Introduction

In the world of industrial maintenance and preparation, sandblasting equipment stands out as a crucial tool. Whether you're looking to clean surfaces, prepare them for painting, or remove rust and contaminants, understanding the nuances of sand blasting can significantly enhance your efficiency and results. This introduction will delve into the various types of sandblasting machines available, their specific applications, and the key benefits that make them indispensable in many industries.

Understanding Industrial Sandblasting Equipment

Industrial sandblasting equipment encompasses a range of machines designed to propel abrasive materials against surfaces at high speeds. This process not only cleans but also smooths out surfaces, making it essential for various applications like automotive refinishing and metal fabrication. Familiarizing yourself with these machines is vital for anyone looking to invest in effective sand blast equipment that meets their specific needs.

Types of Sandblasting Equipment Available

There’s a plethora of sandblasting equipment on the market today, each tailored for different tasks and environments. From portable sand blasting units to larger stationary sand blasting cabinets, each type boasts unique advantages suited for diverse projects. Understanding the differences between these options can help you select the right sandblaster that aligns with your operational requirements.

Key Benefits of Sand Blasting

The benefits of using industrial sandblasting equipment are numerous and impactful. Not only does it provide an efficient means to prepare surfaces by removing dirt, paint, or corrosion, but it also enhances adhesion for subsequent coatings or finishes. Additionally, investing in quality sand blaster sand can lead to improved results while extending the lifespan of your machinery—making it a win-win situation for both productivity and cost-effectiveness.

What is Sandblasting?

Sandblasting, often referred to as abrasive blasting, is a process that uses high-pressure air to propel abrasive materials against surfaces. This technique is widely employed for cleaning, smoothing, or shaping various materials. Understanding the fundamentals of sand blasting can help you appreciate its importance in industrial applications and DIY projects alike.

The Basics of Sand Blasting

At its core, sand blasting involves using a stream of abrasive material—commonly referred to as sand blaster sand—accelerated by compressed air or water to remove unwanted contaminants from surfaces. The equipment used in this process includes various types of sandblasting machines and cabinets designed for specific tasks. Whether you’re looking to restore an old car or prepare a surface for painting, mastering the basics of sand blasting is crucial.

The method's versatility makes it suitable for numerous applications ranging from automotive restoration to industrial cleaning. It’s essential to choose the right type of sandblasting equipment based on your project needs and desired outcomes. With the proper knowledge and tools, anyone can achieve professional-quality results using this powerful technique.

