Introduction

In the world of power lines, ensuring safety and reliability is paramount, and one of the unsung heroes in this arena is the vibration damper for power lines. These ingenious devices play a crucial role in mitigating vibrations that can lead to structural damage or even catastrophic failure. Understanding the vibration damper meaning not only highlights its importance but also showcases how innovations like the Stockbridge vibration damper and Spiral Vibration Damper are reshaping industry standards.

Understanding Vibration Dampers

Vibration dampers are specialized devices designed to absorb and dissipate vibrational energy, thereby enhancing stability and longevity in various applications, including power lines. By utilizing principles of physics, these dampers reduce oscillations caused by wind or mechanical forces, effectively minimizing wear and tear on infrastructure. In essence, they serve as a protective barrier that ensures electrical systems operate smoothly without unnecessary interruptions.

Importance of Safety in Power Lines

Safety in power lines cannot be overstated; even minor vibrations can lead to significant issues such as conductor fatigue or equipment failure. The consequences of neglecting these vibrations can be dire—not just for infrastructure but also for public safety and service reliability. Thus, implementing effective solutions like vibration dampers becomes essential to safeguard both human lives and electrical systems from unforeseen disasters.

Role of Spark Fittings in Innovation

When it comes to innovation in vibration dampers, Spark Fittings stands out as a leader in manufacturing high-quality components designed specifically for power line applications. Their commitment to using advanced materials ensures that products such as the Stockbridge vibration damper meet rigorous safety standards while providing exceptional performance under challenging conditions. By continually pushing boundaries through research and development, Spark Fittings plays a pivotal role in transforming how we understand and implement vibration control technologies across the industry.

What is Vibration Damper Meaning?

When we talk about a vibration damper, we're diving into an essential component that plays a crucial role in various applications, especially in power lines. A vibration damper for power lines is specifically designed to minimize the effects of oscillations caused by environmental factors like wind and seismic activity. Understanding the vibration damper meaning extends beyond just its definition; it encompasses its purpose and functionality in enhancing safety and reliability.

Definition and Purpose

At its core, a vibration damper is a device used to reduce or control vibrations within structures or systems. In the context of power lines, its primary purpose is to absorb energy from oscillations, thereby preventing damage to the line itself or adjacent components. This not only prolongs the lifespan of infrastructure but also significantly enhances safety for both equipment and personnel.

How It Works in Power Lines

A vibration damper works by dissipating vibrational energy through various mechanisms, which can include mass-spring systems or damping materials that convert kinetic energy into heat. In power lines, when wind passes over conductors, it can induce vibrations that may lead to fatigue failure if left unchecked. By strategically placing devices like Stockbridge vibration dampers along the line, these oscillations are mitigated, ensuring that the integrity of the power system remains intact.

Types of Vibration Dampers

There are several types of vibration dampers employed in different scenarios, with each serving distinct purposes based on their design and application requirements. The Stockbridge vibration damper is one of the most commonly used types for power lines due to its effectiveness in reducing aeolian vibrations caused by wind. Another notable type is the Spiral Vibration Damper; this innovative design offers unique characteristics that enhance performance even further under challenging conditions.

The Science Behind Vibration Dampers

When it comes to the mechanics of vibration dampers, understanding the underlying science is crucial. Vibration dampers for power lines are specifically designed to mitigate oscillations caused by wind, seismic activity, and other external forces. These devices ensure that electrical transmission remains stable and safe, reducing wear and tear on infrastructure.

Physics of Vibration Control

At its core, vibration control hinges on the principles of physics—specifically, how energy is absorbed and dissipated. A vibration damper in engine applications operates under similar principles; it absorbs kinetic energy generated by movement, thus preventing excessive vibrations from causing damage. This is where devices like the Stockbridge vibration damper come into play; they utilize mass and stiffness to counteract vibrations effectively.

The design of a Stockbridge vibration damper allows it to be tuned to specific frequencies associated with power line oscillations. By strategically placing these dampers along power lines, engineers can create a system that minimizes resonance effects—those pesky vibrations that can lead to catastrophic failures if left unchecked. Understanding these physical interactions is key to harnessing the full potential of vibration dampers in various applications.

