Introduction

When it comes to overhead line applications, understanding the role of a dead end clamp is crucial for ensuring both safety and efficiency. These fittings are essential components that help secure and support conductors, making them a vital part of any electrical infrastructure. With various options available, knowing the differences between types like the dead end strain clamp and suspension clamp can significantly impact your project’s success.

Understanding Dead End Clamps

A dead end clamp is designed to anchor the end of an overhead conductor securely, preventing it from moving or sagging under tension. This functionality is particularly important for overhead lines where stability is paramount. When choosing a dead end clamp for ABC cable applications, it's essential to consider factors such as load requirements and environmental conditions.

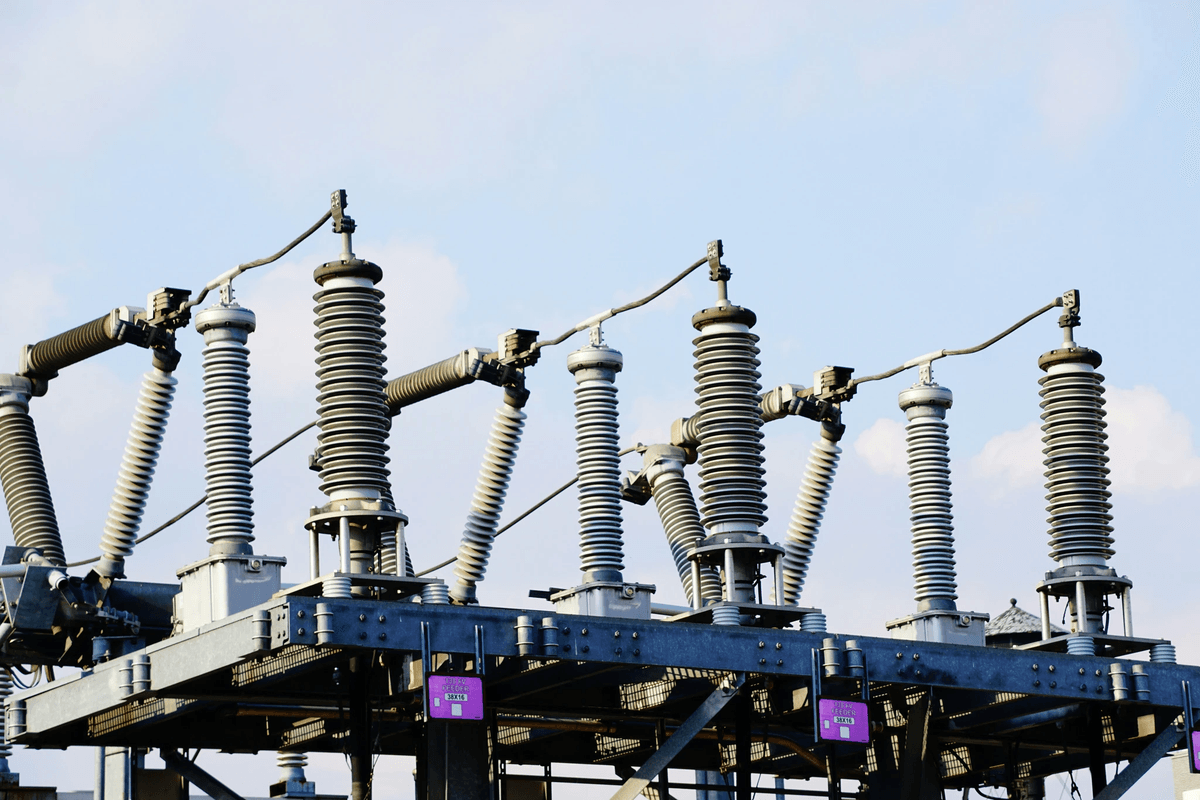

Importance of Quality in Power Fittings

Quality in power fittings cannot be overstated; subpar components can lead to failures that compromise both safety and performance. Investing in high-quality dead end clamps ensures reliability, especially when dealing with high-voltage lines where even minor issues can escalate into significant hazards. The cost may vary—often reflected in the Dead End Clamp price—but opting for reliable products ultimately saves money by reducing maintenance needs and enhancing safety.

