Introduction

In the world of electrical installations, the importance of reliable cable cleats cannot be overstated. These unsung heroes play a crucial role in securing cables, ensuring safety and efficiency in various applications. With an array of options available, understanding the nuances of cable cleats is essential for making informed choices.

Importance of Reliable Cable Cleats

Reliable cable cleats are vital for maintaining the integrity and safety of electrical systems. They prevent excessive movement and strain on cables, which can lead to wear and potential failures over time. Choosing high-quality cleats from reputable cable cleats manufacturers ensures that installations remain secure and compliant with industry standards.

Understanding Spark Fittings

Spark Fittings stands out among cable cleats manufacturers for its commitment to innovation and quality. By utilizing advanced production techniques, they create products that meet the diverse needs of modern electrical installations. Their focus on custom solutions allows clients to find the perfect fit for their specific requirements, whether it’s polymeric cable cleat or aluminium cable cleat.

Benefits of Quality Cable Cleats

Investing in quality cable cleats offers numerous benefits, including enhanced durability and performance under various environmental conditions. High-quality insulation cleats protect cables from damage while ensuring optimal functionality throughout their lifespan. Moreover, understanding factors like cable cleat price can help you make cost-effective decisions without compromising on safety or performance.

Overview of Cable Cleats

These clever devices hold cables in place, preventing movement and potential damage during operation. Understanding their definition and function is essential for anyone involved in electrical installations.

Definition and Function

Cable cleats are mechanical devices designed to secure multiple cables together, providing a neat and organized installation. Their primary function is to prevent cable movement, which can lead to wear and tear over time or even catastrophic failures in electrical systems. By keeping cables tightly secured, they also help maintain the integrity of insulation layers—especially important when using insulation cleats for added protection.

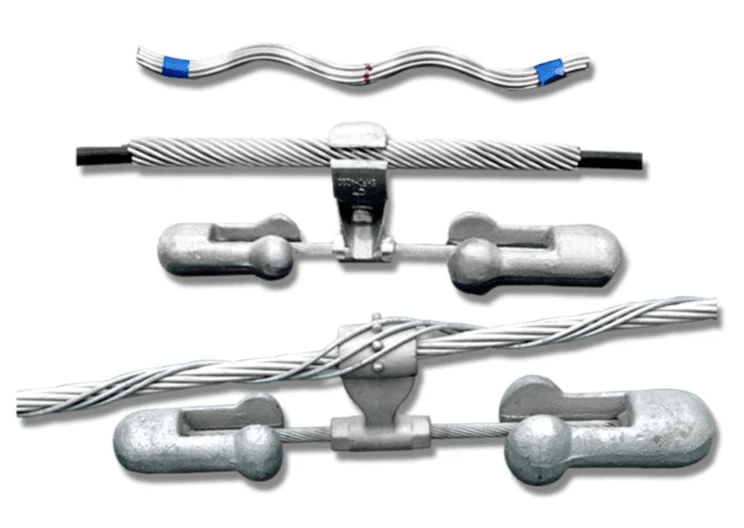

Types of Cable Cleats

There’s an array of cable cleat options available in the market today, catering to various installation needs. Among them are polymeric cable cleats, which offer excellent resistance to environmental factors while being lightweight and easy to install. On the other hand, aluminium cable cleats provide robust support for heavier cables, making them ideal for demanding applications where durability is key.

Relevance of Cable Cleats for Electrical Installations

The relevance of cable cleats in electrical installations cannot be overstated; they play a crucial role in ensuring safety and compliance with industry standards. Many cable cleat manufacturers emphasize the importance of using high-quality materials that withstand harsh conditions while maintaining performance over time. Without proper support from products like insulation cleats or polymeric cable cleat options, the risk of accidents increases significantly—making these seemingly simple components vital for any successful electrical project.

