Introduction

When it comes to the intricate world of high voltage power transmission lines, one component stands out for its crucial role: the suspension type insulator. These unsung heroes are vital in ensuring that electric power transmission is efficient and safe, acting as a barrier between conductive materials and their surroundings. Understanding suspension type insulators is essential for grasping how they facilitate the seamless flow of electricity across vast distances.

Understanding Suspension Type Insulators

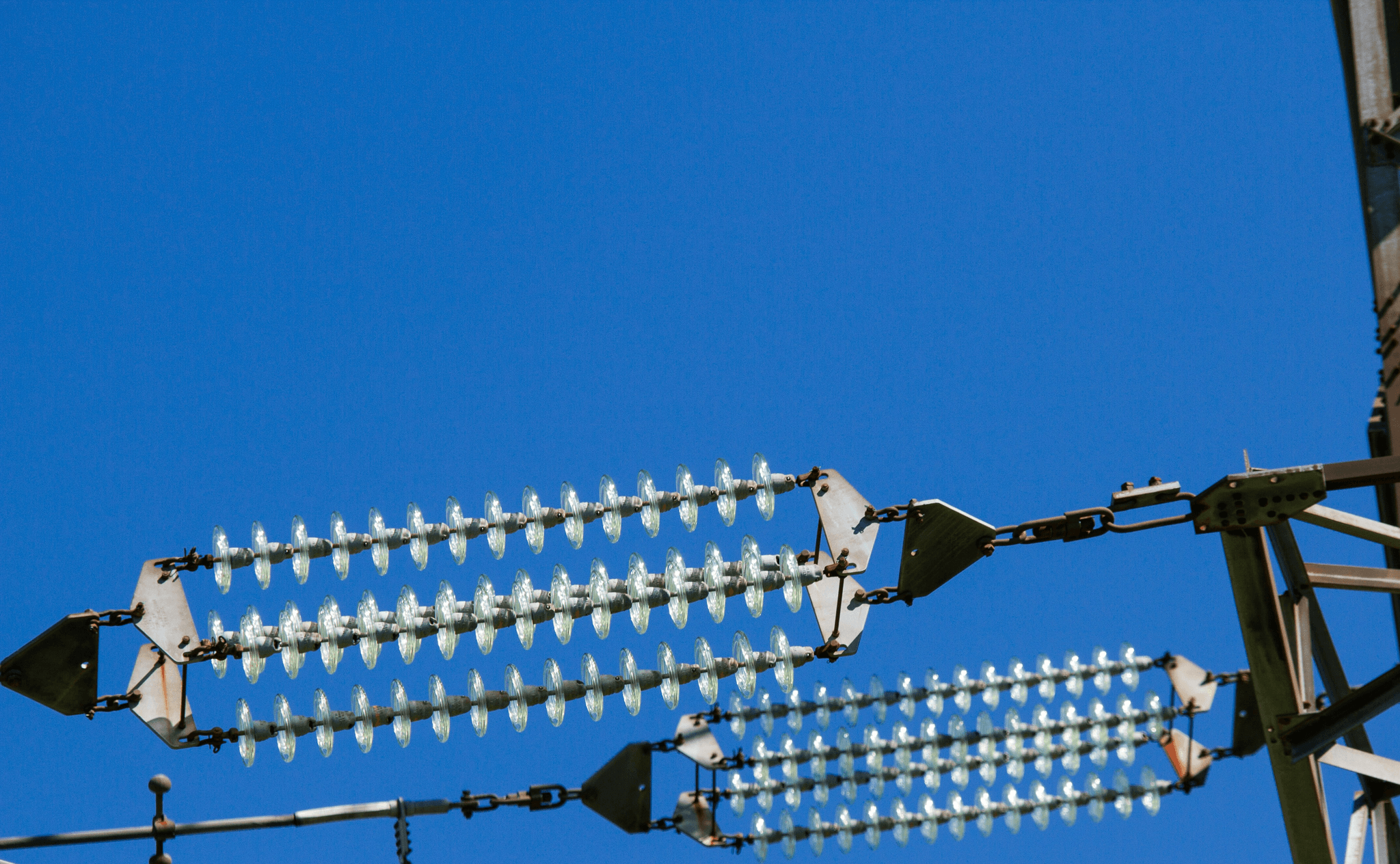

Suspension type insulators are designed to support overhead power lines while preventing electrical current from leaking into the environment. They consist of multiple porcelain or glass discs strung together, forming a chain that hangs from towers or poles. This design not only provides mechanical strength but also offers excellent insulation properties, making them ideal for high voltage lines.

Importance in High Voltage Transmission

In high voltage transmission systems, maintaining an uninterrupted supply of electricity is paramount, and suspension type insulators play a pivotal role in this process. Their ability to withstand extreme weather conditions and electrical stress ensures that power line insulators remain reliable over time. Without these specialized components, the integrity of high voltage power transmission lines would be severely compromised, leading to potential outages and safety hazards.

Functionality in Electric Power Systems

The functionality of suspension type insulators extends beyond mere support; they actively contribute to the stability and efficiency of electric power systems. By isolating conductors from their supporting structures, these insulators help prevent short circuits and other electrical failures that could disrupt service. Additionally, their design allows for flexibility in installation on various types of transmission lines, further enhancing their utility in electric power transmission networks.

What is a Suspension Type Insulator?

Suspension type insulators are crucial components in the world of high voltage power transmission lines. They serve as a barrier between the conductive parts of the power lines and the supporting structures, ensuring that electricity flows smoothly without leakage or short-circuiting. Their primary purpose is to support the weight of conductors while preventing electrical current from flowing to the ground, thus playing an essential role in electric power transmission systems.

Definition and Purpose