Common Issues Caused by Vibration

Vibrations in power lines can lead to several common issues that affect both performance and safety. One major problem is conductor galloping—a phenomenon where wind-induced vibrations cause conductors to sway excessively, potentially leading to contact with other lines or structures. This not only poses risks for electrical outages but also endangers public safety.

Another issue arises from fatigue failure; repeated cycles of stress caused by vibrations can weaken materials over time, leading to breakage or malfunctioning components in power systems. The installation of a spiral vibration damper helps mitigate these risks by providing additional resistance against such oscillatory movements. By addressing these problems head-on through effective damping solutions, we can significantly enhance the longevity and reliability of our power infrastructure.

Benefits of Vibration Dampers in Power Lines

The benefits of incorporating vibration dampers into power line systems are manifold and impactful. First off, they greatly improve operational safety by minimizing risks associated with excessive vibrations—this translates into fewer outages and reduced maintenance costs over time. Additionally, using a vibration damper for power lines can extend the lifespan of conductors and other supporting structures by mitigating wear caused by repetitive stress.

Moreover, implementing solutions like spiral vibration dampers not only enhances structural integrity but also contributes positively toward overall system efficiency—less energy wasted means more reliable service delivery! In an era where sustainability matters more than ever, this becomes an essential consideration for utility companies aiming for excellence in service provision while keeping costs manageable.

Stockbridge Vibration Damper and Its Advantages

The Stockbridge vibration damper is a crucial component in maintaining the integrity of power lines. By effectively reducing vibrations caused by wind and other environmental factors, this device ensures that power lines remain stable and safe. Understanding its design features, applications, and real-world success stories can illuminate why it’s a go-to solution for engineers.