Overview of Spark Fittings

Spark Fittings stands out as a provider specializing in customized solutions tailored to your specific needs within the electrical industry. Their offerings include not just dead end clamps but also innovative products like suspension clamps for ABC cable installations, ensuring you have everything required for your projects. By focusing on quality materials such as aluminum and galvanized steel, Spark Fittings guarantees durability while also considering practical aspects like color coding during installation.

What is a Dead End Clamp

Dead end clamps are essential components in overhead line construction and maintenance, designed to secure the ends of conductors while preventing them from slipping or pulling out. They play a crucial role in ensuring the stability and safety of power lines, especially under varying environmental conditions. Understanding their functionality and types can greatly enhance your selection process when considering options like the dead end clamp for ABC cable.

Definition and Functionality

A dead end clamp is a fitting used to anchor electrical conductors at their termination points, effectively preventing movement or tension loss that could lead to dangerous situations. These clamps work by gripping the conductor tightly, distributing the load evenly across its surface, which minimizes stress concentrations that could cause damage over time. In essence, they provide a reliable means of securing overhead lines while maintaining electrical integrity.

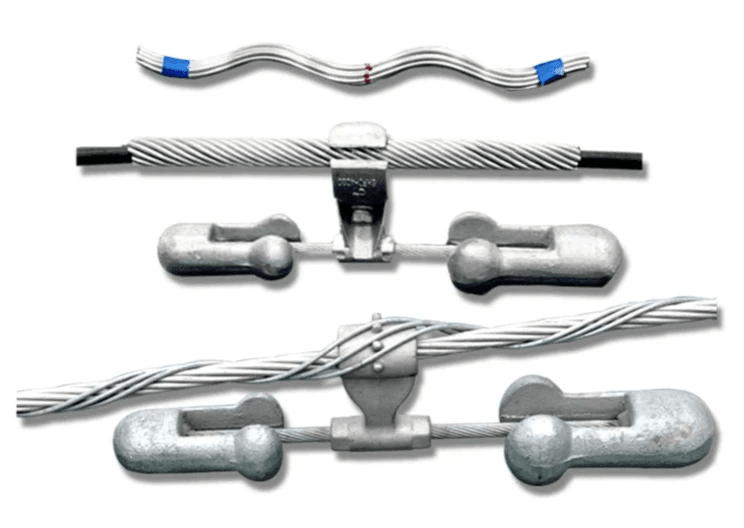

Types of Dead End Clamps

There are various types of dead end clamps available on the market, each tailored for specific applications such as aluminum or copper conductors. For instance, you may come across dead end strain clamps designed for high-tension applications or suspension clamps that support lighter loads without excessive strain on the conductor itself. Choosing between these options often depends on factors like line tension requirements and environmental conditions.

Advantages of Using Dead End Clamps

Using dead end clamps offers numerous advantages that contribute to overall system reliability and safety in overhead line installations. One significant benefit is their ability to withstand extreme weather conditions, ensuring that your power lines remain stable even during storms or high winds—essential for any installation involving a dead end clamp overhead line setup. Additionally, investing in quality fittings can reduce long-term maintenance costs by minimizing wear and tear on cables and connectors; thus making it worth considering different Dead End Clamp prices before making a purchase.

