Introduction

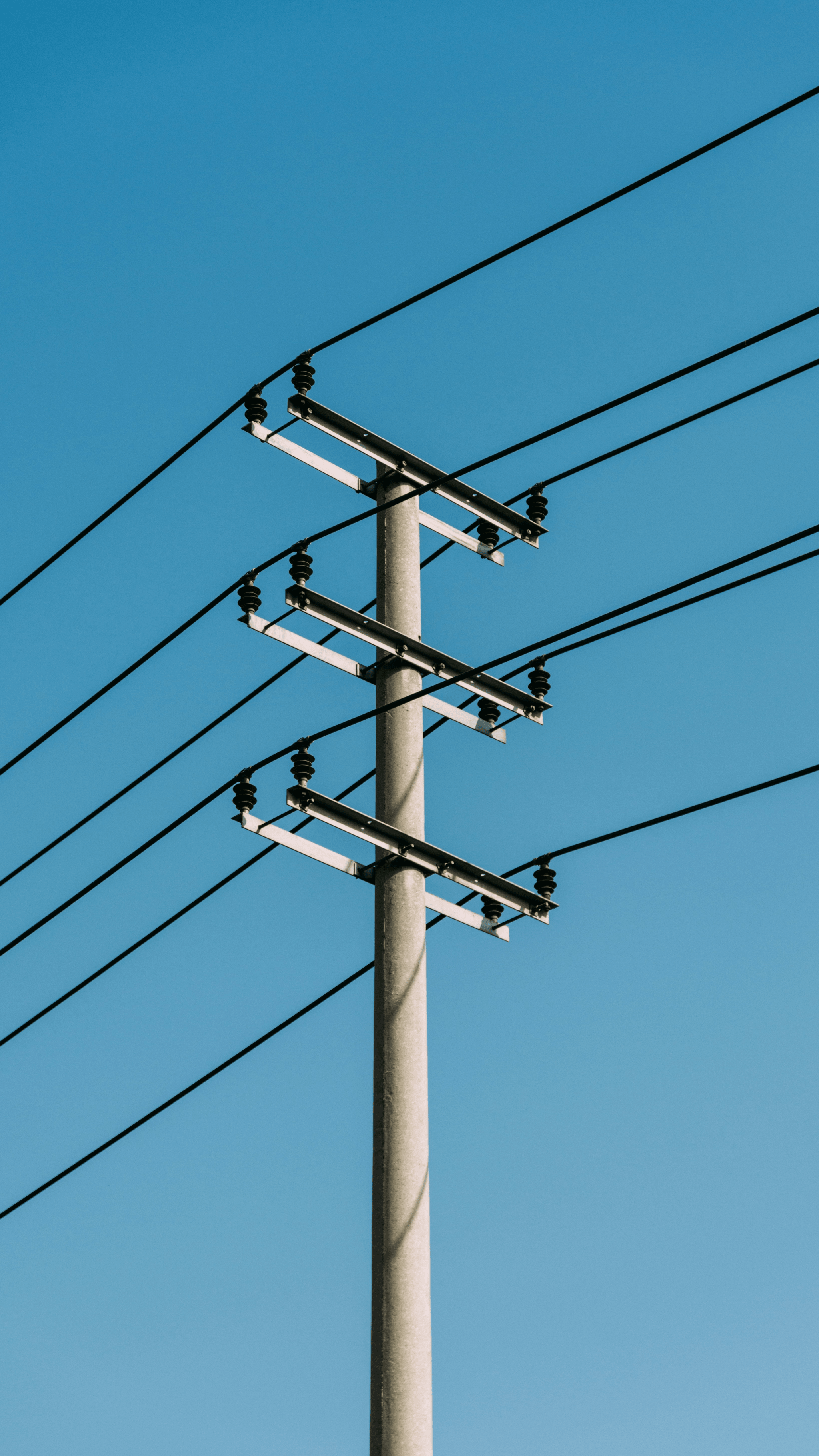

Stay rods are an often-overlooked yet crucial component in the stability and safety of utility poles. These metal rods, along with their accompanying hardware, work tirelessly to ensure that power lines remain upright and functional, even in adverse weather conditions. Understanding their role not only highlights their importance but also emphasizes the need for proper installation and maintenance.