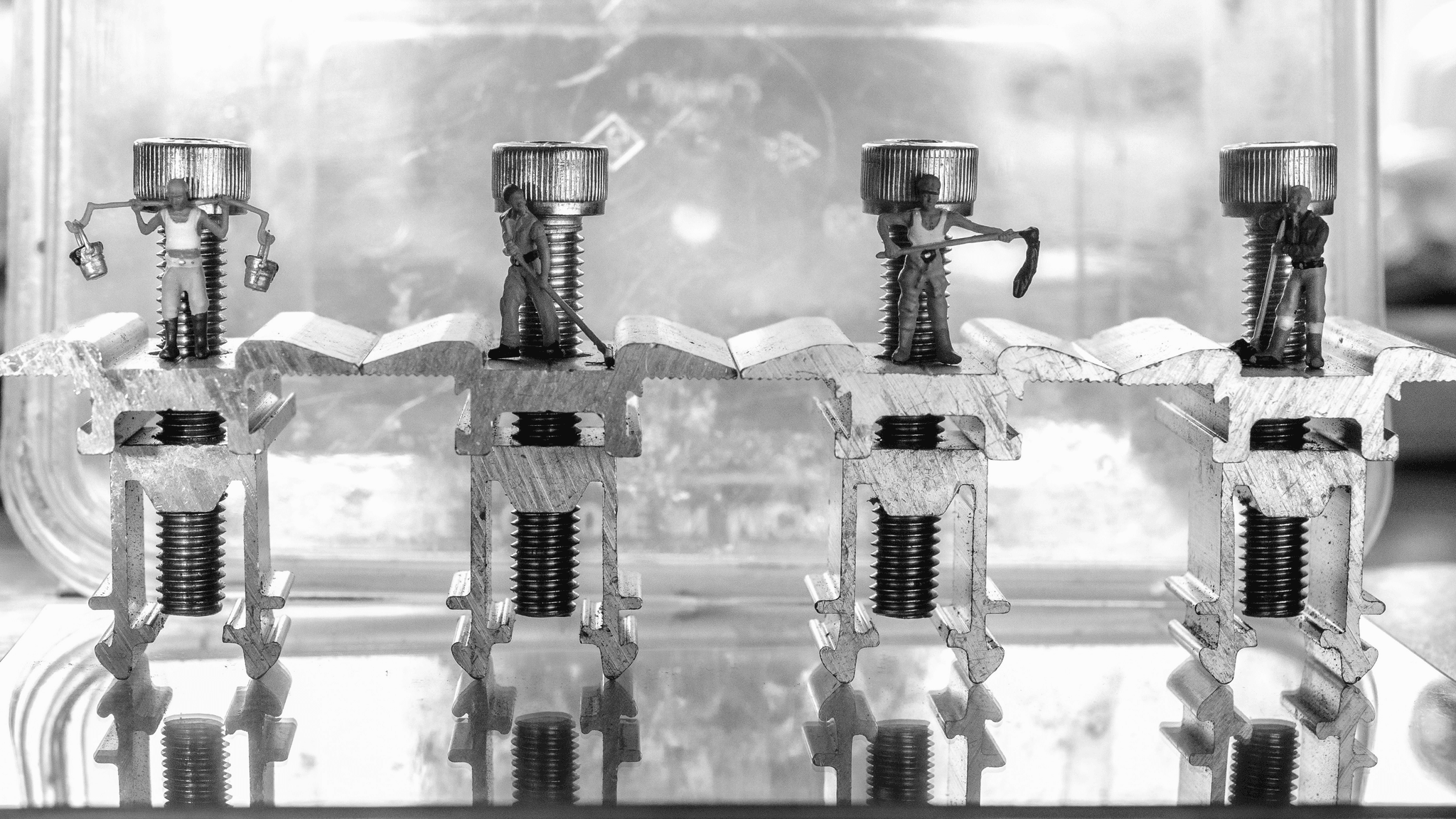

Design Features

The Stockbridge vibration damper boasts a unique design that sets it apart from other types of vibration dampers used in various applications, including engines. Typically consisting of a weight suspended from a flexible clamp, this damper is engineered to counteract the oscillations experienced by power lines. The strategic placement of these weights helps to dissipate energy effectively, making the Stockbridge vibration damper an essential tool for enhancing reliability in power line systems.

