Introduction

In the world of electrical systems, conductor fittings play a crucial role in ensuring safe and efficient electricity flow. These fittings are designed to connect different types of conductors, which leads us to ponder: what are 3 types of conductors? Understanding these components not only enhances our knowledge but also emphasizes the importance of reliability and durability in electrical installations.

A malfunctioning fitting can lead to outages or even hazardous situations, making it essential for engineers and electricians to prioritize high-quality materials and designs. This focus on reliability extends to various aspects of conductor accessories, which help maintain optimal functionality throughout their lifespan.

As we delve deeper into the realm of conductor accessories, we will explore various elements such as insulated conductor fittings and their benefits. Knowing what does a conductor mean in wiring is essential for understanding how these accessories work together seamlessly. Additionally, insights into what is conductor sizing will equip you with the knowledge needed to make informed decisions regarding electrical installations. By examining these topics, we aim to provide a comprehensive overview that underscores the significance of proper installation practices and quality materials in creating safe electrical environments.

What Are Conductor Fittings?

Conductor fittings are essential components in electrical systems, designed to connect and secure conductors together. They ensure that the flow of electricity is reliable and efficient, minimizing the risk of failures or accidents. Without these fittings, the integrity of electrical connections would be compromised, leading to potential hazards.

Definition and Purpose

At their core, conductor fittings serve a straightforward purpose: they hold conductors in place while ensuring optimal conductivity and safety. These fittings can include connectors, terminals, splices, and other accessories that facilitate the seamless transfer of electrical energy. The importance of these components cannot be overstated; they provide stability and reliability in an array of applications.

Types of Conductor Fittings

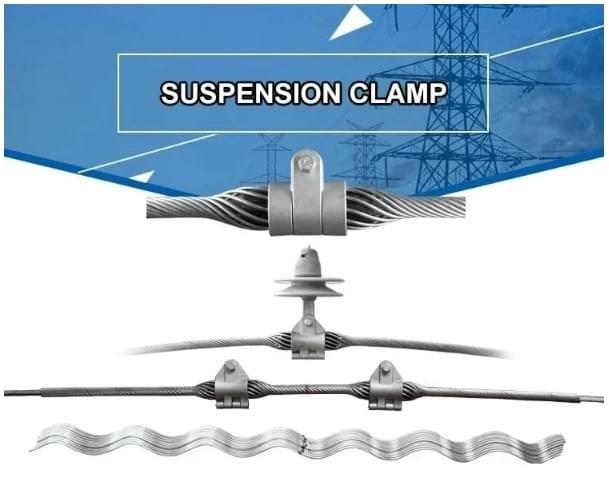

There are several types of conductor fittings available on the market today, each designed for specific applications and conductor types. Some common varieties include compression connectors for aluminum conductors, which are ideal for high-voltage applications; mechanical connectors that allow for easy assembly without special tools; and insulated conductor fittings that enhance safety by preventing accidental contact with live wires. Understanding these different types helps ensure you select the right fitting for your project.

Applications in Electrical Systems

Conductor fittings find their place in various electrical systems ranging from residential wiring to large industrial setups. They are crucial in power distribution networks where reliability is paramount; without proper fittings, even minor issues can lead to significant outages or safety risks. Additionally, insulated conductor fittings play an important role in outdoor installations where exposure to weather elements could otherwise compromise connections.

What Are 3 Types of Conductors?

When discussing conductor fittings, it's essential to understand the different types of conductors available in electrical systems. The choice of conductor can significantly impact the efficiency, reliability, and safety of electrical installations. Here, we will explore three primary types of conductors: copper, aluminum, and composite conductors.

Copper Conductors

Copper conductors are renowned for their excellent conductivity and durability, making them a popular choice in many electrical applications. They have a lower resistance compared to other materials, which allows for efficient electricity flow—crucial when considering what does conductor mean in wiring. Additionally, copper's natural flexibility makes it easier to work with during installation and integration with various conductor fittings.

However, the cost of copper is typically higher than that of aluminum or composite options. This might lead some engineers to opt for alternatives depending on budget constraints and specific project requirements. Regardless, when it comes to reliability and performance in demanding environments, copper conductors often take the crown.

Aluminum Conductors

Aluminum conductors are another widely used option in electrical systems due to their lightweight nature and cost-effectiveness. While they have a slightly higher resistance than copper conductors, advancements in technology have improved their efficiency significantly—making them suitable for overhead power lines where weight is a crucial factor. Understanding what is conductor sizing becomes vital here because proper sizing ensures that aluminum can handle the necessary current without overheating.

