Introduction

In the world of industrial processes, finding reliable sandblasting equipment suppliers can feel like searching for a needle in a haystack. The right sandblasting equipment is crucial for achieving optimal performance and safety, particularly in demanding environments where precision matters. Whether you're looking to clean surfaces, prepare materials for coatings, or remove contaminants, the quality of your sandblast equipment can significantly impact your results.

Finding Reliable Sandblasting Equipment Suppliers

Navigating the landscape of sandblasting equipment suppliers requires diligence and discernment. With numerous options available, it’s essential to identify those who not only offer industrial sandblasting equipment but also stand out in terms of reliability and service. Start by researching potential manufacturers online, checking their credentials, and reading customer reviews to ensure they meet industry standards.

Why Quality Matters in Sandblasting Equipment

Quality should never be an afterthought when selecting sandblast equipment; it is the backbone of efficiency and safety in any operation. High-quality sandblasting equipment ensures consistent results while minimizing downtime due to malfunctions or repairs. When you invest in superior products from reputable Sand Blasting Equipment Manufacturers, you’re not just buying tools; you’re investing in the long-term success of your projects.

What to Look for in a Manufacturer

When evaluating potential manufacturers for your sandblasting needs, consider several key factors that signal reliability and expertise. Look for companies that have established themselves as leaders within the industry—those with a proven track record of delivering durable and efficient products. Additionally, ensure that they offer comprehensive support services such as warranties and after-sales assistance to safeguard your investment.