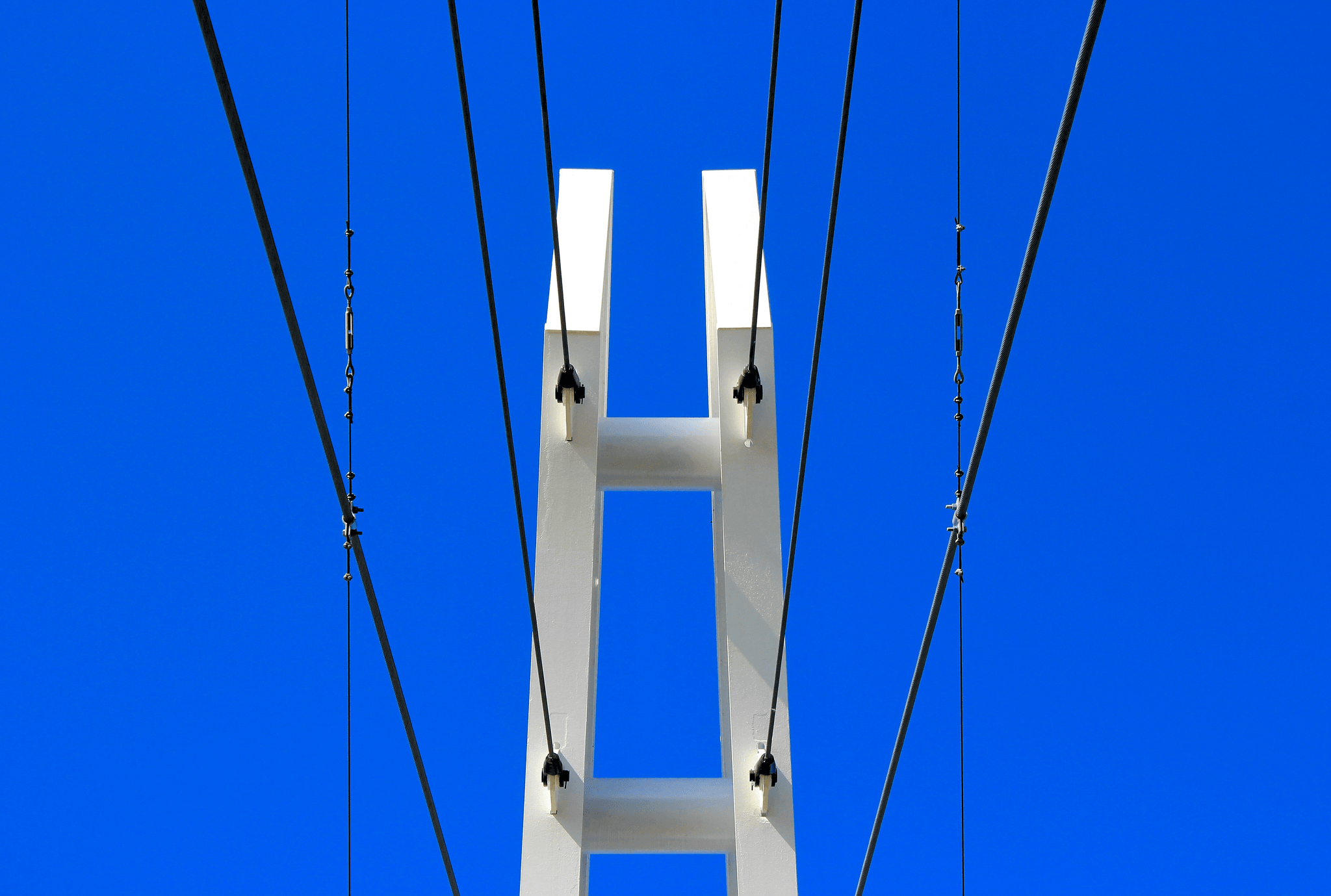

Applications in Power Lines

When it comes to applications in power lines, the Stockbridge vibration damper shines brightly—quite literally! It's primarily used to mitigate vibrations that could lead to fatigue or failure of electrical conductors over time. This is particularly important in areas prone to high winds or severe weather conditions where the integrity of the infrastructure is paramount; using a vibration damper for power lines not only prolongs their lifespan but also enhances safety protocols.

Case Studies and Success Stories

Numerous case studies highlight the success of implementing Stockbridge vibration dampers across various regions. For example, utility companies have reported significant reductions in maintenance costs after installing these devices on existing infrastructure; one case saw a 30% decrease in wear-related issues within just two years! These success stories not only affirm the effectiveness of Stockbridge dampers but also demonstrate their role as game-changers in ensuring reliable electricity distribution.

Spiral Vibration Damper: A Game Changer

When it comes to controlling vibrations in power lines, the Spiral Vibration Damper has emerged as a true game changer. This innovative device not only enhances the stability of power lines but also significantly contributes to safety protocols, making it indispensable in modern electrical infrastructure. With its unique design and functionality, the spiral vibration damper is redefining how we approach vibration control in various applications.