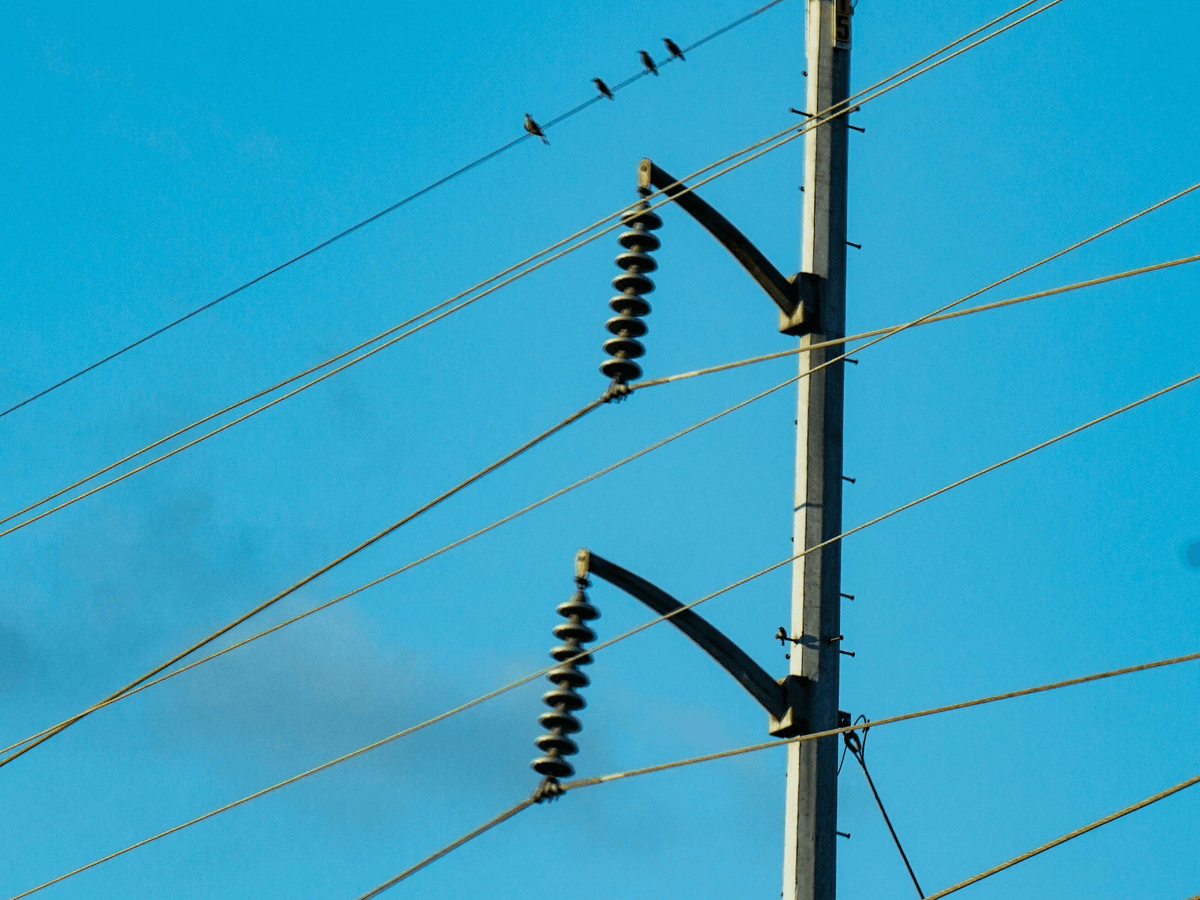

Dead End Clamp for Overhead Line Applications

These clamps are specifically designed to secure conductors at their endpoints, preventing any unwanted movement that could lead to power outages or hazards. Understanding the essential features of a dead end clamp for overhead lines is crucial for anyone involved in electrical installation or maintenance.

Essential Features for Overhead Lines

The essential features of a dead end clamp overhead line include robust construction, weather resistance, and compatibility with various cable types. These clamps are typically made from durable materials like aluminum or galvanized steel, which provide strength while resisting corrosion over time. Additionally, they must accommodate different cable sizes and types—whether it's standard conductors or specialized options such as ABC cable—ensuring versatility in various applications.

Another key feature is the design that allows for easy installation and maintenance. Many dead end clamps come equipped with user-friendly mechanisms that facilitate quick adjustments without compromising safety standards. This is particularly important when working on overhead lines where accessibility can be challenging; having a reliable clamp simplifies the entire process.