Moreover, aluminum's resistance to corrosion makes it an excellent choice for outdoor applications where exposure to elements can be an issue. When paired with high-quality insulated conductor fittings, these conductors can provide reliable performance while keeping installation costs manageable.

Composite Conductors

Composite conductors represent an innovative approach by combining materials like aluminum and carbon fibers or other polymers to enhance performance characteristics further. These advanced materials aim to improve conductivity while reducing weight—addressing some limitations found in traditional aluminum or copper setups. As we dive into what is a conductor line? it's essential to note that composite options often find use in specialized applications such as wind turbine cables or high-voltage transmission lines.

The unique properties of composite conductors allow them not only to be lightweight but also more resistant to environmental factors like temperature fluctuations and electromagnetic interference (EMI). In terms of durability and versatility within various conductor accessories settings, composites are becoming increasingly popular among engineers seeking cutting-edge solutions.

What Does Conductor Mean in Wiring?

When we talk about wiring, the term 'conductor' refers to materials that allow electricity to flow through them. Conductors are essential components in electrical systems, facilitating the movement of electrical current from one point to another. Understanding what conductors mean in wiring is crucial for ensuring safety and efficiency in any electrical installation.

Role of Conductors in Electricity Flow

Conductors play a pivotal role in electricity flow by providing a pathway for electrons to travel. Without these conductive materials, electrical circuits would be incomplete, rendering devices and systems non-functional. The efficiency of conductor fittings directly impacts how effectively electricity can be transmitted, making their selection critical for any project involving wiring.

Importance of Insulation

Insulation is just as vital as the conductors themselves because it prevents unwanted current leakage and protects against short circuits. Proper insulation around conductor fittings ensures that the electrical current remains confined within the conductor, reducing risks associated with electric shocks or fires. In addition, insulated conductor fittings help maintain system integrity by minimizing energy loss during transmission.

Common Wiring Configurations

Wiring configurations can vary widely based on application and design requirements but often include series and parallel arrangements among others. Each configuration has its own set of advantages—series circuits are simpler but may not provide consistent voltage across all components, while parallel circuits allow for independent operation of devices connected to them. Understanding these configurations helps when selecting appropriate conductor fittings and sizing conductors based on specific needs.

What Is Conductor Sizing?

Conductor sizing is a critical aspect of electrical systems that ensures safe and efficient operation. It involves determining the appropriate size of conductors to handle the expected electrical load while minimizing energy loss and preventing overheating. Understanding how conductor fittings play into this process is essential for anyone working with electrical installations.

Factors Influencing Sizing

Several factors influence the sizing of conductors, including the type of conductor used—whether it’s copper, aluminum, or composite—as discussed in What are 3 types of conductors?. The current-carrying capacity, or ampacity, is another crucial factor; it dictates how much current a conductor can handle safely without risk of damage. Additionally, environmental conditions such as temperature and installation methods also play significant roles in determining proper conductor sizing.

Calculating Current Capacity

Calculating current capacity involves understanding both the load requirements and the properties of different conductors. For instance, when exploring What does conductor mean in wiring?, it's important to recognize that each type has specific characteristics that affect its performance under load. Using formulas based on these characteristics helps determine how much current a particular size can carry safely—ensuring reliability and durability in conjunction with high-quality conductor fittings.

Importance of Proper Sizing

Proper sizing is paramount for several reasons: it enhances system efficiency, reduces energy costs, and prevents potential hazards like overheating or electrical fires. When using insulated conductor fittings, ensuring that they match the correctly sized conductors can greatly improve overall safety and performance in an electrical system. Ultimately, investing time in understanding what is involved in What is conductor sizing? pays dividends by extending equipment life and maintaining system integrity.

What Is a Conductor Line?

When we talk about conductor lines, we're diving into the essential pathways that facilitate the flow of electricity. A conductor line is essentially a system of conductors that transmit electrical power from one location to another, often forming the backbone of electrical infrastructure. These lines are crucial for ensuring reliable energy distribution, making them integral to both residential and commercial electrical systems.

Definition and Functions

A conductor line consists of multiple conductors, typically insulated or bundled together, designed to carry electric current efficiently over distances. The primary function of these lines is to transport electricity from power generation sources—like substations—to end-users such as homes and businesses. Additionally, conductor lines can serve various purposes in communication systems, where they help transmit signals alongside power.

Differences Between Conductor Lines and Cables

While both conductor lines and cables are used in electrical systems, they have distinct characteristics that set them apart. Conductor lines usually refer to overhead systems or bare conductors that are exposed to environmental conditions, whereas cables are generally insulated and used for underground or indoor installations. This difference in insulation affects their applications; for instance, insulated conductor fittings are vital for protecting cables from damage while ensuring safety.

