Introduction

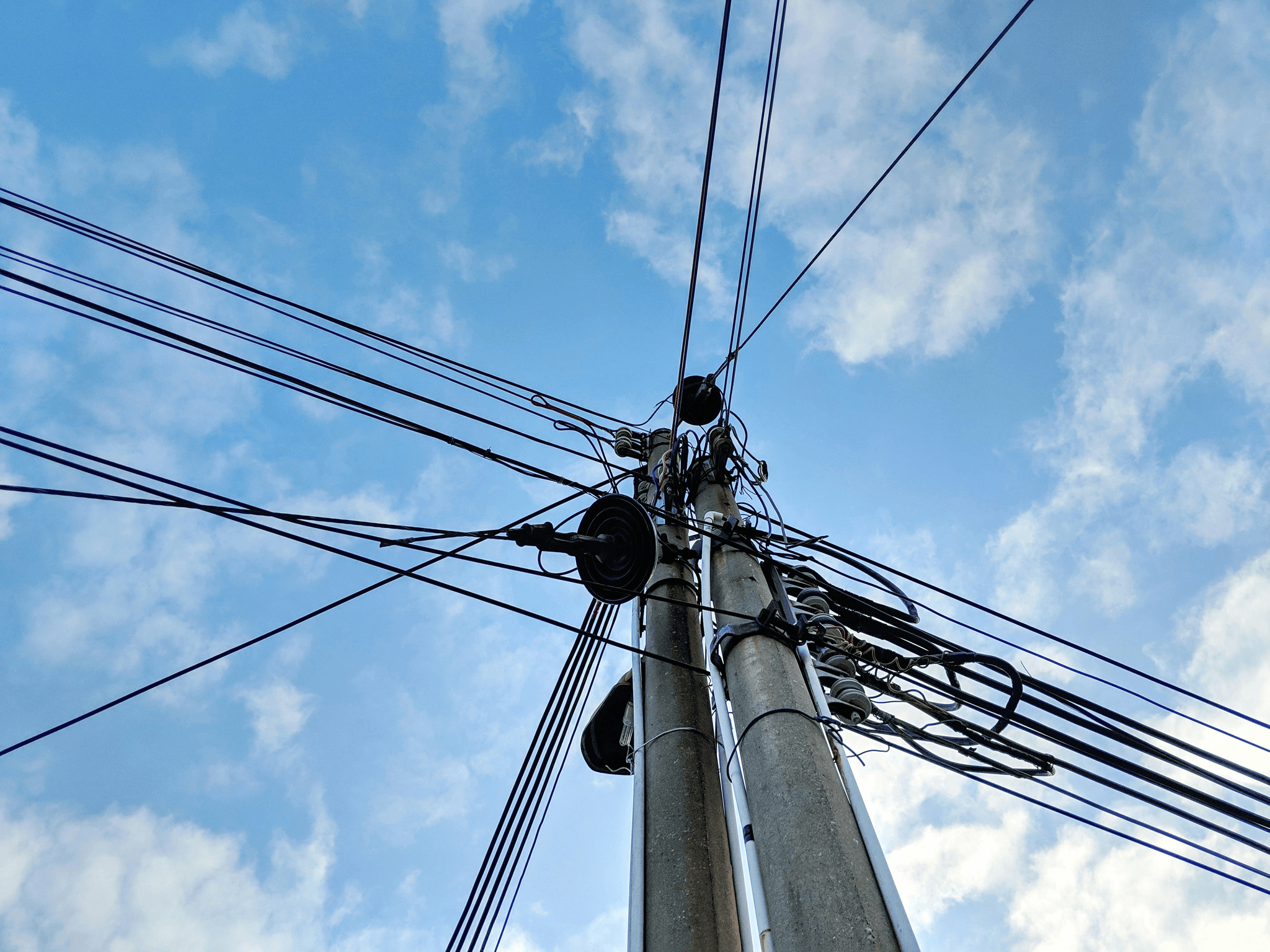

In the world of electrical power transmission, overhead line fittings play a crucial role in ensuring the reliability and efficiency of power lines. These fittings, including cable clamps and wire clamps, are essential components that support and secure conductors, thereby maintaining the integrity of power lining systems. As we delve into this topic, we'll explore how these seemingly simple devices are pivotal in powering our modern lives.

