Introduction

In the realm of engineering, PTFE bearings have emerged as a game-changer, offering exceptional performance and versatility. These innovative components, often synonymous with high-quality materials like Teflon, are designed to withstand various challenges in demanding environments. As we delve into the world of PTFE bearings, we will uncover their significance and explore why they are essential in modern engineering applications.

Understanding PTFE Bearings in Engineering

PTFE bearings, including types like PTFE bridge bearings and PTFE sleeve bearings, represent a unique blend of durability and functionality. The term PTFE bearing refers to components made from polytetrafluoroethylene (PTFE), known for its low friction properties and chemical resistance. Engineers often turn to Teflon bearing pads for their ability to perform under pressure while minimizing wear and tear.

Why High-Performance Matters

High-performance is not just a buzzword; it’s a necessity in engineering applications where reliability is paramount. The advantages offered by PTFE slide bearings include reduced friction and enhanced load-bearing capabilities, making them ideal for critical structures such as bridges and machinery. When choosing materials for projects, selecting high-performance options like PTFE bushings can lead to significant improvements in efficiency and longevity.

Applications of PTFE Bearings

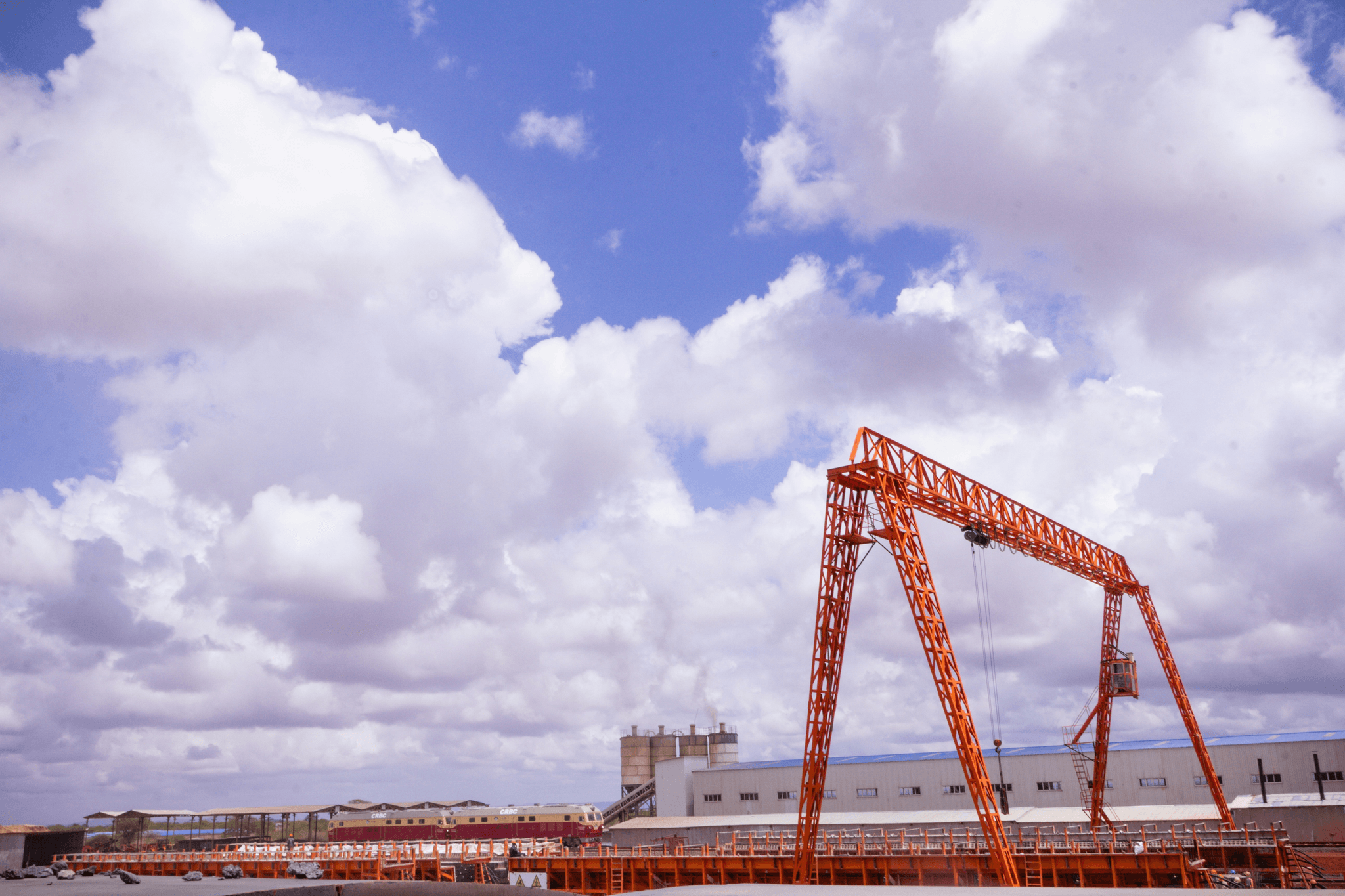

The versatility of PTFE bearings extends across numerous industries, from construction to manufacturing. For instance, engineers often utilize Teflon bearing pads in applications that require excellent chemical resistance or temperature tolerance. Whether it's a bridge needing sturdy support or machinery requiring smooth operation, the adaptability of PTFE bearings ensures they meet diverse engineering needs effectively.

Exceptional Lubrication Properties

Low Friction Coefficients

One of the standout features of PTFE bearings is their remarkably low friction coefficients, often lower than many traditional materials. This characteristic allows PTFE slide bearings to glide smoothly against other surfaces, reducing wear and tear over time. The low friction means that machinery operates more efficiently, leading to energy savings and extended equipment lifespan.

Self-Lubricating Capabilities