Spark Fittings: A Leading Manufacturer

When it comes to cable cleats manufacturers, Spark Fittings stands out for its commitment to quality and innovation. This company has made significant strides in the production of cable cleats for electrical installations, ensuring that their products meet the highest standards. With a focus on both performance and safety, Spark Fittings has earned a reputation as a trusted name in the industry.

Innovative Production Techniques

Spark Fittings employs cutting-edge production techniques that set them apart from other cable cleats manufacturers. By integrating automation and precision engineering into their manufacturing processes, they ensure that each aluminium cable cleat and polymeric cable cleat is crafted with meticulous attention to detail. This innovative approach not only enhances product quality but also improves efficiency, allowing for competitive pricing without sacrificing excellence.

High-Quality Materials Used

The durability of any cable cleat hinges on the materials used in its production, and Spark Fittings excels in this area. They source high-quality raw materials that enhance the strength and longevity of their insulation cleats and polymeric cable cleats. By prioritizing material integrity, they ensure that their products can withstand the rigors of various electrical installations while maintaining affordability—an essential consideration when evaluating cable cleat prices.

Focus on Custom Solutions

Understanding that every project is unique, Spark Fittings offers a range of custom solutions tailored to meet specific client needs. Whether it’s designing specialized aluminium or polymeric cable cleats or providing bespoke insulation options, they are dedicated to delivering what customers require for their specific applications. This customer-centric approach not only reinforces their status among leading cable cleats manufacturers but also ensures clients receive optimal solutions for their electrical installations.

Exploring Cable Cleat Options

When it comes to selecting the right cable cleats for electrical installations, understanding the various options available is crucial. The market offers a range of products tailored to different needs, from polymeric cable cleats to aluminium and insulation variants. Each type brings its own set of benefits and considerations, making it essential for buyers to weigh their choices carefully.

Polymeric Cable Cleats Explained

Polymeric cable cleats are designed using advanced materials that provide excellent flexibility and durability. These cleats are particularly advantageous in environments where corrosion is a concern since they resist moisture and chemicals effectively. Additionally, polymeric cable cleats are lightweight yet robust, making them an ideal choice for various electrical installations.

One of the standout features of polymeric cable cleats is their ability to accommodate thermal expansion and contraction without compromising performance. This adaptability ensures that cables remain secure even under fluctuating temperature conditions. With numerous cable cleat manufacturers offering polymeric options, finding the right fit for your project has never been easier.

Advantages of Aluminium Cable Cleats

Aluminium cable cleats have gained popularity due to their strength and resilience in harsh environments. These cleats are particularly effective in high-load applications where mechanical stress can compromise other materials' integrity. The lightweight nature of aluminium also contributes to ease of installation, reducing labor costs associated with heavy-duty equipment.

Another significant advantage is their resistance to environmental factors such as UV exposure and extreme weather conditions. This makes aluminium cable cleats a reliable choice for outdoor installations or areas prone to severe climate changes. When considering cable cleat prices, aluminium variants often strike a balance between initial investment and long-term durability.

Understanding Insulation Cleats

Insulation cleats serve a specialized purpose within the realm of cable management by providing additional protection against electrical faults and environmental damage. These types of cleats help maintain proper spacing between cables while ensuring that insulation remains intact throughout their lifespan. Insulation cleats are especially beneficial in scenarios where electrical safety is paramount.

The design of insulation cleats often incorporates features that enhance heat dissipation, further safeguarding the cables from overheating issues during operation. As part of your assessment on which type suits your needs best, consider how insulation impacts overall system efficiency and reliability over time. By exploring insulation options among leading cable cleat manufacturers, you can ensure optimal performance in your electrical installations.

Evaluating Cable Cleat Prices

When it comes to selecting the right cable cleats for electrical installations, price is an essential factor that can significantly influence your decision. Understanding the various elements that contribute to cable cleat prices will help you make an informed choice without breaking the bank. With a myriad of options available, from polymeric cable cleats to aluminium cable cleats, it’s crucial to evaluate what you’re getting for your investment.