Understanding Sandblasting Technology

The Basics of Sandblasting

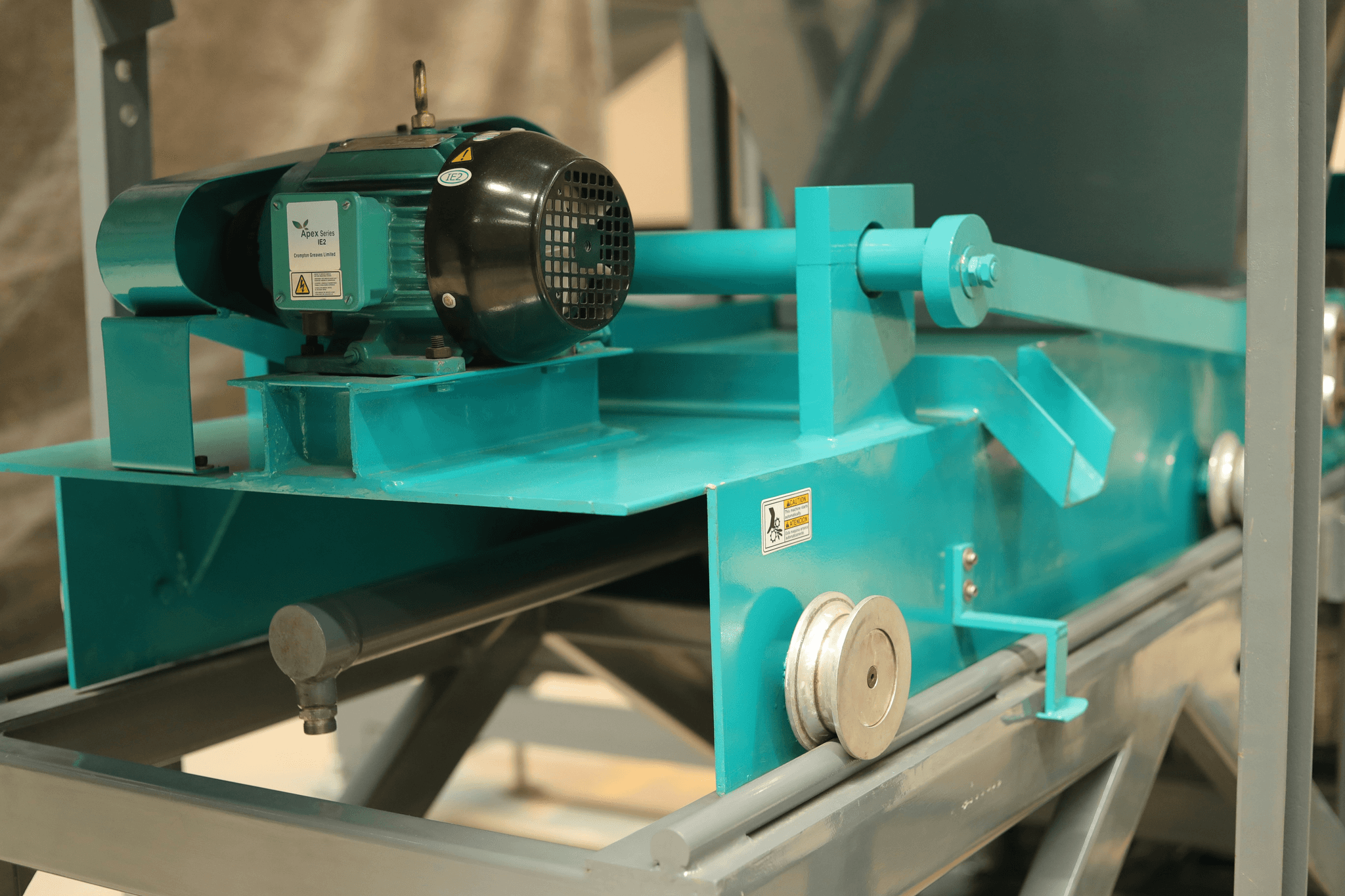

At its core, sandblasting is a method that uses compressed air or water to propel abrasive particles against surfaces. This technique not only removes rust and paint but also prepares surfaces for painting or coating by creating a rough texture. Knowing how this process works helps you appreciate the importance of selecting durable and efficient industrial sandblasting equipment for your projects.

The effectiveness of sandblasting relies on several factors, including the type of abrasive material used, the pressure applied, and the distance between the nozzle and surface. Each variable can significantly influence the outcome, making it essential to understand how different types of sandblast equipment work together as a cohesive unit. With this knowledge in hand, you can better evaluate your options among various sandblast equipment manufacturers.

Types of Sandblasting Equipment

There are several types of sandblasting equipment available on the market today, each designed for specific applications and environments. From portable units suitable for small jobs to large industrial systems capable of handling extensive tasks, understanding these variations will guide your selection process when dealing with reputable sandblasting equipment suppliers.

