Introduction

In the world of manufacturing and construction, formed wire products play a crucial role in various applications, from electrical components to structural supports. Understanding formed wire products not only helps you appreciate their versatility but also the intricate processes involved in their creation. As industries continue to evolve, these products have become indispensable, driving innovation and efficiency.

Understanding Formed Wire Products

Formed wire products are crafted from metal wire that is bent or shaped into specific configurations to meet diverse needs across multiple sectors. These products can range from simple hooks to complex assemblies used in high-tech applications—showing just how versatile formed wire can be. With advancements in technology, the precision and quality of these formed wire items have reached new heights, allowing for even more innovative uses.

The Importance of Wire Product Suppliers

Wire product suppliers are the backbone of any industry relying on formed wire solutions; they provide essential materials that enable companies to function effectively. A reliable supplier ensures that businesses receive high-quality formed wire products and timely deliveries, which ultimately impacts productivity and profitability. Choosing the right supplier can make all the difference when it comes to sourcing durable and efficient Wire Products & Formed Wire.

Innovations in Formed Wire Technology

The landscape of formed wire technology is rapidly changing thanks to continuous innovations aimed at improving performance and sustainability. From advanced manufacturing techniques that enhance precision to new materials that increase durability, these innovations are reshaping how we think about formed wire products. Additionally, integrating conductor accessories into these systems enhances functionality, ensuring that these products meet modern demands while paving the way for future advancements.

Overview of Formed Wire Products

Formed wire products are essential components in various industries, crafted through bending and shaping wire into specific forms to meet diverse applications. These products can range from simple hooks and brackets to complex assemblies used in more intricate designs. Their versatility makes them a go-to choice for manufacturers looking for reliable solutions.

Definition and Applications

Formed wire refers to wire that has been manipulated into desired shapes using specialized machinery or manual techniques, resulting in products tailored for specific uses. Applications of formed wire products are vast, including items like shelving supports, electrical fixtures, and even decorative elements in architecture. As an integral part of many systems, these products often serve functional roles while also contributing to aesthetic appeal.

Key Industries Utilizing Formed Wire

Several key industries rely heavily on formed wire products to enhance their operations. The construction sector uses these items for structural support and framework, while the electrical industry incorporates them as vital components alongside conductor accessories for effective connectivity. Additionally, the automotive and aerospace sectors utilize formed wire in manufacturing processes where precision and reliability are paramount.

Benefits of Using Formed Wire

The benefits of using formed wire products are numerous, making them a preferred choice among manufacturers. Firstly, their customization options allow businesses to create solutions that perfectly fit their needs without compromising quality or performance. Furthermore, these products offer durability and strength while often being lightweight—an ideal combination for many applications across various industries.

Top Wire Product Suppliers

Leading Suppliers in the Market

The landscape of wire product suppliers features several key players known for their exceptional formed wire products. Companies like WireCo WorldGroup, Southwire, and Spark Fittings have established themselves as leaders due to their commitment to quality and innovation in wire manufacturing. These suppliers not only provide a wide range of formed wire but also excel in customer service, making them go-to choices for many industries.

In addition to these giants, there are niche suppliers who specialize in specific applications of formed wire products such as custom fittings or conductor accessories. These specialized companies often provide tailored solutions that larger suppliers may overlook. Whether you're looking for bulk orders or bespoke designs, knowing the leading suppliers will help you identify where to source your formed wire needs.

What Sets Spark Fittings Apart

Spark Fittings distinguishes itself from other wire product suppliers through its unwavering focus on quality and precision engineering in its formed wire products. Their commitment to using high-grade materials ensures that every piece meets stringent industry standards while offering exceptional durability and performance. Additionally, Spark Fittings prides itself on its innovative design capabilities, allowing customers access to customized solutions that cater specifically to their project requirements.