Understanding the Role of Stay Rods

At their core, stay rods serve as tensioning devices that anchor utility poles, preventing them from swaying or toppling over under various loads. They connect the pole to the ground or other structures via components like Stay Bow and Stay Thimble, creating a system that distributes forces effectively. This tensioning mechanism is essential for maintaining the integrity of power distribution networks across urban and rural landscapes alike.

Importance of Stay Rods in Utility Poles

The significance of stay rods can't be overstated; without them, utility poles would be much more susceptible to damage from wind gusts or heavy ice accumulation. Their ability to stabilize poles directly impacts the reliability of electrical services provided to communities, making them indispensable for safe energy transmission. In essence, stay rods act as unsung heroes in ensuring that our power infrastructure remains robust and dependable.

Key Components of Stay Rod Systems

A well-functioning stay rod system consists of several key components: the Stay Plate provides a solid base for anchoring; Tubular Types offer different configurations tailored to specific needs; while Turn Buckles allow for easy adjustments to tension levels as required over time. Additionally, Eye Rods are used at both ends of these systems to facilitate connections with other hardware parts seamlessly. Each element plays a vital role in ensuring that stay rod systems perform optimally under varying conditions.

What are Stay Rods?

Stay rods are essential components in the stability and support of utility poles, ensuring they remain upright against various forces. These rods act as tension members, working in conjunction with other parts of the stay rod system to provide crucial structural integrity. Understanding their definition and functionality helps appreciate their role in maintaining a reliable utility infrastructure.

Definition and Functionality

A stay rod is a tension rod that connects a utility pole to the ground or another structure, helping to stabilize it against lateral forces such as wind or weight from overhead lines. Typically made from durable materials, these rods can endure significant stress while maintaining their shape and function. Their primary functionality lies in transferring loads away from the pole, allowing for safer and more reliable operation of electrical systems.

How Stay Rods Support Utility Poles

Stay rods support utility poles by anchoring them securely to the ground or adjacent structures, creating a triangulated support system that resists tipping or swaying. The combination of stay bows, stay thimbles, and stay plates works harmoniously with the stay rod to distribute forces evenly across the pole's structure. This interconnectedness ensures that even during adverse weather conditions or heavy loads on power lines, the utility poles remain stable thanks to these well-designed components.

Differences Between Stay Rods and Other Supports

While there are various types of supports used for utility poles, such as guy wires and braces, stay rods offer unique advantages that set them apart. Unlike guy wires that require additional tensioning devices like turn buckles for adjustment, stay rods provide a more straightforward installation process with minimal maintenance needs once secured properly. Additionally, stay rods often incorporate tubular types for added strength without excessive weight, making them an efficient choice compared to traditional supports.

