Introduction

When it comes to securing loads and ensuring safety in various applications, understanding anchor shackles is crucial. These robust devices play a pivotal role in connecting different components, especially in construction and marine environments. So, what is a shackle anchor? It’s not just a piece of metal; it’s an integral part of reliable transmission line attachments that keep everything running smoothly.

Reliable transmission line attachments are essential for the stability and safety of electrical systems. Without dependable connections, the risk of failure increases, which can lead to costly downtime or even hazardous situations. This is where anchor shackles come into play; they provide the necessary strength and durability to withstand heavy loads and harsh conditions.

In addition to anchor shackles, spark fittings also deserve attention as key components in this landscape. Spark fittings enhance the reliability of connections by providing secure attachment points for cables and other equipment. Understanding how these elements work together will help you appreciate their importance in maintaining safe operations across various industries.

Understanding Anchor Shackles

Anchor shackles are versatile tools that serve as connectors between different components in lifting and rigging applications. Essentially, they allow for easy attachment and detachment while providing significant strength—perfect for heavy-duty tasks! So, what is an anchor shackle? It’s typically made from high-strength steel or alloy materials designed to handle substantial loads without compromising safety.

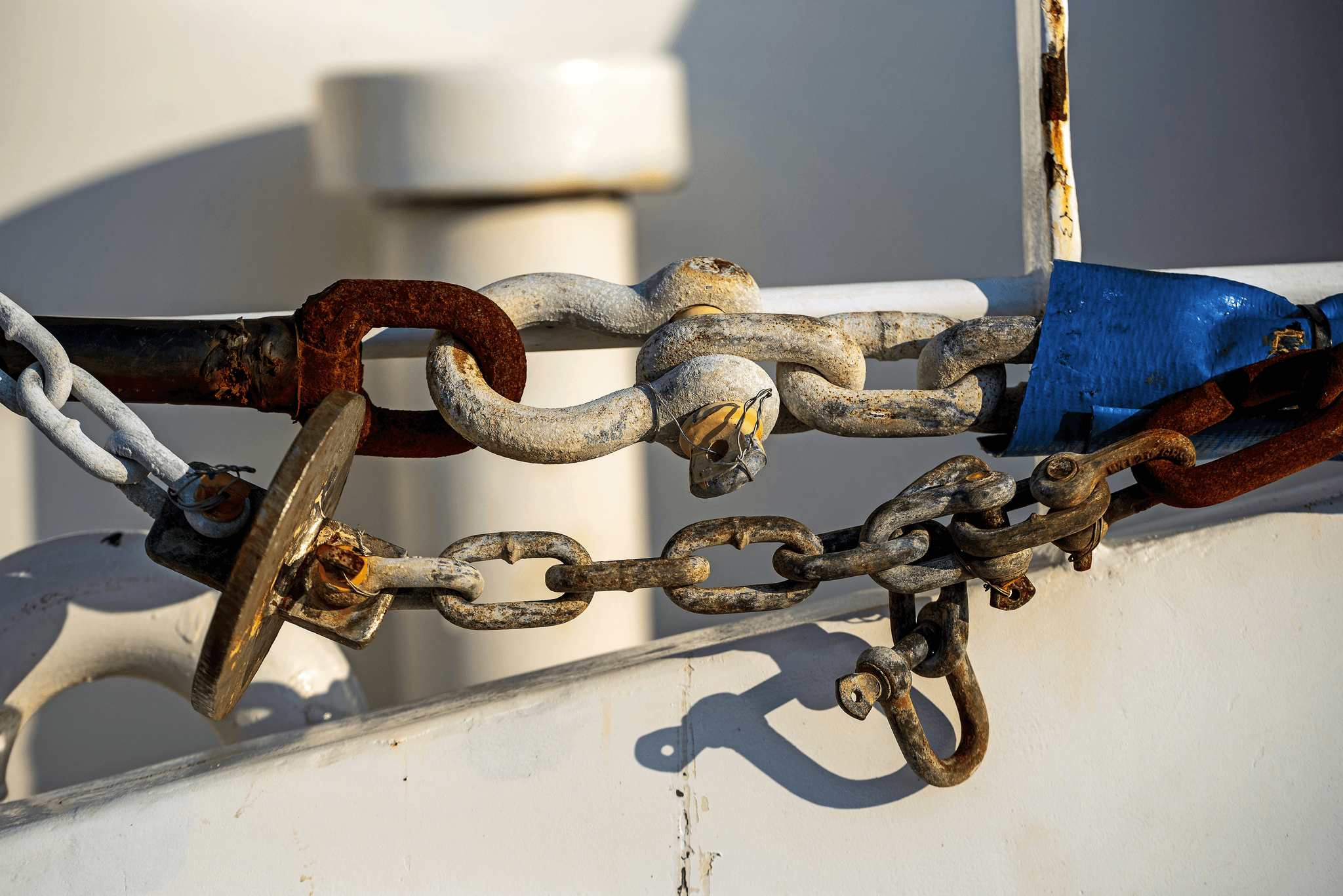

The key components of an anchor shackle include the bow (the curved part), the pin (which secures the connection), and sometimes a latch mechanism for added security. Together, these parts create a reliable fastening solution that can be used across various industries—from construction sites to marine operations. When discussing what is a shackle used for?, think about its ability to connect chains or ropes securely while distributing weight evenly.

There are several types of anchor shackles available on the market today, each designed for specific applications. From screw pin shackles that allow easy assembly and disassembly to safety pin options that provide extra security against accidental release—there's something suited for every need! Understanding these variations ensures you select the right type when considering your project requirements.

Importance of Reliable Transmission Line Attachments

In any electrical infrastructure, reliable transmission line attachments are vital to ensure consistent power delivery without interruptions or failures. A poorly secured connection can lead not only to inefficiencies but also pose serious risks such as electrical fires or equipment damage—definitely not something anyone wants on their hands! This underscores why understanding how different tools like anchor shackles function becomes essential.

Anchor shackles contribute significantly by providing strong connections between cables and structures within transmission lines—it’s all about stability! The question arises: what is a shackle used for? In this context, they facilitate safe load management while allowing flexibility during maintenance operations without compromising structural integrity.

Moreover, using quality equipment like spark fittings alongside anchor shackles enhances overall system reliability even further! With these two working hand-in-hand (or should we say “shackle-to-shackle”?), you can rest assured knowing your transmission lines will operate safely under varying conditions—no more worrying about unexpected outages!

