Introduction

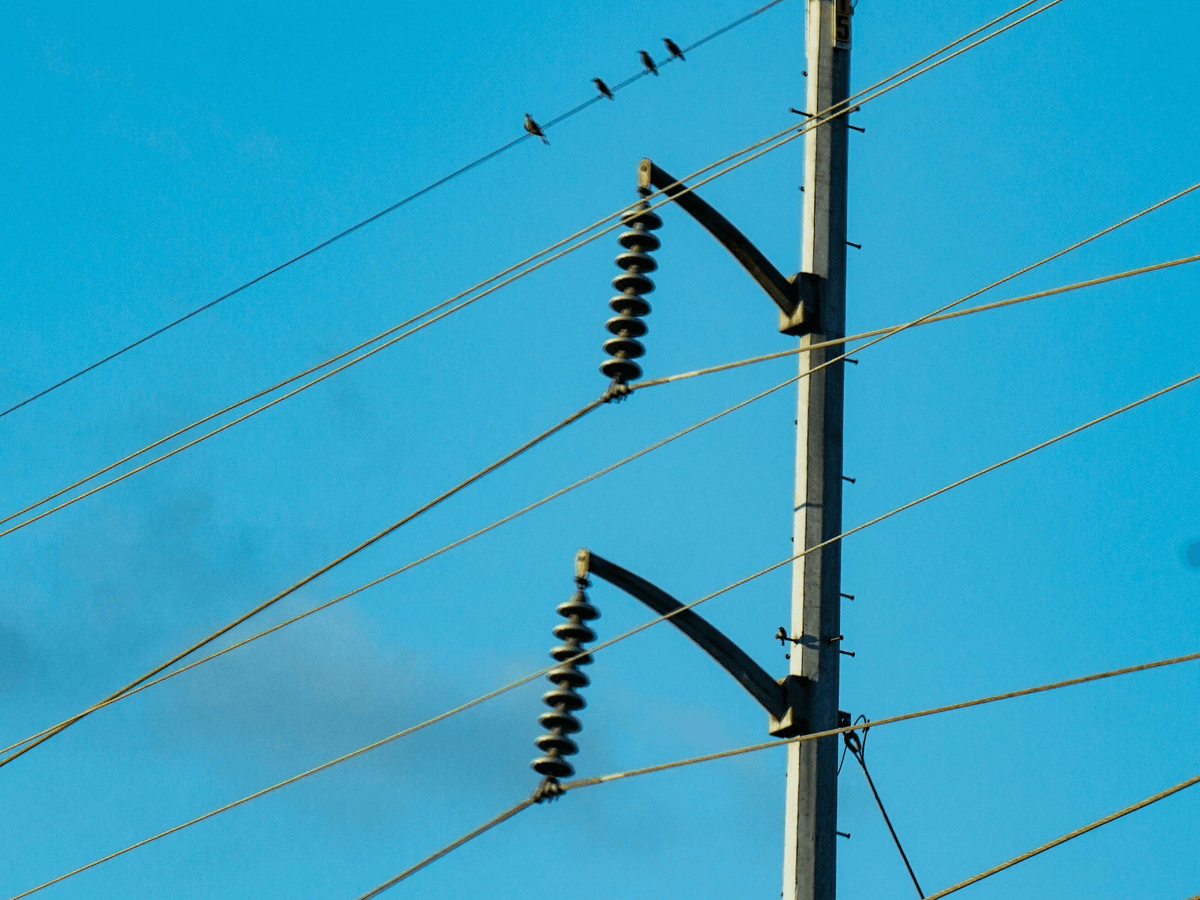

In the world of electrical transmission, preformed armour rods play a pivotal role in ensuring the durability and efficiency of overhead line conductors. These specialized electrical rods are designed to protect and enhance the performance of aluminium overhead line conductors, which are crucial for delivering electricity over long distances. Choosing the right preformed armour rod is essential for optimizing conductor lifespan and functionality, making it a key consideration for engineers and technicians alike.

Understanding Preformed Armour Rods

Preformed armour rods are protective devices that wrap around electrical conductors to provide additional strength and support. They are typically made from materials such as aluminium or galvanized steel wire, allowing them to withstand various environmental stresses while maintaining conductor integrity. By understanding how these preformed armour rods work, professionals can better appreciate their importance in safeguarding electrical systems.