Components of Stay Rod Systems

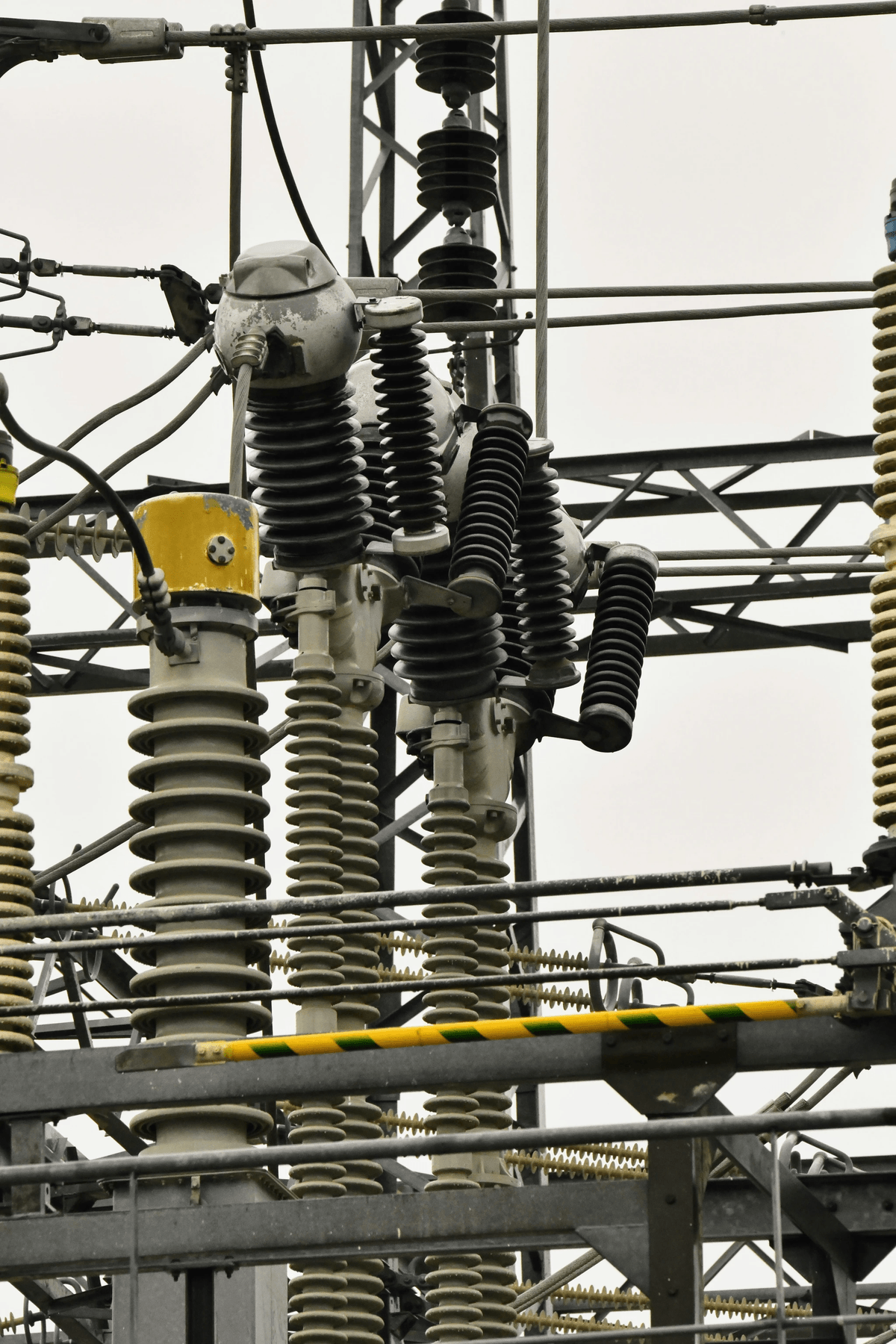

Stay rod systems are essential for maintaining the stability and integrity of utility poles, and their components work together seamlessly to achieve this. Understanding how each part functions can help ensure proper installation and maintenance, ultimately prolonging the life of these critical structures. Let's dive into the key components: Stay Bow, Stay Thimble, Stay Plate, and Tubular Types.