Overview of Overhead Line Fittings

Overhead line fittings encompass a variety of hardware used to connect and secure electrical cables in overhead power transmission systems. Among these fittings, cable clamps hold significant importance as they provide stability and support to the cables while allowing for necessary movement due to environmental factors. Additionally, wire clamps ensure that the entire assembly remains intact during adverse weather conditions, showcasing their vital role in maintaining operational efficiency.

Importance of Quality in Power Lining

When it comes to power lining, the quality of overhead line fittings cannot be overstated; subpar materials can lead to failures that disrupt service and pose safety risks. High-quality cable with clamp solutions not only enhance performance but also extend the lifespan of electrical components by resisting wear from environmental stressors such as corrosion or extreme temperatures. Ultimately, choosing quality fittings translates to reliable service delivery in electrical power transmission lines.

Key Players in the Industry

The industry is home to several key players who specialize in manufacturing high-quality overhead line fittings tailored for various applications. Companies like Spark Fittings, TE Connectivity, and Hubbell Power Systems have established themselves as leaders by consistently delivering innovative solutions that meet rigorous standards for performance and safety. Their commitment to excellence ensures that every component—whether it's a cable clamp or wire clamp—contributes positively to the overall reliability of power lining systems.

Top Manufacturers of Overhead Line Fittings

In the dynamic world of overhead line fittings, several manufacturers stand out for their innovative solutions and commitment to quality. These key players not only supply essential components for power lining but also drive advancements in technology that enhance the reliability and efficiency of electrical power transmission lines. Let's delve into some of the top manufacturers shaping this industry.

Spark Fittings' Innovative Solutions

Spark Fittings has carved a niche for itself by consistently delivering innovative solutions tailored to meet the demands of modern power lining. Their focus on high-quality cable clamps and custom fittings ensures that each component works seamlessly within electrical power transmission lines, providing stability and durability. With a keen eye on emerging technologies, Spark Fittings is at the forefront of integrating smart technology into their products, making them a go-to choice for engineers looking to optimize performance.

TE Connectivity's Diverse Product Range

TE Connectivity boasts an extensive product range that caters to various needs in the overhead line fitting sector. From versatile cable with clamp options to robust wire clamps designed for maximum stability, their offerings are engineered to support diverse applications in power lining projects. TE's commitment to innovation means they are continually evolving their designs, ensuring that customers have access to cutting-edge solutions that enhance the safety and efficiency of electrical power transmission lines.

Hubbell Power Systems' Commitment to Quality

Hubbell Power Systems has built a strong reputation based on its unwavering commitment to quality in manufacturing overhead line fittings. Their rigorous testing processes ensure that every component—from cable clamps to armor rods—meets stringent industry standards for durability and performance under high-voltage conditions. By prioritizing corrosion resistance and reliability, Hubbell Power Systems provides peace of mind for utility companies relying on their products in critical infrastructure projects.

Essential Overhead Line Fittings Types

When it comes to overhead line fittings, understanding the various types is crucial for ensuring the reliability and efficiency of power lining systems. Each component plays a vital role in maintaining the integrity of electrical power transmission lines, and selecting the right fittings can make all the difference. In this section, we will explore some essential types of overhead line fittings, including cable clamps, wire clamps, and armor rods.