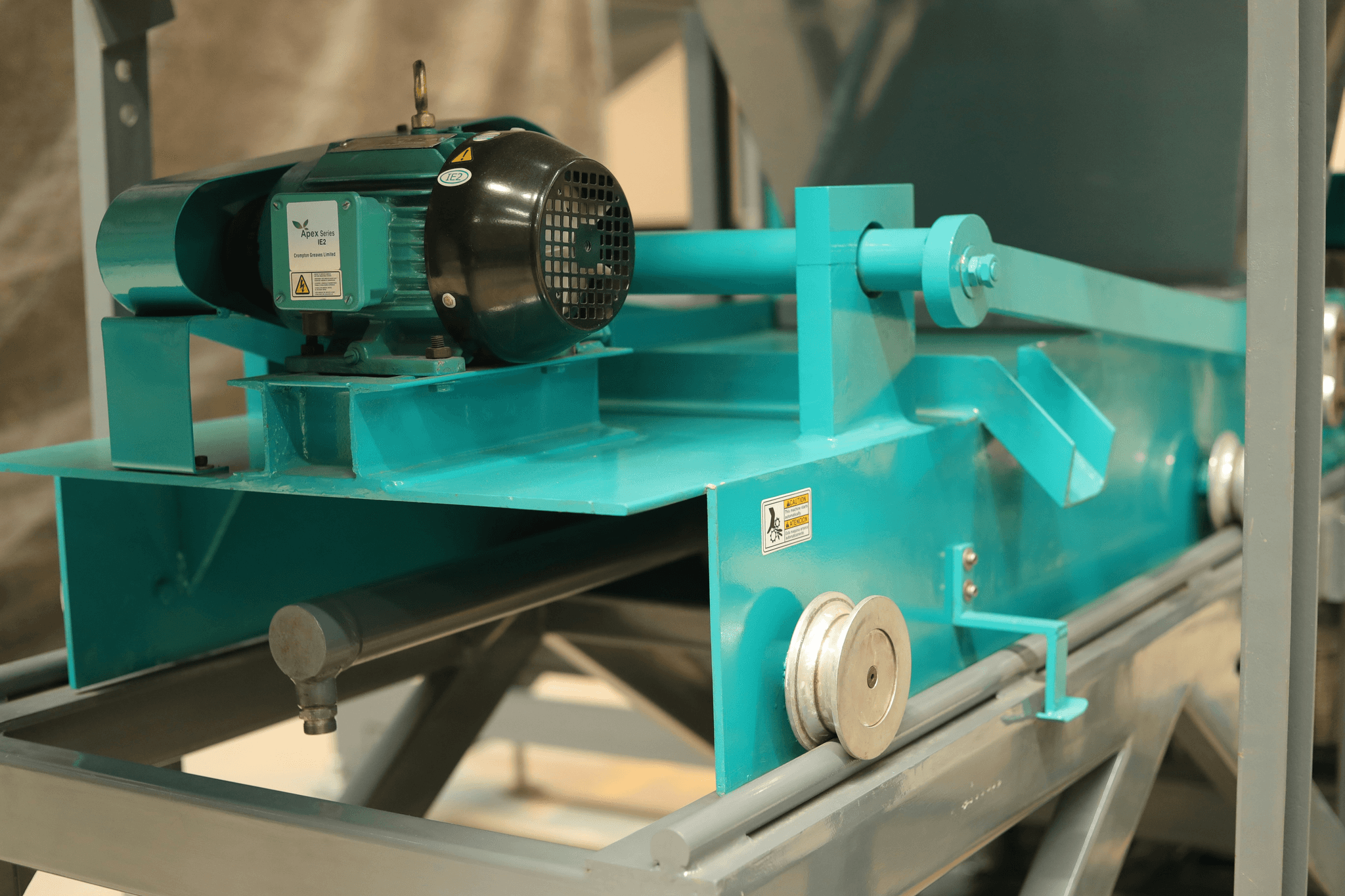

How Sand Blasters Work

Sandblasters operate by drawing abrasive materials from a container and mixing them with compressed air before propelling them through a nozzle at high speeds. This process creates an intense jet stream that effectively strips away dirt, rust, paint, or other unwanted substances from surfaces. Industrial sandblasting equipment typically features adjustable pressure settings that allow users to control the intensity of the blast.

The design of a sand blasting cabinet enables operators to work safely while containing dust and debris generated during the process. Furthermore, many modern machines incorporate advanced technology that enhances efficiency and reduces waste of abrasive materials like sand blaster sand. Understanding how these components function together will help you select the right equipment for your specific needs.

Applications of Sandblasting Equipment

The applications for sandblasting equipment are vast and varied across different industries. From automotive refinishing to metal fabrication, this process plays a critical role in preparing surfaces for further treatment or finishing work. For instance, in construction projects, professionals use industrial sandblasting equipment to clean concrete surfaces before applying sealants or coatings.

In addition to industrial uses, hobbyists often find value in owning smaller-scale models like portable sandblasting cabinets for personal projects at home. Artists also employ this technique creatively when etching designs onto glass or stone surfaces using specialized abrasives tailored for precision work. Ultimately, understanding these diverse applications helps users appreciate how essential effective sand blast equipment can be in achieving desired results across multiple fields.