Another factor that sets Spark Fittings apart is their robust customer support system which guides clients through every step of the purchasing process—from selection to installation of conductor accessories associated with their formed wire products. This level of service fosters long-term relationships with clients who appreciate personalized attention and expertise. Ultimately, it's this combination of quality, customization options, and excellent service that makes Spark Fittings a standout choice among wire product suppliers.

How to Choose the Right Supplier

Selecting the right supplier for your formed wire needs involves careful consideration of various factors beyond just price tags or catalogs full of options. First off, evaluate the supplier’s reputation within the industry; testimonials from previous clients can offer invaluable insights into their reliability and quality control measures regarding formed wire products. Additionally, consider whether they offer customization options if your project requires unique specifications or designs.

Another critical aspect is assessing how well potential suppliers understand your specific industry needs—especially when it comes to conductor accessories that might be vital for your application’s success. A knowledgeable supplier will not only provide high-quality formed wires but also advise on best practices related to installation and maintenance based on real-world applications they’ve encountered before. Finally, ensure they have efficient logistics capabilities so you can receive your orders promptly without unnecessary delays.

Types of Formed Wire and Their Uses

When it comes to formed wire products, the variety available is both impressive and essential across various industries. From simple shapes to intricate designs, formed wire can cater to a multitude of applications. Understanding the common types of formed wire will help in recognizing their versatility and the role they play in enhancing efficiency.

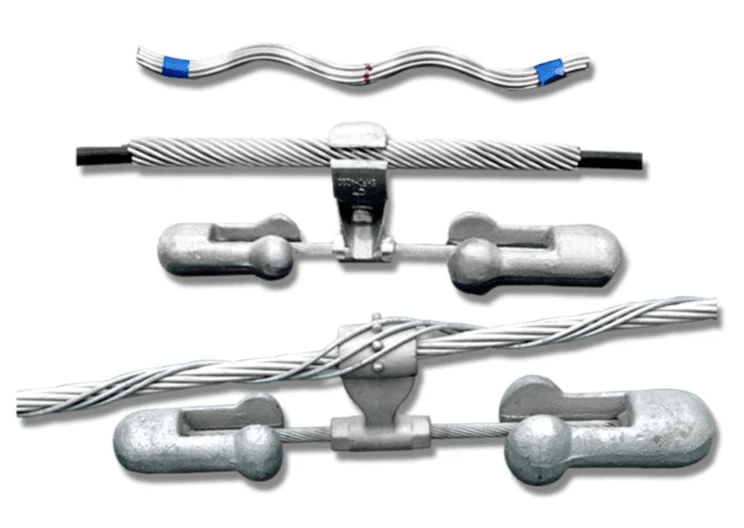

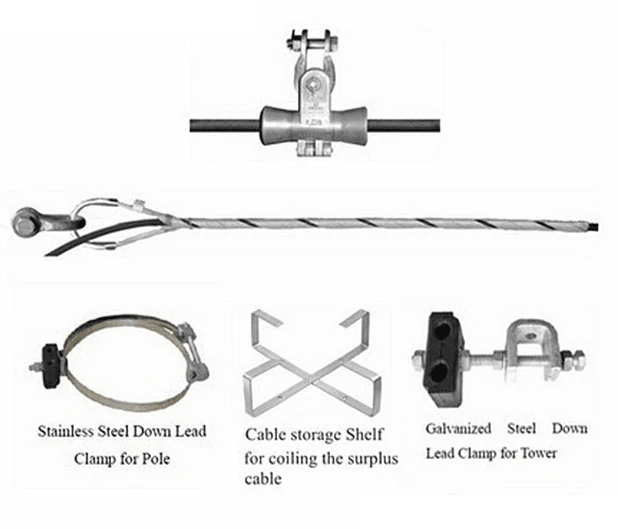

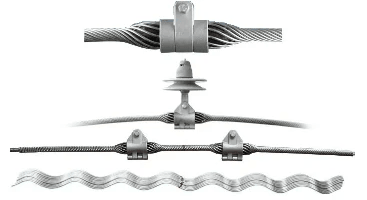

Common Types of Formed Wire

Formed wire products come in several common types, each designed for specific uses. Some popular varieties include hooks, brackets, cages, and clips made from steel or stainless steel materials. These formed wires are often utilized due to their strength and adaptability, making them excellent choices for various projects across different sectors.

