Introduction

In the world of substations, understanding the dynamics of induced vibration is crucial for maintaining operational efficiency. Induced vibrations can stem from various sources, including equipment operation and environmental factors, making it essential to address them proactively. This is where vibration dampers come into play, acting as a vital line of defense against potential disruptions.

Understanding Induced Vibration in Substations

Induced vibration in substations can be likened to an unwelcome guest at a party—persistent and disruptive. It arises from numerous sources such as transformers, circuit breakers, and even external environmental influences like wind or seismic activity. What is a vibration damper? Simply put, it’s a device designed to absorb and reduce these unwanted vibrations, ensuring that your equipment runs smoothly without undue stress.

The Importance of Vibration Dampers

Vibration dampers are not just accessories; they are essential components that enhance system performance and reliability. By mitigating vibrations, these devices help prevent wear and tear on critical equipment components, ultimately saving costs associated with repairs or replacements. Can a damper reduce vibration? Absolutely! They work by dissipating energy through various mechanisms—making them indispensable in any substation setup.

Impact on Longevity and Reliability

The longevity of substation equipment is directly linked to how effectively induced vibrations are managed. When you invest in quality vibration dampers, you're essentially investing in the lifespan of your assets; less wear translates to fewer failures over time. Is a vibration damper necessary? In today’s high-stakes energy environment, the answer is an emphatic yes—especially when considering their role in transmission lines where stability is paramount.

The Nature of Induced Vibration

Understanding the nature of induced vibration in substations is crucial for maintaining operational efficiency and equipment longevity. Various factors contribute to these vibrations, often originating from both internal and external sources. By recognizing these sources, operators can better implement solutions like vibration dampers to mitigate their effects.

Sources of Vibration in Substations

Substations are often bustling hubs of electrical activity, which can lead to a multitude of vibration sources. Equipment such as transformers, circuit breakers, and generators can generate significant vibrations during operation due to mechanical movement or electrical loads. Additionally, external factors like wind-induced oscillation on transmission lines or seismic activity can also introduce unwanted vibrations into the substation environment.

The transmission line itself can be a considerable source of vibration; when wind flows over it, it creates oscillations that travel down the line. This is where devices like the AFL Spiral Vibration Damper come into play—designed specifically to counteract these types of disturbances effectively. Ultimately, identifying all potential sources is essential for understanding how best to deploy vibration dampers.

How Vibration Affects Equipment

Induced vibrations can have detrimental effects on substation equipment if left unchecked. Over time, these vibrations may lead to physical wear and tear on components, resulting in decreased efficiency or even catastrophic failure. For instance, excessive vibrations may loosen connections within electrical panels or cause mechanical components to misalign.

So you might wonder: what is a vibration damper? Essentially, it's a device designed to absorb or mitigate vibrational energy before it reaches sensitive equipment—think of it as a cushion for your machinery! By installing effective dampers throughout the substation infrastructure, operators can significantly prolong equipment life and enhance overall reliability.

Measuring Induced Vibration Levels

To effectively manage induced vibrations in substations, it's crucial first to measure their intensity accurately. Various tools exist for this purpose; accelerometers are commonly used devices that capture data on vibrational frequency and amplitude levels experienced by equipment over time. Regular monitoring allows operators not only to assess current conditions but also helps establish baseline readings for future comparisons.

Can a damper reduce vibration? Absolutely! However, before implementing any solutions like cable dampers or other types of vibration dampers, an accurate measurement ensures that interventions target specific issues effectively based on empirical data rather than guesswork. This proactive approach ultimately leads toward better decision-making regarding maintenance strategies and investments in quality assurance practices.

The Role of Vibration Dampers

Vibration dampers play a crucial role in maintaining the integrity and performance of equipment within substations and transmission lines. By effectively mitigating induced vibrations, these devices enhance the reliability and longevity of essential infrastructure. Understanding the various types of vibration dampers, their benefits, and real-world applications can help stakeholders make informed decisions.

