Introduction

In the world of electrical distribution, understanding dead end insulators is crucial for ensuring the stability and safety of power transmission systems. A dead end insulator serves a vital role in supporting and securing conductors at points where they terminate or change direction. This introduction will explore what a dead end insulator is, its significance, and how high-quality suppliers like Spark Fittings can enhance your electrical infrastructure.

Understanding Dead End Insulators

So, what is a dead end insulator? Essentially, it’s a specialized component designed to hold conductors in place while preventing electrical leakage and maintaining insulation integrity. These insulators are particularly important in high-voltage applications where reliability is paramount. By providing mechanical support and electrical insulation at critical junctions, dead end insulators help ensure that power flows smoothly without interruptions.

Importance of High-Quality Suppliers

When it comes to selecting components for your electrical systems, the importance of high-quality suppliers cannot be overstated. Choosing reliable manufacturers ensures that you receive products that meet stringent industry standards and perform effectively under various conditions. In this context, understanding which insulator is used at dead ends becomes essential; only trusted suppliers can provide the necessary specifications and performance guarantees.

Key Features of Spark Fittings

Spark Fittings stands out as a premier supplier in the field of insulator manufacturing, offering exceptional quality and customization options for their products. Their expertise allows them to deliver tailored solutions that meet specific project requirements while ensuring durability and performance reliability. Additionally, Spark Fittings emphasizes quality assurance through meticulous material selection—key features that make them an invaluable partner when considering what are the 5 types of insulators needed for different applications.

What is a Dead End Insulator?

