Introduction

In the world of electrical utilities, the importance of reliable hardware cannot be overstated. Among these essential components, the dead end clamp plays a critical role in ensuring that overhead lines function safely and effectively. This introduction will explore the significance of dead end clamps, the necessity for quality hardware in utility applications, and provide an overview of Spark Fittings' offerings, which stand out in this competitive market.

Understanding Dead End Clamps' Role

Dead end clamps are pivotal in securing conductors to poles or structures, effectively anchoring them in place to withstand tension and environmental stresses. Their functionality extends beyond mere attachment; they prevent unwanted movement that could lead to conductor failure or damage. By utilizing robust materials like ductile iron, these clamps ensure long-lasting performance under various conditions.

Importance of Quality Hardware in Utilities

Quality hardware is vital for maintaining safety and efficiency within utility infrastructures. Inferior components can lead to significant issues such as line failures or electrical hazards, making it crucial for utilities to invest in high-quality conductor hardware and related accessories like anchors and arresters. The reliability of distribution insulators also hinges on the integrity of the hardware used; thus, selecting dependable products is non-negotiable.

Overview of Spark Fittings' Offerings

Spark Fittings has established itself as a leader in manufacturing top-tier conductor hardware solutions tailored for overhead lines. Their innovative designs encompass a range of products including dead end clamps, anchors, cutouts, and arresters that meet stringent quality standards. With a commitment to excellence backed by customer testimonials and case studies demonstrating their effectiveness, Spark Fittings continues to set benchmarks within the industry.

What is a Dead End Clamp?

These clamps are designed to withstand significant tension, ensuring that the electrical lines remain stable and reliable. Understanding their definition and functionality can help utilities appreciate their importance in maintaining safe and efficient operations.

Definition and Functionality

A dead end clamp is a specialized piece of conductor hardware used to anchor the ends of overhead conductors securely. Its primary function is to hold the conductor firmly in place, preventing any movement that could lead to sagging or disconnection under tension. By providing this stability, dead end clamps help maintain the integrity of electrical systems, especially in areas susceptible to high winds or other environmental stresses.

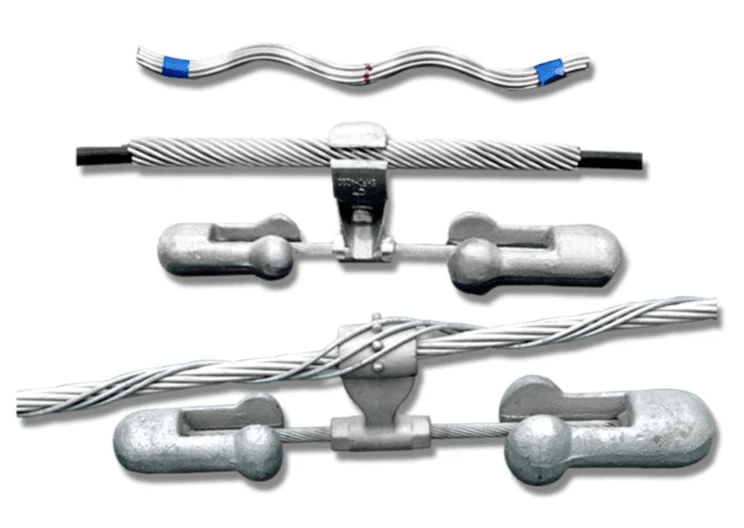

Types of Dead End Clamps

There are several types of dead end clamps available, each designed for specific applications and conductor sizes. Some common varieties include wedge-type clamps, which utilize a wedging mechanism for secure attachment, and compression clamps that use mechanical pressure to grip the conductor tightly. Additionally, there are specialized designs that incorporate features like integrated anchors or arresters for enhanced safety and performance.