PTFE bushing products come with self-lubricating capabilities that eliminate the need for external lubricants in many applications. This feature not only simplifies maintenance but also enhances performance reliability in environments where traditional lubricants might fail due to contamination or high temperatures. As a result, PTFE sleeve bearings are ideal for demanding situations where consistent performance is crucial.

Impact on Performance

The exceptional lubrication properties of PTFE bearings significantly impact overall performance in engineering systems. With reduced friction and self-lubrication, these components can operate under higher loads without compromising functionality or longevity. Consequently, using Teflon bearing pads and other types of PTFE slide bearings leads to smoother operations and decreased downtime due to maintenance issues.

Chemical Resistance and Durability

PTFE bearings are renowned for their exceptional chemical resistance, making them an ideal choice in various engineering applications. Their ability to withstand harsh environments without degradation sets them apart from traditional materials. This durability ensures that PTFE bridge bearings and other types maintain performance over time, even when exposed to corrosive substances.

Resilience Against Harsh Environments

One of the standout features of PTFE bearings is their resilience against harsh environments. Whether it's extreme temperatures, aggressive chemicals, or abrasive conditions, PTFE slide bearings excel where many others fail. This resilience means engineers can confidently use Teflon bearing pads in applications ranging from chemical processing to marine environments without fear of premature failure.

Comparing Teflon Bearing Pads and Others

When comparing Teflon bearing pads with conventional materials, the differences are striking. Traditional bearing materials often succumb to corrosion or wear when exposed to chemicals; however, PTFE bushings remain unscathed due to their non-reactive nature. This comparison highlights why PTFE sleeve bearings are increasingly favored in industries that demand longevity and reliability under challenging conditions.

Long-Term Reliability

Long-term reliability is a hallmark of PTFE bearings that cannot be overlooked. Unlike other materials that may require frequent replacements due to wear or chemical damage, PTFE components like the PTFE slide bearing offer an impressive lifespan with minimal maintenance needs. As a result, engineers can focus on innovation rather than constant repairs—saving both time and resources while ensuring operational efficiency.