A suspension type insulator is designed specifically for use in high voltage lines, where it provides mechanical support and electrical insulation. These insulators are typically made from materials that can withstand extreme weather conditions and high voltages, ensuring reliability over time. The purpose of these insulators on transmission lines is not just to hold up wires but also to ensure safety by minimizing the risk of electrical faults.

How They Work in Power Lines

In high voltage power transmission lines, suspension type insulators function by creating a physical separation between the energized conductor and its supporting structure—usually a tower or pole. When electricity flows through these conductors, it generates an electric field; however, thanks to the insulating properties of suspension type insulators, this field does not reach the ground or other conductive materials nearby. Essentially, they act like a gatekeeper for electricity, allowing it to flow freely while keeping everything else safe and sound.

Components of Suspension Type Insulators

Suspension type insulators are composed of several key elements that work together seamlessly in high voltage applications. The main components include porcelain or glass shells that provide insulation and mechanical strength, metal fittings for secure attachment to towers and conductors, and sometimes additional hardware like armor rods for enhanced durability against environmental stressors. Each component plays a vital role in ensuring that these power line insulators perform effectively under varying conditions.

Key Features of Suspension Type Insulators

Suspension type insulators are crucial components in the world of high voltage power transmission lines, designed to ensure safety and efficiency in electric power transmission. Understanding their key features can help us appreciate their role in maintaining the integrity of power line insulators. Let's dive into the specifics, from voltage ratings to material composition and design considerations.

Voltage Ratings and Durability

One of the standout features of suspension type insulators is their impressive voltage ratings, which can often reach up to several hundred kilovolts. This capability makes them ideal for high voltage lines where insulation effectiveness is paramount to prevent electrical failures or outages. Moreover, their durability allows them to withstand harsh environmental conditions, ensuring longevity and reliability in electric power transmission systems.

The durability of these insulators is not just about withstanding high voltages; it also involves resilience against weather elements like wind, rain, and extreme temperatures. These factors contribute significantly to the operational lifespan of suspension type insulators on transmission lines. Therefore, selecting a suspension type insulator with appropriate voltage ratings is essential for any utility aiming for efficient energy distribution.