Choosing the Right Clamp for Your Needs

Selecting the right dead end clamp involves understanding your specific requirements based on application type and environmental conditions. For instance, if you're working with ABC cable, you’ll want to look closely at clamps designed specifically for this purpose—they often include features tailored to handle the unique characteristics of these cables effectively. Furthermore, considering factors like load capacity and weather resistance will help you find a suitable option.

Price is another critical aspect when choosing a dead end clamp; however, it’s essential not just to focus on cost but also on quality. While some may opt for lower-priced options initially, investing in reliable fittings can save you money in the long run by minimizing maintenance needs and enhancing overall system performance. Remember that finding balance between Dead End Clamp price and quality can significantly impact your project's success.

How Dead End Clamps Enhance Safety

Safety should always be at the forefront when dealing with electrical installations, especially concerning overhead lines where risks can escalate quickly if proper precautions aren’t taken. Dead end clamps enhance safety by providing secure anchoring points that prevent conductor sagging or movement under stress—this stability helps mitigate potential hazards such as electrical shorts or line breakage during storms or high winds.

Moreover, using well-designed dead end strain clamps ensures that forces exerted on cables are evenly distributed across connections, reducing wear and tear over time while maintaining structural integrity throughout their lifespan. By selecting high-quality suspension clamps alongside your dead end solutions—especially suspension clamps for ABC cable—you create an interconnected system that prioritizes safety above all else.

In summary, understanding how various components work together will empower you to make informed decisions regarding your overhead line installations while maximizing safety measures effectively.

Comparison of Dead End Strain Clamps and Suspension Clamps

Both types of clamps serve distinct purposes in power line installations, but their functionalities and applications can be quite different. Choosing the right clamp not only affects installation efficiency but also impacts overall safety and reliability.

Key Differences Explained

Dead end strain clamps are designed to handle the tension applied to overhead lines, securely anchoring cables at the ends of spans or where they change direction. In contrast, suspension clamps are used to support cables along their length without adding significant tension, allowing for flexibility in movement due to wind or thermal expansion. While both types may seem similar at first glance, their specific engineering makes them suitable for diverse applications—particularly when considering factors like a dead end clamp for ABC cable or a suspension clamp for ABC cable.

When to Use Each Type

Selecting between a dead end strain clamp and a suspension clamp depends on the application requirements. If your project involves securing cables at endpoints or areas with high tension—like those seen in overhead line setups—a dead end clamp is your best bet. On the other hand, if you're looking to maintain cable alignment while accommodating movement along spans, a suspension clamp would be more appropriate.

Performance in Real-World Scenarios

In real-world scenarios, the performance of these clamps can significantly influence project outcomes. For instance, using a dead end clamp overhead line ensures stability under load conditions that might otherwise lead to sagging or failure over time. Conversely, employing a suspension clamp allows cables to flex with environmental changes without compromising integrity—a crucial factor when dealing with varying temperatures and wind conditions.

Cost Considerations: Dead End Clamp Price

The cost of a dead end clamp can vary significantly based on several factors, including materials used, design complexity, and manufacturer reputation. Additionally, choosing between different types of clamps—like a dead end strain clamp or suspension clamp—can also influence pricing.

Factors Influencing Pricing

Several key factors contribute to the pricing of dead end clamps. Firstly, the material used plays a pivotal role; aluminum and galvanized steel are common choices, each with its own cost implications. Secondly, the specific application needs—such as whether you require a dead end clamp for ABC cable or an overhead line setup—can affect both performance and price.

The manufacturing process also impacts costs; more complex designs that enhance durability or safety may come at a premium. Furthermore, brand reputation can lead to variations in pricing; well-established manufacturers often charge more due to their proven track record in quality and reliability. Lastly, market conditions and supply chain factors can fluctuate prices unexpectedly.

Quality vs. Cost: Finding the Balance

Striking the right balance between quality and cost is essential when purchasing a dead end clamp for overhead lines. While it might be tempting to opt for cheaper options, lower-priced fittings can lead to increased maintenance costs and potential safety hazards down the line. Investing in high-quality clamps ensures better performance and longevity, ultimately saving money in repairs or replacements.

