Introduction

In the world of construction and manufacturing, the choice of fasteners manufacturers can make or break a project. Reliable manufacturers ensure that the components used, such as Transmission Bolts and other hardware, meet stringent quality standards and are built to last. The integrity of your projects depends on these small yet mighty pieces of hardware, making it crucial to select manufacturers who prioritize excellence.

Importance of Choosing Reliable Manufacturers

A trusted Bolt Nut Manufacturer not only provides high-quality products but also fosters long-term partnerships that can enhance project efficiency and success. Opting for reputable fasteners manufacturers minimizes risks associated with product failures that could lead to costly delays or safety hazards.

Understanding Fastener Quality Standards

Fastener quality standards are the benchmarks that define what constitutes a reliable product in the industry. These standards encompass everything from material specifications to performance testing, ensuring that each component meets rigorous safety and durability criteria. Familiarizing yourself with these standards is essential when selecting Transmission Line Hardware, as they directly impact the functionality and longevity of your projects.

Key Features of Competent Fasteners Manufacturers

Competent fasteners manufacturers exhibit several key features that distinguish them from their competitors. First off, they provide a diverse range of products tailored to various applications—be it Transmission Bolts or specialized hardware for unique needs. Additionally, they maintain robust quality control processes and offer excellent customer support, ensuring you receive not just products but valuable partnership throughout your project's lifecycle.

Assessing Manufacturer's Reputation

Industry Experience Matters

Experience in the industry is crucial when evaluating fasteners manufacturers. Manufacturers with years of expertise often have refined their processes, developed robust quality control measures, and built strong relationships with suppliers. For instance, a seasoned Bolt Nut Manufacturer will likely have a comprehensive understanding of the specific requirements needed for Transmission Bolts and other hardware, allowing for better product offerings.

Furthermore, an experienced manufacturer can navigate challenges more effectively than newer companies. They are likely to have encountered various scenarios that could affect production or delivery timelines, equipping them with the necessary skills to adapt quickly. In short, choosing an experienced manufacturer can lead to better outcomes for your projects.

Customer Reviews and Testimonials

Customer reviews and testimonials provide invaluable insights into the reliability of fasteners manufacturers. Potential clients often share their experiences regarding product quality, customer service, and delivery times—essential factors when considering a partnership. Reading these reviews can help you gauge whether a manufacturer specializes in Transmission Line Hardware or excels in producing high-quality fasteners like Transmission Bolts.

Moreover, don't just settle for glowing reviews; look for constructive feedback as well. This balanced view will give you a clearer picture of what to expect from the Bolt Nut Manufacturer you're considering. Remember that satisfied customers are usually repeat customers—an important indicator of trustworthiness in any industry.

Certifications and Compliance

Certifications and compliance are indicators of a manufacturer's dedication to maintaining high standards in production processes. Fasteners manufacturers should adhere to industry-specific regulations that ensure safety and performance across all products—including Transmission Bolts and various types of hardware components. Certifications from recognized organizations demonstrate that the manufacturer has met rigorous quality benchmarks.

Additionally, compliance with international standards allows for greater market access and assures customers about product consistency across different regions or sectors. It’s wise to ask potential partners about their certifications; after all, working with compliant manufacturers minimizes risks associated with defective products or legal issues down the line. In essence, prioritizing certified manufacturers means prioritizing quality assurance.

Quality Control Processes

In the world of fasteners, quality control processes are the backbone that ensures reliability and performance. Fasteners manufacturers must adhere to stringent standards to guarantee that their products meet or exceed industry expectations. When selecting a manufacturer, understanding their quality control practices can be a game changer in ensuring you receive top-notch transmission bolts and hardware.

Manufacturing Standards and Guidelines

Manufacturing standards serve as the blueprint for producing high-quality fasteners, such as transmission line hardware. These guidelines often align with international standards like ISO or ASTM, ensuring that bolt nut manufacturers maintain consistency in their production processes. By following these established protocols, manufacturers can minimize defects and enhance product reliability, which is crucial for applications where safety is paramount.

