Introduction

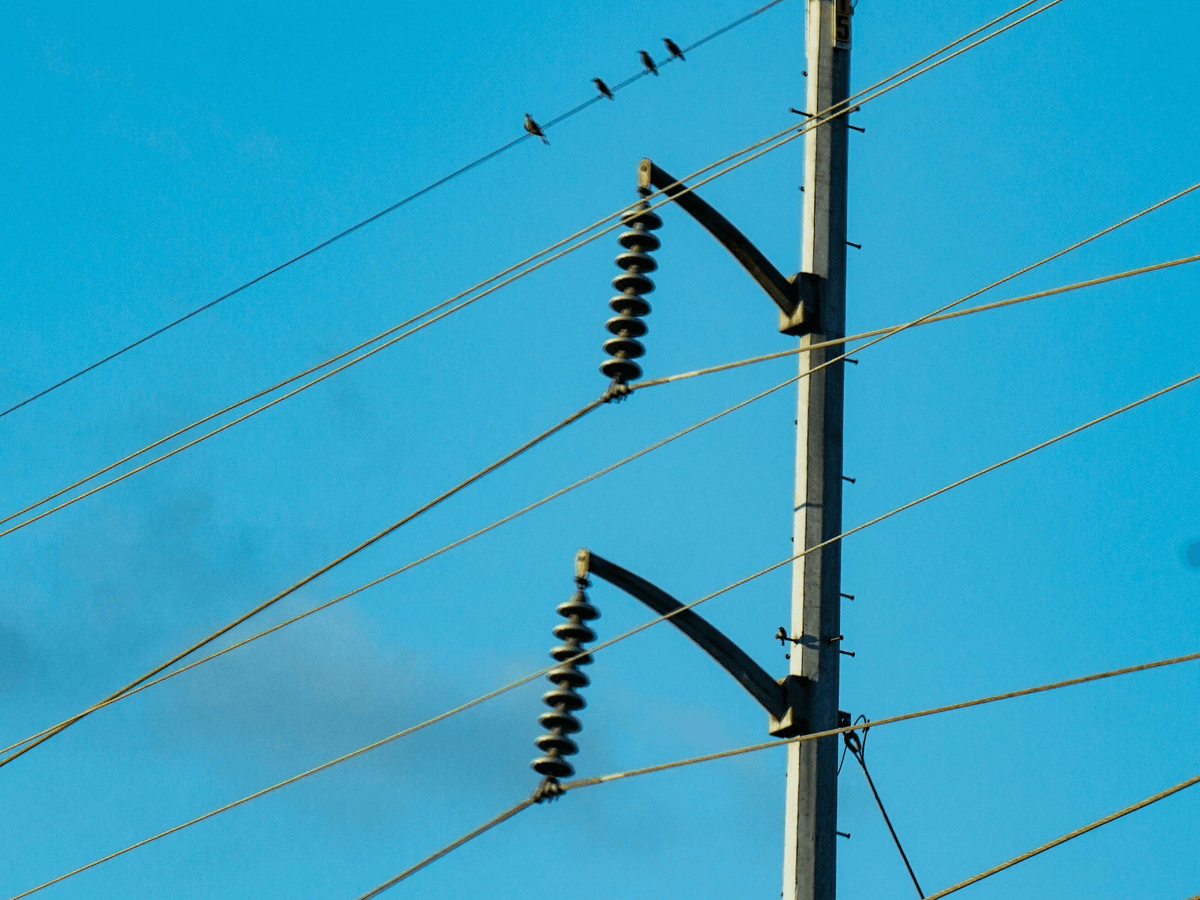

In the world of electric distribution, ensuring the safety and integrity of overhead power lines is paramount. One essential component that plays a crucial role in this regard is the armor rod for transmission line applications. These rods serve as protective barriers, safeguarding conductors from various environmental threats while enhancing the overall efficiency of power transmission.

Understanding the Need for Armor Rods

Armor rods are designed to protect transmission lines from wear and tear caused by factors such as high winds, ice accumulation, and thermal expansion. Without these robust components, overhead power lines would be vulnerable to damage that could lead to costly outages or even hazardous situations. Understanding their importance is vital for anyone involved in maintaining or installing electric distribution systems.