Material Composition and Resistance

The material composition of suspension type insulators plays a pivotal role in their performance on high voltage power transmission lines. Typically made from porcelain or composite materials, these insulators offer excellent electrical resistance while maintaining mechanical strength under load. This combination ensures that they can handle both electrical stress and physical forces without failure.

Resistance to environmental factors such as UV radiation, pollution, and moisture is another critical aspect of material selection for these insulators on transmission lines. High-quality materials not only enhance performance but also reduce maintenance costs over time by minimizing wear and tear due to external conditions. Thus, understanding material composition is essential when considering electric power transmission solutions.

Design Considerations for High Voltage Lines

When it comes to design considerations for high voltage lines, suspension type insulators are engineered with multiple factors in mind to optimize performance and safety. The design must accommodate specific mechanical loads while ensuring that the electrical field distribution remains uniform across the surface area of the insulation material used. This careful engineering helps prevent flashover incidents that could disrupt service or cause damage.

Another important design consideration involves spacing between suspension type insulators on transmission lines; proper spacing can mitigate risks associated with short circuits or arcing under certain conditions like heavy rainfall or foggy weather. Additionally, aesthetic aspects are increasingly being integrated into designs without compromising functionality—an important factor as utilities strive for public acceptance in urban settings where electric power transmission infrastructure must coexist with community aesthetics.

In conclusion, understanding the key features—voltage ratings and durability, material composition and resistance, along with thoughtful design considerations—provides valuable insights into how suspension type insulators play a vital role in the reliability of high voltage power transmission systems.

Applications of Suspension Type Insulators

Suspension type insulators play a vital role in the realm of high voltage power transmission lines, ensuring that electricity travels safely and efficiently across vast distances. These insulators are designed to support conductors while preventing electrical leakage to the ground, making them essential for maintaining the integrity of electric power transmission systems. Their applications extend beyond mere functionality; they also contribute significantly to the reliability and safety of high voltage lines.

Use in High Voltage Power Transmission Lines

High voltage power transmission lines are the lifeblood of modern electric grids, and suspension type insulators are indispensable in this infrastructure. These insulators are specifically engineered to withstand extreme voltages, providing necessary support for overhead conductors while preventing electrical faults. By effectively isolating conductors from their supporting structures, they ensure that energy flows smoothly without interruptions or hazards.

In addition to their primary function, suspension type insulators enhance the longevity and performance of high voltage power transmission lines by minimizing wear and tear due to environmental factors. Their design allows them to absorb vibrations caused by wind or seismic activity, which is crucial for maintaining stability in challenging conditions. This resilience makes them a preferred choice for utility companies looking to optimize their electric power transmission networks.

Role in Electric Power Transmission Systems

The role of suspension type insulators extends beyond individual transmission lines; they are integral components within broader electric power transmission systems. By providing reliable insulation between conductors and supporting structures, these insulators help mitigate risks associated with short circuits or electrical discharges that could lead to catastrophic failures.

Moreover, effective use of suspension type insulators contributes to improved efficiency in energy transfer across regions, facilitating the delivery of electricity from generation sources to end-users without significant losses. This efficiency is paramount as demand for electricity continues to rise globally, necessitating robust infrastructure supported by reliable components like these insulators on transmission lines.

Benefits for Power Line Insulators

The benefits provided by suspension type insulators go well beyond mere safety; they also deliver economic advantages through reduced maintenance costs and increased operational efficiency. With their durable materials designed specifically for high voltage applications, these insulators require less frequent replacements compared to other types available on the market today. This longevity translates into lower overall costs for utility companies managing extensive networks.

Additionally, suspension type insulators contribute positively to environmental sustainability efforts within electric power systems by minimizing energy loss during transmission processes. By ensuring that electricity travels efficiently from point A to point B with minimal leakage or disruption, these components support greener initiatives aimed at reducing carbon footprints associated with energy production and distribution.

In summary, the applications of suspension type insulators not only bolster high voltage power transmission lines but also enhance overall system reliability while promoting economic viability and sustainability within electric power systems.