Importance of Electrical Rods in Transmission

Electrical rods, particularly preformed armour rods, play a critical role in maintaining the reliability of power transmission networks. They help prevent mechanical damage caused by wind, ice, or other external forces that can compromise conductor performance. As a result, utilizing high-quality preformed armour rods becomes indispensable for ensuring uninterrupted electricity flow across vast networks.

Choosing the Right Rod for Conductors

Selecting the appropriate preformed armour rod involves considering various factors such as material compatibility and application requirements. The right choice not only enhances the performance of aluminium overhead line conductors but also contributes to overall system longevity. With multiple options available on the market today, understanding these nuances is vital for making an informed decision that meets specific project needs.

What are Preformed Armour Rods?

Preformed armour rods are specialized components designed to protect and enhance the performance of electrical conductors, particularly in overhead line applications. These rods are typically made from durable materials and are engineered to fit snugly around conductors, providing essential support and protection against environmental stressors. Their primary purpose is to prevent damage from abrasion, weather conditions, and mechanical wear while ensuring the longevity of aluminium overhead line conductors.

Definition and Purpose

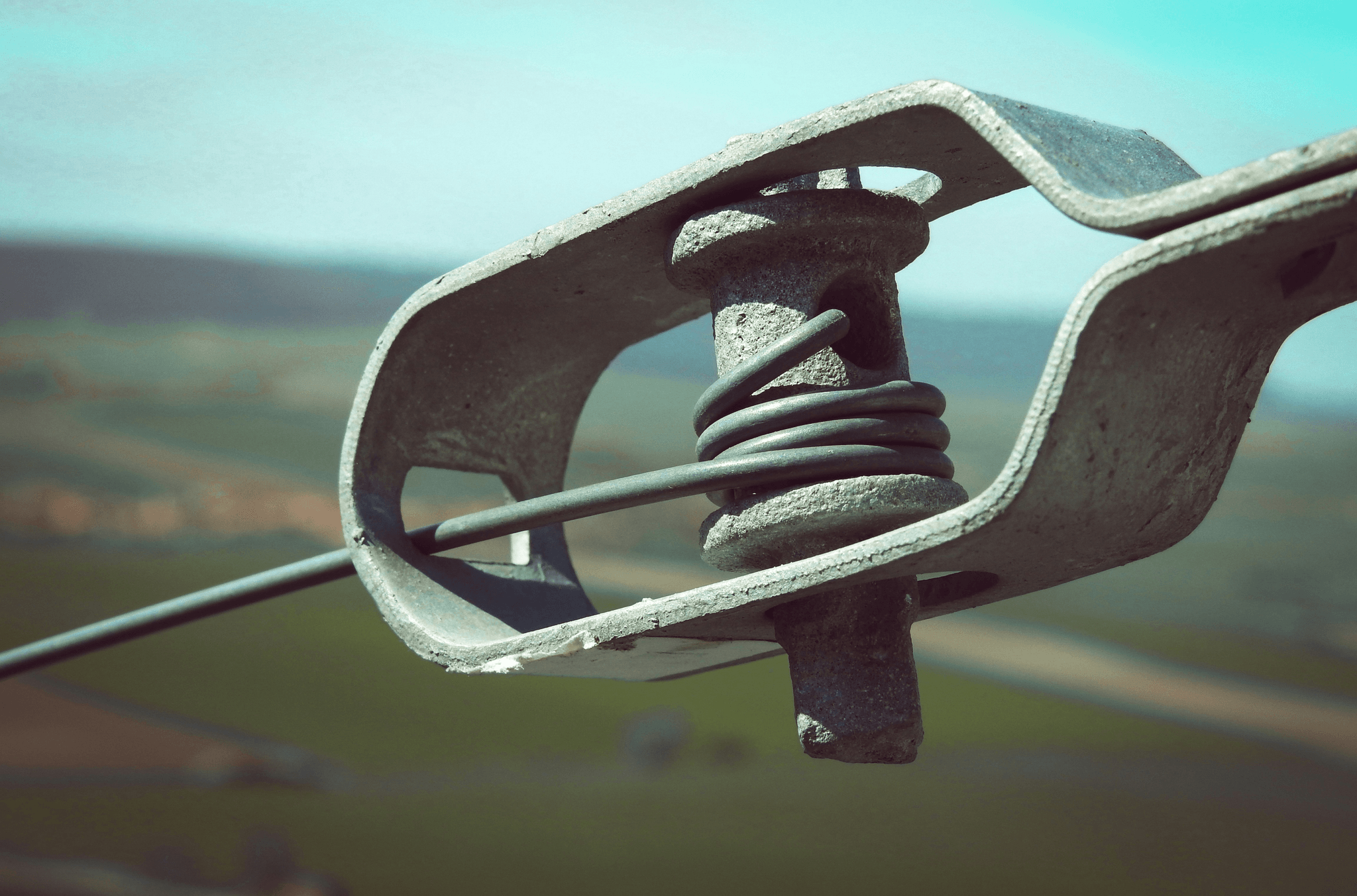

At their core, preformed armour rods serve as protective coverings for electrical rods, specifically designed for use with various types of conductors. They are pre-shaped to conform perfectly to the conductor's profile, ensuring a tight fit that minimizes movement and potential wear over time. The purpose of these rods is not only to safeguard the conductor but also to maintain its structural integrity during installation and throughout its operational life.

Benefits of Using Armour Rods

Using preformed armour rods offers numerous benefits that enhance both safety and efficiency in electrical transmission systems. Firstly, they significantly reduce the risk of conductor damage caused by environmental factors such as wind, ice, or falling debris; this is particularly crucial for aluminium overhead line conductors that can be susceptible to fatigue over time. Additionally, these rods help distribute mechanical stress evenly across the conductor's surface, which can lead to improved performance and reduced maintenance costs in the long run.

