Introduction

In the world of power lines, suspension clamps play a crucial role in ensuring the stability and safety of electrical infrastructure. These seemingly simple devices are essential for securing conductors and maintaining proper tension, making them indispensable in any power line assembly. Understanding the nuances of a suspension clamp for power line applications can significantly impact the overall performance and reliability of electrical systems.

Understanding Suspension Clamps in Power Lines

Suspension clamps are specialized hardware designed to hold conductors securely while allowing for movement due to thermal expansion or environmental factors. They serve as a bridge between the conductor and supporting structures, ensuring that everything remains intact even under challenging conditions. By grasping how these clamps function, engineers can make informed decisions that enhance the durability and efficiency of power lines.

Importance of Quality in Hardware Choices

Selecting high-quality components like suspension clamps ensures not only compliance with safety standards but also longevity and reduced maintenance costs over time. Investing in reliable hardware ultimately translates into fewer outages and better service for consumers, making quality a top priority.

Overview of Spark Fittings and Its Offerings

Enter Spark Fittings—a leader in pole line hardware known for its commitment to excellence and innovation. With an extensive range of products tailored specifically for power line applications, including top-notch suspension clamps, Spark Fittings is dedicated to providing solutions that meet diverse needs. Their expertise ensures that every component is crafted with precision, helping clients build robust electrical infrastructures that stand the test of time.

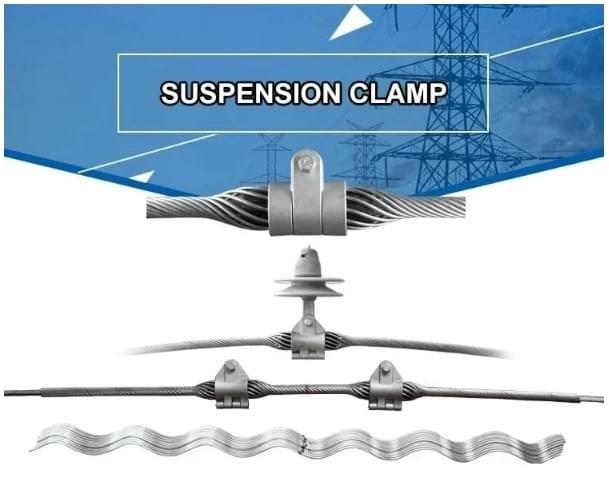

What Are Suspension Clamps?

