Introduction

In the world of electrical infrastructure, the significance of suspension and strain clamps cannot be overstated. These components play crucial roles in ensuring that overhead lines remain secure and functional, enabling reliable power transmission across vast distances. Understanding how these clamps differ and their specific applications is essential for anyone involved in electrical engineering or maintenance.

The Importance of Suspension and Strain Clamps

Suspension clamps are designed to support overhead conductors while allowing for thermal expansion and contraction, making them vital for maintaining the integrity of electrical lines. Similarly, strain clamps are essential for managing tension within these lines, preventing damage from excessive stress. Together, these clamps ensure that systems operate smoothly, minimizing outages and enhancing overall safety.

Differentiating Between Clamp Types

While suspension clamps focus on supporting conductors, strain clamps are engineered to handle tension forces effectively. Tension clamps serve a unique purpose by providing additional support in high-stress areas where conductors may experience significant pull. Understanding the nuances between these types—suspension clamp, strain clamp, tension clamp—enables professionals to select the right tools for their specific needs.

Why Spark Fittings is Key

Their expertise ensures that customers receive not only top-notch products but also tailored solutions such as dead end clamp overhead line options that meet specific project requirements. Choosing Spark Fittings means choosing reliability and innovation in your electrical infrastructure projects.

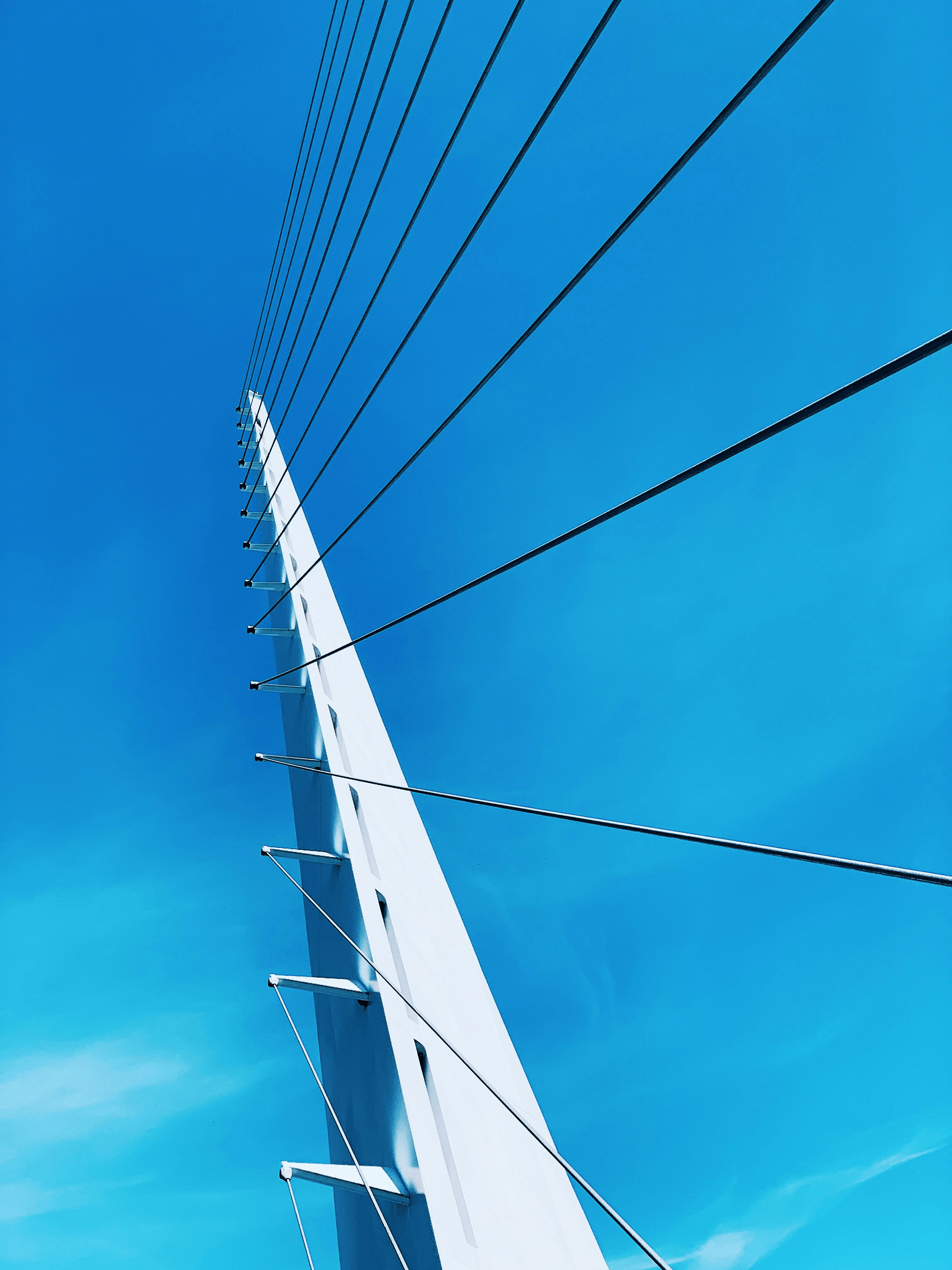

Understanding Suspension Clamps

These clamps are designed to support conductors and maintain their position without bearing any significant tension, which is where strain clamps come into the picture. By effectively managing the weight of the cables, suspension clamps help prevent undue stress on electrical lines.

What Suspension Clamps Do

Suspension clamps serve as a crucial component in overhead power systems by holding conductors securely in place while allowing for some movement due to thermal expansion or wind. Unlike tension clamps, which are designed to handle significant forces, suspension clamps primarily focus on supporting the weight of the cables without exerting pressure that could lead to damage. This unique function makes them an essential part of any electrical infrastructure.

Applications of Suspension Clamps

The applications for suspension clamps are numerous and varied, making them indispensable in many fields involving overhead lines. They are commonly used in power distribution networks where they hold conductors above ground and ensure proper spacing between wires. Additionally, these clamps find their way into telecommunications setups and street lighting systems—anywhere that requires secure cable management without tension-related concerns.

Key Characteristics of Suspension Clamps

When selecting a suspension clamp, it's important to consider several key characteristics that set them apart from other types like strain clamps or dead end clamps. Typically made from durable materials such as aluminum or steel, these clamps offer excellent resistance against environmental factors like corrosion and UV exposure. Their design also allows for easy installation and maintenance—a must-have feature for anyone working with overhead line systems.

