Introduction

Discovering affordable sandblasting equipment can transform your projects, offering high-quality finishes and efficient results at a fraction of the cost. Whether you’re in construction, automotive, or manufacturing, investing in the right sandblasting machine can elevate your operations.

Discover Affordable Sandblasting Equipment

Finding budget-friendly sandblasting equipment doesn’t mean compromising on quality; it means being smart about your choices. With a variety of options available, from compact machines for small jobs to heavy-duty models for larger tasks, there’s something to fit every budget and need. By exploring different manufacturers and retailers, you can uncover deals that make high-performance industrial and commercial sandblasting equipment accessible without breaking the bank.

Why Choose Industrial Sandblasting Machines

Industrial sandblasting machines are designed for heavy use in demanding environments, making them an ideal choice for businesses looking to maximize efficiency and productivity. These machines often come with advanced features that enhance performance while ensuring durability over time. Investing in industrial-grade equipment means you're not just buying a tool; you're securing a reliable partner for your long-term business success.

Benefits of Commercial Sandblasting Solutions

Commercial sandblasting solutions offer numerous advantages tailored to meet the specific needs of various industries. They provide superior cleaning capabilities, allowing businesses to prepare surfaces effectively before painting or coating applications. Additionally, these solutions often come with customizable options that ensure you get exactly what you need—making them a smart investment for any commercial operation.

Understanding Sandblasting Equipment

What is Sandblasting?

Sandblasting, also known as abrasive blasting, is a technique that utilizes compressed air to shoot abrasive materials at high speeds onto surfaces. The primary goal is to clean or prepare surfaces for further treatment like painting or coating. This method can be applied to various materials including metal, wood, glass, and concrete, making it versatile for numerous applications.

Types of Sandblasting Machines

There are several types of sandblasting machines tailored for different tasks and industries. The most common include siphon feed machines that use gravity to draw abrasives from a hopper; pressure feed machines that deliver consistent pressure for faster cleaning; and cabinet blasters that contain the process within an enclosed space for smaller items. Choosing the right type of sandblasting equipment can significantly impact efficiency and results in your projects.

Applications in Industrial and Commercial Settings

Industrial and commercial sandblasting equipment finds its place in various sectors such as automotive repair, construction, manufacturing, and even artistic endeavors like glass etching. In automotive shops, sandblasters are used for stripping paint from vehicles before refinishing them; while in construction, they prepare surfaces for coatings or treatments that enhance durability. The versatility of these machines makes them indispensable tools across multiple industries seeking quality surface preparation solutions.

Key Features of Effective Sandblasting Machines

When diving into the world of sandblasting equipment, understanding the key features that dictate performance is crucial. The right Sandblasting Machine can make all the difference in efficiency, quality, and safety of your projects. In this section, we’ll explore what makes effective industrial and commercial sandblasting equipment stand out.

Power and Efficiency

The power of a sandblasting machine is often measured by its ability to deliver high pressure for effective material removal. A powerful unit not only speeds up the blasting process but also ensures a smoother finish on surfaces, making it ideal for both industrial and commercial applications. Efficiency matters because it directly impacts productivity; an efficient machine minimizes downtime and maximizes output.

Choosing sandblasting equipment with adjustable power settings allows operators to tailor the blasting intensity to specific tasks, whether they’re tackling delicate surfaces or heavy-duty jobs. Additionally, energy-efficient models can significantly reduce operational costs over time without sacrificing performance. Thus, investing in a powerful and efficient sandblasting machine pays off in both immediate results and long-term savings.

Durability and Maintenance

Durability is a non-negotiable feature when selecting sandblasting machines for rugged environments like construction sites or manufacturing plants. Machines built with high-quality materials resist wear and tear better than their cheaper counterparts, leading to longer lifespans and fewer repairs. Regular maintenance is essential; therefore, look for models designed with easy access points for routine checks—this saves time and keeps your industrial or commercial sandblasting equipment running smoothly.