Factors Influencing Cable Cleat Prices

Several factors play a role in determining the price of cable cleats, including materials used, design complexity, and manufacturer reputation. For instance, polymeric cable cleats may be more affordable than their aluminium counterparts due to material costs and manufacturing processes. Additionally, custom solutions or specialized insulation cleats often come at a premium because they require tailored production techniques and higher-quality materials.

Another important aspect is the scale of purchase; bulk orders typically yield discounts from manufacturers. Furthermore, market demand can drive prices up or down depending on supply chain dynamics and competition among cable cleat manufacturers. Understanding these factors will empower you to navigate pricing effectively while ensuring you select high-quality products for your projects.

Comparison of Different Manufacturers

Not all cable cleats manufacturers are created equal—some stand out due to their innovative designs and superior materials while others may offer lower prices with compromised quality. When comparing different manufacturers, consider not just the initial cost but also the durability and reliability of their products over time. For example, while some brands may provide cheaper polymeric cable cleats, they might not withstand harsh environmental conditions as well as more reputable options.

Moreover, customer service and warranty policies should also factor into your comparison process; after all, investing in quality insulation cleats means you want assurance that they will perform as expected over their lifespan. By taking time to research various manufacturers—reading reviews and seeking recommendations—you can find a balance between reasonable pricing and trusted quality for your electrical installations.

Cost-Effectiveness of Choosing Spark Fittings

When evaluating cost-effectiveness in choosing cable cleat solutions, Spark Fittings emerges as a frontrunner among other manufacturers in this space. Not only do they provide high-quality aluminium and polymeric cable cleats at competitive prices but also emphasize innovation in their production techniques that enhance performance without inflating costs unnecessarily. This means that when you choose Spark Fittings’ products for your electrical installations, you're likely getting superior value compared to cheaper alternatives.

Additionally, Spark Fittings offers custom solutions tailored specifically to meet unique project requirements—ensuring that every insulation cleat fits perfectly within its intended application without compromising on safety or efficiency. In essence, investing in Spark Fittings translates into long-term savings by reducing maintenance needs and enhancing system reliability over time.

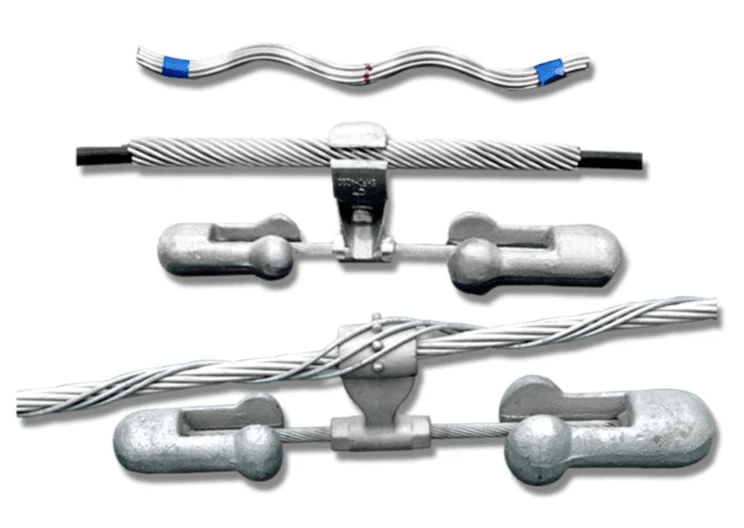

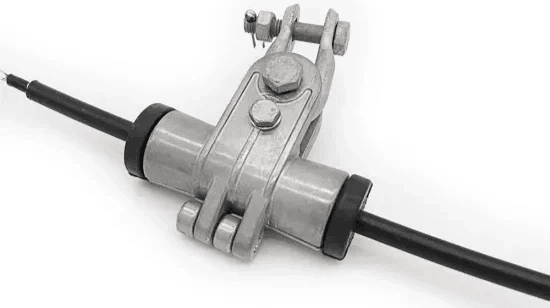

The Role of Armor RodsThese components are designed to protect the conductors from mechanical damage and environmental factors, making them essential for any high-quality cable installation. In conjunction with cable cleats, particularly those offered by reputable cable cleats manufacturers, armor rods help maintain the integrity of cables over time.