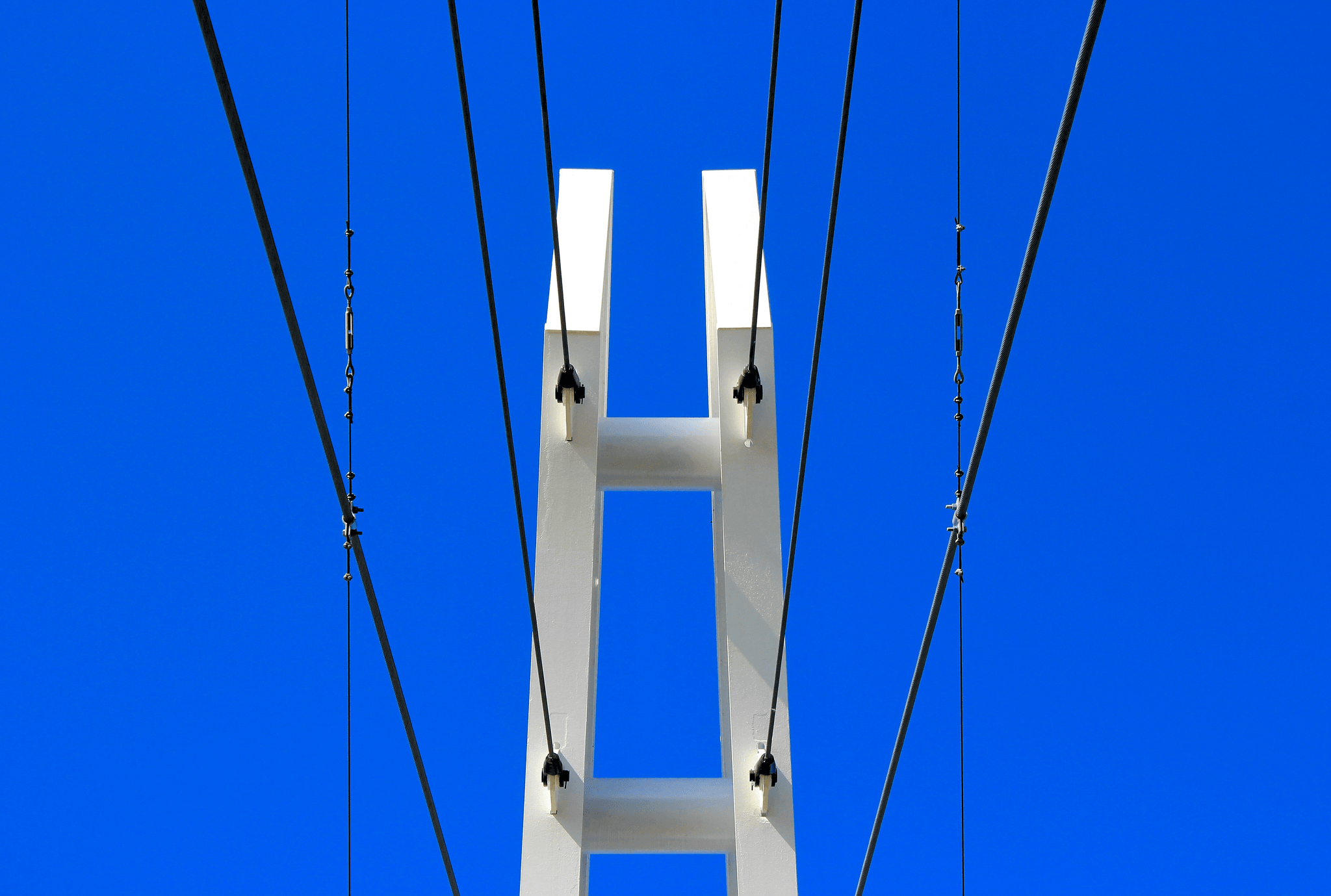

Suspension clamps are essential components in the world of power line infrastructure, serving a critical role in ensuring the stability and reliability of electrical transmission systems. These specialized hardware items support overhead conductors, allowing them to hang securely from poles or towers while accommodating various environmental conditions. In essence, a suspension clamp for power line applications is designed to manage mechanical loads and maintain proper conductor alignment.

Definition and Purpose

At its core, a suspension clamp is a device used to secure electrical conductors to supporting structures like poles or towers without restricting their movement due to thermal expansion or wind forces. The primary purpose of these clamps is to provide reliable support while allowing flexibility for the conductors they hold. This flexibility is crucial because it helps prevent damage from stress that could otherwise lead to costly outages or repairs.

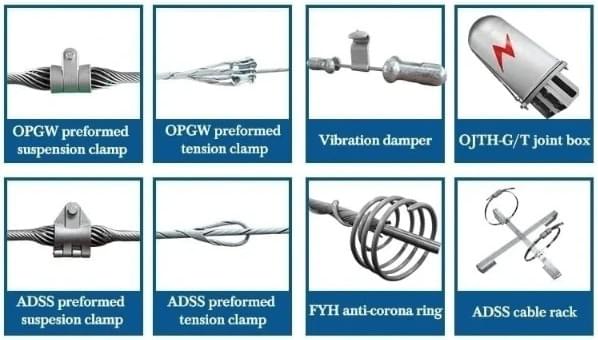

Different Types and Their Uses

There are several types of suspension clamps available, each tailored for specific applications within power line systems. For instance, some clamps are designed for use with aluminum conductors, while others cater specifically to steel or composite materials. Additionally, there are variations such as dead-end clamps and strain clamps that serve different purposes; dead-end clamps are used at the ends of lines where tension is applied, whereas strain clamps help manage forces along the length of the conductor.

Importance in Power Line Infrastructure

The importance of suspension clamps in power line infrastructure cannot be overstated; they play a vital role in maintaining system integrity and safety. Properly installed suspension clamps ensure that conductors remain stable under various conditions, reducing the risk of sagging or snapping during extreme weather events. By choosing high-quality options like those offered by Spark Fittings, utility companies can enhance their operational efficiency and minimize maintenance costs over time.

The Role of Armor Rods

These components are designed to protect conductors from wear and tear, particularly at points where they connect with suspension clamps for power line applications. Understanding their significance can help in making informed decisions about hardware choices in power line infrastructure.