Moreover, consider machines that come with warranties or service plans as they can provide peace of mind regarding durability concerns. A well-maintained sandblasting machine not only performs better but also ensures safety by reducing risks associated with malfunctioning equipment. In essence, durability combined with low-maintenance requirements makes for an attractive investment in your business’s future.

Safety Features to Consider

Safety should always be at the forefront when dealing with any type of heavy machinery, including sandblasting equipment. Look for features like pressure relief valves that prevent over-pressurization—an essential aspect that protects both operators and machinery alike during operation. Additionally, integrated dust collection systems are vital; they help maintain air quality by capturing harmful particles generated during blasting processes.

Another important consideration is operator protection gear compatibility; ensure that your selected Sandblasting Machine supports necessary attachments like helmets or visors designed to shield users from flying debris or harmful dust clouds. Furthermore, emergency shut-off switches can provide an added layer of security in case something goes awry during operation—always better safe than sorry! Investing in machines equipped with robust safety features not only protects your workforce but also reflects positively on your commitment to workplace safety standards.

Where to Buy Affordable Sandblasting Equipment

Top Online Retailers for Sandblasting Solutions

The internet is a treasure trove for finding affordable sandblasting equipment. Major online retailers like Amazon and eBay offer a wide variety of sandblasting machines at competitive prices, often with customer reviews that can guide your decision-making process. Additionally, specialized websites dedicated to industrial tools frequently provide discounts and promotions on their inventory of industrial and commercial sandblasting equipment.

Shopping online not only gives you access to a broader selection but also allows you to compare prices effortlessly from the comfort of your home or workshop. Many retailers even offer free shipping on larger purchases, making it easier than ever to equip yourself with quality sandblasting machines without overspending. Just remember to check return policies and warranties before clicking buy!