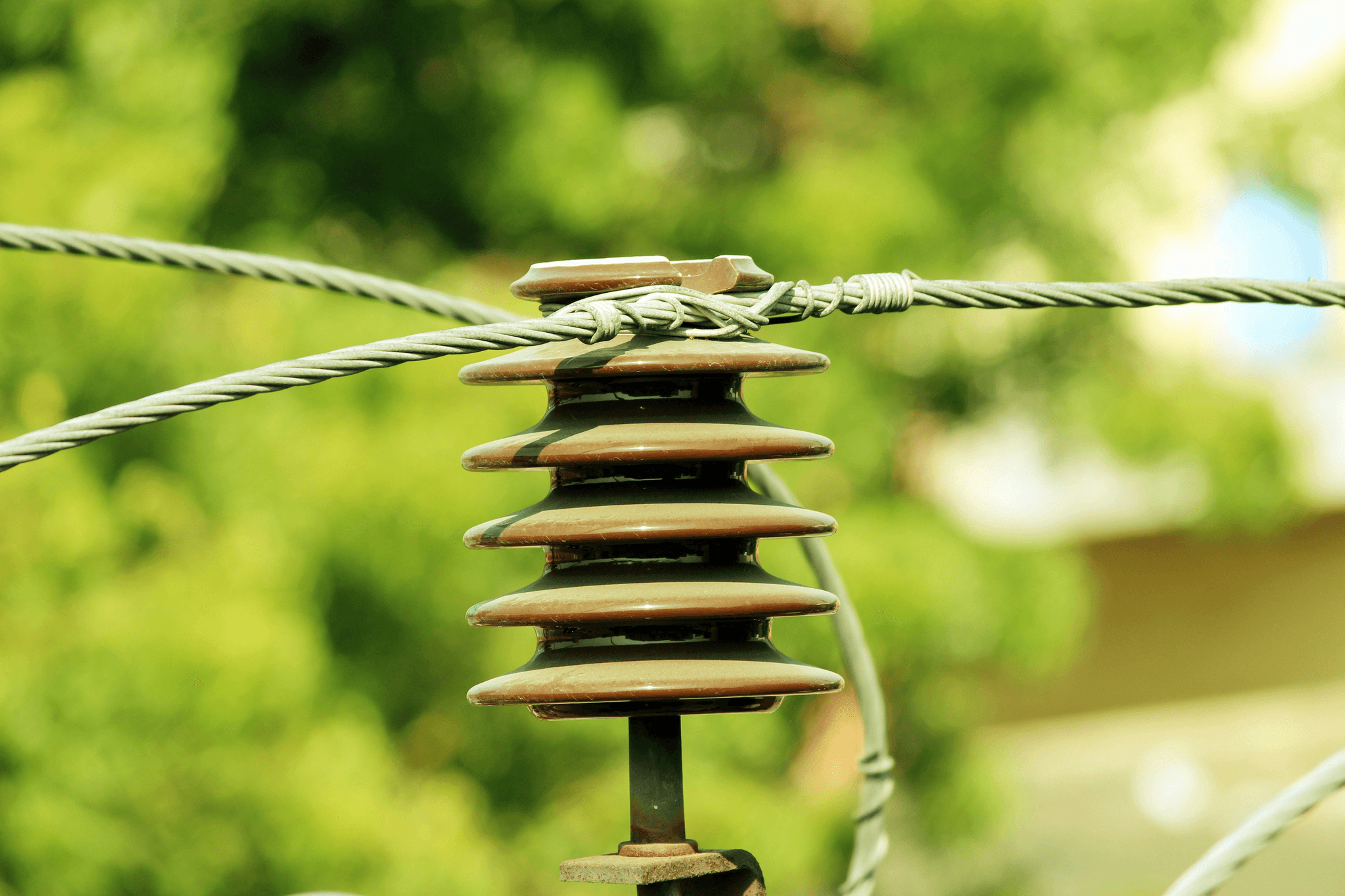

Dead end insulators play a crucial role in electrical power systems, designed specifically to handle the mechanical and electrical stresses at the termination points of overhead lines. So, what is a dead end insulator? Essentially, it's an insulating device that secures conductors at dead ends or corners in power transmission lines, ensuring that the line remains stable while preventing any electrical leakage. These insulators are vital for maintaining the integrity and safety of electrical networks.

Definition and Functionality

A dead end insulator is primarily defined by its ability to support and anchor power lines where there are abrupt changes in direction or where lines terminate. This type of insulator functions by providing both mechanical support for the conductor and electrical insulation from surrounding structures or other conductors. By doing so, it minimizes the risk of short circuits and enhances overall system reliability.

In essence, when you ask, Which insulator is used at dead ends? the answer lies with these specialized devices that ensure effective load management while also accommodating thermal expansion and contraction due to varying temperatures. Their design typically includes materials that can withstand harsh environmental conditions, making them indispensable for outdoor applications.

Types of Dead End Insulators

When exploring what are the 5 types of insulators, it’s important to note that dead end insulators come in several varieties tailored for specific applications. The most common types include porcelain, glass, polymer composite, and even some newer designs made from advanced materials like silicone rubber. Each type offers unique advantages depending on factors such as voltage level, environmental conditions, and installation requirements.

Porcelain dead end insulators are known for their durability and resistance to weathering but can be heavier than their counterparts. Glass options provide excellent visibility for inspections but may be more fragile under certain stress conditions. Polymer composite insulators have gained popularity due to their lightweight nature and resistance to pollution—ideal for urban settings where space is limited.

Applications in Power Transmission

The applications of dead end insulators in power transmission extend beyond merely supporting wires; they ensure safe operation across various scenarios including substations, overhead distribution lines, and even renewable energy setups like wind farms or solar arrays. They effectively manage high voltages while preventing arcing or flashover incidents which could lead to catastrophic failures.

In addition to traditional power grids, these insulators find use in specialized environments such as railway electrification systems where they help maintain stability under dynamic loads from moving trains. As technology advances within the industry—especially with smart grid implementations—the importance of reliable dead end insulation continues to grow alongside evolving energy demands.

Which Insulator is Used at Dead Ends?

When it comes to dead end insulators, understanding their role is crucial for anyone involved in power transmission systems. These insulators are specifically designed to handle the mechanical stress and electrical insulation required at points where overhead lines change direction or terminate. So, which insulator is used at dead ends? Let’s dive into the details.

Overview of Dead End Insulators

A dead end insulator is a specialized component that serves as a critical link in power transmission lines. What is a dead end insulator? Essentially, it provides both mechanical support and electrical insulation at locations where conductors are anchored or redirected. These insulators come in various shapes and sizes, tailored to meet specific load requirements while ensuring safety and reliability.