How Stay Bow and Stay Thimble Work

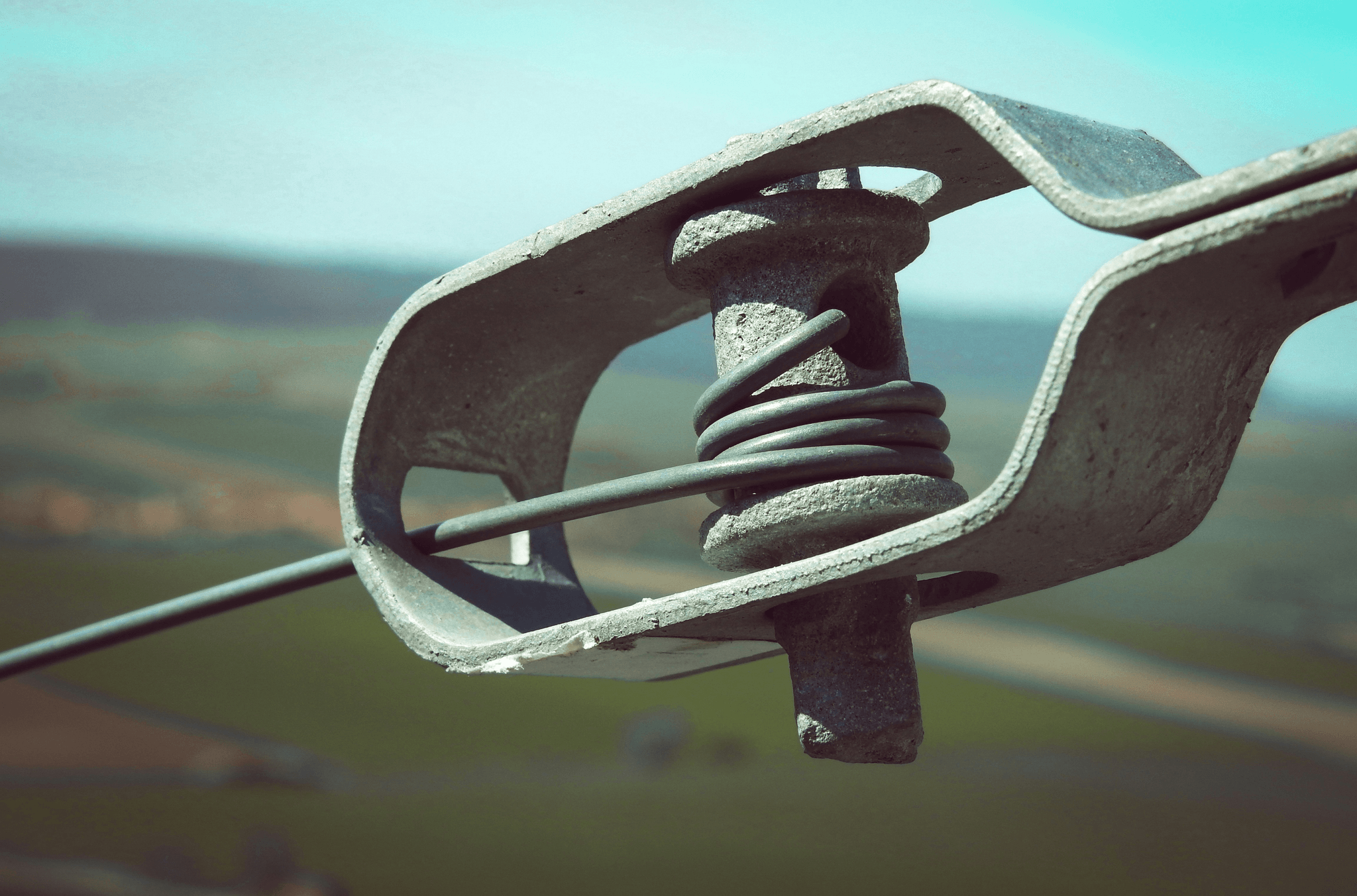

The Stay Bow is a crucial component that provides tension to the stay rod system while allowing for some flexibility under load. It acts as a curved support that helps distribute forces evenly across the utility pole structure. Meanwhile, the Stay Thimble serves as a protective fitting that prevents wear on the stay rod where it connects to other components, ensuring longevity in tough weather conditions.

Together, these two elements work harmoniously; when you tighten a Turn Buckle connected to a Stay Rod, it pulls on the Stay Bow while being anchored by the Stay Thimble. This combination creates an effective tensioning system that keeps utility poles upright against wind loads or other external pressures. Without these critical pieces working in tandem, your utility pole might be at risk of leaning or even falling over time.

The Role of Stay Plate in Stability

The Stay Plate acts as an anchor point for stay rods and plays a significant role in stabilizing utility poles during high winds or adverse weather conditions. By distributing the load from multiple stay rods evenly across its surface area, it minimizes stress concentrations on any single point of attachment. This distribution is vital for maintaining structural integrity over time.

Additionally, using quality materials for your stay plate ensures resistance against corrosion and wear caused by environmental factors like rain or salt exposure near coastal areas. When properly installed with Armour Rods providing extra support at conductor points, the entire stay rod system becomes even more robust against potential failure points. So next time you admire those tall poles standing proudly against nature’s fury, remember: it's often thanks to their trusty stay plates!

Understanding Tubular Types and Their Uses

When it comes to tubular types used in stay rod systems, there are several options available depending on specific application needs and environmental conditions they will face over time. Commonly used materials include steel or aluminum tubes designed for enhanced durability while remaining lightweight enough not to add unnecessary strain on existing structures like utility poles.

Tubular types can vary significantly; some may feature additional coatings or treatments designed specifically to resist rusting or corrosion caused by moisture exposure over long periods—ideal if you're dealing with challenging climates! Moreover, Eye Rods are often incorporated into tubular designs since they provide efficient attachment points for securing stays without compromising overall strength.

In summary, understanding these various tubular types ensures that you choose wisely based on your unique requirements—after all; no one wants their hard work undone due to subpar materials! With well-chosen components like Armour Rods integrated into your setup alongside durable tubular designs such as Eye Rods ensuring secure connections throughout every stage of installation—you'll be well-equipped for success!