Types of Vibration Dampers

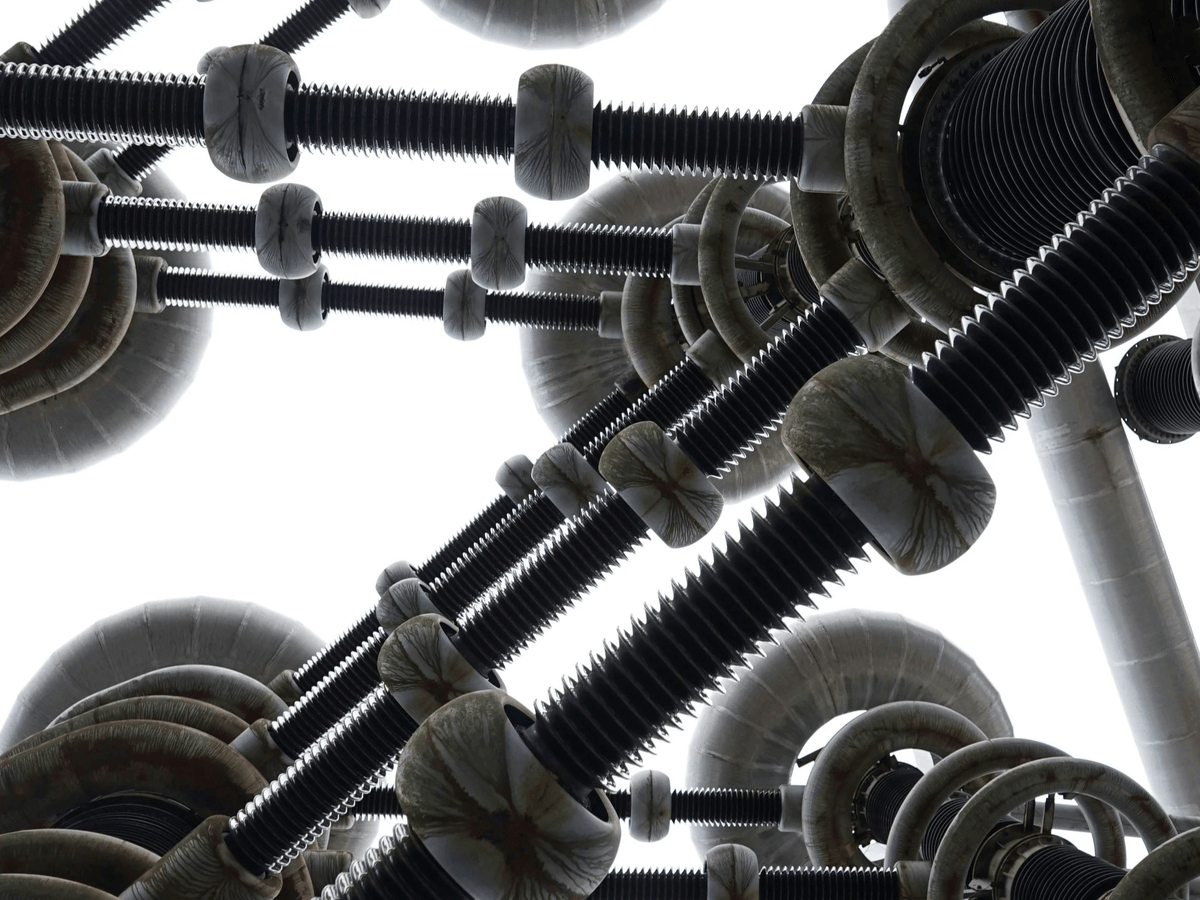

When exploring what is a vibration damper, it's essential to note that they come in various forms tailored to specific applications. Common types include cable dampers, such as the AFL Spiral Vibration Damper, which are designed specifically for use in transmission lines to counteract oscillations caused by wind or other external forces. Additionally, there are elastomeric dampers that absorb vibrations through deformation and metallic dampers that rely on mass inertia principles to dissipate energy effectively.

Understanding how do cable dampers work is key to appreciating their value; they utilize a combination of mass and spring elements that move out-of-phase with the vibrations, thereby reducing their amplitude. Each type serves a unique purpose based on the environment it operates in and the specific challenges presented by induced vibrations. Choosing the right vibration damper is critical for ensuring optimal performance across different applications.

Benefits of Using Vibration Dampers

So, can a damper reduce vibration? Absolutely! The primary benefit lies in their ability to minimize wear and tear on equipment by absorbing excess energy from vibrations before it can cause damage. This not only extends the lifespan of critical components but also enhances operational efficiency by reducing noise levels associated with mechanical resonance.

Is a vibration damper necessary? In many cases, yes! Especially in substations where heavy machinery operates continuously or where environmental factors contribute to increased vibration levels. By investing in high-quality vibration dampers like those from Spark Fittings, operators can ensure that their systems remain reliable under challenging conditions while also reducing maintenance costs over time.

Case Studies of Successful Implementations

Real-world examples illustrate just how effective vibration dampers can be when applied correctly. In one case study involving a major utility company’s transmission line project, engineers implemented AFL Spiral Vibration Dampers along several spans experiencing significant wind-induced oscillation issues. The results were impressive: after installation, there was a marked reduction in both visible sway and audible noise levels during windy conditions.

Another notable implementation occurred at an urban substation where routine inspections revealed excessive wear on transformers due to nearby construction activities generating sustained vibrations. By strategically placing elastomeric vibration dampers around sensitive equipment, operators reported improved performance metrics within weeks—demonstrating not only effectiveness but also rapid return on investment for this preventative measure.