Materials Used for Armor Rods

Armor rods are typically made from a variety of materials that cater to different environmental conditions and application needs. Common materials include fiberglass, which provides excellent strength-to-weight ratios, as well as high-density polyethylene (HDPE) for its durability and resistance to moisture. Additionally, aluminum is often used for its lightweight properties and corrosion resistance, making it a popular choice among leading cable cleats manufacturers.

The choice of material significantly impacts both performance and cost; therefore, understanding these options can help in selecting the right armor rod for specific installations. For example, when paired with polymeric cable cleats or insulation cleats, the right material can enhance overall system performance while ensuring compliance with safety standards. Ultimately, selecting the appropriate materials is crucial in achieving optimal protection for electrical systems.

Importance of Material Compatibility

Material compatibility is critical when selecting armor rods for use with various types of cable cleats and electrical installations. Using incompatible materials can lead to unforeseen issues such as corrosion or degradation over time due to chemical reactions between dissimilar substances. For instance, pairing aluminum armor rods with certain types of polymeric cable cleats may not yield the best results if they react negatively under specific environmental conditions.

Ensuring that all components work harmoniously together not only extends the lifespan of your installation but also enhances safety measures in place. This compatibility consideration becomes even more vital when dealing with insulation cleats or specialized aluminum cable cleat designs that may have unique requirements. By prioritizing material compatibility during selection processes, you can mitigate risks associated with improper installations.

Customization Options Available

Many leading manufacturers offer custom lengths, diameters, and even coatings that enhance protective qualities against environmental stressors such as UV exposure or chemicals present in industrial settings. This level of customization ensures that you’re not just settling for standard solutions but investing in tailored products designed specifically for your application needs.

In addition to physical attributes like size and coating type, some manufacturers also provide personalized design consultations to ensure optimal compatibility between armor rods and various types of cable cleats—including polymeric options or insulation designs tailored specifically for your project’s demands. This attention to detail contributes significantly towards achieving seamless integration within existing systems while enhancing overall performance reliability over time.

With careful consideration given towards customization choices available today—from selecting appropriate materials through ensuring compatibility—one can make informed decisions regarding their investments into quality products like those offered by top-tier cable cleat manufacturers.

Conclusion

In the world of electrical installations, the choice of cable cleats can significantly impact safety and performance. Spark Fittings stands out among cable cleats manufacturers for its commitment to innovation and quality. By focusing on custom solutions and high-quality materials, Spark Fittings ensures that their products meet diverse installation needs.

Key Features of Spark Fittings

Spark Fittings is known for its innovative production techniques that set it apart from other cable cleats manufacturers. Their use of high-quality materials, whether polymeric or aluminium cable cleat options, guarantees durability and reliability in various environments. Additionally, their focus on customization allows clients to find solutions tailored specifically to their unique requirements.

Advantages of Quality Cable Cleats

Investing in quality cable cleats brings numerous advantages that cannot be overlooked. For instance, insulation cleats provide enhanced protection against environmental factors while maintaining the integrity of electrical installations. Furthermore, choosing a reliable manufacturer like Spark Fittings can lead to cost-effective solutions when evaluating cable cleat prices across the market.

Making Informed Decisions on Cable Cleats

When selecting cable cleats for electrical installations, it's essential to consider factors such as material compatibility and application-specific needs. Understanding the differences between polymeric cable cleat options and aluminium cable cleat choices can help you make informed decisions that align with your project requirements. Ultimately, by prioritizing quality from reputable manufacturers like Spark Fittings, you ensure long-lasting performance and safety in your installations.