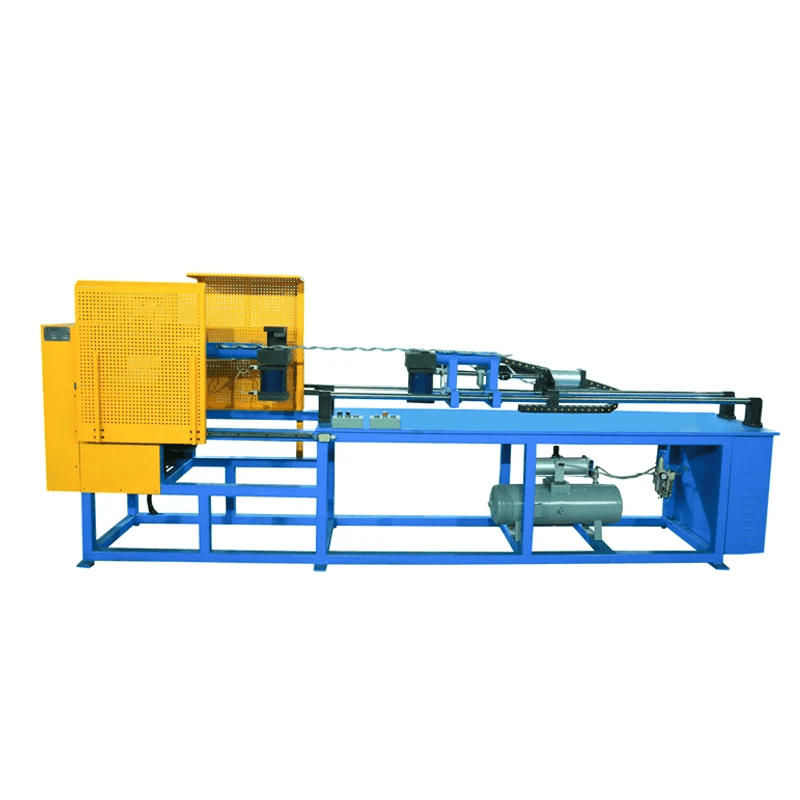

Common types include siphon feed systems that draw abrasive material from a container using suction and pressure feed systems that deliver consistent flow through pressurized tanks. Additionally, there are wet blasting systems that mix water with abrasives to minimize dust while enhancing surface treatment effectiveness. Knowing these differences will help you choose between options offered by various industrial sandblasting equipment providers based on your unique needs.