It's important to assess what you're getting for your investment; sometimes paying a little extra upfront means avoiding costly issues later on. For instance, when considering options like suspension clamps versus dead end strain clamps for ABC cable applications, higher-quality products often offer superior load-bearing capabilities and resilience against environmental stressors.

In essence, while price matters, prioritizing quality will yield better long-term value in your projects involving overhead lines.

Value of Investing in Reliable Fittings

Investing in reliable fittings like dead end clamps pays dividends over time by enhancing safety and reducing maintenance headaches. When you opt for high-quality products designed specifically for your intended application—be it a dead end clamp overhead line setup or specialized fittings for ABC cables—you ensure that your infrastructure remains robust under various conditions.

Moreover, reputable manufacturers often provide warranties or guarantees on their products which adds an extra layer of security to your investment decision. These warranties not only cover defects but also indicate confidence from manufacturers regarding their product's durability and effectiveness in real-world scenarios.

Ultimately, making informed choices about the type of fittings you use will reflect positively on project outcomes—ensuring that both safety standards are met while keeping operational costs manageable over time.

Spark Fittings' Offerings: Customized Armor Rods

When it comes to ensuring that your overhead lines are equipped with the best fittings, Spark Fittings stands out with its customized armor rods. These rods are designed to meet the specific needs of various applications, including those involving a dead end clamp for overhead line installations. With a focus on quality and adaptability, Spark Fittings provides solutions that enhance performance and safety.

Tailoring to Your Specific Needs

Every project has unique requirements, especially when dealing with power fittings like dead end clamps and armor rods. Spark Fittings understands this necessity and offers tailored solutions that cater to different specifications and environments. Whether you need a dead end clamp for ABC cable or specialized options for other configurations, customization is key to achieving optimal performance in real-world scenarios.

Materials Used: Aluminum and Galvanized Steel

The durability of your fittings is paramount, which is why Spark Fittings utilizes high-quality materials like aluminum and galvanized steel in their armor rods. These materials not only ensure longevity but also provide resistance against environmental stressors that can affect overhead lines over time. When considering dead end clamp price, it's crucial to remember that investing in robust materials translates into long-term savings by reducing maintenance costs.

Importance of Color Coding in Installation

Color coding plays an essential role in the installation process of suspension clamps and other fittings used in power line applications. By using distinct colors for different components, technicians can easily identify what goes where during installation or maintenance work—especially vital when handling a suspension clamp for ABC cable applications where clarity is key. This simple yet effective practice enhances safety and efficiency while minimizing the risk of errors associated with improper installations.

Conclusion

In summary, understanding dead end clamps is crucial for anyone involved in electrical installations, especially for overhead lines. These fittings ensure that cables are securely anchored, preventing sagging and potential hazards. Whether you're considering a dead end clamp for ABC cable or weighing the differences between a dead end strain clamp and suspension clamp, quality matters.

Key Takeaways About Dead End Clamps

Dead end clamps are essential components in overhead line applications, designed to provide stability and safety for electrical cables. They come in various types, each tailored to specific needs—such as the dead end clamp for ABC cable or traditional wire configurations. Remember that investing in high-quality fittings can save you from costly repairs down the line.

Making an Informed Purchase Decision

When it comes to purchasing a dead end clamp, price is often a deciding factor; however, it shouldn't be the only one. Look beyond just the dead end clamp price to consider factors such as durability, material quality, and suitability for your application—whether it’s a suspension clamp or a dead end strain clamp. A well-informed decision will ultimately lead you to reliable fittings that enhance safety and performance.

The Role of Spark Fittings in Your Projects

Spark Fittings stands out by offering customized solutions tailored specifically to your project needs—be it armor rods or specialized clamps like those used for overhead lines. Their commitment to quality materials ensures that whether you're using aluminum or galvanized steel components, you're getting the best performance possible from your fittings. By choosing Spark Fittings, you’re not just buying products; you’re investing in peace of mind knowing your installations are secure with top-tier equipment.