Overview of Spark Fittings

Spark fittings may not get as much attention as their more robust counterparts like anchor shackles but they play an equally important role in ensuring safety within electrical systems. These fittings serve as connectors that allow seamless integration between wires or cables while minimizing potential hazards associated with loose connections—because nobody wants sparks flying around!

Understanding spark fittings involves recognizing their design features which often include insulation properties aimed at preventing short circuits or electric shocks during operation—a must-have when discussing safety measures! In combination with sturdy elements such as what is an anchor shackle?, these components create comprehensive solutions tailored specifically for demanding environments like power plants or offshore platforms.

As we delve deeper into this topic throughout our discussion on topics such as what are three shackles in the water? or why is a shackle 27.5 m?, remember that both types of hardware work synergistically towards achieving optimal performance standards across diverse applications—from lifting heavy loads safely down at sea level all way up high on utility poles!

What is an Anchor Shackle?

Anchor shackles are essential components in various industries, particularly in construction and marine applications. They serve as a critical link in securing loads and ensuring safety during operations. Understanding what an anchor shackle is and its functionalities can greatly enhance your operational efficiency.

Definition and Purpose

So, what is a shackle anchor? An anchor shackle is a type of fastening device used to connect ropes, chains, or cables to other components. Its primary purpose is to provide a secure point for load attachment while allowing for flexibility in movement; this makes it indispensable in both construction projects and marine settings.

In essence, the anchor shackle acts like the unsung hero of heavy lifting—strong yet adaptable. It ensures that whatever you’re hoisting stays firmly attached while allowing for some degree of movement when needed. This versatility is crucial when considering the various applications of shackles in different environments.

Key Components of Anchor Shackles

An anchor shackle consists of several key components that work together to provide strength and reliability. The main parts include the body, pin, and sometimes a safety latch or clip to prevent accidental release. The body forms the primary structure that bears the load, while the pin secures it all together.

The design may vary slightly depending on whether you're using it for marine tasks or construction purposes; however, all shackles share these fundamental elements. Understanding these components will help you appreciate how they contribute to making an effective shackle anchor for your specific needs. Additionally, knowing how to properly maintain these parts can extend their lifespan significantly.

Types of Anchor Shackles

When it comes to types of anchor shackles, there are several variations tailored for different applications and environments. Common types include bow shackles and D shackles—each serving unique functions based on their structural design. For instance, bow shackles offer a wider opening which allows multiple connections at once; whereas D shackles excel at handling heavy loads with their robust structure.