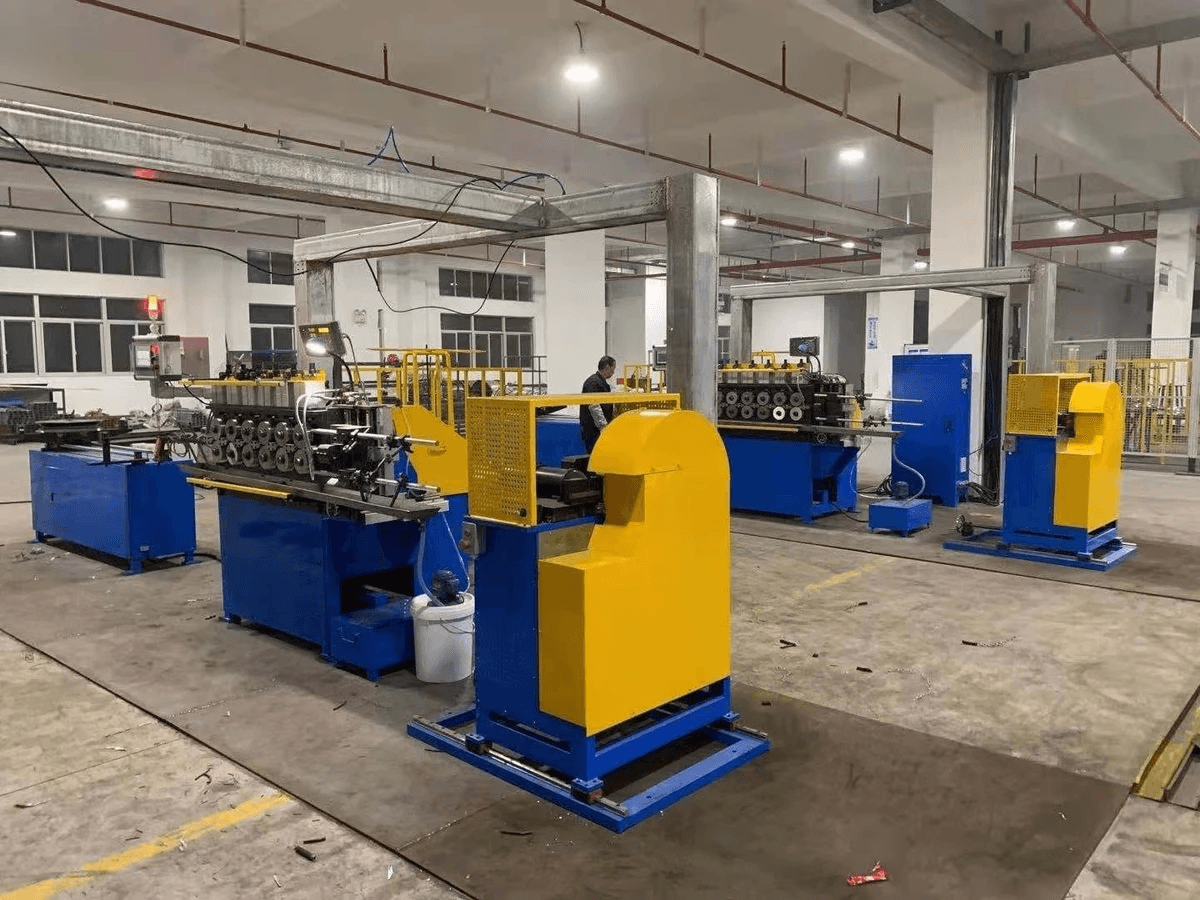

Types of Sandblasting Machines

Overview of Sandblasting Machines

Sandblasting machines come in several configurations, each suited for specific tasks and environments. Generally, these machines utilize compressed air to propel abrasive materials—like sand blaster sand—onto surfaces that require cleaning or finishing. The right choice of sand blasting equipment can make all the difference in productivity and quality.

In essence, the main categories include pressure blasters and suction blasters, each with distinct operational methods. Pressure blasters deliver high velocity by using compressed air to push the abrasive material through a nozzle at high speeds. On the other hand, suction blasters rely on ambient air pressure to pull the abrasive from a reservoir, making them suitable for lighter applications.

Comparing Pressure vs. Suction Sandblasters

When comparing pressure versus suction sandblasters, it's essential to consider their respective strengths and weaknesses relative to your specific needs. Pressure sandblasters are known for their superior speed and efficiency; they provide a more powerful blast that can tackle tougher surfaces more effectively than their suction counterparts. If you’re working on heavy-duty projects or need quick results, pressure models are often the go-to choice among professionals.

Conversely, suction sandblasters tend to be more user-friendly and versatile for smaller jobs or delicate materials where precision is key. They generally have lower operational costs due to less wear on components but may require more time for extensive projects compared to pressure systems. Ultimately, selecting between these two types boils down to balancing power needs against project scale and complexity.

Choosing the Right Sandblasting Machine

Choosing the right sandblasting machine involves evaluating several factors: project size, material type, desired finish quality, and budget constraints are all critical considerations when selecting industrial sandblasting equipment. For larger projects requiring heavy-duty performance with consistent results over time, investing in a high-quality pressure machine may be worthwhile despite its higher upfront cost.

If you're tackling smaller jobs or working with sensitive materials like wood or glass where finesse is crucial, a suction model might be more appropriate without breaking the bank on unnecessary features found in larger machines designed for industrial use cases. Additionally, consider whether you need supplementary tools like a dedicated sand blasting cabinet for contained workspaces; this could enhance safety while improving efficiency during operations involving fine abrasives like specialized sands.

Ultimately, doing thorough research on available options—including reading reviews about leading brands—can guide you toward making an informed decision that meets both your immediate needs and long-term goals within any given project scope involving effective use of sandblast equipment.