Temperature Tolerance

High and Low Temperature Performance

PTFE bearings exhibit remarkable resilience under extreme temperatures, which is a significant advantage over traditional bearing materials. These Teflon bearing pads can function effectively from -200°C to +260°C, ensuring that machinery operates smoothly regardless of the environment. This versatility means that engineers can confidently use PTFE sleeve bearings in applications where others might fail due to thermal stress.

Use Cases in Extreme Conditions

The unique properties of PTFE slide bearings make them ideal for use cases that involve extreme conditions, such as aerospace, automotive, and industrial machinery applications. For instance, in aerospace engineering, where components face both intense heat during operation and cold temperatures at high altitudes, PTFE bushings provide the necessary durability without compromising performance. Similarly, these materials are used in chemical processing plants where temperature fluctuations are common and reliability is paramount.

PTFE Sleeve Bearing Advantages

One of the standout features of PTFE sleeve bearings is their ability to self-lubricate under varying temperatures while maintaining low friction levels. This not only enhances their lifespan but also reduces maintenance needs significantly compared to conventional bearings. The combination of temperature tolerance and exceptional lubrication properties makes PTFE bearings a top choice for engineers looking for long-lasting solutions that can withstand the rigors of demanding environments.

Versatile Design Options

When it comes to PTFE bearings, versatility is key. The adaptability of these components allows for a wide range of applications, from bridge construction to industrial machinery. This section explores the customizable options available in PTFE bridge bearings, the varied uses of PTFE slide bearings, and innovative solutions offered by companies like Spark Fittings.

Customizable PTFE Bridge Bearings

PTFE bridge bearings are engineered to meet specific load requirements and environmental conditions, making them a preferred choice in civil engineering projects. The ability to customize these bearings ensures that they can accommodate unique design specifications while maintaining optimal performance. By utilizing Teflon bearing pads in bridge applications, engineers can enhance structural integrity while minimizing maintenance needs.

Customizing PTFE bridge bearings involves selecting the appropriate dimensions, shapes, and configurations tailored to each project’s demands. This flexibility not only improves functionality but also extends the lifespan of the structure by allowing for efficient load distribution and movement accommodation. Ultimately, customizable PTFE bridge bearings play a crucial role in modern infrastructure development.

PTFE Slide Bearings for Various Applications

PTFE slide bearings are designed to provide smooth motion across surfaces while reducing friction significantly—an essential feature in numerous applications such as machinery and automotive systems. Their low friction coefficients make them ideal for scenarios where sliding action is required without compromising on durability or performance. By incorporating PTFE sleeve bearing technology into designs, manufacturers can achieve remarkable efficiency and longevity.

The versatility of PTFE slide bearings means they can be used across various industries—from aerospace to manufacturing—where reliability is paramount. Whether it's supporting heavy loads or facilitating movement between components, these slide bearings deliver consistent results under diverse operating conditions. With their self-lubricating properties and resistance to wear, they are a top choice for engineers seeking dependable solutions.

Innovative Solutions from Spark Fittings

Spark Fittings has made waves in the industry with its innovative approach to designing PTFE bushings and other bearing solutions that cater to modern engineering challenges. Their commitment to quality means that every product is crafted with precision and attention to detail—ensuring optimal performance across all applications involving PTFE bearings. From custom designs that address specific project needs to ready-to-install options that streamline assembly processes, Spark Fittings provides a comprehensive portfolio of products.

Their offerings include advanced Teflon bearing pads designed specifically for high-load scenarios where traditional materials may fail under pressure or adverse conditions. Additionally, Spark Fittings continuously seeks new ways to enhance the functionality of their products through research and development initiatives aimed at improving thermal conductivity and chemical resistance in their designs. As industries evolve, so do their innovative solutions—making them leaders in the field of versatile design options for PTFE components.

Cost-Effectiveness and Maintenance

When it comes to engineering solutions, cost-effectiveness and maintenance are crucial factors that can make or break a project. PTFE bearings, including PTFE bridge bearings and PTFE sleeve bearings, offer significant advantages in these areas. Their long lifespan and low maintenance requirements translate into reduced replacement costs, making them an attractive option for engineers looking to maximize value.