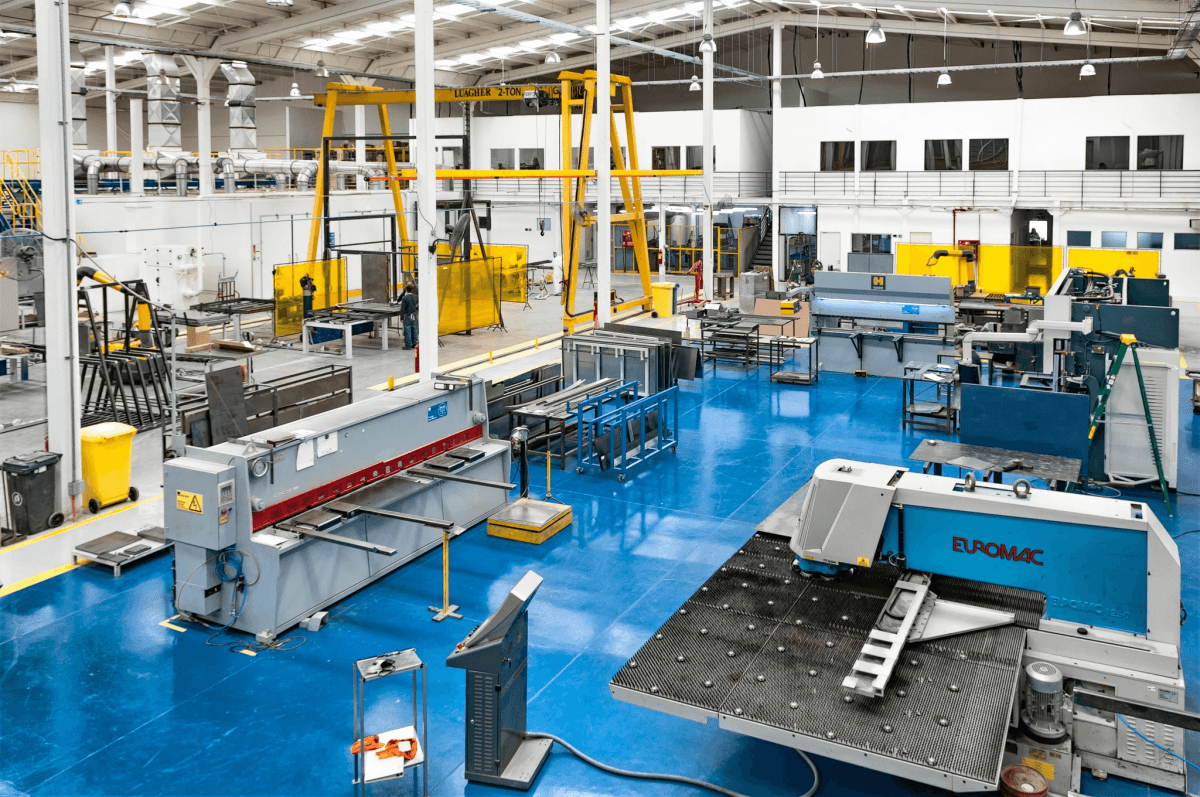

Direct Manufacturers: A Smart Choice

If you're seeking quality and affordability in one package, consider purchasing directly from manufacturers of sandblasting equipment. By cutting out the middleman, you often gain access to lower prices as well as exclusive deals on bulk orders for industrial and commercial applications. Many manufacturers also provide customization options tailored specifically for your needs—ensuring that the sandblasting machine you choose is perfectly suited for its intended use.

Moreover, buying directly means you'll likely receive better customer support and service if any issues arise post-purchase. Manufacturers are usually more invested in ensuring customer satisfaction since they have a direct stake in their products' performance in real-world applications. So why not explore this avenue? You might just uncover some hidden gems!

Local Distributors and Their Benefits

Don’t overlook local distributors when searching for affordable sandblasting equipment! Local suppliers often carry an impressive selection of industrial and commercial sandblasting machines while providing personalized service that online retailers can't match. Plus, visiting a local distributor allows you to physically inspect the machinery before making any commitments—a huge advantage when investing in such essential tools.

Another perk? Local distributors usually have strong ties within the community, which can lead to valuable recommendations based on firsthand experiences with various types of sandblasting equipment available in your area. They may also offer training sessions or workshops that help familiarize you with your new purchase—an invaluable resource if you're new to using these powerful machines! Supporting local businesses not only benefits them but also strengthens your community’s economy.

Spotlight on Spark Electronic Technology

Innovative Sandblasting Solutions

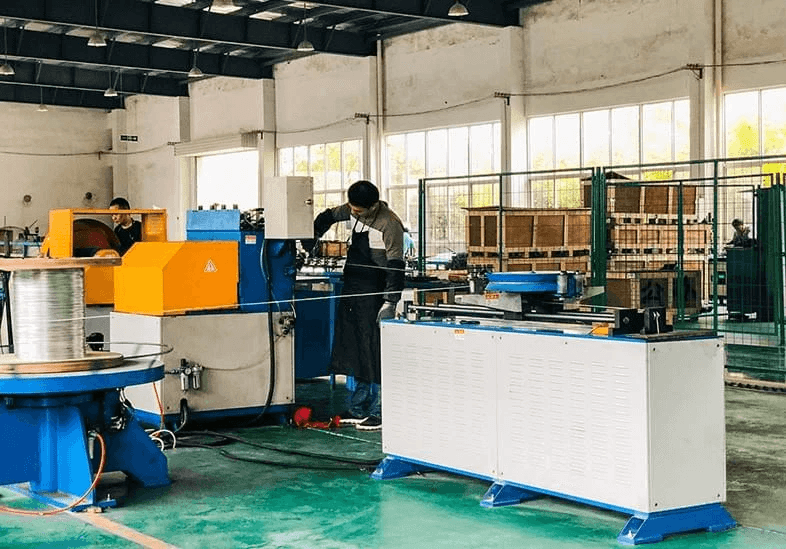

Spark Electronic has redefined what it means to be innovative in the realm of sandblasting solutions. Their advanced technology incorporates smart features that optimize performance while minimizing waste, making them a preferred choice for many businesses. By integrating automation into their sandblasting machines, they ensure that users can achieve consistent results with less effort.

Overview of Key Equipment Offered

The range of sandblasting equipment offered by Spark Electronic is impressive and diverse, catering to various needs across industries. From portable units ideal for small-scale operations to large industrial machines designed for heavy-duty use, there’s something for everyone. Key offerings include automated blast cabinets, pressure and suction systems, and specialized nozzles that enhance precision and control during operation.