Testing Procedures for Fasteners

Once fasteners are manufactured, rigorous testing procedures come into play to ensure they meet quality expectations. This may involve tensile strength tests, corrosion resistance evaluations, and fatigue tests to assess how well transmission bolts hold up under stress. A reputable bolt nut manufacturer will have an extensive testing regimen that not only checks for compliance but also guarantees durability in real-world applications.

Importance of Traceability

Traceability is an often-overlooked yet vital aspect of quality control processes among fasteners manufacturers. It allows for tracking each batch of products back to its origin, ensuring accountability in case any issues arise post-delivery. This practice not only enhances consumer confidence but also enables swift corrective actions if a particular lot of transmission line hardware fails to perform as expected.

Product Range and Specialization

Variety of Fastener Options

Fasteners manufacturers offer an impressive variety of fastener options, which is crucial for meeting the unique demands of different projects. These options can range from simple screws to complex fastening systems designed for heavy-duty applications. The ability to choose from an extensive catalog not only enhances efficiency but also aids in maintaining quality standards across various sectors.

Moreover, having access to multiple types of fasteners means that you can easily find solutions tailored specifically for your project’s requirements—be it automotive, construction, or electronics. This versatility is particularly important when considering components like Transmission Bolts that are essential in ensuring secure connections under high-stress conditions. Ultimately, a manufacturer with a wide variety of fastener options provides peace of mind knowing that you can rely on them for all your fastening needs.

Highlighting Transmission Bolts and Hardware

Among the many products offered by fasteners manufacturers, Transmission Bolts hold a special place due to their critical role in machinery and infrastructure. These bolts are engineered specifically to withstand significant loads and vibrations while ensuring reliability over time. When selecting a Bolt Nut Manufacturer, it's essential to evaluate their expertise in producing high-quality transmission hardware that meets industry standards.

Transmission line hardware is another area where specialization pays off; these components must be durable enough to handle environmental stressors while maintaining optimal performance levels. Quality transmission bolts not only enhance safety but also contribute significantly to the longevity of equipment and structures they support.

Niche Expertise: Cable Accessories

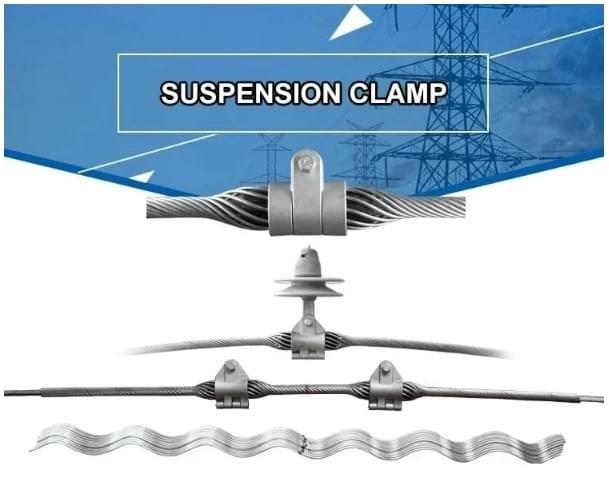

In addition to traditional fasteners like Transmission Bolts, many fasteners manufacturers excel in niche markets such as cable accessories. These products often require specialized knowledge due to their unique applications within telecommunications or electrical installations. A reputable Bolt Nut Manufacturer will have dedicated lines focusing on cable accessories designed for both strength and adaptability.

Cable accessories include items such as clamps, connectors, and insulators—all vital components ensuring efficient transmission lines operate smoothly without failure over time. The importance of selecting a manufacturer with niche expertise cannot be overstated; their understanding of material properties and application-specific requirements leads directly to better performance outcomes in challenging environments. Thus, when sourcing cable accessories from established manufacturers, you'll benefit from enhanced reliability backed by industry knowledge.

Supply Chain and Delivery Reliability

When it comes to choosing fasteners manufacturers, supply chain and delivery reliability are paramount. A dependable manufacturer ensures that your orders are fulfilled on time, which is crucial for maintaining project schedules. This reliability not only reflects a manufacturer's commitment to quality but also their ability to manage inventory effectively, keeping production lines running smoothly.