Applications of Sandblasting

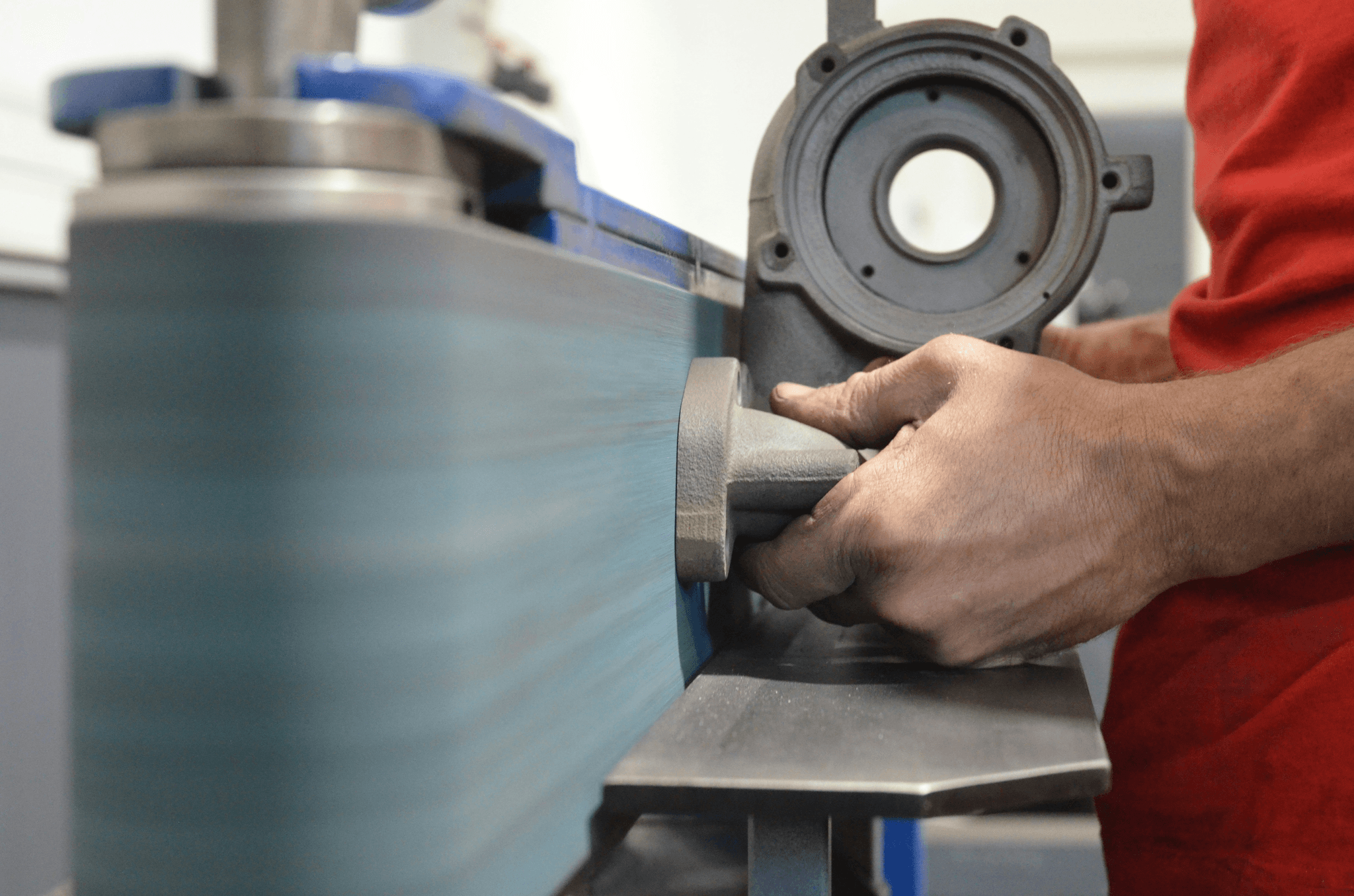

Sandblasting finds its way into numerous industries due to its versatility in applications ranging from automotive refinishing to restoration projects in construction and manufacturing sectors. It is widely used for cleaning metal surfaces before welding or painting as well as preparing wood surfaces for staining or sealing—each requiring specific types of sand blasting equipment tailored for optimal results.

Moreover, creative industries utilize decorative blasting techniques on glass or stone surfaces to create intricate designs or textures that enhance aesthetic appeal. As such, understanding these applications allows businesses to select appropriate tools from trusted manufacturers while ensuring they meet industry standards and performance expectations set forth by leading sandblast equipment manufacturers.

Top Sandblasting Equipment Manufacturers

Leading Brands in the Industry

Several brands have established themselves as leaders among sandblasting equipment suppliers, renowned for their quality and reliability. Companies like Graco, Axxiom Manufacturing, and Clemco Industries consistently rank high due to their innovative designs and robust product lines. These manufacturers not only provide traditional sand blasting equipment but also specialize in advanced systems that enhance efficiency and safety.

In addition to these giants, there are niche players that focus on specific applications or types of industrial sandblasting equipment. For example, some brands may excel in portable systems while others dominate in larger fixed installations. This diversity means that regardless of your project requirements, there's likely a reputable manufacturer whose products will meet your needs.

Comparing Features and Benefits

When evaluating different sand blasting equipment options from various manufacturers, it's crucial to compare features and benefits meticulously. Some models may offer superior pressure control or more efficient media usage, which can significantly impact overall performance and cost-effectiveness over time. Others might include user-friendly controls or advanced safety features that make operation easier for workers.

Moreover, considering the materials used in construction is vital; durable components often translate into longer lifespans for your industrial sandblasting equipment. Pay attention to warranty offerings as well since a strong warranty can indicate a manufacturer's confidence in their product's durability and performance. Ultimately, by weighing these factors carefully against your specific operational needs, you'll be better equipped to choose the right piece of sand blasting equipment.

Customer Reviews and Experiences

Nothing beats firsthand accounts when it comes to understanding how well a particular brand's products perform in real-world situations. Customer reviews often highlight not just performance metrics but also aspects like customer service experiences with different sandblasting equipment suppliers. Many users share insights on reliability during extended use periods or how easily they could source replacement parts when needed.

Additionally, forums dedicated to industrial applications frequently feature discussions around various sandblast equipment manufacturers where professionals exchange tips based on their experiences with specific models or brands. Such community feedback can be invaluable when deciding which manufacturer aligns best with your operational goals and expectations for quality assurance.

The Importance of Supplier Trustworthiness

Evaluating Manufacturer Reputation

Evaluating the reputation of sandblast equipment manufacturers involves digging deeper than glossy brochures and flashy websites. Look for reviews from previous customers, testimonials, and case studies that highlight the performance and reliability of their industrial sandblasting equipment. If a supplier has consistently high ratings across multiple platforms, it's a good sign that they take their commitment to quality seriously.