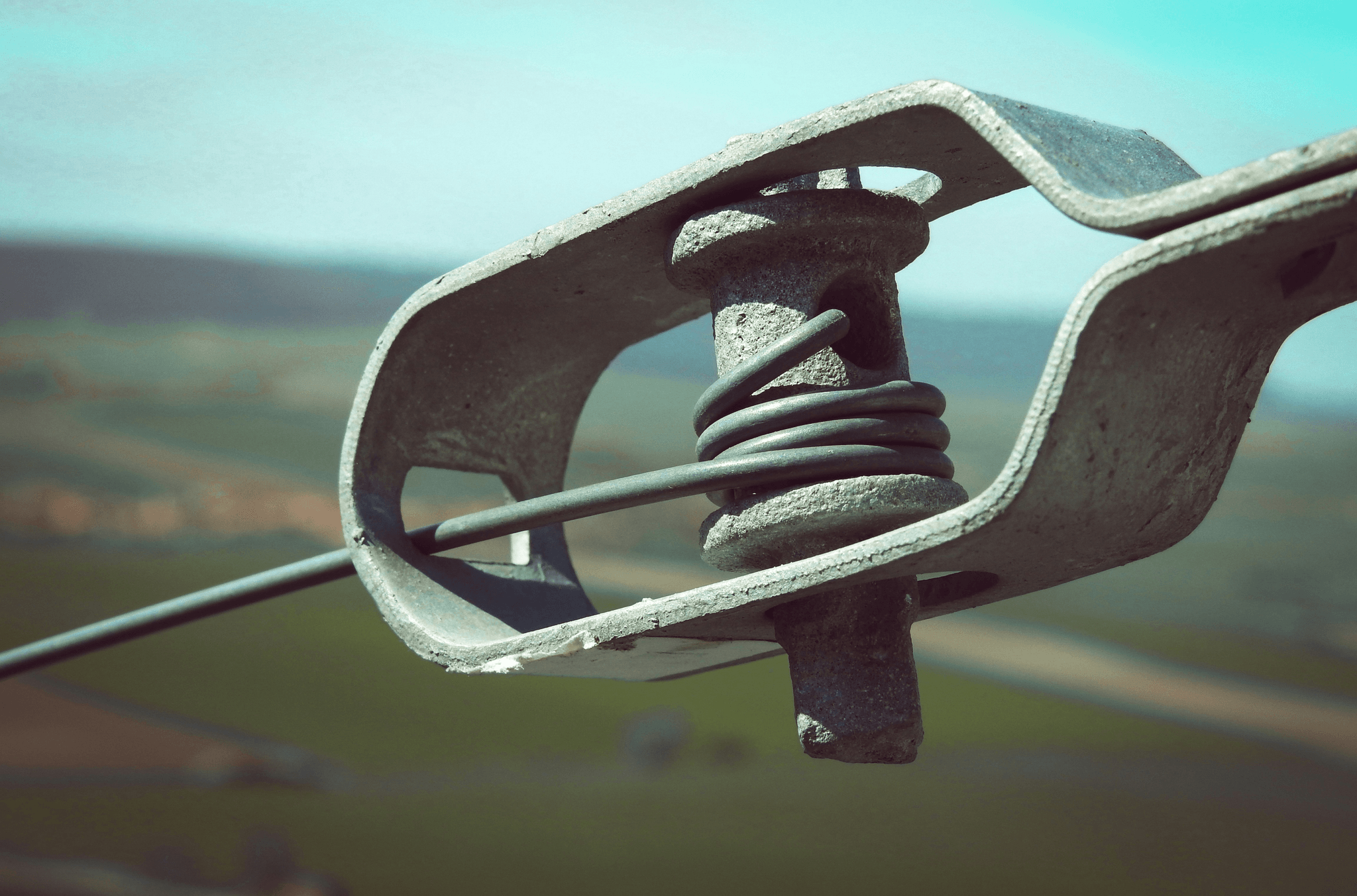

Unique Characteristics

The Spiral Vibration Damper stands out due to its distinctive spiral shape and construction materials that optimize performance. Unlike traditional vibration dampers, this design effectively dissipates energy from oscillations, minimizing stress on power line structures. Additionally, the spiral configuration allows for easy installation and adaptability across different types of power lines, ensuring that a vibration damper for power lines can be tailored to specific needs.

Moreover, its lightweight yet durable materials provide an excellent balance between strength and flexibility, making it suitable for various environmental conditions. This versatility is crucial for utility companies looking to enhance their infrastructure without incurring excessive costs or labor time. In essence, the unique characteristics of the Spiral Vibration Damper make it an essential tool in modern engineering practices.

Enhanced Safety Protocols

Safety is paramount when dealing with high-voltage power lines, and the incorporation of a Spiral Vibration Damper plays a significant role in enhancing safety protocols. By reducing vibrations that can lead to fatigue failure or structural damage over time, these dampers help maintain the integrity of electrical systems. This proactive approach not only safeguards equipment but also protects workers who maintain these vital infrastructures.