Dead end insulators are typically made from durable materials like porcelain or polymer composites, which can withstand harsh environmental conditions. Their design allows them to effectively manage tension from the wires they support, preventing damage to both the lines and the surrounding infrastructure. In essence, they play an indispensable role in maintaining system integrity.

Comparison with Other Insulators

When comparing dead end insulators with other types of electrical insulators, it's essential to understand their unique functions. For instance, while standoff insulators serve primarily to maintain spacing between conductors and supporting structures—what is the purpose of a standoff insulator—they do not bear the same mechanical loads as dead end varieties do. This distinction highlights why selecting the right type of insulation is crucial for efficiency.

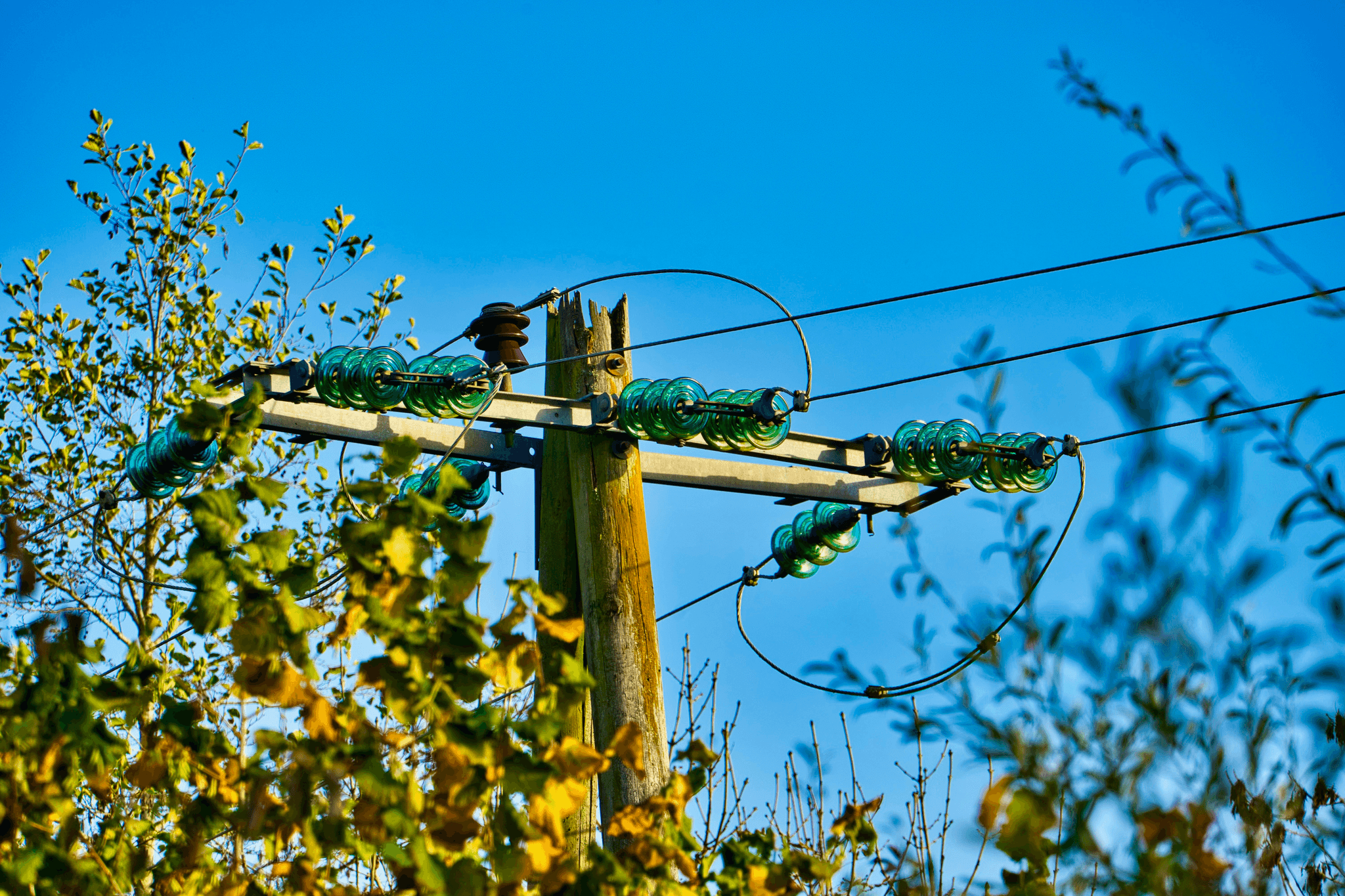

Moreover, other common types include suspension insulators and pin-type insulators; each has its specific applications based on factors like voltage levels and environmental conditions. What are the 5 types of insulators? They generally consist of pin-type, suspension-type, strain-type (which includes dead ends), standoff types, and bushing-type—each serving distinct purposes within an electrical grid.

In terms of performance under stress or extreme weather conditions, dead end insulators often outperform standard suspension models due to their robust construction aimed specifically at handling tension loads effectively.

Best Practices in Installation

Installing a dead end insulator requires careful attention to detail to ensure optimal performance over time. First off, it's vital that installers follow manufacturer guidelines closely; improper installation can lead to premature failure of these critical components. Additionally, ensuring proper alignment during installation helps distribute mechanical loads evenly across all parts of the system.

Regular inspections should also be part of maintenance routines after installation; this ensures that any wear or damage can be addressed before it leads to bigger issues down the line. It's also worth noting that using quality materials from reputable suppliers significantly enhances longevity—this ties back into our earlier discussion about high-quality suppliers being essential for successful installations.

Lastly, when considering best practices for installation around various environments—such as coastal areas with salt exposure or regions prone to severe weather—it’s essential that chosen dead end insulators are rated appropriately for those conditions so they can perform reliably throughout their lifespan.

What is the Purpose of a Standoff Insulator?

Standoff insulators play a crucial role in the world of electrical distribution, serving as vital components that help maintain the integrity and safety of power lines. These insulators are designed to support overhead conductors while keeping them at a safe distance from structures and other objects, thereby preventing electrical faults. Understanding what is the purpose of a standoff insulator can illuminate its importance in ensuring efficient and reliable power transmission.