Another effective way to gauge a manufacturer's credibility is by checking their history in the industry. Established sandblasting equipment suppliers with years of experience are likely to have weathered market fluctuations and maintained customer trust over time. Don’t hesitate to ask for references or contact other businesses that have worked with them; firsthand accounts can provide invaluable insights.

Certifications and Standards to Consider

Certifications play an essential role in ensuring that sandblasting equipment meets industry standards for safety and performance. When evaluating potential suppliers, look for certifications such as ISO 9001 or those specific to manufacturing practices in the sandblasting sector. These designations indicate that the manufacturer adheres to strict quality control processes, which can significantly impact the durability and efficiency of their products.

Additionally, consider whether the supplier complies with environmental regulations relevant to industrial sandblasting equipment production. Compliance not only reflects a commitment to sustainability but also reduces risks associated with legal issues down the line. Remember: choosing certified manufacturers is not just about ticking boxes; it’s about investing in reliable solutions for your business.

Case Studies of Trusted Suppliers

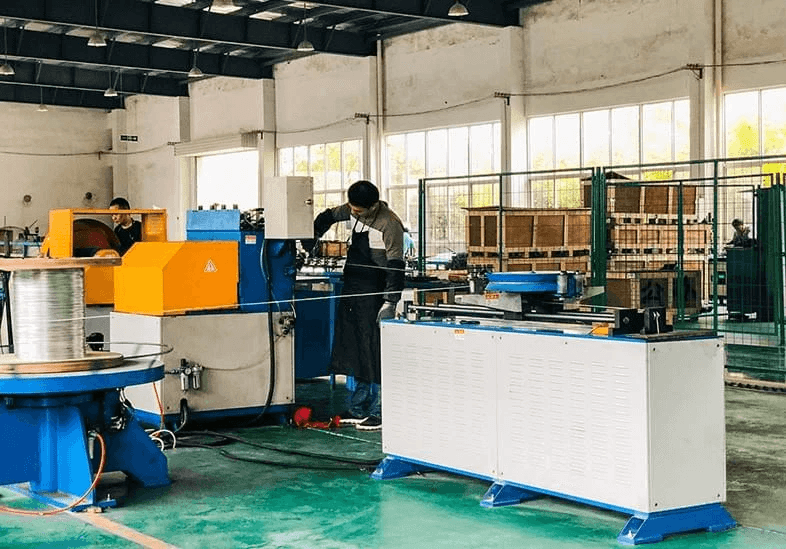

To illustrate how trustworthiness plays out in real-world scenarios, let’s look at some case studies involving reputable sand blasting equipment manufacturers who have made significant impacts on their clients’ operations. For instance, one well-known supplier provided custom-designed industrial sandblasting equipment for a major automotive manufacturer facing production delays due to inadequate machinery. By delivering high-quality solutions promptly, they helped reduce downtime significantly while enhancing overall productivity.

Another compelling example involves a construction company that switched suppliers after experiencing frequent breakdowns with their previous provider's products. After partnering with an established brand known for its robust customer support and warranty options on its sand blasting equipment, they reported improved efficiency and fewer maintenance issues over time—a clear testament to how selecting trustworthy suppliers pays off.

In conclusion, when searching for reliable sandblasting equipment suppliers, prioritize evaluating manufacturer reputation through reviews and case studies while considering necessary certifications as indicators of quality assurance.

Spotlight on Spark Fittings

Overview of Spark Fittings

Spark Fittings has established itself as a leading player among sandblast equipment manufacturers, specializing in high-quality fittings and accessories for sandblasting operations. Their product range includes everything from hoses to nozzles, each designed with durability and efficiency in mind. With a focus on customer satisfaction, Spark Fittings ensures that their offerings cater to various applications within the realm of industrial sandblasting equipment.

Innovations in Sandblasting Technology

Innovation is at the heart of what Spark Fittings does, continually pushing the envelope in sandblasting technology. They have introduced cutting-edge designs that enhance performance while reducing downtime—key factors for any business relying on effective sandblasting solutions. From advanced nozzle designs that optimize material flow to ergonomic fittings that improve user experience, their innovations make them a frontrunner among other sandblasting equipment suppliers.