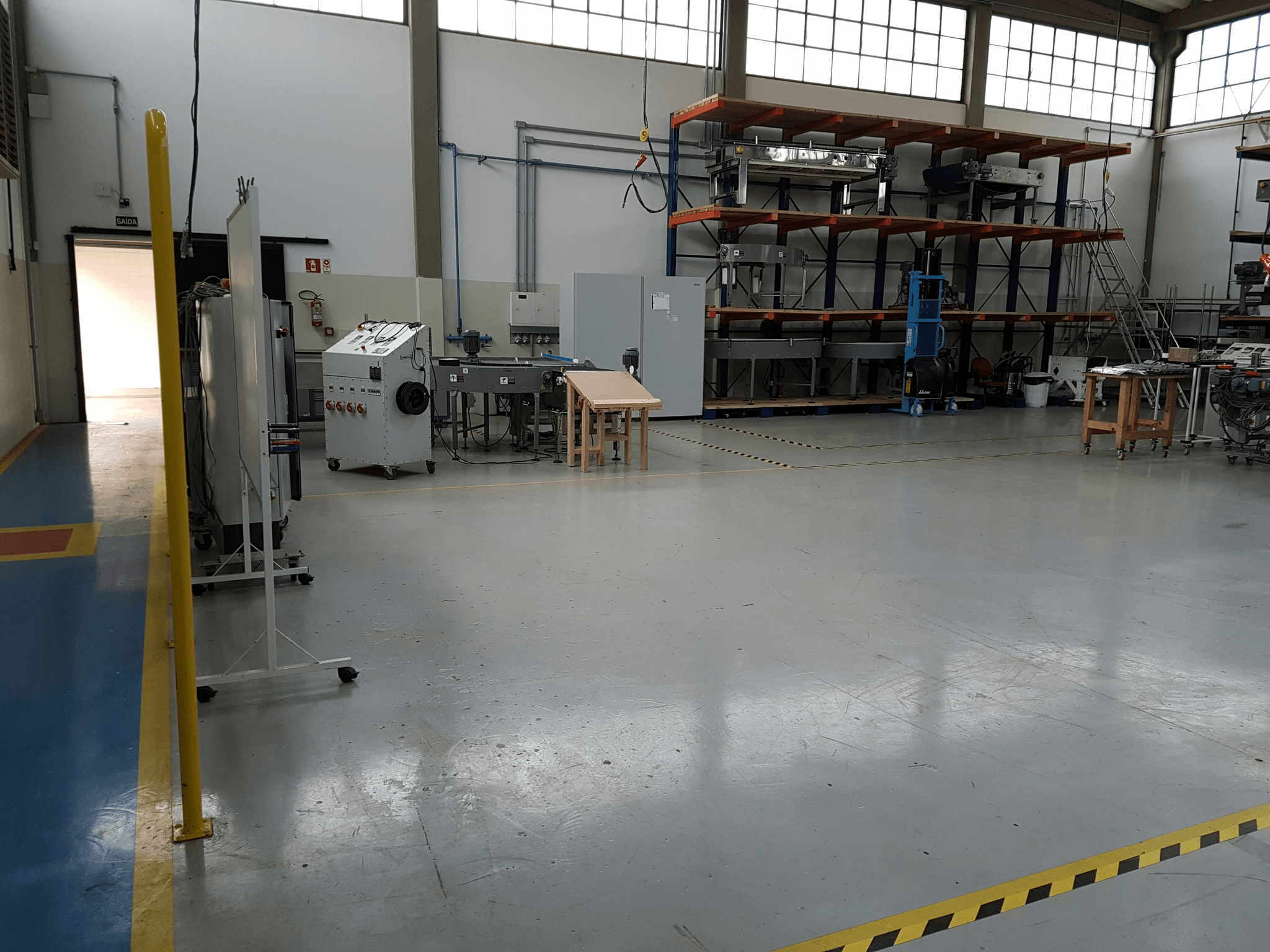

Essential Sand Blasting Cabinets

Importance of Sandblasting Cabinets

Sandblasting cabinets play a crucial role in any workshop utilizing sand blasting techniques. They not only enhance safety by containing dust and debris but also improve the quality of work by providing a consistent blasting environment. Moreover, these essential pieces of sand blast equipment help in recycling abrasive materials, making them cost-effective for long-term use.