The Role of Armor Rods in Electrical Safety

The primary function of armor rods is to ensure electrical safety by providing a protective layer around conductors on overhead power lines. This added layer helps prevent accidental contact with other objects and minimizes the risk of short circuits or electrical fires. By incorporating these critical components into power line designs, utilities can significantly enhance safety measures while powering communities efficiently.

Benefits of Durable Armor Rods

Durable armor rods offer numerous benefits beyond mere protection; they contribute to the longevity and reliability of transmission lines as well. Made from high-quality materials that resist corrosion and wear, these rods ensure that electric distribution remains uninterrupted even under harsh conditions. Investing in durable armor rods not only enhances safety but also reduces maintenance costs over time, making them an essential choice for any project involving overhead power lines.

What Are Armor Rods?

Armor rods are essential components in the realm of electrical distribution, specifically designed to enhance the durability and reliability of overhead power lines. These robust protective devices are strategically placed on conductors to shield them from various environmental stresses and mechanical wear. By integrating armor rods into your transmission line infrastructure, you can significantly extend the lifespan of your power lines while ensuring consistent electricity delivery.

Overview of Armor Rods

An armor rod for transmission line is a cylindrical protective sheath that encases a conductor, offering a first line of defense against physical damage and weather-related challenges. Typically made from high-strength materials, these rods can withstand harsh conditions such as extreme temperatures, wind loads, and even ice accumulation. Their primary purpose is not only to protect the conductors but also to maintain the integrity of electric distribution systems by preventing costly outages and repairs.

Key Materials Used

The effectiveness of an armor rod for transmission line largely hinges on the materials used in its construction. Commonly utilized materials include fiberglass, aluminum, and composite polymers, each chosen for their unique properties that contribute to strength and flexibility. For instance, fiberglass offers excellent resistance to corrosion while being lightweight; aluminum provides exceptional conductivity; and composite materials combine durability with reduced weight—making them ideal for overhead power lines.

Importance of Material Matching

Matching the right material for your armor rod with that of the conductor is crucial in ensuring optimal performance in electric distribution systems. When materials are compatible, it minimizes risks such as galvanic corrosion or thermal expansion mismatches that could compromise system integrity over time. Proper material matching not only enhances protection but also supports efficient energy transfer across the transmission line—powering the power you rely on every day!

How Armor Rods Protect Transmission Lines

When it comes to safeguarding our vital power lines, armor rods play a crucial role in ensuring the longevity and reliability of transmission lines. These unsung heroes are designed to withstand various environmental challenges while protecting the conductors that help power our communities. In this section, we’ll explore how armor rods shield overhead power lines from the elements and maintain their integrity.

Protection Against Weather Elements

Weather is one of the most significant threats to overhead power lines, with wind, rain, snow, and ice all taking their toll on conductor performance. Armor rods for transmission line applications provide a protective barrier that helps prevent damage caused by these harsh conditions. By absorbing impacts and reducing wear from environmental factors, these durable components ensure that electric distribution remains uninterrupted even during extreme weather events.

Moreover, the design of armor rods allows them to deflect water and debris away from the conductors, minimizing corrosion risks over time. This proactive approach not only extends the life of transmission lines but also enhances overall system reliability. When severe weather strikes, having robust armor rods in place can mean the difference between maintaining service or facing outages.

Prevention of Conductor Damage

Conductor damage can occur due to various factors beyond just weather; mechanical stress and abrasion are also significant concerns for any electric distribution system. Armor rods act as a first line of defense against such threats by providing additional support and cushioning for conductors under tension or movement. This extra layer of protection reduces wear on critical components and ensures that they remain intact over time.

In addition to physical protection, properly installed armor rods help distribute forces more evenly across the conductor's surface area during high-stress situations like storms or heavy loads. By preventing localized stress points where damage might occur, they contribute significantly to maintaining efficient power line operations. Ultimately, using an armor rod for transmission line applications leads to fewer repairs and less downtime—benefits every utility company appreciates.