Material Selection for Armor Rods

Choosing the right materials for armor rods is crucial to their performance and longevity. Typically, these rods are made from high-strength aluminum or steel alloys that provide excellent tensile strength while remaining lightweight enough for easy installation. The selection process should consider factors like electrical conductivity, thermal expansion, and environmental conditions to ensure that the armor rod complements the suspension clamp for power line setups effectively.

Corrosion Prevention Strategies

To combat this issue, various prevention strategies are employed, such as applying protective coatings or using corrosion-resistant materials during manufacturing. Regular inspections and maintenance also play a vital role in identifying potential corrosion issues before they compromise the integrity of both armor rods and suspension clamps for power line systems.

Spark Fittings' Customized Solutions

Spark Fittings takes pride in offering customized solutions tailored specifically to meet the unique needs of each project involving suspension clamps for power lines. Their team works closely with clients to understand specific requirements and challenges, ensuring that every armor rod is designed with precision and care. With Spark Fittings’ expertise, customers can rest assured that they’re investing in top-quality products that enhance the overall safety and efficiency of their power line infrastructure.

Choosing the Right Suspension Clamp for Your Line

Selecting the right suspension clamp for power line applications is a critical decision that can significantly impact the performance and reliability of your electrical infrastructure. With various options available, it’s essential to understand the specific requirements of your project and how different clamps can meet those needs. A well-chosen suspension clamp not only ensures safety but also enhances the longevity of your power line system.

Factors to Consider

When choosing a suspension clamp for power line use, several factors should be taken into account. First, consider the environmental conditions where the clamp will be installed; factors like temperature fluctuations, humidity, and exposure to corrosive elements can affect material selection. Additionally, load-bearing capacity is crucial—ensure that the selected clamp can support the weight of the conductor while withstanding wind loads and other external forces.

Another important factor is ease of installation; a user-friendly design can save time and reduce labor costs during setup. The compatibility with existing hardware is equally vital; you want your suspension clamp to integrate seamlessly with other components in your power line system. Finally, don’t overlook manufacturer reputation—choosing a reliable brand like Spark Fittings ensures quality assurance and access to customized solutions tailored to your specific needs.

Compatibility with Conductor Materials

Compatibility with conductor materials is paramount when selecting a suspension clamp for power lines. Different conductors are made from various materials such as aluminum or copper, each requiring specific types of clamps designed to avoid galvanic corrosion or mechanical failure over time. For example, aluminum conductors may necessitate clamps made from materials that prevent oxidation while ensuring optimal conductivity.

Moreover, it's crucial to match the size and shape of the conductor with an appropriate suspension clamp design; improper sizing could lead to inadequate support or damage during operation. Always consult product specifications provided by manufacturers like Spark Fittings to ensure you select clamps that are compatible with both current standards and future upgrades in technology or material usage.

Common Mistakes to Avoid

While selecting a suspension clamp for power line applications may seem straightforward, several common pitfalls can lead to costly mistakes down the road. One frequent error is overlooking environmental factors; failing to consider local weather conditions could result in premature wear or failure of hardware components due to corrosion or mechanical stress.

Another mistake involves ignoring load specifications; always verify that any chosen clamp meets or exceeds required load limits based on real-world conditions rather than theoretical estimates alone. Lastly, don’t rush through installation without proper training—improperly installed clamps not only compromise safety but may also void warranties on equipment from manufacturers like Spark Fittings.

Spark Fittings: A Leader in Pole Line Hardware

When it comes to pole line hardware, Spark Fittings stands out as a leader in the industry, especially with their innovative suspension clamp for power line applications. With a commitment to quality and performance, they have established themselves as a trusted name among utility companies and contractors alike. Their comprehensive approach to manufacturing ensures that each product meets rigorous standards for durability and efficiency.

Overview of Their Manufacturing Capabilities

Spark Fittings boasts state-of-the-art manufacturing facilities equipped with advanced technology that enables them to produce high-quality suspension clamps for power lines. Their processes are designed for precision, ensuring that each component is crafted to withstand the harshest environmental conditions. From material selection to final assembly, every step is meticulously controlled, allowing Spark Fittings to deliver reliable solutions that meet the evolving demands of the electrical infrastructure market.