Features to Look for in a Sand Blast Cabinet

When selecting a sand blasting cabinet, there are several key features to consider that can make or break your experience with your sandblasting machine. First and foremost is the size; ensure that the cabinet can accommodate your largest workpieces without compromising accessibility. Additionally, look for features such as adjustable pressure settings, visibility through high-quality viewing windows, and an effective dust collection system to keep your workspace clean.

Another important aspect is durability; heavy-duty construction materials will ensure longevity under constant use with various types of abrasives like different grades of sand blaster sand. Ergonomic designs that make loading and unloading easier can also enhance productivity while reducing operator fatigue during extended sessions of using industrial sandblasting equipment.

Leading Brands in Sandblasting Cabinets

The market boasts several reputable brands known for their high-quality sand blasting cabinets designed specifically for industrial applications. Brands like Grizzly Industrial and Eastwood have established themselves as leaders by consistently delivering reliable and durable products tailored to meet diverse user needs. Additionally, companies such as TP Tools & Equipment offer customizable options that cater to specific project requirements while ensuring excellent performance with their advanced sandblasting equipment.

Investing in one of these leading brands ensures you’re getting top-notch quality along with robust support systems should you encounter any issues down the line—because nobody wants their productive day ruined by faulty equipment!

Sand Blaster Sand and Materials

Selecting the right materials for sandblasting is crucial to achieving optimal results with your industrial sandblasting equipment. The type of sand used can significantly impact the efficiency of your sand blasting process, influencing everything from surface finish to equipment longevity. Understanding the various options available allows you to make informed choices that enhance your overall sandblasting experience.

Different Types of Sand for Sandblasting

Common choices include silica sand, aluminum oxide, and glass beads, each offering unique properties suited for different applications. Silica sand is often favored for its cost-effectiveness and availability, while aluminum oxide provides a sharper cutting edge, making it ideal for tougher surfaces; glass beads are great for polishing without damaging the substrate.

Moreover, there are specialty abrasives designed specifically for certain tasks or industries—such as garnet or walnut shell media—which can provide additional versatility in your sandblasting cabinet. Each type of abrasive has its own set of advantages and drawbacks depending on the project at hand, so it's essential to consider these factors when selecting your materials. Ultimately, choosing the right type of sand will help maximize the performance of your sandblasting machine.

Importance of Choosing the Right Abrasive

The choice of abrasive material plays a pivotal role in the effectiveness and safety of any sand blast equipment operation. Using an inappropriate abrasive can lead to poor surface finishes or even damage to both the workpiece and your industrial sandblasting equipment itself. For instance, using too coarse an abrasive may cause excessive wear on components or result in uneven results on delicate surfaces.

Additionally, different abrasives have varying levels of dust generation and health risks associated with them; therefore, selecting a suitable material is not just about performance but also about ensuring safety during operation. It’s worth investing time into understanding these nuances because they ultimately affect productivity and cost-efficiency in long-term operations with your sand blasting setup. Remember: quality abrasives lead to quality results!

How to Source Quality Sand Blaster Sand

Finding high-quality materials for your industrial sandblasting equipment doesn’t have to be a daunting task if you know where to look! Start by sourcing from reputable suppliers who specialize in abrasives; online reviews can provide insight into their reliability and product quality. Local distributors may also offer samples so you can test different types before making bulk purchases.

Another option is exploring industry-specific trade shows or expos where manufacturers showcase their latest offerings—this allows you not only to see products firsthand but also engage directly with experts who can answer specific questions about their abrasives’ suitability for various applications within your sanding cabinet setup. Always prioritize suppliers who adhere strictly to safety standards as well; after all, using subpar materials could compromise both performance and worker safety during operations.