Role in Maintaining Power Line Integrity

Maintaining the integrity of overhead power lines is essential not only for delivering reliable electricity but also for ensuring safety in surrounding areas. Armor rods play a pivotal role in this aspect by reinforcing conductors against sagging or displacement caused by temperature fluctuations or external forces like wind loads. When properly utilized within an electric distribution network, these components help keep everything aligned as intended.

Furthermore, when issues do arise—such as conductor movement due to thermal expansion—armor rods provide critical stabilization that prevents more severe failures down the line (pun intended). This stability is vital for reducing operational risks associated with damaged infrastructure while promoting overall system efficiency and performance longevity. By investing in quality armor rods for transmission line projects today, utilities are essentially future-proofing their networks against unforeseen challenges tomorrow.

Choosing the Right Armor Rod for Your Project

Selecting the right armor rod for your project is crucial for ensuring the longevity and safety of your overhead power lines. With various options available, understanding the specific needs of your transmission line will help you make an informed choice. Let’s delve into some key factors to consider when choosing an armor rod for transmission line applications.

Understanding Conductor Materials

The first step in selecting an armor rod is to understand the materials used in your conductors. Different conductor materials, such as aluminum or copper, have distinct properties that can affect their interaction with armor rods. Matching the right armor rod with your conductor material not only enhances protection but also ensures optimal performance across your electric distribution system.

For instance, if you're using aluminum conductors, you’ll want an armor rod designed to accommodate their unique expansion and contraction characteristics due to temperature changes. On the other hand, copper conductors may require a different approach due to their weight and flexibility. By taking these factors into account, you can effectively power the power lines while minimizing potential damage.

Spark Fittings’ Customization Options

One of the standout features of Spark Fittings is their range of customization options for armor rods tailored specifically for various projects. Whether you need a specific length or unique fittings that accommodate unusual conductor sizes, Spark Fittings has got you covered. This level of customization ensures that each armor rod perfectly suits your transmission line requirements while maintaining high standards of quality and safety.

Additionally, custom solutions from Spark Fittings allow you to address unique environmental challenges faced by overhead power lines in different regions. From extreme weather conditions to varying terrain types, having tailored solutions means better protection against potential hazards. Ultimately, this attention to detail can significantly enhance the durability and effectiveness of your electric distribution system.

Color Coding for Easy Identification

Color coding is another vital aspect when choosing an armor rod for transmission line projects that often gets overlooked but can save time during installation and maintenance checks. By implementing a color-coding scheme based on function or conductor type, technicians can quickly identify which armor rods belong where in complex networks of overhead power lines. This simple visual aid streamlines operations and reduces errors during both installation and ongoing maintenance.

Moreover, clear identification through color coding helps ensure that all personnel working on electric distribution systems are aware of which components they are handling at any given time—enhancing overall safety standards on-site as well! When everyone knows what they're dealing with at a glance, it minimizes confusion and maximizes efficiency during critical operations involving transmission lines.

In conclusion, selecting the right armor rod goes beyond just picking one off a shelf; it involves understanding materials used in conductors, leveraging customization options provided by manufacturers like Spark Fittings, and employing effective color-coding strategies for easy identification on-site.

Installation Process of Armor Rods

Installing armor rods is a crucial step in ensuring the safety and longevity of overhead power lines. Proper installation not only enhances the protection of conductors but also contributes to the overall efficiency of electric distribution systems. Let's dive into the tools you'll need and the steps involved to get it right.

Tools Required for Installation

Before you start, gather all necessary tools to streamline your installation process and avoid any hiccups along the way. Essential tools include a torque wrench for securing fittings, a pair of insulated gloves for safety, and a wire cutter for trimming excess conductor material. Additionally, having a ladder or lift can help you reach those high transmission line areas safely.

Step-by-Step Installation Guide

1. **Preparation**: Begin by reviewing your project plan and ensuring that you have selected an appropriate armor rod for your transmission line based on conductor type and size.