Long Lifespan Reducing Replacement Costs

One of the standout features of PTFE bearings is their impressive longevity. Unlike traditional materials that may wear out quickly under stress, Teflon bearing pads are designed to withstand the rigors of various applications without significant degradation over time. This durability means fewer replacements are needed, allowing companies to save on both material costs and labor associated with frequent replacements.

Moreover, the extended lifespan of PTFE slide bearings contributes to overall project efficiency. By minimizing downtime due to bearing failures or replacements, projects can stay on schedule and within budget constraints. In a world where every penny counts, investing in high-quality PTFE bushings is a smart choice that pays off in the long run.

Maintenance-Free Features of PTFE Bushings

PTFE bushings are particularly appealing because they often require little to no maintenance throughout their operational life. The self-lubricating properties inherent in these materials mean that they can function effectively without regular intervention from maintenance crews. This not only saves time but also reduces labor costs associated with routine upkeep.

Additionally, the maintenance-free nature of PTFE sleeve bearings allows engineers to allocate resources more efficiently elsewhere in their projects. With fewer concerns about wear and tear or lubrication schedules, teams can focus on innovation rather than upkeep—an invaluable benefit in fast-paced engineering environments where agility is key. As a result, using Teflon bearing pads can lead to smoother operations across various applications.

Economic Benefits in Engineering Projects

The economic advantages of integrating PTFE bearings into engineering projects extend beyond mere savings on replacement parts and labor costs; they also encompass improved performance metrics over time. With their ability to operate effectively under extreme conditions while maintaining low friction coefficients, these bearings enhance overall system efficiency—a factor that translates directly into financial benefits for organizations.

Furthermore, as industries increasingly prioritize sustainability alongside cost-effectiveness, the durability and longevity of PTFE bridge bearings align perfectly with these goals. Fewer resources spent on replacements mean less waste generated over time—an essential consideration for environmentally conscious companies looking to boost their green credentials while still achieving stellar results with products like PTFE slide bearings.

In summary, choosing high-quality PTFE bushings not only secures long-term reliability but also fosters economic growth by minimizing unnecessary expenditures across various engineering endeavors.

Conclusion

In wrapping up our exploration of PTFE bearings, it's clear that these components are not just ordinary parts but essential elements in high-performance engineering. From their exceptional lubrication properties to their remarkable durability in extreme conditions, PTFE bearings—be it PTFE bridge bearings or Teflon bearing pads—offer unparalleled advantages across various applications. Understanding the meaning and functionality of PTFE sleeve bearings and slide bearings can significantly influence the efficiency and longevity of engineering projects.

Key Takeaways on PTFE Bearings

PTFE bearings stand out for their low friction coefficients, making them ideal for applications where smooth movement is crucial. Their self-lubricating capabilities further enhance performance by reducing wear and tear, ensuring a longer lifespan compared to traditional alternatives like metal or rubber bearings. Additionally, features such as chemical resistance and temperature tolerance solidify the role of PTFE bushings as reliable choices in demanding environments.

The Importance of Choosing Quality

When it comes to selecting PTFE bearings, quality should never be compromised. High-quality PTFE bridge bearings or Teflon bearing pads not only provide better performance but also contribute to overall project cost-effectiveness by minimizing maintenance needs and replacements over time. Investing in reputable manufacturers ensures that you receive products designed with precision, ultimately leading to enhanced operational efficiency.

Future Trends in PTFE Bearing Technology

The future of PTFE bearing technology looks promising with ongoing innovations aimed at enhancing performance even further. Developments in materials science may lead to new formulations of PTFE that offer improved resistance against wear while maintaining low friction characteristics—think next-gen PTFE sleeve bearing solutions! As industries continue to demand more from their components, we can expect a surge in customizable options for PTFE slide bearings tailored to specific applications, ensuring that engineers have access to cutting-edge solutions.