Introduction

When you think about the structures that reach into the sky or the lines that connect our communication networks, guy wires are often the unsung heroes holding everything together. These tensioned cables provide stability and support to towers, poles, and other vertical structures, ensuring they remain upright against wind and other forces. But what size is guy wire appropriate for your project? Understanding this critical component can make all the difference in your construction or utility setup.

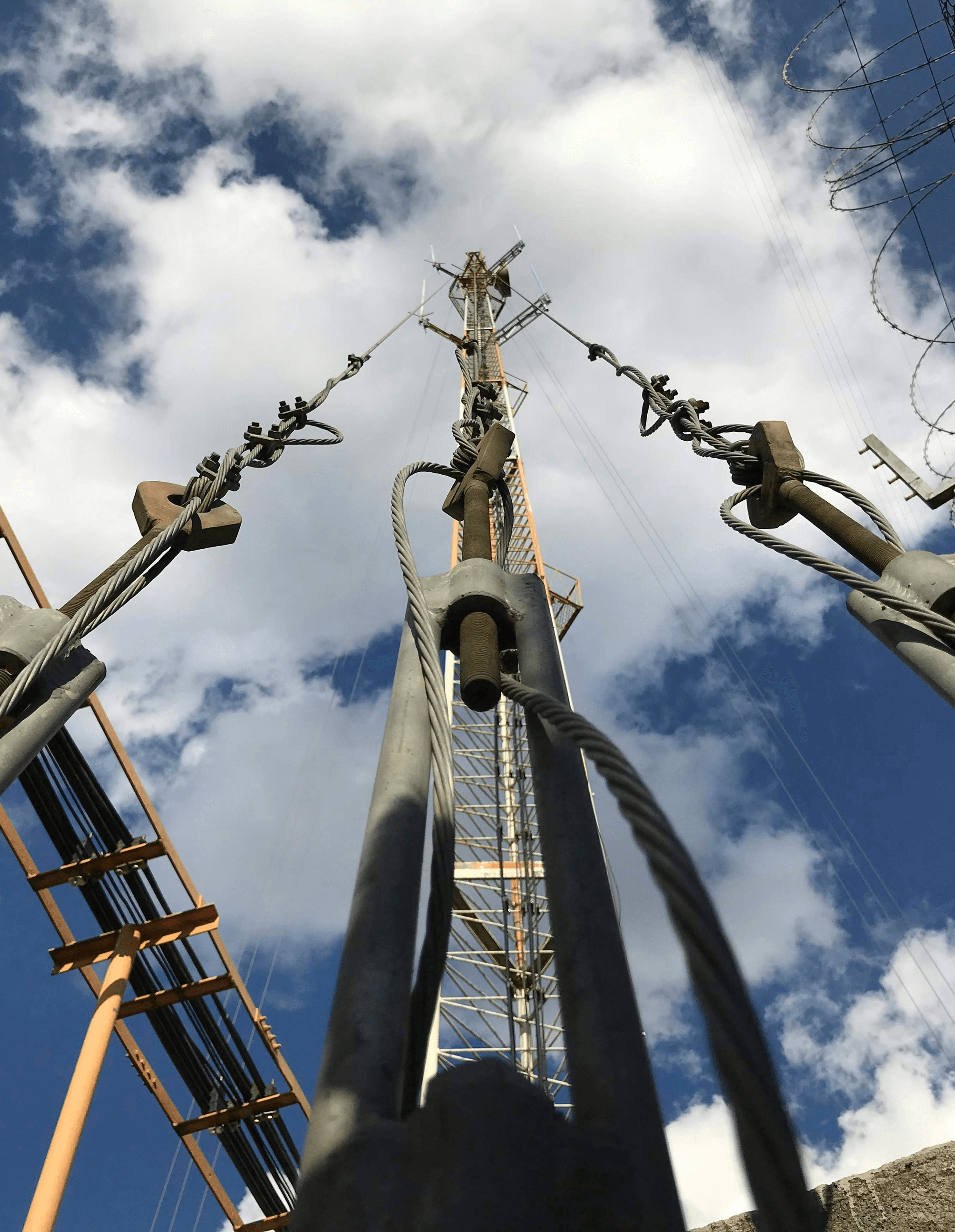

The Basics of Guy Wire

So, what is a guy wire? It's essentially a robust cable designed to stabilize tall structures by anchoring them to the ground or another solid point. You might wonder, why is it called a guy wire? The term guy comes from an old nautical term meaning to guide, since these wires help guide and support the structure they are attached to.

Understanding Alumoweld Technology

In recent years, Alumoweld technology has revolutionized the way we think about guy wires. This innovative material combines aluminum's lightweight properties with steel's strength, creating a durable option that stands up well in harsh environments. With questions like “how many guy wires do I need?” frequently arising in planning stages, understanding Alumoweld’s advantages can streamline decisions regarding quantity and installation.

Applications of Type M Guy Wire

Type M guy wire is particularly popular in telecommunications and utilities due to its strength-to-weight ratio and resistance to corrosion. This makes it ideal for supporting antennas, power lines, and other essential infrastructure components that require reliable performance over time. As you consider your options for stabilization solutions, keep in mind how Type M can meet your specific needs while addressing questions like “what is the difference between wire rope and guy wire?”

What is a Guy Wire and Its Purpose

When you think of structures that scrape the sky, you might picture towering radio towers or utility poles. These giants often rely on an unsung hero: the guy wire. A guy wire is a tensioned cable designed to stabilize and support these tall structures, preventing them from swaying in the wind or toppling over.

Definition of Guy Wire

A guy wire is essentially a strong cable that provides lateral support to tall structures like antennas, masts, and towers. It works by anchoring these vertical elements to the ground or nearby structures, ensuring they remain upright even in challenging weather conditions. So, when someone asks, What size is guy wire? it's important to remember that size can vary based on the specific application and environmental factors.