Exploring Strain Clamps

Strain clamps are essential components in electrical infrastructure, ensuring that conductors remain secure and stable under varying tension levels. Understanding their functionality, applications, and advantages can help you make informed decisions when selecting the right clamp for your needs.

Functionality of Strain Clamps

A strain clamp is designed to hold conductors tightly while allowing for some movement due to thermal expansion or contraction. Unlike suspension clamps that primarily support cables without tension, strain clamps are specifically engineered to absorb and distribute forces along the line. This unique ability helps prevent damage from excessive strain or movement, which is crucial for maintaining the longevity of overhead lines.

Where Strain Clamps Are Used

Strain clamps find their place in various applications within electrical networks, particularly on overhead lines where tension management is vital. They are commonly used at dead end points where cables change direction or terminate; this is where a dead end clamp comes into play as well. Additionally, strain clamps are often found in areas prone to high winds or heavy ice loads—any situation that demands robust support and stability for electrical conductors.

Advantages of Using Strain Clamps

The benefits of using strain clamps extend beyond mere functionality; they enhance safety and reliability within electrical systems too. By effectively managing tension forces, they reduce wear on cables and prevent failure points that could lead to outages or hazards—something no one wants on a stormy night! Furthermore, their compatibility with other components like suspension clamps and dead end clamps makes them versatile tools for any installation project requiring solid cable management.

The Role of Tension Clamps

Understanding Tension in Electrical Lines

Tension in electrical lines is an essential factor that affects both safety and performance. When wires are installed, they experience various forces due to environmental conditions like wind or ice accumulation. Tension clamps help manage these forces by securely anchoring the wires, preventing excessive movement that could lead to wear or failure.

Tension Clamp vs. Suspension Clamp

While both tension clamps and suspension clamps are vital for overhead line installations, they serve different purposes. A suspension clamp primarily supports the weight of the wire without applying significant tension, allowing for some movement as needed. Conversely, a tension clamp actively maintains the wire's tautness under load, providing stability where it’s most needed—especially in high-stress environments.

When to Use Tension Clamps

Knowing when to use a tension clamp versus other types like strain clamps or dead end clamps is key for effective installation. If your overhead line experiences significant lateral forces or requires precise alignment during installation, a tension clamp is your best bet. In contrast, if you simply need to support cables without added stressors, a suspension clamp may suffice.