Selecting the Right Equipment

Choosing the right vibration dampers for your substation or transmission line is crucial for maintaining equipment integrity and longevity. With a variety of options available, making an informed decision can significantly impact performance and reliability. This section will guide you through essential factors to consider when selecting vibration dampers, highlight recommended products from Spark Fittings, and emphasize the importance of quality assurance.

Factors to Consider When Choosing Vibration Dampers

When pondering What is a vibration damper? it's essential to recognize that not all dampers are created equal. First, assess the specific type of vibrations present in your environment; different sources may require tailored solutions. Additionally, consider the operational conditions such as temperature fluctuations, humidity levels, and potential exposure to chemicals that could affect damper performance.

Another key factor is the installation process—how do cable dampers work in your setup? Ensure compatibility with existing infrastructure to avoid costly modifications later on. Moreover, evaluate whether a damper can reduce vibration effectively under various load scenarios; this will help determine its suitability for your application.

Finally, remember that while it might be tempting to opt for cost-effective solutions, investing in high-quality vibration dampers can yield significant long-term savings by minimizing maintenance needs and extending equipment lifespan. Is a vibration damper necessary? The answer is often yes; without proper damping systems in place, equipment may suffer from premature wear or failure.

Recommended Products from Spark Fittings

Spark Fittings offers an impressive array of vibration dampers designed specifically for substations and transmission lines. One standout product is the AFL Spiral Vibration Damper—a reliable choice known for its innovative design that effectively mitigates vibrations caused by wind or other external forces. This particular damper excels in reducing oscillations along transmission lines while ensuring minimal impact on line tension.

In addition to the AFL Spiral Vibration Damper, Spark Fittings provides various other options tailored to meet diverse needs across different environments. Their product range includes cable dampers suitable for both overhead lines and substations where induced vibrations pose significant risks. Each product has been engineered with durability and efficiency in mind, ensuring optimal performance under challenging conditions.

Selecting products from reputable manufacturers like Spark Fittings not only guarantees quality but also provides access to expert support should any issues arise during installation or operation. By choosing trusted brands that specialize in vibration control solutions, you can rest assured knowing you're making an investment in your infrastructure's resilience.

Importance of Quality Assurance

Quality assurance plays a pivotal role when it comes to selecting effective vibration dampers—after all, you want your investment to stand the test of time! Comprehensive testing protocols ensure that each damper meets established industry standards before reaching consumers' hands. This means you'll benefit from products designed with precision engineering aimed at achieving maximum performance.

Furthermore, regular audits and certifications are vital components of any reputable manufacturer’s commitment to delivering reliable solutions like vibration dampers. These practices ensure consistency across production batches while also addressing evolving industry requirements related to safety and efficacy—especially important as technology advances over time.

Ultimately, prioritizing quality assurance not only enhances immediate operational efficiency but also contributes significantly towards long-term reliability across substations and transmission lines alike—because who wants unnecessary headaches down the road? Investing wisely today will pay dividends tomorrow!

Maintenance Strategies for Longevity

Maintaining the effectiveness of vibration dampers is crucial to ensuring the longevity and reliability of substation equipment. Regular maintenance not only extends the lifespan of these components but also enhances overall system performance. Implementing a structured approach to inspections and upkeep can prevent costly downtime and repairs.

Routine Inspections and Monitoring

Routine inspections are essential for identifying potential issues with vibration dampers before they escalate into significant problems. These inspections should include checking the physical condition of the vibration damper in transmission lines, ensuring there are no signs of wear or damage. Additionally, monitoring vibration levels can help determine if a damper is functioning correctly; if levels exceed acceptable thresholds, it might indicate that a damper isn’t able to reduce vibration effectively.

Regular monitoring also allows for timely adjustments or replacements when necessary, ensuring that the equipment continues to operate smoothly. Understanding how do cable dampers work can further enhance inspection processes by highlighting specific areas that may require closer scrutiny. Ultimately, routine inspections foster a proactive approach to maintenance, reducing unexpected failures.

Best Practices for Vibration Damper Maintenance

Implementing best practices for vibration damper maintenance is key to maximizing their effectiveness and longevity. First and foremost, it’s important to keep all components clean and free from debris that could hinder performance; regular cleaning helps maintain optimal functionality. Furthermore, understanding what is a vibration damper can aid in recognizing when specific maintenance actions are required.

Another best practice involves scheduling periodic assessments based on operational conditions; this ensures that any wear or fatigue on dampers like the Afl Spiral Vibration Damper is addressed promptly. Training personnel on proper handling techniques during installation or adjustment can also mitigate risks associated with improper use. By adhering to these practices, substations can significantly enhance their equipment's reliability.