Moreover, preformed armour rods contribute to increased operational reliability by minimizing failures due to wear or environmental impact. They also simplify installation processes since they come ready-to-use without requiring extensive modifications or adjustments on-site. Ultimately, investing in quality armour rods translates into better reliability for electrical systems while enhancing safety standards for both workers and infrastructure.

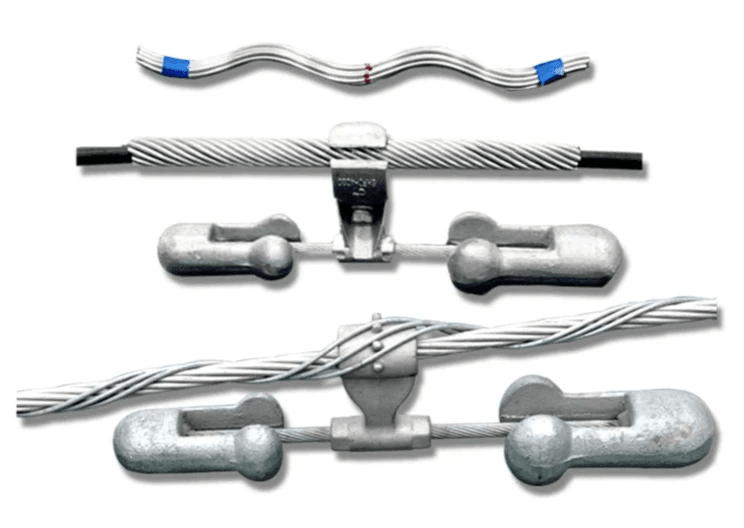

Types and Applications

Preformed armour rods come in various types tailored for specific applications within electrical transmission networks. Common variations include those designed specifically for ACSR (Aluminium Conductor Steel Reinforced) conductors or pure aluminium overhead line conductors; each type has unique specifications based on material composition and intended use case scenarios.

These versatile components find applications across diverse sectors including utility companies managing high-voltage power lines as well as telecommunications providers needing reliable transmission solutions for their networks. Their adaptability makes them suitable not just for new installations but also retrofitting existing systems where enhanced protection is required.

In summary, understanding what preformed armour rods are—along with their definition, purpose, benefits, types, and applications—highlights their essential role in maintaining efficient electrical transmission systems while safeguarding valuable infrastructure investments.

The Role of Preformed Armour Rods in ACSR Conductors

In the world of electrical transmission, preformed armour rods play a pivotal role in enhancing the longevity and efficiency of ACSR (Aluminium Conductor Steel Reinforced) conductors. These specialized electrical rods are designed to withstand various environmental stresses, ensuring that overhead line conductors maintain their integrity and performance over time. By distributing mechanical stress evenly across the conductor, preformed armour rods significantly reduce wear and tear, leading to improved durability.