Uses in Telecommunications and Utilities

Guy wires are indispensable in telecommunications and utilities for maintaining the integrity of communication lines and electrical poles. They help secure everything from cell towers to power lines, ensuring reliable service delivery even during storms or high winds. If you're wondering how many guy wires do I need for your installation? The answer depends on factors like tower height and local regulations; typically, more wires mean better stability.

Why is it Called a Guy Wire?

The term guy actually has its roots in nautical language; it refers to a rope used to steady a ship's mast or other parts of its rigging. Over time, this terminology transitioned into engineering lingo as tall structures began using similar cables for stability—hence guy wire. So next time someone asks why it’s called a guy wire, you can impress them with this maritime connection while also mentioning how these cables differ from their cousins: wire ropes.

Material Matters: The Alumoweld Advantage

What is Alumoweld Aluminum Clad Steel?

Alumoweld is a composite material made by bonding a layer of aluminum to a core of high-strength steel. This fusion creates a product that harnesses the best properties of both metals, offering superior durability and resistance to rust and corrosion. When considering what size is guy wire for your project, opting for Alumoweld can provide peace of mind knowing that you're using a robust option designed for longevity.

Benefits Over Traditional Materials

The benefits of using Alumoweld over traditional materials are numerous and compelling. First off, its lightweight nature makes installation easier compared to heavier options like solid steel wires; this means less strain on poles and towers during setup. Additionally, when pondering how many guy wires do I need? The efficiency gained from using Alumoweld allows you to use fewer wires without sacrificing strength or safety—talk about cost-effectiveness!

Applications in Harsh Environments

Alumoweld's unique properties make it particularly well-suited for applications in harsh environments where other materials might falter. For instance, telecommunications and utility companies often deploy 10m guy wire configurations in areas prone to extreme weather conditions; here, the resilience of Alumoweld shines through. Moreover, understanding what is the difference between wire rope and guy wire becomes crucial when selecting materials for these demanding situations—Alumoweld not only meets but exceeds expectations.