How Spark Electronic Supports Quality Production

Quality production is paramount in any business, and Spark Electronic understands this better than most when it comes to sandblasting equipment. Their machines are built with durable materials that withstand rigorous use while ensuring safety features are prioritized for operator protection. Additionally, their ongoing support and maintenance services help clients keep their industrial and commercial sandblasting equipment running smoothly over time.

Comparing Industrial and Commercial Sandblasting Equipment

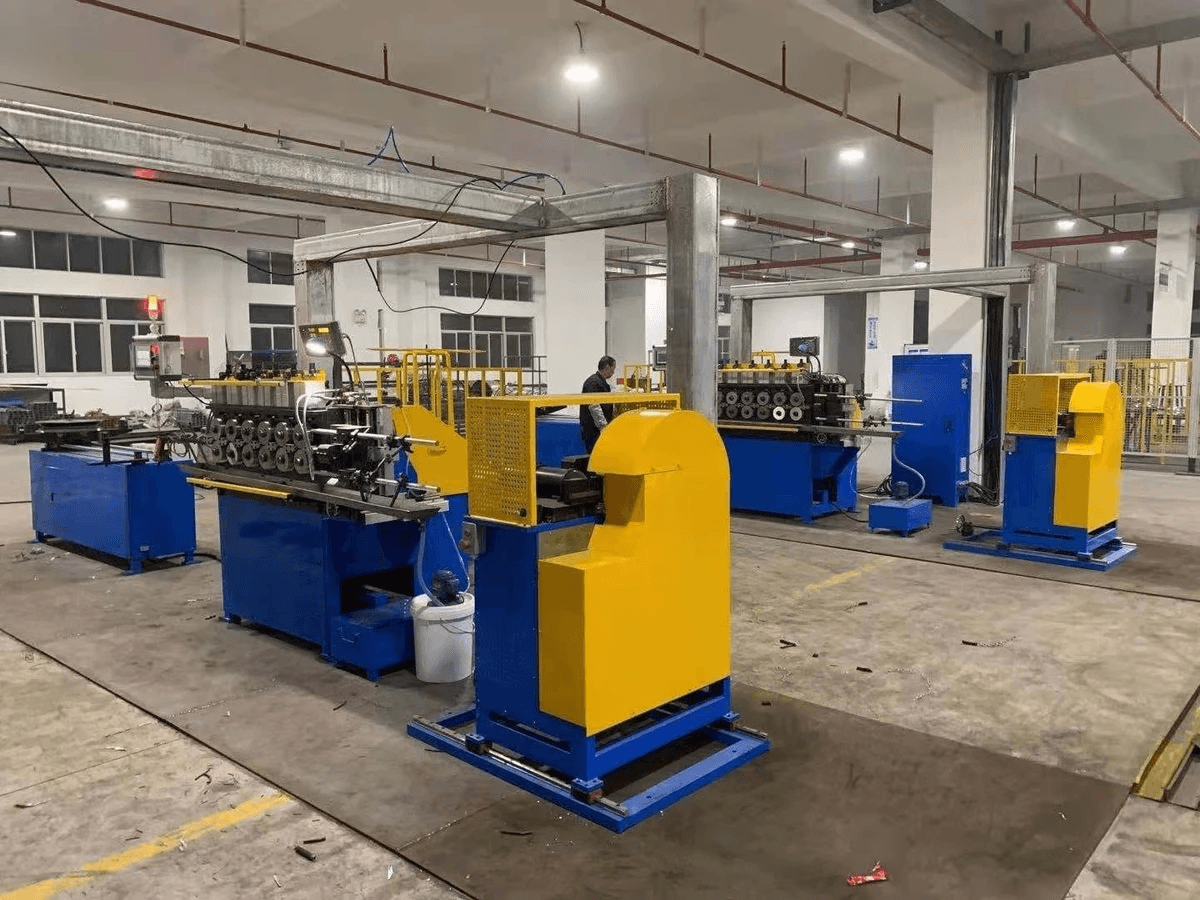

While both types serve the purpose of surface preparation and cleaning, their designs and functionalities can vary significantly. Industrial sandblasting machines are typically built for heavy-duty tasks, featuring robust components that withstand rigorous usage, while commercial models often prioritize portability and ease of use.