Furthermore, implementing vibration dampers can lead to fewer service interruptions caused by environmental factors such as wind or seismic activity. The enhanced stability provided by these devices means that utility providers can deliver more reliable service while minimizing risks associated with equipment failure. Ultimately, using a vibration damper in engine applications alongside power line systems helps create a safer operational environment across multiple sectors.

Installation Process and Best Practices

Installing a Spiral Vibration Damper requires careful planning and execution to ensure optimal performance and longevity. First and foremost, it's essential to assess the specific requirements of your power line system before selecting an appropriate damper model—this includes considering factors like line tension and environmental conditions where it will be deployed. Once you have identified your needs, following manufacturer guidelines during installation is crucial for achieving desired results.

Best practices recommend using trained professionals who understand both installation techniques and safety measures when working with high-voltage equipment. Proper alignment during installation will maximize effectiveness while reducing potential wear on both the damper itself and surrounding components of the power line system. Regular inspections after installation will ensure continued effectiveness; addressing any issues early on can prevent costly repairs down the road.

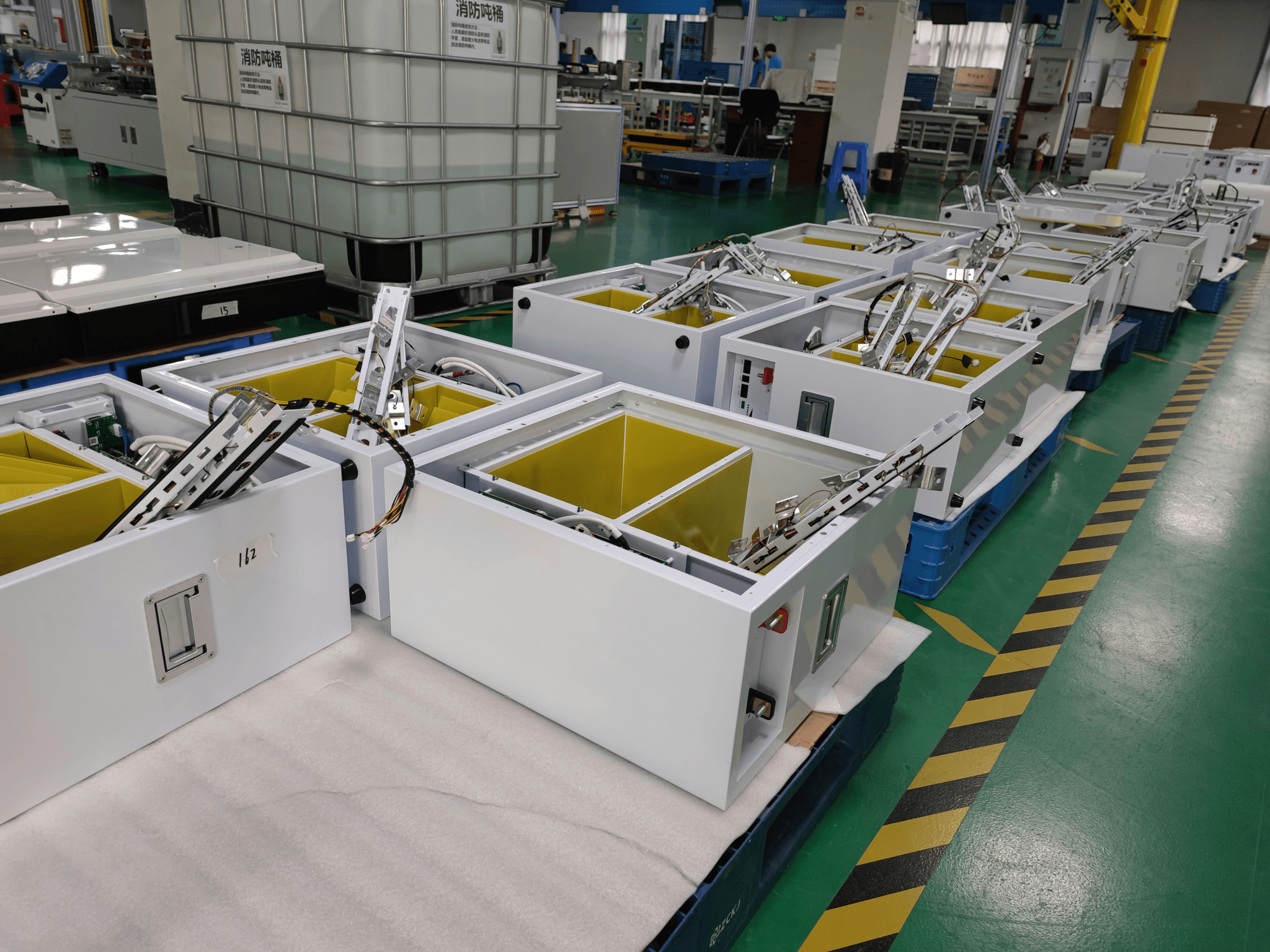

Spark Fittings: Leaders in Armor Rod Manufacturing

When it comes to ensuring the safety and reliability of power lines, Spark Fittings stands at the forefront of armor rod manufacturing. Their commitment to quality and innovation has made them a trusted name in the industry, particularly in the realm of vibration dampers for power lines. With a focus on advanced materials and engineering, they provide solutions that enhance performance while minimizing maintenance needs.

Overview of Armor Rod Materials

Armor rods are essential components designed to protect overhead conductors from wear and mechanical stress, especially in areas prone to vibration. Spark Fittings utilizes high-strength materials like fiberglass and aluminum alloys that are lightweight yet incredibly durable. This careful selection ensures that their armor rods can withstand harsh environmental conditions while effectively mitigating issues caused by vibrations—whether from wind or other external forces.

Importance of Material Selection

Choosing the right material for armor rods is crucial for maximizing their effectiveness as vibration dampers in power lines. The right material not only enhances durability but also optimizes performance against vibrations that can lead to conductor fatigue or failure over time. Spark Fittings emphasizes rigorous testing and research when selecting materials, ensuring they meet industry standards while providing long-lasting solutions.