Choosing the Right Size: What Size is Guy Wire?

Selecting the right size of guy wire is crucial for ensuring stability and safety in any installation. The size you choose can significantly affect the performance of your structures, especially in telecommunications and utility applications. So, what size is guy wire? Well, it depends on several factors that we’ll dive into.

Factors Affecting Guy Wire Size

When determining what size is guy wire for your needs, various factors come into play. First and foremost, the height of the structure being supported will influence your choice; taller structures typically require thicker wires to withstand greater tension and environmental forces. Additionally, environmental conditions such as wind load and ice accumulation will also dictate the necessary strength of your guy wire—after all, no one wants a 10m guy wire snapping in a storm!

Another critical factor to consider is the weight of the equipment that will be attached to or supported by the guy wire system. Heavier loads necessitate stronger wires to ensure stability and safety over time. Lastly, local regulations may have specific requirements regarding guy wire sizes based on typical weather conditions or structural standards.

Common Sizes and Their Uses

Guy wires come in various sizes, each suited for different applications. For instance, a common choice for moderate installations might be a 10m guy wire; this length provides ample support for smaller towers or poles without being overly cumbersome. In contrast, larger installations often utilize thicker wires with diameters ranging from 3/16 inch to 1/2 inch depending on their height and load requirements.

In telecommunications setups where antennas are involved, you might find that specific sizes are recommended based on both wind load calculations and equipment weight considerations. Understanding these common sizes can help streamline your decision-making process when selecting what size is guy wire best suited for your project.

How Many Guy Wires Do I Need?

Now that you know about sizing let’s tackle another crucial question: how many guy wires do I need? The answer isn't straightforward as it largely depends on factors like structure height and design specifications; however, most guidelines suggest at least three wires for standard installations to ensure even distribution of tension across all points.

For taller structures or those subjected to harsher weather conditions, additional guys may be necessary to enhance stability further—think of it as an insurance policy against Mother Nature’s whims! So when planning your installation, always err on the side of caution; after all, it's better to have more support than not enough.

Comparing Guy Wires with Wire Ropes

When it comes to securing structures, both guy wires and wire ropes play essential roles, but they serve different purposes. A guy wire is primarily used for stabilization, while wire ropes are often employed for lifting or pulling heavy loads. Understanding the differences between these two types of cables can help you determine which is best suited for your specific needs.

What is the Difference Between Wire Rope and Guy Wire?

At its core, the difference between wire rope and guy wire lies in their design and intended use. While a guy wire is typically a single strand or multiple strands of steel designed to support structures like telecommunication towers, a wire rope consists of several wires twisted together to form a more robust cable capable of handling dynamic loads. This distinction answers the question: what is the difference between wire rope and guy wire? The former excels in heavy lifting applications, whereas the latter provides stability against lateral forces.

Additionally, guy wires are usually tensioned to maintain stability in structures like poles or masts, while wire ropes can be slack or under tension depending on their application. This means that if you're asking yourself what size is guy wire? you'll find that it's often thinner than traditional lifting cables because its primary job isn't about bearing weight but rather resisting sideways forces. In summary, understanding these differences can help you make an informed decision when selecting your materials.

Strength and Durability Considerations

When evaluating strength and durability considerations between guy wires and wire ropes, it’s crucial to recognize that each has unique attributes tailored for specific applications. Guy wires are engineered primarily for tensile strength; they need to withstand significant lateral forces without sagging or breaking under pressure. On the other hand, while some high-strength wire ropes can handle enormous loads vertically, they might not have the same resistance to side loading as a well-installed 10m guy wire would.

Moreover, environmental factors play a significant role in determining durability; alumoweld technology used in some guy wires offers superior resistance against corrosion compared to standard steel options found in many types of wire ropes. If you’re working in harsh environments where moisture or chemicals are present, this could tilt your choice toward using a robust 10m guy wire instead of traditional alternatives. Ultimately, choosing between these two will depend on your project's specific needs regarding strength and durability factors.