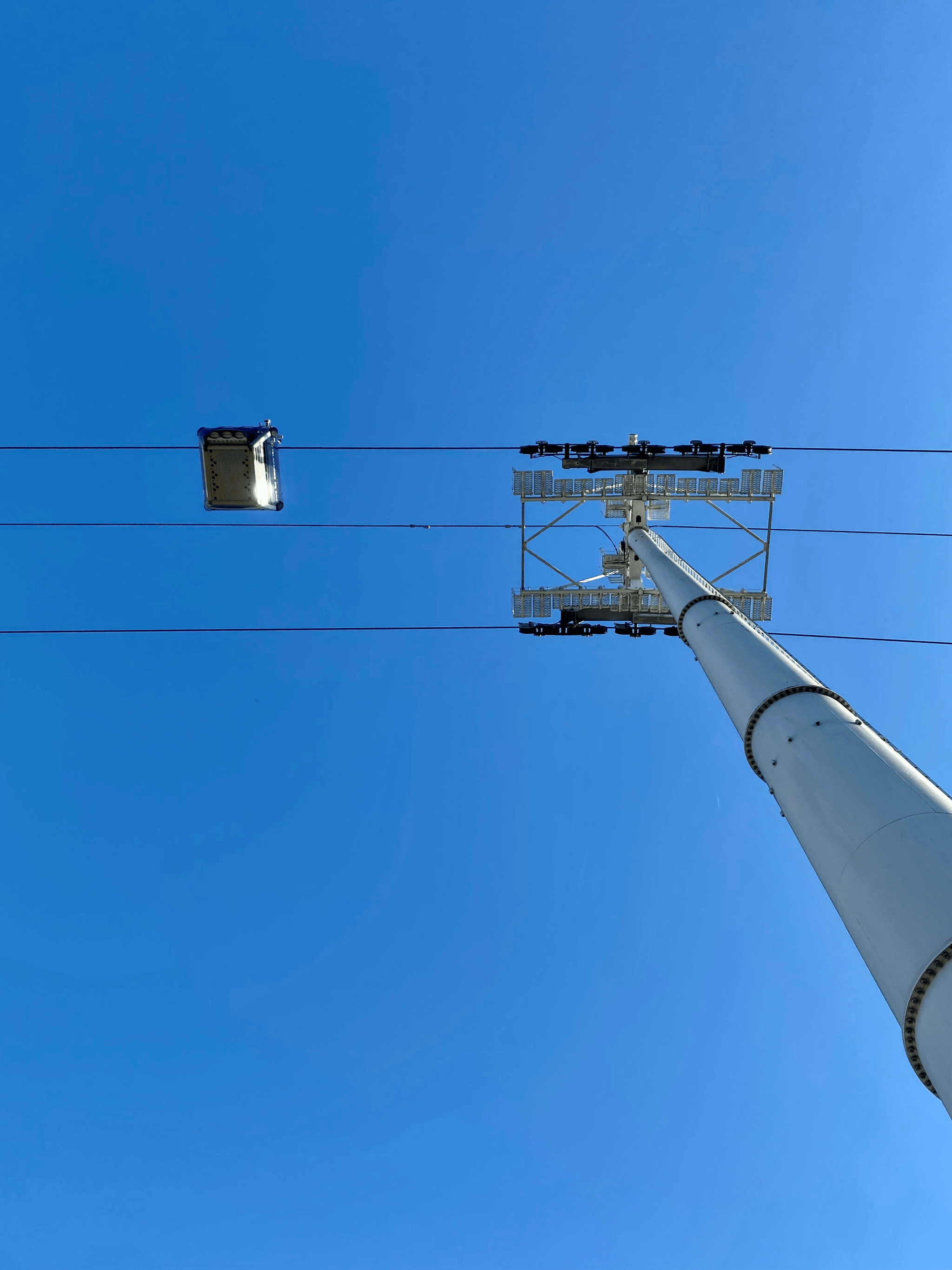

The Mechanics of Dead End Clamps

When it comes to overhead lines, the mechanics behind Dead End Clamps play a crucial role in ensuring stability and safety. These clamps are designed to secure the end of a conductor, preventing it from pulling through or slipping out under tension. Unlike Suspension Clamps that support conductors along their length, Dead End Clamps take on the heavy lifting at the termination points.

What is a Dead End Clamp?

A Dead End Clamp is a specialized device used to anchor electrical conductors at their endpoints, effectively managing tension within overhead lines. This clamp prevents any unwanted movement that could lead to wear and tear or even catastrophic failure of the line. In contrast to Strain Clamps, which manage forces during operation, Dead End Clamps are all about securing the conductor firmly in place.