Custom Solutions for Power Line Safety

Spark Fittings understands that each power line installation may have unique challenges requiring tailored solutions. They offer custom-designed armor rods that integrate seamlessly with existing infrastructure while enhancing overall safety through effective vibration damping techniques such as Stockbridge vibration dampers and Spiral Vibration Dampers. Their expertise allows them to collaborate with clients to develop innovative solutions that address specific needs, ultimately contributing to safer and more reliable power distribution systems.

Conclusion

As we wrap up our exploration of vibration dampers, it’s clear that these devices play a pivotal role in enhancing safety and efficiency in power lines. The significance of a vibration damper for power lines cannot be overstated; they protect against the damaging effects of oscillations that can lead to catastrophic failures. By understanding the vibration damper meaning, engineers can better implement solutions that ensure the integrity and longevity of power infrastructure.

Enhancing Safety with Vibration Dampers

Vibration dampers serve as the unsung heroes in the realm of electrical safety, particularly in power lines where external forces can wreak havoc. The Stockbridge vibration damper is a prime example, effectively mitigating vibrations caused by wind or other environmental factors, thereby reducing strain on cables and hardware. With innovations like the Spiral Vibration Damper also emerging, our ability to safeguard infrastructure continues to improve significantly.

The Future of Vibration Control Technology

Looking ahead, the future of vibration control technology appears promising and ripe for innovation. As we develop smarter materials and more efficient designs for devices like the vibration damper in engine applications, we can expect enhanced performance across various sectors including energy transmission. These advancements will not only bolster safety but also pave the way for more sustainable engineering practices worldwide.

Why Choose Spark Fittings for Your Needs

When it comes to selecting a provider for your vibration damper needs, Spark Fittings stands out as an industry leader dedicated to quality and innovation. Their commitment to developing robust solutions such as armor rods ensures that your power lines are equipped with reliable protection against vibrations—whether through Stockbridge or Spiral Vibration Dampers. By choosing Spark Fittings, you’re investing in advanced technology tailored specifically for maximizing safety and efficiency.