Understanding Cable Clamps and Their Uses

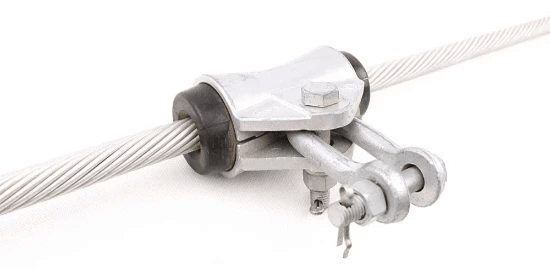

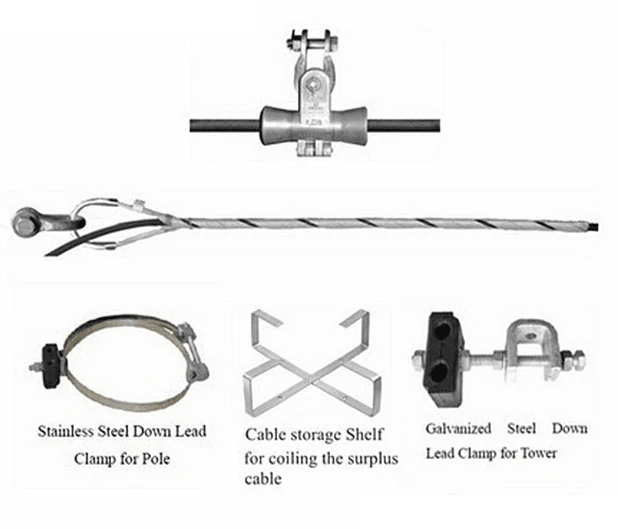

Cable clamps are indispensable components in overhead line fittings that securely hold cables in place while allowing for necessary movement due to thermal expansion or contraction. These clamps come in various designs tailored for different applications, ensuring that they can accommodate various cable sizes and types without compromising performance. By providing a strong grip on cables, cable clamps help prevent wear and tear on electrical power transmission lines while enhancing overall system safety.

In addition to stability, cable clamps also play a significant role in minimizing vibrations caused by wind or other environmental factors. The right clamp can absorb shocks and reduce stress on cables, which is essential for maintaining the longevity of both the fittings and the cables themselves. Therefore, when choosing a cable clamp for your overhead line fitting needs, it's important to consider not only its holding capacity but also its ability to withstand external forces.

The Role of Wire Clamps in Stability

Wire clamps are another critical type of overhead line fitting that contributes significantly to the stability of power lining systems. These fittings are designed specifically to secure wires within an assembly or connection point, ensuring that everything remains intact even under challenging conditions. By effectively holding wires together, wire clamps prevent disconnections or short circuits that could lead to costly downtime or safety hazards.

Moreover, wire clamps provide additional protection against environmental elements such as moisture and corrosion that could compromise electrical connections over time. Their robust design allows them to endure extreme weather conditions while maintaining their effectiveness in securing wires across vast distances in electrical power transmission lines. Choosing high-quality wire clamps is vital for anyone looking to enhance system reliability and ensure optimal performance throughout their network.

Selecting the Right Armor Rods

Armor rods serve as protective coverings for conductors at points where they experience high levels of stress or potential damage—typically around suspension points or terminations within an overhead line fitting system. These rods help distribute mechanical loads evenly across conductors while safeguarding them from abrasions caused by wind or other external forces during operation. When selecting armor rods for your application, it’s essential to consider factors such as material composition and diameter compatibility with existing cables.

The right armor rod will not only protect your cables but also contribute significantly to overall system durability—a crucial aspect when dealing with high-voltage applications where failures can lead to severe consequences. Additionally, armor rods come equipped with features like corrosion resistance which can extend their lifespan even further when exposed to harsh environments typical of many installation sites across different regions worldwide. Choosing appropriate armor rods ensures that your overhead line fitting solutions remain reliable under pressure while extending service life across all components involved.

Innovations in Overhead Line Fitting Technology

In the ever-evolving world of power lining, overhead line fittings are becoming more sophisticated with each passing year. The innovations in materials and technology are pushing the boundaries of what is possible in electrical power transmission lines. This section will delve into advanced materials, customization impacts, and the integration of smart technology in clamps cable.

Advanced Materials in Cable With Clamp

The use of advanced materials in cable with clamp applications is revolutionizing overhead line fitting designs. Manufacturers are increasingly opting for lightweight yet durable composites that enhance performance while reducing overall weight. These materials not only improve the efficiency of power lining but also ensure that components like wire clamps withstand harsh environmental conditions without compromising safety or reliability.