Enhancing Durability and Performance

Preformed armour rods are engineered to provide exceptional protection for aluminium overhead line conductors. Their unique design allows them to absorb impacts and prevent damage from external forces such as wind, ice, and other environmental factors. This enhancement not only prolongs the life of the conductor but also ensures optimal performance under challenging conditions—making preformed armour rods an essential component in any reliable electrical transmission system.

Moreover, these electrical rods contribute to maintaining consistent electrical conductivity by minimizing physical damage that could lead to disruptions or failures. The use of preformed armour rods can also help reduce maintenance costs over time due to fewer repairs being needed on damaged conductors. In essence, they are a smart investment for utility companies looking to boost both durability and performance.

Protecting Aluminium Overhead Line Conductors

The primary function of preformed armour rods is to safeguard aluminium overhead line conductors from various forms of damage that can arise during operation or installation. Whether it’s abrasion from neighboring lines or mechanical stress from weather conditions, these robust electrical rods act as a first line of defense against potential harm. By encasing vulnerable sections of the conductor with these protective elements, utilities can ensure that their infrastructure remains operational even in adverse conditions.

Furthermore, using preformed armour rods helps mitigate issues related to fatigue failure—a common problem with aluminium overhead line conductors subjected to constant tension and movement. This protective measure not only enhances safety but also promotes reliability within the power distribution network. Ultimately, investing in quality preformed armour rods is crucial for maintaining efficient energy delivery while minimizing risks associated with conductor failures.

Case Studies of Successful Implementations

Several case studies illustrate how effectively preformed armour rods have been integrated into existing ACSR systems across various regions. For instance, one utility company in a snow-prone area reported significant improvements after installing these electrical rods on their overhead lines; outages due to ice accumulation were reduced by over 30%. This success story highlights how tailored solutions like preformed armour rods can address specific challenges faced by utilities operating under harsh weather conditions.

Another case study involved a utility that experienced frequent mechanical failures due to high wind speeds in coastal areas. After implementing preformed armour rod technology on their aluminium overhead line conductors, they noted a dramatic decrease in maintenance calls related to conductor breakage—proving that proactive measures yield substantial long-term benefits for reliability and cost-effectiveness.

These examples underscore the importance of integrating effective protective measures like preformed armour rods into power infrastructure strategies—demonstrating not just enhanced performance but also increased public trust in energy providers’ capabilities.

Choosing the Right Material for Armour Rods

Each material has its unique properties that cater to different applications in electrical rod setups. Understanding these differences is crucial for ensuring long-lasting protection for your aluminium overhead line conductors.

Aluminium vs. Galvanized Steel Wire

Aluminium preformed armour rods are lightweight and resistant to corrosion, making them a popular choice for many utility companies. They offer excellent conductivity and are often used in conjunction with aluminium overhead line conductors, creating a cohesive system that maximizes efficiency. On the other hand, galvanized steel wire provides superior strength and rigidity, which can be advantageous in areas where mechanical stress is a concern.

When deciding between these materials, consider the environment in which your electrical rods will operate. For instance, if you’re dealing with coastal regions or areas prone to moisture, aluminium may be more suitable due to its corrosion resistance. Conversely, if you're looking at applications requiring enhanced mechanical support or longevity under heavy loads, galvanized steel might be the way to go.

Importance of Material Compatibility

Material compatibility is paramount when choosing preformed armour rods for your electrical systems. Using incompatible materials can lead to galvanic corrosion, which diminishes the effectiveness of your protective measures over time. Therefore, it’s essential to ensure that any preformed armour rod you select harmonizes well with both your conductors and other components within your electrical setup.

For example, pairing aluminium rods with aluminium overhead line conductors creates a uniform thermal expansion rate and minimizes stress points during temperature fluctuations. In contrast, mixing metals without proper attention can lead to premature failure of either component due to differing rates of corrosion or wear. By prioritizing compatibility in your selections, you ensure not just performance but longevity as well.

Corrosion Prevention Strategies

Corrosion can be an insidious enemy when it comes to maintaining electrical systems; hence implementing effective prevention strategies is essential for protecting your preformed armour rods and conductors alike. One common approach involves applying protective coatings or sealants specifically designed for use on metal surfaces exposed to harsh environments. These coatings act as barriers against moisture and corrosive elements that could compromise the integrity of both aluminium and galvanized steel components.

Another strategy involves regular inspections and maintenance routines aimed at catching early signs of wear or corrosion before they escalate into more significant issues. Additionally, utilizing sacrificial anodes can help divert corrosive activity away from critical parts of your electrical setup by attracting corrosive elements towards themselves instead—an elegant solution that prolongs the life of your preformed armour rods significantly!