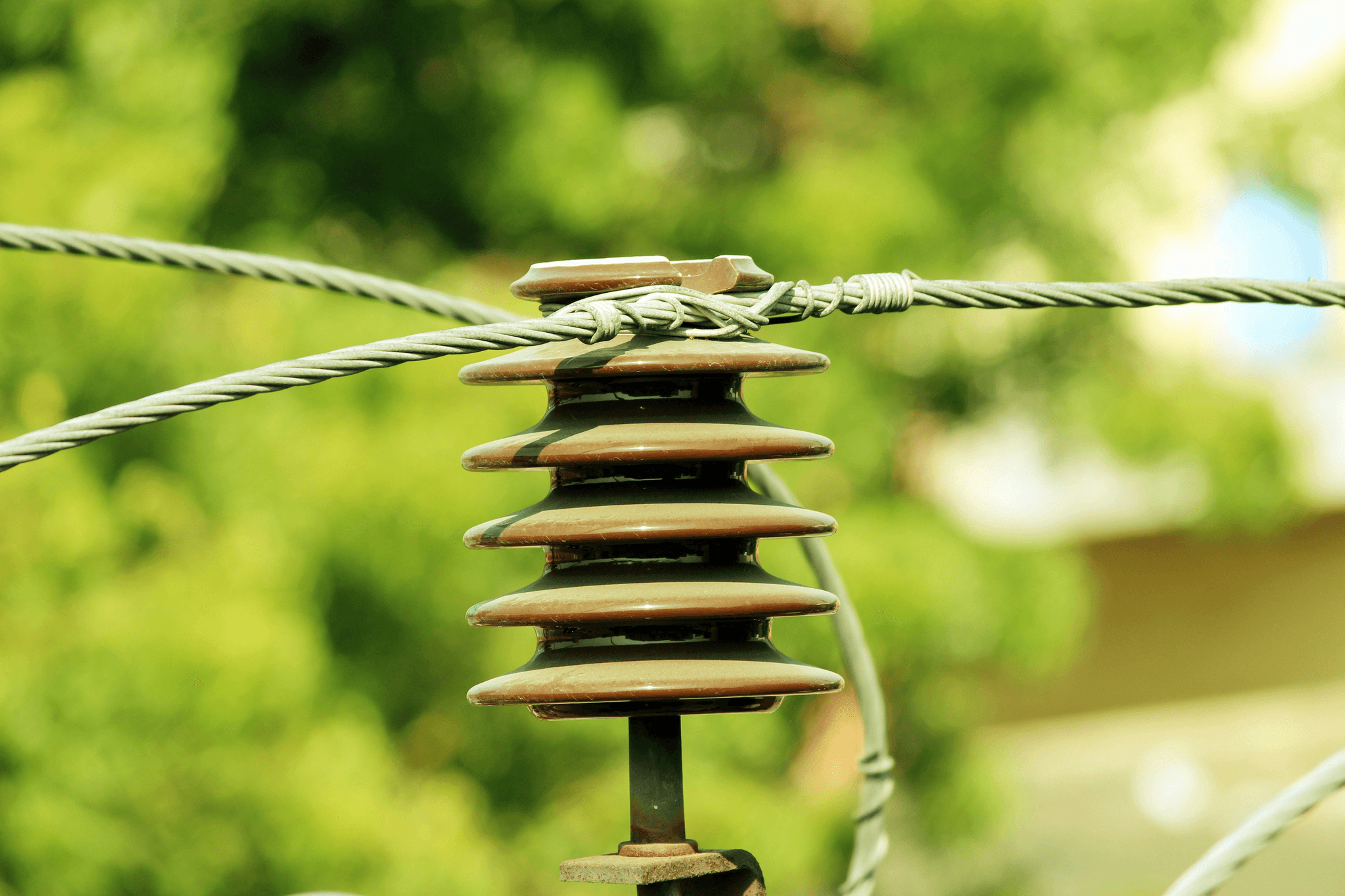

Applications in Overhead Lines

Dead end clamps find their primary application in overhead power lines where they serve as critical components for maintaining electrical distribution systems. They are often used at pole tops or along spans where conductors need anchoring due to changes in direction or elevation. Furthermore, these clamps play a vital role when paired with distribution insulators or cutouts, ensuring that electrical currents flow safely without risk of disconnection during adverse weather conditions.

Key Materials for Dead End Clamps

These components must endure significant stress and environmental challenges while ensuring the safety and reliability of overhead lines. Understanding the key materials used in their manufacture can help utilities make informed decisions regarding conductor hardware.

Why Ductile Iron Is Preferred

Ductile iron is often the material of choice for dead end clamps due to its remarkable strength and flexibility. Unlike traditional cast iron, ductile iron can withstand higher loads without fracturing, making it ideal for supporting heavy conductors and anchors in overhead line applications. Its ability to absorb shock also makes it a reliable option in areas prone to severe weather or seismic activity.

Moreover, ductile iron's resistance to corrosion enhances its longevity, reducing maintenance costs over time. This durability means that utilities can trust ductile iron dead end clamps to perform effectively throughout their operational lifespan, even under challenging conditions. As a result, many manufacturers prioritize this material when designing components like distribution insulators and cutouts.

Exploring Different Alloys

While ductile iron is a top contender for dead end clamp construction, various alloys also play significant roles in enhancing performance. For instance, aluminum alloys are lightweight yet strong alternatives that resist corrosion effectively; they are particularly beneficial where weight reduction is critical in overhead line systems. Additionally, stainless steel offers exceptional resistance to environmental factors but may come at a higher cost than other materials.