Importance in Overhead Lines

Dead End Clamps are indispensable in maintaining the integrity of overhead power lines by handling significant mechanical stress caused by wind, ice, and other environmental factors. They ensure that cables remain taut and secure while also distributing loads evenly throughout the structure. Without these clamps, overhead lines would be prone to sagging or even breaking under strain—an outcome no one wants when it comes to electrical infrastructure.

Choosing the Right Dead End Clamp

Selecting the appropriate Dead End Clamp for an overhead line involves considering several factors including conductor size, material type, and environmental conditions. It's essential to match your clamp with its intended application; using a strain clamp where a dead end clamp is required could lead to serious issues down the line—literally! Always consult with manufacturers or experts who specialize in these components to ensure you’re making an informed choice tailored for your specific needs.

Spark Fittings: A Leader in Clamps

When it comes to the world of clamps, Spark Fittings stands out as a premier provider of high-quality solutions tailored for various applications. Their extensive product line includes strain clamps, suspension clamps, tension clamps, and dead end clamps specifically designed for overhead lines. With a focus on innovation and reliability, Spark Fittings is committed to enhancing infrastructure with their top-of-the-line offerings.

Overview of Spark Fittings' Offerings

Spark Fittings offers an impressive range of products that cater to the diverse needs of electrical infrastructure. Their lineup includes essential components like strain clamps and suspension clamps that ensure secure connections in overhead lines. Additionally, their tension clamp and dead end clamp solutions are engineered to withstand the rigors of environmental stress while maintaining optimal performance.

Customers can trust that each product from Spark Fittings is crafted with precision and durability in mind. The company’s commitment to quality means that whether you need a strain clamp for a specific application or a dead end clamp for overhead line installations, you’re guaranteed reliable performance. This dedication has established Spark Fittings as a go-to source for all your clamping needs.

Specialized Armor Rod Solutions

One standout feature of Spark Fittings is their specialized armor rod solutions designed to protect electrical cables from wear and tear. These armor rods are particularly beneficial when used alongside tension clamps or dead end clamps, ensuring that cables remain secure while minimizing damage over time. By integrating these armor rods into your setup, you enhance the longevity and reliability of your electrical systems.

Moreover, the armor rod solutions come in various sizes and materials to meet different operational requirements across industries. Whether you're dealing with high voltage lines or standard utility installations, there's an option perfectly suited for your needs. This specialization demonstrates how Spark Fittings goes above and beyond by providing not just standard products but tailored solutions that truly make a difference.

Customization Options for Armor Rods

Customers can work directly with their team to design armor rods that meet specific dimensions or material requirements based on unique project demands. This level of customization ensures optimal compatibility with existing systems while enhancing overall efficiency.

Additionally, these customized armor rods can be integrated seamlessly with other products such as suspension clamps or tension clamps within your infrastructure setup. By allowing customers this flexibility, Spark Fittings empowers users to create tailored configurations that maximize performance while minimizing potential issues down the line. Ultimately, this commitment to customization reinforces why so many choose Spark Fittings as their trusted partner in electrical infrastructure projects.

Conclusion

In the world of electrical infrastructure, clamps are not just accessories; they are essential components that ensure safety and reliability. From suspension clamps that hold cables in place to strain clamps that manage tension, each type serves a unique purpose in maintaining the integrity of overhead lines. Understanding the role of these clamps can make a significant difference in both installation and maintenance processes.

The Essential Role of Clamps in Infrastructure

Clamps like suspension clamps, strain clamps, tension clamps, and dead end clamps form the backbone of electrical systems. They provide stability and support for overhead lines, preventing sagging or damage from environmental factors. Without these crucial components, infrastructure could face severe challenges, leading to potential outages or hazards.

Choosing the Right Clamp for Your Needs

Selecting the right clamp is paramount; it’s not a one-size-fits-all scenario. Depending on your specific application—whether you need a strain clamp to handle high tension or a dead end clamp for secure anchoring—you must consider various factors such as load capacity and environmental conditions. Consulting with professionals can help ensure you choose the appropriate clamp type to meet your needs effectively.

How Spark Fittings Can Help You Today

With specialized solutions tailored to fit unique requirements—including custom options for armor rods—Spark Fittings ensures you have what you need when you need it. Their expertise can guide you through selecting the best strain clamp or any other type necessary for your project.