Moreover, these innovative materials exhibit superior corrosion resistance, a critical factor for outdoor installations where exposure to elements can lead to premature failure. By utilizing such advanced solutions, companies can extend the lifespan of their fittings and reduce maintenance costs significantly. As a result, electrical power transmission lines become more resilient, ensuring that they can effectively power the power systems they serve.

The Impact of Customization in Electrical Power Transmission Lines

Customization plays a pivotal role in optimizing overhead line fittings for specific applications within electrical power transmission lines. Tailoring components to meet unique requirements allows manufacturers to address challenges such as varying load demands and geographic considerations effectively. This bespoke approach enables engineers to design solutions that enhance stability and performance across diverse environments.

For instance, custom cable clamps can be engineered to accommodate different conductor sizes or configurations, ensuring optimal tensioning and support throughout their service life. This level of personalization not only improves operational efficiency but also fosters a sense of reliability among users who depend on these fittings for uninterrupted service delivery. Ultimately, customized solutions empower utility companies to maintain robust infrastructure while adapting to evolving energy demands.

Smart Technology Integration in Clamps Cable

The integration of smart technology into clamps cable is ushering in a new era for overhead line fittings within the power lining industry. These intelligent devices come equipped with sensors that monitor various parameters such as temperature, tension, and even structural integrity over time. By harnessing real-time data analytics, utilities can proactively identify potential issues before they escalate into costly failures.

Additionally, smart clamps enable enhanced communication between components within electrical power transmission lines, allowing for improved coordination during maintenance operations or emergency responses. This technological advancement not only optimizes performance but also contributes significantly to overall system efficiency and safety standards across networks. As we continue down this path toward smarter infrastructure solutions, it’s clear that innovation will remain at the forefront of overhead line fitting development.

Quality and Safety Standards in Manufacturing

In the world of overhead line fittings, quality and safety standards are paramount. These standards ensure that the products not only meet regulatory requirements but also perform reliably under various environmental conditions. In power lining applications, where the stakes are high, adherence to these standards can make all the difference between success and failure.

Industry Certifications for Overhead Line Fittings

When it comes to overhead line fittings, industry certifications play a crucial role in establishing trust and reliability. Manufacturers often seek certifications from recognized bodies like ANSI, IEC, or ISO to validate their products' quality and performance. These certifications assure customers that their chosen cable clamps and wire clamps have undergone rigorous testing for safety and efficiency in electrical power transmission lines.

Furthermore, a certified product typically indicates compliance with international standards, which is essential for companies operating across borders. This not only enhances marketability but also fosters confidence among stakeholders in the power lining sector. Ultimately, choosing certified overhead line fittings can mitigate risks associated with equipment failure or safety hazards.

The Importance of Corrosion Resistance

Corrosion resistance is a non-negotiable feature when selecting overhead line fittings for outdoor applications. Given that these components are exposed to harsh weather conditions—rain, snow, wind—corrosion can significantly compromise their integrity over time. High-quality cable with clamp designs incorporate materials that resist rusting and degradation, ensuring longevity and reliability.

Moreover, manufacturers often employ advanced coatings or treatments to enhance corrosion resistance further. This attention to detail is vital because failing to account for corrosion can lead to costly repairs or replacements down the line—literally! Investing in corrosion-resistant clamps cable ensures that electrical power transmission lines remain functional without frequent interruptions due to maintenance issues.

Evaluating Durability in High-Voltage Applications

Durability is another critical factor when assessing overhead line fittings designed for high-voltage applications. These components must withstand not just electrical stress but also mechanical loads from wind or ice accumulation on power lines. Therefore, selecting robust wire clamps and cable clamps made from high-strength materials becomes essential for maintaining system integrity.

Manufacturers often conduct extensive testing on their products to ensure they meet specific durability criteria under extreme conditions typical of electrical power transmission lines. This includes evaluating how well these fittings perform over time while subjected to fluctuating temperatures and environmental stressors. By prioritizing durability in your selection process, you safeguard against unexpected failures that could disrupt service delivery and impact overall operational efficiency.

Future Trends in Power Lining Solutions

The future of power lining solutions is being shaped by a blend of sustainability, technological advancements, and a keen focus on energy efficiency. As the demand for reliable electrical power transmission lines continues to grow, so does the need for innovative overhead line fittings that can meet these evolving requirements. This section explores the trends that are set to redefine the industry in the coming years.