2. **Safety First**: Always wear insulated gloves and ensure that power is turned off before approaching any live lines to maintain safety during installation.

3. **Positioning**: Carefully position the armor rod over the designated area on the conductor, making sure it's aligned correctly with respect to other components like insulators.

4. **Securing**: Use your torque wrench to tighten down all fittings securely, following manufacturer specifications to ensure proper tension without damaging the conductor.

5. **Final Check**: Once installed, double-check all connections and fittings to confirm they are secure before restoring power to the line.

By following these steps diligently, you can effectively protect your transmission line with durable armor rods that enhance performance in electric distribution systems.

Common Mistakes to Avoid

Even seasoned professionals can make mistakes during installation; however, being aware of common pitfalls can help you avoid them! One frequent error is neglecting proper alignment; if an armor rod isn’t positioned correctly, it may not provide adequate protection against environmental factors or mechanical stress on overhead power lines.

Another mistake is over-tightening fittings; while it’s important for security, too much pressure can damage both the armor rod and conductor materials—leading to costly repairs down the line! Lastly, failing to conduct a thorough final check after installation can result in overlooked issues that could compromise power integrity later on.

By keeping these tips in mind during your installation process, you'll be well-equipped to successfully implement armor rods that will safeguard your transmission lines effectively!

Why Spark Fittings Stands Out

When it comes to providing reliable solutions for overhead power lines, Spark Fittings has established itself as a leader in the industry. Their commitment to excellence is evident in every armor rod for transmission line they manufacture, ensuring that each product meets stringent safety and performance standards. With a combination of innovation and experience, they are dedicated to powering the power needs of electric distribution systems worldwide.