In conclusion, carefully considering material choices when selecting preformed armour rods ensures optimal performance while safeguarding against environmental challenges—making all the difference in maintaining reliable electricity transmission over time.

Installation Tips for Armour Rods

Installing preformed armour rods correctly is crucial to ensure the longevity and effectiveness of your electrical rods. A little knowledge goes a long way, especially when it comes to understanding the specifics of installation. This section will guide you through the essentials, from color codes to common pitfalls.

Understanding the Color Code System

The color code system is an essential aspect of working with preformed armour rods, particularly when dealing with various sizes and types. Each color corresponds to a specific diameter or application, helping you select the right preformed armour rod for your aluminium overhead line conductor. Familiarizing yourself with this system will not only streamline your installation process but also enhance safety by ensuring compatibility.

Step-by-Step Installation Guide

To install preformed armour rods efficiently, follow these steps: First, ensure that you have all necessary tools and materials at hand, including gloves for safety. Next, clean the conductor surface thoroughly to remove any debris or corrosion that might affect adhesion; this step is critical for optimal performance of your electrical rods. Finally, position the preformed armour rod over the conductor and secure it tightly according to manufacturer guidelines—this ensures maximum protection and durability.

Common Mistakes to Avoid

Even seasoned professionals can make mistakes when installing preformed armour rods—here are some common pitfalls to watch out for! One frequent error is neglecting proper alignment; misaligned rods can lead to uneven stress distribution on aluminium overhead line conductors, compromising their integrity. Additionally, failing to adhere strictly to the manufacturer's instructions can result in improper installation; always double-check before securing those electrical rods in place!

Custom Solutions from Spark Fittings

When it comes to preformed armour rods, Spark Fittings stands out as a leader in the industry. Their commitment to quality and innovation ensures that customers receive electrical rods tailored to meet their specific needs. With extensive experience in providing solutions for aluminium overhead line conductors, Spark Fittings has earned a reputation for excellence.

Overview of Spark Fittings’ Expertise

Spark Fittings has been at the forefront of designing and manufacturing custom preformed armour rods for years. Their team comprises skilled engineers and technicians who understand the nuances of electrical rod applications, particularly in challenging environments. This expertise allows them to create products that not only meet but exceed industry standards, ensuring reliability and performance.

Customizing Armour Rods for Specific Needs

One of the key advantages of working with Spark Fittings is their ability to customize preformed armour rods according to individual project requirements. Whether it’s adjusting dimensions or selecting specific materials, they cater to diverse needs in the field of electrical transmission. This level of customization is crucial when dealing with various types of aluminium overhead line conductors, ensuring optimal protection and durability.

Innovative Products and Technologies

Spark Fittings continually invests in research and development to bring innovative products and technologies to market. Their latest advancements include enhanced corrosion-resistant coatings for preformed armour rods, which significantly extend their lifespan in harsh conditions. By integrating cutting-edge technology into their designs, they ensure that their electrical rods remain reliable under all circumstances.

Conclusion

In wrapping up our exploration of preformed armour rods, it’s clear that these electrical rods play a pivotal role in the longevity and efficiency of transmission systems. As we look to the future, innovations in materials and designs will only enhance their effectiveness, ensuring that they remain a staple in the industry. The right preformed armour rod not only protects conductors but also contributes to overall system reliability.

The Future of Electrical Rods

The future of electrical rods is bright, with advancements in technology paving the way for even more robust solutions. As demand for sustainable energy sources grows, so too does the need for durable components like preformed armour rods that can withstand environmental challenges. With ongoing research and development, we can expect to see enhanced materials that promise greater resilience and performance for aluminium overhead line conductors.

Ensuring Longevity with Proper Materials

Choosing the right materials is crucial for ensuring the longevity of preformed armour rods. Whether opting for aluminium or galvanized steel wire, compatibility with existing systems must be prioritized to prevent premature failure. Additionally, implementing effective corrosion prevention strategies will further enhance the lifespan of these essential electrical rods.

Final Thoughts on Spark Fittings’ Offerings

Spark Fittings stands out as a leader in providing customized solutions tailored to specific needs within the electrical industry. Their expertise in creating high-quality preformed armour rods ensures that customers receive products designed for optimal performance and durability. As we move forward, Spark Fittings continues to innovate, setting new standards in quality and service.