Installing Stay Rods: A Step-by-Step Guide

Installing stay rods is an essential task for ensuring the stability of utility poles. Proper installation not only enhances the safety of the structures but also prolongs their lifespan. This guide will walk you through the necessary tools, tips for securing the rods, and common pitfalls to avoid during installation.

Necessary Tools for Installation

Before diving into installation, gather your toolkit to ensure a smooth process. Essential tools include a wrench for tightening turn buckles, a drill with appropriate bits for anchoring stay thimbles, and a level to confirm vertical alignment of your stay rods. Don’t forget safety gear like gloves and goggles; you’ll want to protect yourself while working with these sturdy components.

In addition to these basics, having a measuring tape handy will help you determine the correct lengths needed for both stay rods and eye rods. If you're working with tubular types, make sure you have specific fittings that match their diameter. Lastly, consider using a torque wrench to apply precise tension on your stay plate connections—this ensures everything is secure without over-tightening.

Tips for Properly Securing Stay Rods

Securing stay rods effectively involves more than just tightening bolts; it's about ensuring they can withstand environmental stressors like wind and ice load. Start by positioning your stay bow at the correct angle before attaching it to the utility pole; this helps distribute tension evenly across all components including the stay thimble and turn buckle. Once in place, use your level again to check that everything remains straight as you tighten each connection.

When fastening eye rods or other fittings, ensure they are snug but not overly tight—over-tightening can lead to metal fatigue or even breakage over time! Regularly check that all connections are secure during routine inspections; this proactive approach can save significant headaches down the line. Remember that proper alignment contributes significantly to overall stability—take your time here!

Common Mistakes to Avoid

Even seasoned professionals can stumble when installing stay rod systems if they're not careful about certain details. One common mistake is neglecting routine checks on existing installations before adding new components; this could lead to misalignment or structural weaknesses going unnoticed until it’s too late!

Another pitfall is using incompatible parts—always double-check that your armour rods, stay bows, and other fittings are designed for use together within similar load specifications. Finally, don’t underestimate weather conditions during installation; working in high winds or rain can complicate securing processes and increase risk factors significantly.

By avoiding these mistakes and following best practices throughout installation, you'll set up a strong foundation for any utility pole system equipped with reliable stay rod technology.

The Importance of Armour Rods

Armour rods are an essential component in the world of utility poles, providing critical protection to conductors. These protective devices are typically made from materials like fiberglass or aluminum, designed to absorb stress and distribute loads effectively. Understanding their role helps ensure the longevity and reliability of electrical systems.

What are Armour Rods?

Armour rods are cylindrical protective devices that wrap around electrical conductors, acting as a shield against environmental factors and mechanical stress. They come in various sizes and shapes to accommodate different tubular types of conductors, ensuring a snug fit without compromising performance. By utilizing armour rods, utility companies can significantly reduce the risk of conductor damage due to wind, ice, or other external forces.

How Armour Rods Protect Conductors

The primary function of armour rods is to protect conductors from abrasion and wear caused by movement or environmental conditions. When installed correctly alongside components like stay thimbles and stay plates, they help maintain the integrity of the conductor while allowing for flexibility during installation and operation. This protection is vital for preventing costly outages and ensuring that power remains uninterrupted for consumers.

Spark Fittings' Role in Armour Rod Manufacturing

Spark fittings play a crucial role in the manufacturing process of armour rods by providing secure attachment points for these protective devices on utility poles. These fittings work seamlessly with other components such as stay bows and turn buckles to create a robust support system that enhances overall stability. The combination of spark fittings with quality armour rods ensures that conductors remain protected under various conditions while maintaining optimal performance.

Maintenance of Stay Rod Systems

Maintaining stay rod systems is crucial for ensuring the stability and safety of utility poles. Regular upkeep can prevent costly repairs and enhance the longevity of components like Stay Bow, Stay Thimble, and Stay Plate. By implementing a routine inspection schedule, you can identify potential issues before they escalate into significant problems.

Routine Inspections and Updates

Routine inspections should be conducted at least twice a year to ensure that all components, including the Stay Rods and Tubular Types, are in good condition. During these inspections, pay special attention to the connections between the Stay Rods and their respective fittings such as Turn Buckles and Eye Rods. Any signs of rust or corrosion on these components can indicate a need for immediate maintenance or replacement.