Timely Delivery and Inventory Management

Timely delivery can make or break a project, especially when working with critical components like Transmission Bolts. Fasteners manufacturers should have robust inventory management systems in place to track stock levels and anticipate demand fluctuations. By optimizing their supply chain processes, these manufacturers can ensure that essential products like bolt nuts are readily available when you need them most.

Production Capabilities and Scalability

The production capabilities of a bolt nut manufacturer directly impact their ability to scale operations according to demand. Manufacturers should be equipped with advanced machinery and technology that allow for efficient mass production of various fasteners, including Transmission Line Hardware. This scalability ensures that as your projects grow in size or complexity, your chosen manufacturer can keep pace without compromising quality.

Communication and Support Services

Effective communication is the backbone of any successful partnership with fasteners manufacturers. A reliable manufacturer will provide consistent updates throughout the production process while being responsive to any inquiries or concerns you may have regarding your order—whether it's about Transmission Bolts or specialized cable accessories. Exceptional support services enhance the overall experience, ensuring you feel valued as a customer while receiving high-quality products tailored to your needs.

Pricing and Value Assessment

When selecting fasteners manufacturers, pricing is a critical factor that can significantly impact your project budget. However, it’s essential to understand that the cheapest option isn’t always the best. A balance between cost and quality should be your guiding principle when evaluating potential suppliers of Transmission Bolts and other fastener products.

Competitive Pricing Strategies

Fasteners manufacturers often employ various competitive pricing strategies to attract customers while maintaining profitability. Some may offer bulk purchase discounts or loyalty programs for repeat clients, which can lead to substantial savings over time. Additionally, understanding regional market dynamics can help you identify manufacturers that provide high-quality products at reasonable prices, especially in specialized areas like Transmission Line Hardware.

Understanding Cost vs. Quality

Navigating the cost versus quality dilemma is crucial when dealing with a Bolt Nut Manufacturer or any fastener supplier. While lower prices might seem appealing initially, they could result in compromised quality, leading to increased failure rates and ultimately higher costs due to replacements or repairs down the line. Investing in high-quality fasteners not only ensures reliability but also enhances overall project performance—after all, you don’t want your Transmission Bolts giving way under pressure!

Long-Term Value Considerations

When assessing pricing, consider the long-term value of your investment in fasteners manufacturers’ products rather than just immediate costs. High-quality fasteners may come with a higher upfront price tag but can save you money through durability and reduced maintenance needs over time. In sectors where safety is paramount—like those relying on Transmission Line Hardware—the value of reliable components cannot be overstated; they are worth every penny spent.

Conclusion

In the world of fasteners, choosing the right manufacturers can make or break your project. High-quality fasteners are not just about holding things together; they ensure safety and reliability in various applications, from construction to automotive industries. By considering factors such as reputation, quality control processes, and product range, you can make an informed decision that serves your needs well.

Key Takeaways for Selecting Manufacturers

When selecting fasteners manufacturers, prioritize those with a solid reputation backed by industry experience and customer testimonials. Certifications and compliance with recognized standards also play a crucial role in determining a manufacturer's credibility. Lastly, don’t overlook the importance of communication; a responsive manufacturer can make your purchasing process much smoother.

Importance of Quality in Fasteners

Quality fasteners are essential for maintaining structural integrity and operational efficiency in any application—especially when it comes to critical components like Transmission Bolts or Transmission Line Hardware. Poor-quality fasteners can lead to failures that not only compromise safety but also increase long-term costs due to repairs or replacements. Therefore, investing in reliable bolt nut manufacturers ensures that you get products that meet stringent quality standards.

Spotlight: Spark Fittings and Their Expertise

Spark Fittings stands out among fasteners manufacturers for their specialization in high-quality Transmission Bolts and innovative cable accessories. With years of experience under their belt, they have built a reputation for excellence through rigorous quality control processes and extensive product offerings tailored to meet diverse needs. Their commitment to customer satisfaction makes them a go-to choice for those looking for dependable fastening solutions.