Unique Features of Spark Fittings Products

One of the standout features of Spark Fittings products is their innovative design tailored specifically for optimal performance in power line applications. Each suspension clamp for power line is engineered with unique attributes such as enhanced load-bearing capabilities and corrosion resistance, ensuring longevity even under challenging conditions. Additionally, Spark Fittings offers customization options that allow clients to tailor products according to specific project requirements—making them not just a supplier but a partner in success.

Client Testimonials and Success Stories

The reputation of Spark Fittings is bolstered by numerous client testimonials praising their exceptional products and customer service. Utility companies have reported significant improvements in reliability after switching to their suspension clamps for power lines, citing reduced maintenance costs and increased operational efficiency. Success stories abound where projects were completed ahead of schedule due to the ease of installation and superior performance of Spark's hardware solutions.

Installation Best Practices for Suspension Clamps

Step-by-Step Guide to Proper Installation

1. **Preparation**: Before you begin, gather all necessary tools and materials, including the suspension clamp for power line, wrenches, torque tools, and safety gear. Make sure to review the installation manual provided by the manufacturer for specific instructions related to their products.

2. **Inspection**: Inspect both the suspension clamp and conductor before installation to ensure there are no defects or damages that could compromise performance later on. Pay close attention to any signs of wear or corrosion which could affect functionality.

3. **Installation**: Position the suspension clamp around the conductor at an appropriate height on your pole structure, ensuring it is aligned correctly with other hardware components. Tighten bolts gradually in a crisscross pattern to distribute pressure evenly; this helps prevent any misalignment that might occur if you tighten them sequentially.

Following these steps will ensure that your suspension clamp is securely installed and ready for action!

Safety Considerations

Safety should always be at the forefront during installation processes involving a suspension clamp for power line applications. First and foremost, always wear appropriate personal protective equipment (PPE), such as gloves, helmets, and eye protection—after all, safety first!

Additionally, ensure that all electrical systems are de-energized before beginning work on any power lines; this minimizes risks associated with accidental electrocution or equipment damage during installation. Finally, maintain clear communication among team members throughout the process—this ensures everyone is aware of their roles and can respond quickly should an issue arise.

Maintenance Tips for Longevity

To maximize the lifespan of your suspension clamp for power line systems, regular maintenance is essential. Start by conducting periodic inspections every few months; check for signs of corrosion or wear on both clamps and conductors so you can address issues before they escalate into larger problems.

In addition to visual inspections, consider applying a protective coating or anti-corrosion treatment specifically designed for outdoor electrical hardware; this can significantly enhance resistance against environmental factors like moisture or salt exposure over time. Lastly, keep records of maintenance activities—this documentation can be invaluable when assessing performance trends or planning future upgrades.

By adhering to these best practices in installation and maintenance, you'll not only optimize performance but also contribute positively to overall infrastructure reliability.

Conclusion

In wrapping up our exploration of suspension clamps for power lines, it’s clear that these components are not just minor players; they are fundamental to the integrity and reliability of power line infrastructure. We’ve delved into the definition and purpose of suspension clamps, their various types, and the critical role they play in ensuring safe and efficient power transmission. Additionally, we highlighted the importance of quality hardware choices, particularly when it comes to selecting a reputable manufacturer like Spark Fittings.

Recap of Key Points on Suspension Clamps

Suspension clamps serve a vital function in maintaining the stability and security of power lines by holding conductors in place while allowing for necessary movement due to temperature changes or wind. Different types cater to specific needs, ensuring that each installation is optimized for performance and safety. The significance of choosing high-quality suspension clamps cannot be overstated; subpar products can lead to failures that compromise entire systems.

The Importance of Choosing Spark Fittings

When it comes to sourcing your suspension clamp for power line applications, Spark Fittings stands out as a leader in manufacturing top-notch hardware solutions. Their commitment to quality ensures that every product is designed with durability and reliability in mind, making them a preferred choice among industry professionals. With customized solutions tailored to meet diverse requirements, choosing Spark Fittings means investing in long-term success for your power line projects.

Final Thoughts on Power Line Hardware Choices

In conclusion, selecting the right hardware for your power line infrastructure is paramount—not just for functionality but also for safety and longevity. Suspension clamps are essential components that should never be overlooked or compromised upon; after all, they hold up more than just wires—they uphold our electrical grid's integrity! So next time you’re planning your project or reviewing your options, remember that quality matters—choose wisely with Spark Fittings.