Each alloy brings unique properties that can be tailored to specific applications within conductor hardware setups. By understanding these differences, utility companies can select the most suitable materials for their needs—whether prioritizing weight savings or enhanced durability against harsh conditions. Ultimately, exploring different alloys allows manufacturers like Spark Fittings to innovate continuously and meet diverse market requirements.

Durability in Varying Weather Conditions

The durability of dead end clamps is crucial when considering their exposure to varying weather conditions throughout the year. From intense heat waves to freezing temperatures and heavy precipitation, these components must remain functional regardless of external factors—ensuring that overhead lines stay secure and operational at all times. High-quality materials such as ductile iron and specialized alloys contribute significantly to this resilience.

Furthermore, effective design plays an essential role in mitigating wear caused by environmental stresses; well-engineered dead end clamps will feature protective coatings or treatments that enhance corrosion resistance while maintaining structural integrity under load-bearing scenarios. Utilities should prioritize products that have been tested against extreme weather conditions during selection processes for conductor hardware solutions like anchors and arresters as well as cutouts designed for distribution insulators.

In conclusion, understanding the key materials used in dead end clamps not only aids utilities in making informed decisions but also ensures safe and reliable infrastructure development across regions with diverse climates.

The Importance of Anchors and Arresters

When it comes to maintaining the integrity of overhead lines, anchors and arresters play a pivotal role. These components work in tandem with dead end clamps to ensure that conductor hardware remains securely in place, even in challenging weather conditions. Their importance cannot be overstated, as they are essential for the stability and safety of electrical distribution systems.

Securing Overhead Lines Effectively

Anchors are designed to provide a firm foundation for overhead lines, preventing excessive movement that could lead to sagging or breakage. By effectively securing dead end clamps and other conductor hardware, anchors help maintain optimal tension within the system. This ensures that distribution insulators remain properly aligned, minimizing the risk of electrical faults or outages.

Arresters complement this security by protecting against voltage surges that could damage the entire system. They act as guardians, redirecting excess energy away from sensitive components like cutouts and ensuring that everything operates smoothly. When combined with robust dead end clamps, these elements create a resilient network capable of withstanding environmental challenges.

Preventing Electrical Hazards

The integration of anchors and arresters is crucial for preventing electrical hazards in overhead line installations. Without proper anchoring, lines can shift or sway dangerously during storms or high winds, leading to potential short circuits or line failures. Dead end clamps alone cannot mitigate these risks; it’s the combination of all components working together that enhances safety.

Arresters are equally important in safeguarding against electrical surges caused by lightning strikes or equipment malfunctions. By diverting excess voltage away from critical parts of the system, they protect not only the conductor hardware but also surrounding infrastructure from catastrophic failures. Investing in quality anchors and arresters is essential for any utility looking to ensure long-term reliability and safety.

Recommendations for Quality Products

When selecting anchors and arresters for your overhead line projects, prioritize products made from durable materials like ductile iron. This ensures longevity and resistance against harsh weather conditions while providing reliable performance over time. Look for manufacturers who specialize in high-quality conductor hardware designed specifically for utility applications.

Furthermore, consider options that have been tested under various environmental stressors to guarantee their effectiveness in real-world scenarios. Collaborating with reputable suppliers will also give you access to innovative solutions tailored to modern utility needs—ensuring your installations remain safe and efficient year-round. Remember: choosing quality products today can save you significant costs on repairs down the road!

Choosing the Right Conductor Hardware

Choosing the right conductor hardware is crucial for ensuring the reliability and safety of overhead line systems. With various options available on the market, it can be overwhelming to determine which components, such as dead end clamps, anchors, and arresters, will best meet your specific needs. By understanding the differences between products and their applications, you can make informed decisions that enhance your utility infrastructure.

Comparing Options Available

When it comes to conductor hardware, there are several options to consider beyond just dead end clamps. Various types of anchors and arresters serve distinct purposes; for instance, anchors provide stability while arresters protect against voltage surges. Additionally, cutouts and distribution insulators play vital roles in ensuring safe operation under varying conditions—each piece working together to create a robust system.

It's essential to compare materials used in these components as well. Ductile iron is often preferred for its strength and durability compared to other metals; however, different alloys may offer unique benefits depending on your specific application requirements. Ultimately, understanding these differences will guide you toward selecting the best conductor hardware for your project.

Factors to Consider for Selection

Selecting the right conductor hardware involves evaluating several key factors that can impact performance and safety. First off is load capacity: ensure that your chosen dead end clamp can handle the tension exerted by overhead lines without compromising structural integrity. Additionally, consider environmental factors such as temperature fluctuations or exposure to corrosive elements—these conditions could necessitate more robust materials like ductile iron or specialized coatings.