Common Issues and Solutions

Despite diligent maintenance efforts, common issues with vibration dampers may still arise; however, knowing how to address them can save time and resources in the long run. One frequent problem is excessive wear due to prolonged exposure to high vibrations; this often leads operators to question if a vibration damper is necessary at all in certain applications. The solution typically involves reassessing the type of damper used—sometimes an upgrade or replacement with more robust options like specialized cable dampers may be warranted.

Another issue could be improper installation leading to ineffective performance; in such cases, reviewing installation guidelines ensures that all parameters meet manufacturer specifications—after all, if you don’t know how do cable dampers work properly during setup, you might be setting yourself up for failure! Lastly, monitoring environmental factors such as temperature fluctuations can inform decisions about whether additional protective measures are needed for sensitive equipment.

Future Trends in Vibration Control

The landscape of vibration control is rapidly evolving, driven by technological advancements and the increasing need for reliability in substations. Innovations in vibration dampening technology are paving the way for more effective solutions, while the integration of IoT is revolutionizing how we monitor vibrations. Moreover, as industries adapt to changing demands, anticipating shifts in industry standards will be crucial for maintaining optimal performance.

Innovations in Vibration Dampening Technology

In recent years, innovations in vibration dampers have emerged that significantly enhance their effectiveness and application range. New materials and designs have been developed to create vibration dampers that are lighter yet more robust, allowing them to absorb vibrations more efficiently. For instance, Afl Spiral Vibration Dampers utilize a unique spiral design that maximizes energy absorption while minimizing weight—perfect for installation on transmission lines where every ounce counts.

What is a vibration damper? Essentially, it’s a device designed to reduce oscillations or vibrations caused by external forces. With advancements like these, it becomes increasingly clear: can a damper reduce vibration? The answer is a resounding yes! Enhanced designs allow these devices to tackle even the most challenging vibrational issues effectively.

The Role of IoT in Monitoring Vibration

The Internet of Things (IoT) is transforming how we approach monitoring induced vibrations within substations and transmission lines. By incorporating smart sensors into vibration dampers, real-time data collection becomes feasible—allowing operators to understand precisely how equipment responds under various conditions. This level of insight facilitates proactive maintenance strategies that can prevent costly downtimes.

Is a vibration damper necessary? With IoT capabilities integrated into these systems, the answer becomes clearer; they not only help mitigate existing issues but also provide critical data that informs future upgrades and interventions. The ability to analyze trends over time allows operators to make informed decisions about when and where additional damping measures might be required.

Anticipating Changes in Industry Standards

As technology progresses and our understanding of structural integrity deepens, changes in industry standards regarding vibration control are inevitable. Regulatory bodies are likely to update guidelines based on new research findings related to induced vibrations and their impact on equipment longevity and reliability. Staying ahead of these changes means investing early in advanced solutions like modern vibration dampers.

The conversation surrounding what constitutes an effective solution continues to evolve; hence understanding how do cable dampers work becomes crucial for compliance with upcoming regulations. By anticipating these shifts proactively rather than reactively addressing them later on, companies can maximize their investment in substation equipment while ensuring adherence to best practices moving forward.

Conclusion

In the dynamic world of substations, enhancing reliability through effective vibration control is not just a luxury—it's a necessity. Vibration dampers play a pivotal role in mitigating the adverse effects of induced vibrations caused by various operational factors. By understanding what a vibration damper is and how it functions, operators can significantly improve the longevity and performance of their equipment.

Enhancing Reliability Through Vibration Control

Vibration dampers are essential components designed to reduce unwanted oscillations in electrical equipment, ensuring smoother operation and minimizing wear and tear. Understanding how do cable dampers work can empower engineers to select the right solutions tailored to their specific needs. By incorporating these devices into transmission lines, substations can experience improved stability and reliability, ultimately leading to enhanced operational efficiency.

Long-Term Benefits of Vibration Dampers

The long-term benefits of utilizing vibration dampers extend far beyond immediate noise reduction; they also contribute significantly to the overall lifespan of substation equipment. Can a damper reduce vibration? Absolutely! With effective vibration dampening solutions like the AFL Spiral Vibration Damper, substations can maintain optimal functionality while reducing maintenance costs over time.

Maximizing Investment in Substation Equipment

Investing in quality vibration dampers is crucial for maximizing returns on substation equipment investments. Is a vibration damper necessary? The answer is an emphatic yes—especially when considering potential downtime and repair costs associated with unaddressed vibrations. By prioritizing high-quality products from reputable manufacturers, operators ensure that their infrastructure remains robust against the challenges posed by induced vibrations.