Lines

When it comes to railway electrical lines, the hardware and fittings for overhead lines must meet stringent requirements to ensure safety and reliability. These fittings are not just about holding cables; they play a critical role in the overall efficiency of train operations. With the unique demands of rail systems, selecting the right line fitting is essential for optimal performance.

Unique Requirements for Railway Fittings

Railway fittings must be designed to withstand extreme weather conditions, vibrations from moving trains, and other environmental stressors. Unlike standard fittings for overhead cables, railway-specific hardware often incorporates features that enhance durability and resilience. This means utilizing advanced materials that can handle both mechanical loads and electrical demands while ensuring minimal maintenance.

Impact of Quality Hardware on Safety

The quality of hardware used in railway electrical lines directly impacts safety levels across the network. High-quality line fittings reduce the risk of failures that could lead to power outages or accidents on tracks. By employing reliable connectors for substations and robust damping systems, rail operators can enhance operational safety while minimizing downtime caused by equipment malfunctions.

Innovations in Railway Fitting Solutions

The railway sector is witnessing exciting innovations in fitting solutions that enhance both performance and safety. Companies are developing specialized fittings for OPGW (Optical Ground Wire) and ADSS (All-Dielectric Self-Supporting) cables, ensuring seamless integration with existing infrastructure. Furthermore, advancements in armour rods technology are being leveraged to protect conductors effectively while maintaining flexibility within design constraints.

Conclusion

In the world of overhead line fittings, understanding the various components and their roles is crucial for ensuring safety and efficiency. From armour rods that protect conductors to specialized connectors for substations, each element plays a vital part in the overall functionality of electrical systems. As we’ve explored, quality hardware and fittings for overhead lines are not just optional; they are essential for reliable electrification.

Key Takeaways on Overhead Line Fittings

Overhead line fittings encompass a diverse array of components including connectors for substation applications, damping systems that enhance stability, and fittings tailored specifically for OPGW and ADSS cables. The importance of using high-quality line fittings cannot be overstated; they ensure durability and performance under various environmental conditions. Additionally, innovations in fittings for railway electrical lines highlight the industry's commitment to safety and efficiency.

Importance of Reliable Hardware in Electrification

Reliable hardware is at the heart of effective electrification efforts. Without sturdy line fittings, overhead cables could suffer from premature wear or failure, leading to costly outages or dangerous situations. Thus, investing in quality hardware and fittings for overhead lines not only safeguards infrastructure but also enhances overall electrical efficiency across networks.

Future Trends in Fittings for Overhead Lines

Looking ahead, we can expect significant advancements in the technology surrounding fittings for overhead cables. Innovations such as smart damping systems will likely emerge to further improve stability and performance under extreme weather conditions. Moreover, as renewable energy sources gain traction, specialized fittings designed specifically for new cable types will become increasingly important to accommodate evolving energy demands.