Another critical aspect is compatibility with existing infrastructure; you'll want to ensure that new components integrate seamlessly with current installations like anchors or distribution insulators without requiring extensive modifications. Finally, don’t overlook manufacturer reputation; choosing reputable suppliers who prioritize quality will ultimately lead you towards reliable products that stand the test of time.

Integrating with Existing Utility Infrastructure

Integrating new conductor hardware into an existing utility infrastructure requires careful planning and consideration of multiple factors. First and foremost is assessing current equipment compatibility: make sure that any new dead end clamps or anchors align with existing poles and lines without causing undue stress or misalignment in your setup. This ensures a smooth transition while maintaining operational efficiency.

Moreover, when introducing new components like arresters or cutouts into your system, take into account how they interact with current distribution insulators—cohesiveness among all parts is paramount for optimal performance in overhead lines. Finally, always consult with experienced professionals when making these upgrades; their insights can help avoid pitfalls during integration while enhancing overall system reliability.

Spark Fittings: A Leader in Manufacturing

Spark Fittings has carved out a niche as a premier manufacturer of utility hardware, specializing in products that ensure the reliability and safety of overhead lines. Their extensive range includes deadend clamps, anchors, arresters, conductor hardware, cutouts, and distribution insulators. With a commitment to quality and innovation, Spark Fittings stands out in the competitive landscape of utility solutions.

Overview of Spark Fittings' Products

At the heart of Spark Fittings' offerings is their impressive lineup of deadend clamps designed for maximum durability and performance. These clamps are crafted from high-quality ductile iron to withstand the rigors of various environmental conditions while providing optimal support for overhead lines. In addition to deadend clamps, their product range also features robust anchors and arresters that enhance safety and stability in electrical distribution systems.

The company prioritizes innovation by continuously evolving its product line to meet industry demands. Their conductor hardware is engineered with precision to ensure seamless integration with existing infrastructure while maintaining high performance standards. This focus on quality extends across all products, including cutouts and distribution insulators that are vital for effective power management.

Innovations in Dead End Clamps and More

They utilize advanced manufacturing techniques that incorporate cutting-edge materials like ductile iron alloys which offer superior strength without compromising weight or ease of installation. These innovations not only improve functionality but also enhance safety by reducing the risk associated with overhead line installations.

Furthermore, Spark Fittings continuously explores new technologies to improve their anchors and arresters as well as other conductor hardware solutions. This proactive approach ensures they remain ahead of industry trends while addressing emerging challenges faced by utilities worldwide. The result is a suite of products that not only meets but exceeds expectations for reliability and performance.

Customer Testimonials and Case Studies

Customer satisfaction speaks volumes about the quality provided by Spark Fittings; numerous testimonials highlight how their deadend clamps have transformed overhead line projects across various sectors. Utility companies have reported significant improvements in installation efficiency thanks to the intuitive design and robust construction of these clamps. Additionally, clients praise the effectiveness of their anchors and arresters in preventing electrical hazards during severe weather conditions.

Case studies illustrate successful implementations where Spark Fittings’ products played a pivotal role in enhancing system reliability for major utilities. For instance, one case study detailed how integrating their ductile iron conductor hardware into an existing grid reduced maintenance costs significantly over time due to increased durability against environmental stressors. Customers consistently report peace of mind knowing they can rely on high-quality components from a trusted leader like Spark Fittings.

Conclusion

In wrapping up our exploration of dead end clamps and their significance in the utility industry, it’s clear that these components play a pivotal role in ensuring the safety and reliability of overhead lines. From securing conductors to providing essential support for distribution insulators, dead end clamps are indispensable. Their robust design, often constructed from ductile iron, ensures durability and performance even in challenging weather conditions.

Recap of Dead End Clamp Benefits

Dead end clamps offer numerous advantages that enhance the efficiency of overhead line installations. They effectively secure conductors to poles or towers, reducing strain and preventing damage during adverse weather events. Moreover, when paired with anchors and arresters, they create a comprehensive solution for maintaining electrical safety while optimizing the overall infrastructure.

How to Choose Reliable Suppliers

Selecting reliable suppliers for conductor hardware is crucial for maintaining high standards in utility operations. Look for manufacturers who prioritize quality materials like ductile iron and demonstrate a commitment to innovation in products such as dead end clamps and distribution insulators. Additionally, customer testimonials can provide insight into product performance; always check reviews before making a decision.

Future Trends in Overhead Line Hardware

The future of overhead line hardware is evolving with advancements in technology and materials science. We can expect innovations that enhance the functionality of components like dead end clamps while improving their environmental resilience through better alloys and coatings. Moreover, as utilities shift towards smart grid technologies, integrating modern solutions such as intelligent cutouts with traditional hardware will become increasingly important.