Choosing the Right Insulator

Selecting the appropriate insulator for high voltage power transmission lines is crucial for ensuring safety, reliability, and efficiency in electric power transmission. The right suspension type insulator can make a significant difference in performance and longevity, which ultimately impacts the overall effectiveness of power line insulators. Factors such as environmental conditions, voltage ratings, and mechanical strength must be carefully evaluated to optimize the choice of insulators on transmission lines.

Factors to Consider

When choosing a suspension type insulator, several factors come into play that can affect its performance in high voltage applications. First and foremost is the electrical rating; it’s essential to select an insulator that can handle the voltage levels present in high voltage power transmission lines without risking breakdown or failure. Additionally, mechanical load capacity should be considered to ensure that the insulator can withstand wind pressure and other physical stresses encountered by power line insulators.

Another critical factor is environmental conditions—insulators exposed to harsh weather or corrosive environments require materials that can resist degradation over time. The geographical location plays a role too; areas prone to pollution or salt spray need specially designed suspension type insulators that offer enhanced durability and resistance. Ultimately, understanding these factors will guide you toward making an informed decision when selecting insulation solutions for your electric power transmission needs.

Matching Insulators to Transmission Lines

Matching suspension type insulators to specific high voltage lines requires a nuanced understanding of both the line characteristics and the operational environment. Different types of electric power transmission systems may have varying requirements based on their design and application; thus, it's essential to align these aspects with suitable insulators on transmission lines. For example, longer spans may necessitate larger or more robust suspension type insulators capable of handling increased mechanical stress.

Moreover, compatibility with existing infrastructure should not be overlooked—ensuring that new insulation solutions fit seamlessly into existing systems promotes efficiency and reduces installation complications. It’s also wise to consider future scalability; selecting versatile suspension type insulators allows for easier upgrades as demand increases without having to replace entire sections of your electric power transmission network. This foresight ultimately leads to cost savings and improved system reliability.

Importance of Corrosion Resistance

Corrosion resistance is paramount when it comes to choosing suspension type insulators for high voltage applications—after all, they are often exposed to various environmental challenges throughout their service life. Insulators made from materials specifically designed for corrosion resistance will significantly enhance longevity while maintaining performance standards in electric power transmission systems. This consideration becomes even more crucial in coastal areas where saltwater exposure accelerates deterioration.

Utilizing corrosion-resistant materials not only prolongs the lifespan of suspension type insulators but also minimizes maintenance costs associated with repairs or replacements due to wear and tear from environmental factors. By investing in quality materials upfront, operators can ensure their high voltage power transmission lines remain functional over time without frequent interruptions caused by faulty insulation solutions on transmission lines. In conclusion, prioritizing corrosion resistance is not just smart—it's essential for reliable operation.

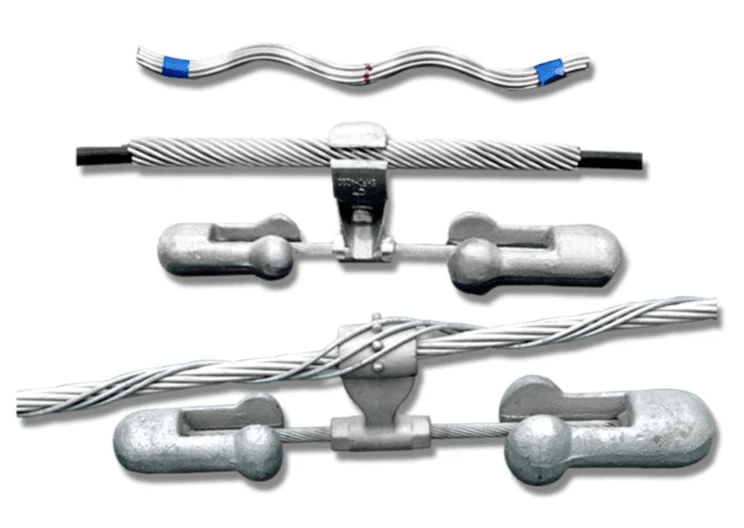

Spark Fittings and Armor Rods

In the realm of high voltage power transmission lines, spark fittings and armor rods play a crucial role in ensuring the integrity and safety of electric power transmission systems. These components are designed to enhance the performance of suspension type insulators, providing additional protection against electrical discharges and mechanical stresses. Understanding their function and application is essential for optimizing the reliability of power line insulators.