Role in Electrical Distribution

In electrical distribution, standoff insulators act as barriers that separate live wires from supporting structures such as poles or buildings. This separation is essential for preventing short circuits and ensuring that electricity flows smoothly without interference. Additionally, they provide mechanical support to conductors at dead ends, which raises the question: which insulator is used at dead ends? The answer often involves utilizing both dead end insulators and standoff insulators to achieve optimal performance.

Benefits of Using Standoff Insulators

The benefits of using standoff insulators extend beyond mere physical separation; they also enhance safety and reliability within electrical systems. By providing robust insulation against environmental factors like moisture and temperature fluctuations, these insulators help minimize wear on conductors over time. Furthermore, their design allows for easier maintenance access—which is particularly important when considering what are the 5 types of insulators—ensuring that any necessary repairs can be conducted with minimal disruption.

Applications in Various Industries

Standoff insulators find applications across several industries beyond just traditional power distribution networks. For instance, they are commonly used in telecommunications to support overhead cables while maintaining signal integrity and reducing interference from nearby structures. Additionally, industries such as renewable energy utilize these insulators for wind turbines and solar farms—demonstrating their versatility alongside dead end insulator solutions tailored for specific operational needs.

What are the 5 Types of Insulators?

When delving into the world of electrical systems, understanding the various types of insulators is crucial. Insulators play a vital role in ensuring safe and efficient power transmission, including specific applications like dead end insulators. By grasping the distinctions between these five types of insulators, one can better appreciate their functionalities and select the right type for any project.

Overview of Insulator Types

The five primary types of insulators include pin insulators, suspension insulators, strain insulators, dead end insulators, and standoff insulators. Each type serves a unique purpose in electrical distribution systems while ensuring safety and reliability. Understanding what is a dead end insulator compared to other types can help clarify their specific roles within power transmission networks.

Specific Uses of Each Type

Pin insulators are typically used in low-voltage lines where they attach directly to poles or structures. Suspension insulators are ideal for high-voltage lines as they allow for flexibility and support over long spans between towers. Strain insulators handle tension forces effectively while dead end insulators provide stability at line terminations; meanwhile, standoff insulators serve to maintain distance from structures while supporting conductors—each fulfilling essential roles within their respective applications.