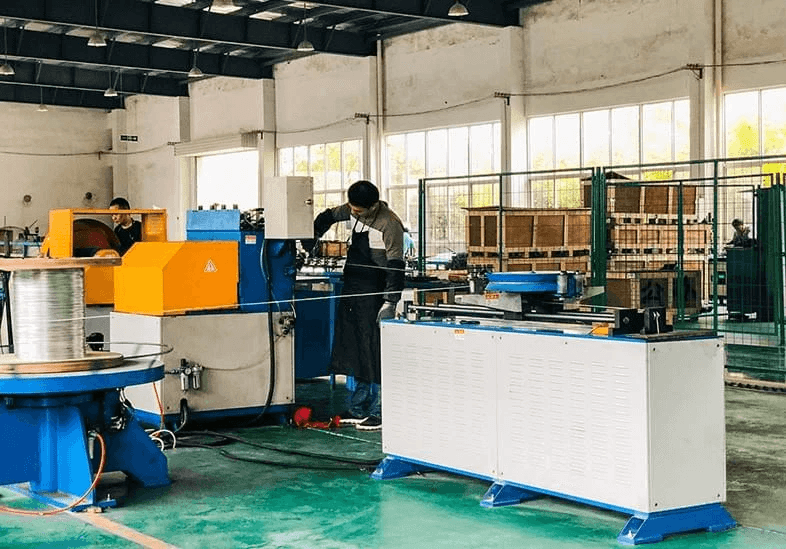

Spotlight on Spark Electronic Technology

In the realm of industrial sandblasting equipment, innovation is key to maintaining efficiency and effectiveness. Spark Electronic Technology stands out as a leader in this field, pushing the boundaries of what sand blasting can achieve. Their commitment to integrating advanced technology into sandblasting machines has revolutionized the way professionals approach surface preparation.

Innovation in Sandblasting Equipment

Spark Electronic Technology has introduced several groundbreaking features that enhance the performance of sand blast equipment. These innovations include automated controls, which allow for precise adjustments during the blasting process, ensuring optimal results every time. Additionally, their focus on energy-efficient designs not only reduces operational costs but also minimizes environmental impact—something every modern business should consider.

The incorporation of smart technology into sandblasting equipment means that operators can monitor and control processes remotely, increasing safety and convenience. This technological edge allows users to achieve consistent finishes with less manual intervention, making it an attractive option for large-scale applications. Overall, Spark's innovative approach sets a new standard for efficiency in the world of industrial sandblasting.

Key Products for Commercial Applications

Their line-up includes high-performance sand blasting cabinets designed for various scales of operation—from small workshops to large manufacturing facilities. Each product is engineered with durability and versatility in mind, allowing businesses to tackle different projects without compromising on quality.

One standout product is their advanced suction sandblaster, which excels in precision work while minimizing material waste—a crucial factor when selecting any type of sandblasting machine. Furthermore, these cabinets are equipped with features like integrated dust collection systems that ensure a cleaner working environment and better visibility during operations. Such attention to detail not only enhances productivity but also elevates user experience across commercial settings.

Reliability and Quality in Manufacturing

Reliability is paramount when investing in industrial sandblasting equipment; after all, downtime can be costly for any business operation. Spark Electronic Technology prides itself on producing robust machines that withstand rigorous use while maintaining peak performance levels over time. Their commitment to quality assurance ensures that each piece of equipment meets stringent standards before reaching customers.

Moreover, customer feedback consistently highlights the longevity and reliability of their products—an essential consideration when choosing a supplier for your sand blast equipment needs. With an emphasis on high-quality materials and expert craftsmanship, Spark’s offerings stand out as trustworthy options within this competitive market segment. Investing in their reliable machinery means investing in peace of mind for your business's future success.

When it comes to commercial applications, Spark Electronic Technology offers an impressive lineup of products tailored specifically for various industries. Their range includes versatile sandblasting machines that can handle everything from automotive parts to heavy machinery components with ease. Each product is designed with durability in mind, ensuring they withstand rigorous daily use while maintaining high performance.

Conclusion

In conclusion, the world of industrial sandblasting equipment is vast and constantly evolving. Whether you're a seasoned professional or just dipping your toes into the sand blasting waters, understanding the nuances of different sandblasting machines and their applications can significantly enhance your projects. From selecting the right sand blaster sand to investing in a high-quality sand blasting cabinet, every decision plays a crucial role in achieving optimal results.

Final Thoughts on Sandblasting Equipment

Sandblasting equipment has become an indispensable tool across various industries due to its efficiency and effectiveness in surface preparation. The right choice of industrial sandblasting equipment can save time and improve outcomes, whether you're cleaning metal surfaces or preparing them for painting. As technology advances, we can expect even more innovative features in future sand blast equipment that will further streamline processes.

Choosing the Right Equipment for Your Needs

A well-chosen sand blasting cabinet can make all the difference in terms of both performance and safety during operation. Take time to evaluate different options available on the market to ensure you invest in reliable sandblasting equipment that meets your needs without breaking the bank.

Future Trends in Industrial Sandblasting

The future of industrial sandblasting is looking bright with advancements in technology paving the way for more efficient and environmentally-friendly practices. Innovations such as automated systems and smart monitoring tools are set to revolutionize how we approach surface preparation tasks with our trusted sand blast equipment. As sustainability becomes a priority across industries, expect new materials for abrasives like eco-friendly alternatives that maintain effectiveness while reducing environmental impact.