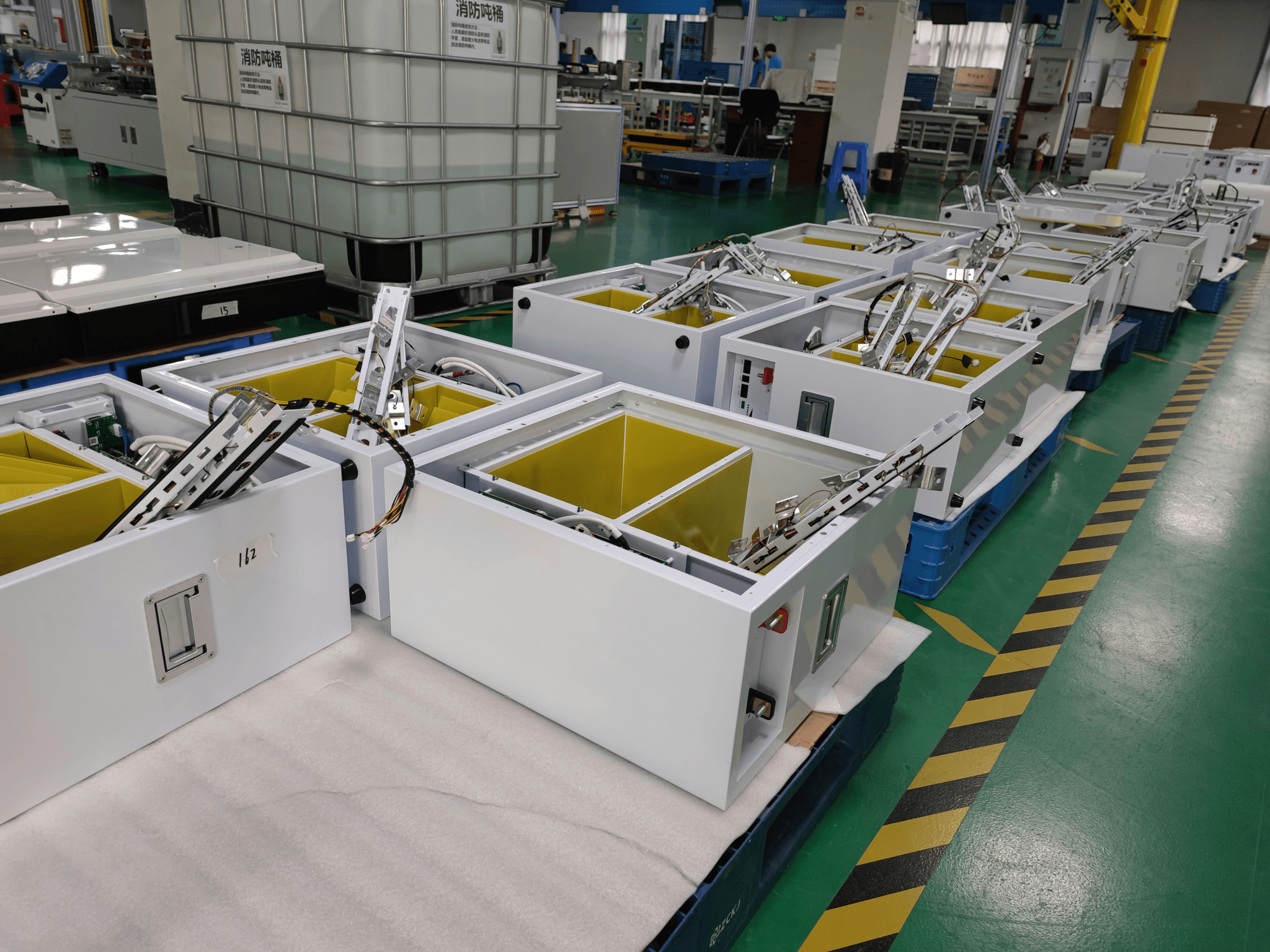

Expertise in Armor Rod Manufacturing

Spark Fittings boasts years of specialized experience in armor rod manufacturing, which sets them apart from competitors. Their team understands the intricacies involved in creating an effective armor rod for transmission line applications, ensuring that each product is designed with precision and care. This expertise translates into superior products that withstand the rigors of environmental challenges, safeguarding vital power lines from wear and tear.

Comprehensive Product Range

What truly makes Spark Fittings shine is their extensive range of products tailored for various electric distribution needs. From different sizes and materials to customized solutions, they have an armor rod for transmission line that fits nearly any requirement you might have. This comprehensive product offering not only simplifies the selection process but also guarantees that customers find exactly what they need to maintain their overhead power lines effectively.

Commitment to Quality and Safety

At Spark Fittings, quality and safety are non-negotiable principles embedded in their manufacturing process. Each armor rod undergoes rigorous testing to ensure it meets high safety standards before it ever reaches the market, giving clients peace of mind when using their products on critical transmission lines. By prioritizing these values, Spark Fittings empowers electric distribution companies to operate confidently while protecting both infrastructure and personnel alike.

Conclusion

In summary, armor rods are essential components in the world of electrical distribution, ensuring the safety and longevity of overhead power lines. By understanding their role and benefits, stakeholders can make informed decisions that enhance the reliability of transmission lines. As we look to the future, integrating advanced materials and innovative designs will only further empower our electric distribution systems.

Key Takeaways on Armor Rod Usage

Armor rods serve as a protective shield for transmission lines, safeguarding them from environmental wear and tear while preventing conductor damage. Their proper installation is crucial for maintaining power line integrity, ensuring that energy flows smoothly to power homes and businesses alike. Remembering to match materials appropriately will help maximize the effectiveness of these armor rods in your projects.

The Future of Electrical Distribution Safety

The future of electrical distribution safety lies in continuous innovation and adaptation to emerging technologies. With advancements in material science, we can expect even more durable armor rods that provide enhanced protection against weather elements and other hazards faced by overhead power lines. As electric distribution networks evolve, prioritizing safety through reliable components like armor rods will be key to powering our communities efficiently.

Choosing Spark Fittings for Your Needs

When it comes to selecting an armor rod for transmission line applications, Spark Fittings stands out due to its commitment to quality and expertise in manufacturing durable products tailored for specific needs. Their comprehensive product range ensures you find exactly what you need for your project while benefiting from customization options that suit various conductor materials. Trusting Spark Fittings means investing in reliable solutions that not only enhance safety but also contribute significantly to the efficiency of electric distribution systems.