Customer Success Stories

The proof is in the pudding—or rather, in the success stories shared by satisfied customers who have turned to Spark Fittings for their sandblasting needs. Many users report significant improvements in efficiency and output after switching to their products, highlighting how these innovations translate into real-world benefits. Testimonials abound from industries ranging from automotive repair to metal fabrication, showcasing how choosing Spark Fittings has led to enhanced productivity and reduced operational costs.

Tips for Selecting a Sandblasting Supplier

Choosing the right sandblasting equipment suppliers can make or break your project. With so many options available, it’s crucial to ask the right questions and ensure that you’re partnering with a reliable supplier. This section will guide you through essential considerations when selecting from the myriad of industrial sandblasting equipment options.

Key Questions to Ask Suppliers

Before sealing the deal, it’s important to have a list of key questions ready for potential sandblast equipment manufacturers. Start by asking about their experience in the industry; a supplier with years of expertise is often more equipped to handle your specific needs. Additionally, inquire about their range of products—do they offer various types of sandblasting equipment suitable for different applications?

Don’t forget to discuss pricing and payment terms as well; transparency here can save you from unexpected costs down the line. Finally, ask about their sourcing practices—knowing where and how they manufacture their sandblasting equipment can give you insight into quality control measures in place.

Importance of After-Sales Service

Once you've selected your preferred supplier, after-sales service becomes crucial in maintaining your investment in industrial sandblasting equipment. A good supplier should offer robust support post-purchase, including assistance with installation and training on how to use the equipment effectively. This ensures that you get optimal performance out of your sand blasting equipment right from day one.

Moreover, reliable after-sales service can be a lifesaver when issues arise; having quick access to technical support can minimize downtime and keep your projects on track. A partner who stands by their products demonstrates confidence in their offerings and helps foster long-term relationships between customers and suppliers.

Understanding Warranty and Support

When investing in sandblasting equipment, understanding warranty terms is vital for protecting your purchase against defects or malfunctions. Different manufacturers provide varying warranty lengths and coverage options, so be sure to clarify what is included before committing to any purchase from sandblast equipment manufacturers.

Additionally, pay attention to what kind of support is available during the warranty period; some suppliers may require you to ship items back while others might offer on-site repairs or replacements—knowing this could save time and hassle later on! Choosing suppliers that provide comprehensive warranties along with strong customer support ensures that you're not just buying a piece of machinery but also peace of mind.

Conclusion

In the world of industrial applications, the choice of sandblasting equipment suppliers can significantly impact the quality and efficiency of your operations. Building a long-term partnership with trustworthy manufacturers not only ensures a steady supply of high-quality sandblasting equipment but also fosters collaboration that can lead to innovation and improved processes. By investing time in selecting reputable sandblast equipment manufacturers, you can create a foundation for success that benefits both parties.

Building a Long-Term Partnership

Establishing a strong relationship with reliable sandblasting equipment suppliers is essential for achieving consistent results in your projects. When you partner with trusted manufacturers, you gain access to expert advice, timely support, and tailored solutions that meet your specific needs. Over time, this partnership can evolve into a valuable alliance where both parties thrive through shared knowledge and resources.

Investing in Quality Equipment

Investing in high-quality industrial sandblasting equipment pays off in the long run by enhancing productivity and minimizing downtime due to repairs or replacements. Quality sand blasting equipment not only performs better but also ensures safety for operators and improves overall project outcomes. By prioritizing reputable sandblast equipment manufacturers known for their durability and reliability, you're making an investment that will serve your business well.

Ensuring Optimal Performance and Safety

When it comes to sandblasting operations, optimal performance is non-negotiable; it directly correlates with safety standards and efficiency levels on-site. Choosing dependable sandblasting equipment helps mitigate risks associated with subpar tools while maximizing output quality across various applications. Remember, safety is paramount—selecting trusted suppliers means you're not just purchasing machinery; you're also safeguarding the wellbeing of your team.