But what is the difference between anchor shackles and D shackles? While both serve similar purposes in securing loads, their shapes dictate their best use cases—bow shackles are more versatile due to their wider frame compared to the more streamlined D shape designed primarily for direct load applications. Knowing which type suits your task can make all the difference between efficiency and potential mishaps.

What is a Shackle Used For?

When it comes to securing loads and facilitating connections, shackles are indispensable tools in various industries. A shackle anchor, for instance, plays a critical role in both construction and marine applications by providing a robust attachment point for cables, chains, and other rigging equipment. Understanding what a shackle is used for can help ensure safe and effective operations across multiple settings.

Applications in Construction and Marine

In construction, shackles are often employed to secure heavy loads during lifting operations. They serve as connectors between slings or chains and the load being lifted, making them essential for crane operations or hoisting systems. In marine environments, the question What is a shackle anchor? frequently arises; here, shackles secure mooring lines to buoys or vessels, ensuring stability in turbulent waters.

Marine applications also utilize shackles extensively for towing purposes. They connect tow lines to vessels or barges while providing the necessary strength to withstand harsh conditions at sea. The versatility of shackles makes them invaluable across various sectors—whether it’s lifting steel beams on a construction site or anchoring boats safely at harbor.

Benefits in Transmission Line Maintenance

Shackles play an equally important role in transmission line maintenance by securely connecting conductors to poles or towers. The ability of an anchor shackle to withstand significant tension ensures that transmission lines remain stable and functional during adverse weather conditions. Additionally, using high-quality shackles minimizes the risk of equipment failure, which can lead to costly outages.

When performing maintenance on existing power lines, crews often ask: What is a shackle used for? The answer lies in their reliability; they facilitate quick adjustments while maintaining structural integrity throughout the process. This efficiency not only enhances safety but also contributes significantly to reducing downtime—an essential aspect of keeping electricity flowing smoothly.

Safety Considerations

Using shackles comes with inherent safety considerations that must not be overlooked. Properly securing your load with an anchor shackle can prevent accidents that could result from dropped loads or equipment failure during operation. Therefore, understanding how do you safety wire an anchor shackle becomes crucial; this technique helps prevent accidental opening under stress by adding an extra layer of security.

Regular inspections are also vital when using any type of shackle—especially those exposed to harsh environmental conditions like saltwater corrosion in marine settings. Knowing what are three shackles in the water can guide users toward selecting appropriate options based on specific needs while ensuring they meet safety standards as well as operational requirements like “Why is a shackle 27.5 m?”—a common length used for specific marine applications due to its balance between flexibility and strength.

Ultimately, whether you're asking about the difference between anchor shackles and D shackles or contemplating your next project involving these tools, prioritizing safety will always lead you down the right path toward successful outcomes.

The Difference Between Anchor Shackles and D Shackles

When it comes to securing loads, understanding the difference between anchor shackles and D shackles is crucial. Both types of shackles serve important roles in various applications, but they have distinct structural features that set them apart. So, what is a shackle anchor? And how do these differences impact their use in real-world scenarios?

Structural Differences Explained

Anchor shackles are designed with a wider body and a more robust construction compared to D shackles, which feature a more streamlined shape. This design difference allows anchor shackles to handle greater loads and stresses, making them ideal for heavy-duty applications like marine operations or construction projects. In contrast, D shackles are typically lighter and easier to handle, which makes them suitable for less demanding tasks.

A key aspect of the shackle anchor's structure is its pin mechanism; while both types utilize a pin for securing loads, the pins on anchor shackles often have safety features that prevent accidental release. This added safety measure is particularly important when considering what is a shackle used for in high-stakes environments like transmission line maintenance or heavy lifting in construction sites. Understanding these structural differences can help you make informed decisions about which type of shackle best meets your needs.

Where Each Shackle Excels

Anchor shackles shine in situations where maximum strength and load-bearing capacity are required; they're commonly used in marine settings where strong connections are essential for safety. For instance, when dealing with heavy mooring lines or securing large vessels at docks, the durability of an anchor shackle becomes indispensable. On the other hand, D shackles excel in versatility and ease of use; they’re often favored for lighter applications such as rigging or connecting components in smaller machinery.

If you're wondering about practical implications—like what are three shackles in the water?—the answer lies largely within their application scope: anchor shackles provide stability while D shackles offer flexibility during operations such as towing or lifting lighter equipment. Additionally, if you've ever asked why is a shackle 27.5 m?—it’s typically related to specific requirements based on load length and working conditions rather than being tied strictly to one type of shackle over another.