Updating your maintenance protocols based on inspection findings is also essential. If you notice any wear on the Stay Plate or other structural elements during inspections, it may be time to consider upgrades or replacements to enhance overall system integrity. Regular updates not only prolong equipment life but also help maintain compliance with safety standards.

Identifying Signs of Wear and Tear

Identifying signs of wear and tear in stay rod systems is vital for preventing failures that could compromise utility pole stability. Look for visible damage such as fraying or cracking in the armour rods that protect conductors from abrasion; this could indicate underlying issues with your support system. Additionally, check for bent or misaligned components like the Stay Bow which may affect how evenly weight is distributed along the pole.

Another critical aspect to monitor is any loosening of connections involving Turn Buckles or Eye Rods; this can lead to instability in your entire setup if left unaddressed. If you observe any unusual movement in your stay rod systems during windy conditions or storms, it’s time to investigate further for hidden damage that might not be immediately visible. Keeping an eye out for these signs ensures that you catch problems early before they escalate into more serious issues.

When to Replace Stay Rods

Knowing when to replace stay rods is essential for maintaining a reliable support system for utility poles. Generally, if any component shows significant wear—such as cracks in the Stay Thimble or severe rusting on Tubular Types—it’s wise to consider replacing them promptly to avoid catastrophic failure down the line. As a rule of thumb, if an inspection reveals more than 30% deterioration in structural integrity across multiple components like armour rods and stay plates, replacement should be prioritized.

In addition to visual assessments during routine checks, keep track of how long each component has been in use; older installations may require more frequent replacements due to material fatigue over time. Also remember that environmental factors such as exposure to extreme weather conditions can accelerate wear; thus staying proactive about replacements will save both time and resources later on. Ultimately, regular evaluations will guide you on when it's best to refresh your stay rod systems effectively.

Conclusion

In wrapping up our exploration of stay rods, it's clear that these unsung heroes play a crucial role in maintaining the stability and integrity of utility poles. By understanding the advantages of quality stay rod systems, we can appreciate their importance in our daily lives and the infrastructure we rely on. From stay bows to tubular types, each component contributes to a robust support system that keeps our utilities running smoothly.

Advantages of Using Quality Stay Rod Systems

Quality stay rod systems provide numerous advantages that enhance the overall performance and safety of utility poles. For instance, using durable materials for components like the stay plate and eye rod ensures longevity, reducing maintenance costs over time. Moreover, well-installed stay rods equipped with turn buckles allow for easy adjustments, ensuring optimal tension is maintained under various weather conditions.

Another significant benefit is the protection against environmental stresses; quality stay rods are designed to withstand high winds and heavy loads without compromising stability. This resilience not only prolongs the life of utility poles but also minimizes service interruptions caused by structural failures. Ultimately, investing in top-notch stay rod systems translates into a safer environment for both service providers and consumers alike.

The Impact of Stay Rods on Utility Stability

Stay rods are pivotal in ensuring that utility poles remain upright and functional, directly impacting overall utility stability. By anchoring poles securely to the ground or nearby structures, they distribute loads evenly and prevent swaying during storms or high winds. This stability is essential for maintaining reliable power delivery and communication services across communities.

Furthermore, when combined with other components such as armour rods and stay thimbles, these systems enhance durability against wear over time. The synergy between these elements ensures that even under extreme conditions, utility infrastructure remains intact—keeping lights on when they matter most! Without effective stay rods in place, we risk frequent outages that could disrupt daily life.

Future Innovations in Stay Rod Technology

The future holds promising innovations for stay rod technology that could revolutionize how we approach utility pole support systems. Emerging materials like advanced composites may offer lighter yet stronger alternatives to traditional steel components such as tubular types or eye rods—enhancing ease of installation without sacrificing performance. Additionally, smart technology integration could allow real-time monitoring of tension levels within stay rod systems through sensors connected to a centralized network.

Moreover, advancements in design may lead to more aesthetically pleasing options while still providing superior functionality; imagine sleek designs that blend seamlessly into urban landscapes! As research continues into enhancing durability through corrosion-resistant coatings or improved fastening mechanisms like turn buckles, we can expect more resilient solutions tailored to meet modern demands for energy efficiency and sustainability.