Sustainable Materials in Overhead Line Fittings

Sustainability is no longer just a buzzword; it's becoming a fundamental aspect of manufacturing overhead line fittings. Manufacturers are increasingly turning to eco-friendly materials that not only reduce environmental impact but also enhance performance and durability. For instance, using recycled metals and biodegradable composites in cable clamps not only supports green initiatives but also ensures that these fittings can withstand harsh weather conditions while minimizing their carbon footprint.

Moreover, sustainable materials in cable with clamp designs allow for lighter weight products that facilitate easier installation and maintenance, making them more appealing to contractors and utility companies alike. The shift towards renewable resources reflects a broader commitment across industries to adopt practices that prioritize both quality and environmental responsibility. As consumers become more environmentally conscious, manufacturers who embrace sustainable practices will likely gain a competitive edge.

The Rise of Smart Grids and Their Requirements

The emergence of smart grids is revolutionizing how we think about electrical power transmission lines and their components, including overhead line fittings. These advanced systems rely on real-time data collection and communication technologies to optimize energy distribution and improve reliability. Consequently, there’s an increasing demand for innovative clamps cable solutions that can integrate seamlessly with smart grid technology.

Smart grids require overhead line fittings that not only provide mechanical support but also feature built-in sensors for monitoring performance metrics such as load stress or temperature fluctuations. This integration enhances overall system efficiency while providing utilities with valuable insights into operational health—ultimately leading to reduced downtime and maintenance costs. As smart grid implementation expands globally, manufacturers must adapt their product offerings accordingly to meet these sophisticated requirements.

Innovations in Energy Efficiency for Power Transmission

Energy efficiency is at the forefront of innovations within the power lining sector as stakeholders seek ways to minimize energy loss during transmission processes. Overhead line fittings play a critical role here; advancements like improved wire clamp designs help ensure optimal connectivity while reducing resistance within electrical circuits. By focusing on efficient design principles, manufacturers are creating products that not only perform better but also contribute significantly to overall system efficiency.

Additionally, new technologies such as high-temperature superconductors are being explored as alternatives for traditional conductors used in electrical power transmission lines—potentially allowing for greater capacity without increasing physical infrastructure demands. These innovations reflect an industry-wide commitment to enhancing energy efficiency while ensuring reliability across various applications—from residential neighborhoods to sprawling industrial complexes. As these trends continue shaping the sector's landscape, we can expect even more cutting-edge solutions emerging from leading manufacturers.

Conclusion

In the world of overhead line fittings, several manufacturers stand out for their quality and innovation. Companies like Spark Fittings, TE Connectivity, and Hubbell Power Systems have established themselves as leaders in providing reliable solutions that meet the diverse needs of power lining projects. Their commitment to excellence ensures that electrical power transmission lines are equipped with fittings that can withstand various environmental challenges.

Recap of Leading Overhead Line Fitting Manufacturers

To recap, Spark Fittings offers innovative solutions that push the boundaries of what’s possible in overhead line fitting technology. TE Connectivity stands out with its extensive product range, catering to a wide array of applications in power lining. Meanwhile, Hubbell Power Systems is renowned for its unwavering commitment to quality and durability, making them a trusted partner for utility companies globally.

Importance of Choosing Quality Fittings

Choosing quality overhead line fittings is paramount for ensuring the longevity and safety of electrical power transmission lines. High-quality cable clamps and wire clamps not only enhance stability but also contribute to operational efficiency by reducing maintenance costs over time. When you invest in reliable fittings like cable with clamp systems, you're investing in the overall integrity and performance of your infrastructure.

Future Outlook for Power Lining Industry

Looking ahead, the future of the power lining industry appears bright with exciting trends on the horizon. The integration of sustainable materials into overhead line fittings is gaining momentum as environmental concerns grow among consumers and regulators alike. Additionally, advancements in smart grid technology will demand more sophisticated clamps cable solutions that can adapt to changing energy demands while maximizing efficiency.