Introduction to Spark Fittings

Spark fittings are specialized devices used in conjunction with suspension type insulators to mitigate the risk of electrical arcing. These fittings serve as a bridge between conductors and insulators on transmission lines, effectively managing electrical stress during operation. By preventing sparks from jumping between conductive elements, they protect both the insulator and surrounding infrastructure from potential damage.

The importance of spark fittings cannot be overstated; they are particularly vital in high voltage lines where electrical discharges can be catastrophic. Without these protective devices, power line insulators would face increased wear and tear, potentially leading to failures that disrupt electric power transmission. Thus, incorporating spark fittings into high voltage systems is a proactive measure against operational hazards.

Customized Armor Rod Solutions

Armor rods are another critical component that enhances the durability of suspension type insulators on high voltage power transmission lines. These rods provide physical protection to conductors at points where they connect with insulators, reducing wear caused by environmental factors such as wind or ice accumulation. Customization options for armor rods allow engineers to tailor solutions specific to various applications and conditions.

The design of armor rods can vary based on factors like conductor size, environmental conditions, and expected mechanical loads on electric power transmission systems. This customization ensures that each installation can withstand unique challenges while maintaining optimal performance levels for suspension type insulators. Consequently, properly designed armor rods contribute significantly to extending the lifespan of both conductors and associated insulation systems.

Significance of Material Matching in Armor Rods

When it comes to selecting materials for armor rods, matching them with both conductors and suspension type insulators is paramount for achieving maximum efficiency in high voltage lines. Using compatible materials minimizes issues related to galvanic corrosion or thermal expansion mismatches that could compromise system integrity over time. Therefore, careful consideration must be given during material selection processes in electric power transmission applications.

Moreover, proper material matching enhances overall system resilience against harsh environmental conditions often encountered by power line insulators on transmission lines—be it extreme temperatures or exposure to moisture. A well-matched armor rod not only protects conductors but also supports the longevity of insulation systems across various climatic zones. This strategic approach ultimately leads to lower maintenance costs while improving reliability within electric power transmission networks.

Conclusion

In summary, suspension type insulators play a pivotal role in the realm of high voltage power transmission lines. Their unique design and functionality ensure that electric power transmission remains efficient and reliable, safeguarding both infrastructure and the environment. By understanding their features, applications, and importance, we can appreciate how these insulators contribute to the overall stability of power line systems.

Summary of Suspension Type Insulator Features

Suspension type insulators are designed specifically for use in high voltage lines, providing essential support while preventing electrical leakage. Their construction typically includes durable materials that withstand harsh environmental conditions, ensuring longevity and reliability across various climates. Furthermore, these insulators are engineered to maintain high voltage ratings while minimizing the risk of failure in electric power transmission systems.

Future Trends in Power Line Insulators

Looking ahead, advancements in material science and engineering are likely to enhance the performance of suspension type insulators even further. Innovations such as smart monitoring technologies could provide real-time data on insulator health, leading to proactive maintenance strategies for high voltage power transmission lines. Additionally, increased focus on sustainability may drive the development of eco-friendly materials for power line insulators that reduce environmental impact without compromising performance.

Final Thoughts on High Voltage Applications

In conclusion, suspension type insulators are indispensable components in ensuring the safety and efficiency of high voltage applications within electric power transmission networks. As technology evolves and demands for energy grow, understanding the intricacies of these vital components will be crucial for engineers and utility companies alike. Ultimately, investing in quality suspension type insulators not only enhances system reliability but also supports a more sustainable future for energy distribution.