Notably, wire forms can be produced in numerous gauges and dimensions to meet specific requirements. For instance, lighter gauge wires may be used for delicate applications like display stands or hangers, while heavier gauges are ideal for structural support in construction settings. Wire product suppliers often offer these standard types along with custom solutions tailored to client specifications.

Applications in Electrical and Construction Fields

The applications of formed wire products are vast, particularly within electrical and construction fields where reliability is paramount. In electrical settings, formed wires serve critical functions as conductor accessories that ensure connections remain secure and efficient during operation. This includes everything from cable supports to connectors that enhance overall system integrity.

In construction, formed wire finds its place as reinforcing elements within concrete structures or as part of scaffolding systems that provide safety during building processes. The strength and flexibility of these products make them indispensable in creating robust frameworks that withstand environmental stresses over time. Ultimately, using high-quality formed wire not only promotes safety but also enhances overall project durability.

Customization Options for Formed Wire

Customization options for formed wire are nearly limitless—allowing businesses to tailor solutions precisely according to their needs. Many wire product suppliers offer bespoke services where clients can specify dimensions, materials, finishes, and even unique designs based on project requirements or aesthetic preferences. This level of personalization ensures that every application is met with the highest standards.

Moreover, customization extends beyond mere size adjustments; it also encompasses functional enhancements such as corrosion resistance treatments or specialized coatings that improve longevity in harsh environments. By utilizing customized formed wires alongside standard offerings from reliable suppliers, companies can optimize performance while maintaining cost-effectiveness across their operations.

In conclusion, understanding the types of formed wire available is crucial when selecting suitable options for your projects—whether it's electrical installations or construction endeavors needing robust reinforcement solutions.

The Role of Conductor Accessories

Conductor accessories play a vital role in the performance and reliability of formed wire products. These components ensure that electrical connections are secure, efficient, and safe, making them indispensable in various applications. Understanding the significance of conductor accessories is essential for anyone involved in the wire products industry.

Importance of Conductor Accessories

Conductor accessories serve as the unsung heroes in the world of formed wire products, enhancing safety and functionality. They provide crucial support to wires by minimizing energy loss, preventing short circuits, and ensuring longevity under various conditions. Without these essential components, even the best wire products would struggle to deliver optimal performance.

How They Enhance Formed Wire Products

The integration of conductor accessories with formed wire products can significantly elevate their effectiveness. These accessories not only improve connectivity but also enhance mechanical strength and environmental resistance. By utilizing high-quality conductor accessories from trusted wire product suppliers, manufacturers can maximize the benefits of their formed wire offerings.

Real-World Applications and Benefits

In real-world scenarios, conductor accessories are found everywhere—from residential wiring systems to large industrial setups utilizing formed wire products. Their ability to reduce maintenance costs while increasing system reliability makes them invaluable across industries like construction and electronics. By investing in quality conductor accessories alongside formed wire solutions, businesses can ensure seamless operations and improved safety standards.

Emerging Trends in Formed Wire Products

The landscape of formed wire products is evolving at a rapid pace, driven by technological advances and sustainability efforts. As industries increasingly rely on innovative solutions, wire product suppliers are stepping up to meet the demand for high-quality, efficient products. This section will delve into the latest trends shaping the future of formed wire.

Technological Advances in Manufacturing

Manufacturing processes for formed wire products have seen significant upgrades thanks to automation and advanced materials. Cutting-edge machinery now allows for precision engineering, resulting in formed wire that meets stringent industry standards while enhancing performance. Additionally, innovations like 3D printing and robotic assembly are streamlining production, making it easier for wire product suppliers to offer customized solutions tailored to specific needs.