Importance of Selection for Efficiency

Choosing the correct type of insulation is paramount for efficiency in electrical systems; using an inappropriate type can lead to failures or safety hazards. For instance, opting for a dead end insulator where another type would suffice may result in unnecessary costs or complications during installation. Ultimately, selecting the right insulation not only enhances performance but also extends the lifespan of electrical components—ensuring that systems operate smoothly without interruptions.

The Spark Fittings Advantage

When it comes to dead end insulators, Spark Fittings stands out as a leader in the industry. With years of experience under our belt, we understand the intricacies involved in manufacturing high-quality insulators that meet stringent safety standards. This expertise is crucial for ensuring that our products, including dead end insulators and standoff insulators, perform optimally in various applications.

Expertise in Insulator Manufacturing

At Spark Fittings, our expertise in insulator manufacturing is unmatched. We have honed our skills over time to produce dead end insulators that not only meet but exceed industry expectations. Understanding what a dead end insulator is and how it functions allows us to create products tailored for specific applications, ensuring reliability and durability.

Moreover, we stay updated on the latest technological advancements and best practices in the field. This commitment enables us to develop innovative solutions that cater to both traditional power transmission needs and modern electrical distribution systems. Our knowledge extends beyond just which insulator is used at dead ends; it encompasses all aspects of insulation technology.

Customization Options for Armor Rods

Customization is key when selecting the right components for any electrical system, especially when considering what is the purpose of a standoff insulator or other types of insulators. At Spark Fittings, we offer a range of customization options for armor rods that can be tailored to fit specific project requirements. Whether you need unique dimensions or specialized materials, we work closely with clients to ensure their exact needs are met.

These customization options not only enhance performance but also improve installation efficiency across various applications—be it power lines or telecommunications setups. Understanding which type of insulation works best can significantly impact overall system reliability and longevity. Our focus on personalized service means you won’t just get a product; you'll receive a solution designed specifically for your challenges.

Quality Assurance and Material Selection

Quality assurance is at the heart of everything we do at Spark Fittings, especially when dealing with critical components like dead end insulators and standoff insulators. We meticulously select materials that withstand environmental stresses while maintaining superior electrical performance—essentially ensuring each product meets rigorous safety standards before reaching our customers’ hands.

In addition to using top-grade materials, we conduct extensive testing on all our products to guarantee they perform as expected under real-world conditions. This practice not only reinforces trust with our clients but also highlights the importance of choosing trustworthy suppliers when dealing with what are the 5 types of insulators available today. By prioritizing quality assurance throughout production processes, we ensure longevity and efficiency across all installations involving our products.

Conclusion

In summary, understanding the various types of insulators, such as the dead end insulator, is crucial for anyone involved in electrical distribution and power transmission. A dead end insulator plays a pivotal role in maintaining system integrity by supporting conductors at critical points. Additionally, knowing which insulator is used at dead ends can help ensure that installations are both safe and effective.

Key Takeaways on Insulator Types

The five types of insulators—pin, suspension, strain, dead end insulators, and standoff insulators—each have unique functionalities suited for different applications. Among these, the dead end insulator stands out due to its specific purpose in anchoring overhead lines and providing reliable support at junctions. Understanding what is a dead end insulator allows engineers to select the best option for their projects while optimizing efficiency and safety.

Importance of Trustworthy Suppliers

Quality assurance ensures that each product meets rigorous standards essential for long-term performance in challenging environments. As we’ve seen with Spark Fittings’ expertise in manufacturing high-quality products tailored to specific needs, having reliable suppliers can significantly impact overall project success.

The Future of Dead End Insulators in Industry

Looking ahead, the demand for efficient electrical infrastructure will likely increase the importance of specialized components like the dead end insulator. Innovations in materials and design are expected to enhance performance while reducing maintenance costs across various industries. Moreover, as we continue to explore what is the purpose of a standoff insulator alongside other types like dead ends, it’s clear that advancements will play a critical role in shaping future power transmission systems.