Cost-Effectiveness of Each Option

Cost-effectiveness often becomes a deciding factor when comparing materials like 10m guy wires versus various types of wire ropes for construction projects. Generally speaking, while initial costs may vary depending on material quality—alumoweld being more expensive upfront due to its advanced properties—long-term savings may emerge from reduced maintenance requirements associated with less corrosion-prone materials like alumoweld guys compared to ordinary steel cables.

Additionally, consider how many guy wires do I need? Properly calculating this can save money by minimizing waste during installation; fewer high-quality 10m guy wires may outperform numerous lower-quality alternatives over time due to enhanced performance characteristics such as increased lifespan and reduced replacement frequency. In essence, although upfront costs matter significantly when making decisions about which type of cable system suits your project best—considering longevity alongside performance could lead you toward greater overall value down the line.

Installation and Maintenance Tips

When it comes to installing guy wires, following best practices is crucial for ensuring stability and safety. Proper installation not only enhances the performance of your guy wire system but also extends its lifespan, making it a smart investment for any telecommunications or utility project. So, what size is guy wire appropriate for your needs? Let's dive into the specifics!

Best Practices for Installation

First off, always consult local regulations and guidelines before starting your installation; they often dictate how many guy wires do I need based on the height and load of your structure. When choosing a 10m guy wire, ensure that you have adequate tension to withstand environmental factors like wind or ice loads—this will help prevent sagging or snapping over time. Additionally, make sure to use proper anchoring techniques; this could mean setting anchors deep in the ground or using concrete footings to secure your setup.

How to Ensure Longevity and Safety

To keep your guy wires in top shape for years to come, regular inspections are key. Look out for signs of wear and tear, such as fraying or corrosion—especially if you’re using traditional materials instead of Alumoweld aluminum clad steel which offers better resistance against harsh environments. Always check tension levels too; an improperly tensioned wire can lead to structural failure, so don’t skip on this basic maintenance step!

Role of Spark Fittings in Guy Wire Systems

Spark fittings play a pivotal role in enhancing both safety and functionality in guy wire systems. They help prevent electrical arcing that can occur between conductive materials when exposed to high voltage lines—something you definitely want to avoid! By integrating spark fittings into your system, you're not just investing in longevity but also ensuring compliance with safety standards while minimizing risks associated with electrical hazards.

Conclusion

In wrapping up our discussion on guy wire, it’s clear that these essential components play a pivotal role in providing stability and support across various applications. Whether in telecommunications, utilities, or construction, understanding the importance of guy wire is crucial for safety and functionality. As we’ve explored, the right choice of materials and sizes can significantly impact performance, making it vital to consider factors like What size is guy wire? when planning your projects.

Recap of the Importance of Guy Wire

Guy wires are not just metal strands; they are lifelines for structures that require additional support to withstand environmental forces. Their use ensures that towers remain upright against wind loads and other stresses while keeping communication lines intact. So, when you ponder Why is it called a guy wire?, remember that these wires are indeed the unsung heroes holding everything together.

Key Benefits of Choosing Alumoweld

Choosing Alumoweld technology for your guy wire needs offers several advantages over traditional materials. The aluminum cladding not only enhances corrosion resistance but also provides substantial weight savings without compromising strength—perfect for harsh environments where durability matters most. When considering how many guy wires do I need?, opting for Alumoweld can help you achieve optimal performance with fewer resources.

Future Trends in Guy Wire Technology

Looking ahead, advancements in guy wire technology promise even greater efficiency and reliability in supporting structures across various industries. Innovations may include smart materials equipped with sensors to monitor tension levels and environmental conditions in real-time, revolutionizing installation practices and maintenance strategies alike. As we continue to ask questions like What is the difference between wire rope and guy wire?, it's evident that the future holds exciting possibilities for enhancing structural integrity through ongoing research and development.