Real-World Examples

In practical terms, consider the overhead power lines you see strung between utility poles—these are classic examples of conductor lines at work. They transport high-voltage electricity across vast distances before it gets stepped down for local use through transformer stations. Similarly, in urban settings where underground installations dominate, you might find insulated cables running beneath streets—both serving the same purpose but tailored to different environments.

Exploring Insulated Conductor Fittings

Insulated conductor fittings play a crucial role in enhancing the safety and efficiency of electrical systems. These fittings are designed to protect conductors from environmental factors, mechanical stress, and electrical faults. By incorporating insulation, they ensure that the flow of electricity remains uninterrupted while minimizing potential hazards.

Benefits of Insulated Fittings

One of the primary benefits of insulated conductor fittings is their ability to provide an additional layer of protection against short circuits and electrical fires. This insulation not only safeguards the conductors but also enhances overall system reliability, making it a vital component in various applications. Furthermore, insulated fittings contribute to improved energy efficiency by reducing power loss during transmission, which is particularly important when considering what are 3 types of conductors used in different settings.

Another advantage is that these fittings are often designed for easy installation and maintenance, allowing technicians to work with them without extensive training. This ease-of-use factor translates into reduced downtime for electrical systems, which is a significant benefit for both residential and commercial applications. With proper conductor sizing and selection of insulated fittings, users can ensure optimal performance across their wiring setups.

Leading Manufacturers like Spark Fittings

When it comes to high-quality insulated conductor fittings, Spark Fittings stands out as a leading manufacturer in the industry. Their products are known for durability and reliability, providing robust solutions that meet stringent safety standards. Spark Fittings offers a wide range of options tailored to various applications—whether you're dealing with copper or aluminum conductors or exploring composite conductors.

In addition to offering an extensive product line, Spark Fittings emphasizes innovation by incorporating advanced technologies into their designs. This commitment ensures that their insulated conductor fittings not only meet current needs but also anticipate future trends in electrical systems. As industries increasingly focus on sustainability and energy efficiency, manufacturers like Spark Fittings continue to lead the way with cutting-edge solutions.

Installation Best Practices

Installing insulated conductor fittings requires careful attention to detail to maximize their effectiveness and longevity. First and foremost, it's essential to ensure that you have selected the right size fitting based on what is conductor sizing principles; using improperly sized components can lead to serious issues down the line. Additionally, following manufacturer guidelines during installation helps maintain warranty coverage while ensuring compliance with local codes.

Proper handling during installation cannot be overlooked either; avoid damaging insulation materials as this could compromise safety features inherent in these products. It's also wise to perform regular inspections post-installation—checking for signs of wear or damage will help catch any potential problems early on before they escalate into major failures affecting your wiring systems or even leading back into discussions about what does conductor mean in wiring contexts.

By adhering strictly to best practices during installation and maintenance phases while utilizing reliable products from reputable manufacturers like Spark Fittings, you can significantly enhance your system’s performance through effective use of insulated conductor fittings.

Conclusion

In wrapping up our exploration of conductor fittings and their significance in electrical systems, it's clear that understanding these components is crucial for any reliable installation. From the variety of conductor types, including copper, aluminum, and composite conductors, to the essential role they play in wiring, every aspect contributes to a robust electrical infrastructure. Moreover, with advancements in conductor accessories and insulated conductor fittings, the future looks promising for enhancing safety and efficiency in electrical applications.

Key Takeaways on Conductor Fittings

Conductor fittings are vital connectors that ensure the seamless operation of electrical systems. They come in various forms tailored to different types of conductors—whether it’s copper or aluminum—each serving specific purposes within wiring configurations. Understanding what does conductor mean in wiring can help clarify how these fittings support effective electricity flow while maintaining safety standards.

Future Trends in Conductor Accessories

The landscape of conductor accessories is evolving rapidly with innovations aimed at improving performance and reliability. Future trends indicate a growing emphasis on smart technologies integrated into insulated conductor fittings that enhance monitoring capabilities and energy efficiency. Additionally, as industries push for sustainability, we may see a rise in composite conductors designed for greater durability and reduced environmental impact.

Ensuring Quality with Reliable Solutions

To ensure quality when selecting conductor fittings and other accessories, it’s essential to prioritize reputable manufacturers known for their commitment to durability and performance. Understanding what is conductor sizing can aid professionals in making informed choices about which products are best suited for specific applications based on current capacity needs. By investing time into understanding both the technical aspects and practical applications of these components, one can achieve reliable solutions that stand the test of time.