Choosing the Right Shackle for Your Needs

Selecting between an anchor shackle and a D shackle boils down to understanding your unique requirements: load size, environment conditions, and safety considerations all play significant roles in this decision-making process. If you need something that can withstand extreme forces without failure—especially if you’re engaging with high-tension lines—an anchor shackle would be your go-to choice due to its robust design and enhanced safety features like how do you safety wire an anchor shackle?

Conversely, if your tasks involve lighter loads where ease of connection matters more than sheer strength—think rigging sails on a boat or attaching smaller equipment—a D shackle may be more appropriate due to its lightweight nature and user-friendly design. Ultimately, knowing what is the difference between anchor shackles and D shackles will empower you to make choices that prioritize both efficiency and safety.

Safety Measures for Using Shackles

When it comes to using shackles, safety should always be at the forefront of your mind. Whether you're dealing with an anchor shackle or any other type, knowing how to properly secure and maintain them is crucial for both efficiency and safety. Let's dive into some essential safety measures that will keep your operations smooth and secure.

How Do You Safety Wire an Anchor Shackle?

Safety wiring an anchor shackle is a straightforward process that can significantly enhance its reliability during use. Start by threading a wire through the pin of the shackle, ensuring it wraps around securely before looping back through itself. This extra layer of security prevents the pin from loosening or falling out during operation, which is especially important in high-stress environments like marine applications.

Understanding what is a shackle anchor and how to wire it correctly can save you from potential mishaps on the job site. When done right, this technique not only boosts safety but also extends the life of your equipment by preventing wear and tear on critical components. Remember, taking these small steps can make all the difference when you're out there managing heavy loads or navigating tricky waters.

Best Practices for Securing Shackles

Securing shackles properly involves more than just tightening them up; it's about understanding what is a shackle used for in various contexts and applying best practices accordingly. Always ensure that your anchor shackle is rated for the load it will bear—overloading can lead to catastrophic failures. Additionally, regularly inspect shackles for signs of wear or damage before each use; if you notice any issues, replace them immediately.

Another key practice is to avoid using damaged or corroded shackles, as they may not perform as expected under stress—this applies whether you're working with an anchor shackle or a D shackle. Also, be mindful of environmental factors like saltwater corrosion if you're operating in marine settings; consider using stainless steel options when necessary. By following these best practices, you ensure that your operations remain safe while maximizing efficiency.

Regular Maintenance Tips

Regular maintenance is essential to prolonging the life of your shackles and ensuring they function safely when needed most. Make it a habit to clean your anchor shackles after each use—especially if they've been exposed to seawater—to prevent rust buildup that could compromise their integrity over time. Additionally, lubricating moving parts will help maintain smooth operation and prevent wear caused by friction.

It's also wise to keep records of inspections and maintenance performed on your equipment; this way you’ll know exactly when each piece was last checked—especially important in industries where safety regulations are stringent! Understanding what are three shackles in the water can also help you visualize maintenance needs across multiple types; knowing their unique requirements ensures nothing slips through the cracks.

In summary, whether you're asking why is a shackle 27.5 m long or pondering what is the difference between anchor shackles and D shackles, remember that proper care leads to reliable performance every time you need them most!

Conclusion

In summary, anchor shackles are essential components in various applications, particularly in construction and marine settings. Understanding what a shackle anchor is and its purpose can significantly enhance safety and reliability in operations. As we've explored, the differences between anchor shackles and D shackles are crucial for selecting the right equipment for your needs.

Key Takeaways on Anchor Shackles

To recap, an anchor shackle is designed to connect various components securely, ensuring that loads are managed effectively. What is a shackle used for? The answer lies in its versatility; from lifting heavy materials to securing transmission lines, these devices play a pivotal role in maintaining structural integrity. Furthermore, knowing the key features of different types of shackles can help you make informed decisions when choosing equipment for specific tasks.

Choosing Spark Fittings for Quality Equipment

When it comes to selecting spark fittings, quality should never be compromised. Opting for reliable brands ensures that your shackle anchors perform optimally under pressure—after all, nobody wants to deal with the consequences of subpar gear! Additionally, understanding practical questions like Why is a shackle 27.5 m? or What are three shackles in the water? can guide you toward making better choices tailored to your operational requirements.

Final Thoughts on Safety and Reliability

Safety should always be at the forefront when dealing with any rigging or anchoring equipment. Knowing how do you safety wire an anchor shackle properly can prevent accidents and ensure peace of mind during operations. In conclusion, whether you're pondering what is an anchor shackle or exploring the nuances between different types of shackles, prioritizing quality and safety will lead to more successful outcomes.