These technological advances not only improve efficiency but also reduce waste during manufacturing. With better control over material usage, suppliers can minimize excess scrap and optimize resource allocation. Consequently, businesses that utilize these advanced formed wire products benefit from improved reliability and cost-effectiveness.

Moreover, the integration of smart technologies is paving the way for enhanced quality control in the production of formed wire. Real-time monitoring systems can detect issues early on, ensuring that every piece meets quality benchmarks before it reaches customers. As a result, industries relying on conductor accessories can trust that their components will perform consistently under various conditions.

Sustainability Practices in Wire Production

Sustainability is no longer just a buzzword; it's a fundamental principle guiding many manufacturers of formed wire products today. Wire product suppliers are increasingly adopting eco-friendly practices by using recyclable materials and implementing energy-efficient processes throughout their operations. This shift not only reduces environmental impact but also appeals to consumers who prioritize sustainable sourcing.

Furthermore, companies are exploring alternative materials that offer similar performance characteristics while being less harmful to the environment. For instance, some suppliers are incorporating bioplastics into their formed wire designs or utilizing recycled metals to create robust conductor accessories without compromising quality or durability. By embracing these practices, businesses can contribute positively to global sustainability efforts while still meeting customer demands.

As regulations around environmental responsibility tighten worldwide, manufacturers focusing on sustainable practices will likely gain a competitive edge in the market for formed wire products. Customers increasingly favor companies committed to reducing their carbon footprint—making it essential for suppliers to adapt swiftly or risk falling behind.

Future Prospects for Formed Wire Innovations

Looking ahead, the future of formed wire products seems bright with endless possibilities fueled by ongoing innovations and market demands. The rise of smart cities and infrastructure projects necessitates more sophisticated conductor accessories capable of supporting advanced technologies like IoT devices and renewable energy systems. As industries evolve toward greater connectivity and automation, so too must the wires that support them.

Additionally, research into new alloys and composites promises even stronger yet lighter options for formed wires—ideal for applications ranging from aerospace to telecommunications where weight savings translate directly into performance gains or cost reductions over time. Suppliers who stay ahead of these trends will undoubtedly position themselves as leaders within this dynamic sector.

Ultimately, as we embrace an era defined by rapid change in technology and sustainability considerations alike, collaboration between manufacturers and end-users becomes crucial in driving innovation forward within the realm of formed wire products. By working together towards shared goals—be it enhanced functionality or reduced environmental impact—the industry can ensure its continued growth well into the future.

Conclusion

In summary, formed wire products offer a versatile and efficient solution for various industries, enhancing functionality and durability in applications ranging from construction to electrical systems. The advantages of using formed wire are evident in their ability to meet specific needs while providing robust support through innovative designs. As we’ve explored, the combination of quality materials and skilled manufacturing processes positions formed wire products as essential components in modern engineering.

Recap of Formed Wire Product Benefits

The benefits of formed wire products are manifold, including their adaptability to different applications and their strength-to-weight ratio that makes them ideal for a variety of uses. These products not only streamline production processes but also ensure safety and reliability in critical environments such as construction sites or electrical installations. Moreover, the availability of customization options allows businesses to tailor formed wire solutions precisely to their specifications, making them an invaluable resource across multiple sectors.

Importance of Quality Wire Product Suppliers

A reputable supplier ensures that all formed wire meets industry standards while also offering insights into innovations that can enhance performance further. By partnering with established suppliers known for their commitment to excellence, businesses can secure high-quality conductor accessories that complement their formed wire needs effectively.

Looking Ahead: The Future of Formed Wire

The future of formed wire is bright, with emerging trends indicating advancements in technology and sustainability practices shaping its evolution. Innovations such as smart manufacturing techniques are poised to revolutionize how these products are made, ensuring greater efficiency and lower environmental impact. As industries continue to demand more from formed wire products and conductor accessories alike, we can expect ongoing developments that will push the boundaries of what’s possible in this dynamic field.