Differences in Design and Functionality

Industrial sandblasting machines are engineered with high-capacity tanks and powerful compressors to handle large-scale operations efficiently. These machines often include advanced features like automated controls for precision blasting, making them ideal for factories or production facilities. In contrast, commercial sandblasting equipment tends to be more compact, focusing on user-friendly interfaces that allow smaller businesses to achieve effective results without the need for extensive training.

The design differences also extend to the materials used; industrial models may incorporate heavier-duty metals capable of resisting wear from abrasive materials over time. Commercial units might utilize lighter materials that enhance mobility but could require more frequent maintenance under heavy use conditions. Understanding these nuances helps businesses select the right type of sandblasting machine tailored to their operational demands.

Cost-Effectiveness for Various Industries

Cost-effectiveness is a significant consideration when comparing industrial and commercial sandblasting equipment. For large manufacturers or construction companies requiring consistent high-volume output, investing in industrial machines can lead to lower operational costs over time due to their durability and efficiency. On the other hand, smaller enterprises or service providers may find that commercial models offer a better return on investment by meeting their specific needs without overspending on unnecessary features.

Moreover, maintenance costs play a vital role in determining overall value; industrial equipment might have higher upfront costs but could save money long-term through reduced downtime and fewer repairs. Conversely, commercial options provide flexibility at a lower price point but may incur higher ongoing expenses if they require frequent servicing or replacement parts due to less robust construction. Ultimately, businesses should evaluate their unique requirements against budget constraints when selecting between these two categories of sandblasting solutions.

Tailoring Solutions to Your Needs

Tailoring your choice of sandblasting equipment involves assessing not only your current needs but also anticipating future demands as your business grows or changes direction. Customization options are available in both industrial and commercial units; however, industrial machines tend to offer more scalability with modular designs that allow users to upgrade components as needed easily. This adaptability can be a game-changer for companies planning significant expansions or diversifying their services.

For those operating in niche markets or specialized applications, it’s essential to consider how well each type of machine aligns with specific tasks—be it automotive refinishing, metal restoration, or even artistic endeavors like glass etching. Some manufacturers provide bespoke solutions tailored precisely for such unique applications within both categories of sandblasting equipment. By taking time upfront to evaluate your business's distinct requirements against available options in both segments, you’ll ensure optimal performance from your chosen machine while maximizing efficiency.

Conclusion

In the realm of industrial and commercial operations, sandblasting equipment stands as an invaluable asset. Elevating your business with a reliable Sandblasting Machine can enhance efficiency, improve surface preparation, and ultimately lead to superior results. Whether you are in manufacturing, automotive repair, or restoration services, investing in quality sandblasting solutions can set you apart from competitors.

Elevate Your Business with Sandblasting

Harnessing the power of sandblasting equipment allows businesses to tackle a variety of tasks with precision and speed. From cleaning surfaces to preparing materials for painting or coating, a quality Sandblasting Machine can significantly streamline processes. By integrating effective industrial and commercial sandblasting equipment into your workflow, you not only increase productivity but also ensure that your projects meet the highest standards.

Finding the Right Equipment for You

Different industries may require specialized machines tailored to their unique challenges—whether it’s heavy-duty industrial models or compact units for smaller jobs. By thoroughly researching options and understanding what each type of Sandblasting Machine offers, you can make an informed decision that aligns with your operational goals.

Investing in Quality for Long-Term Success

Investing in high-quality industrial and commercial sandblasting equipment pays dividends in durability and performance over time. While it may be tempting to opt for cheaper alternatives initially, remember that quality machinery often translates into lower maintenance costs and fewer operational hiccups down the line. Ultimately, choosing reliable sandblasting solutions is an investment in your business’s long-term success—ensuring that you stay competitive while delivering top-notch results.